Documente Academic

Documente Profesional

Documente Cultură

Split Case Pump Mos

Încărcat de

Fakhreddine EzzahiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Split Case Pump Mos

Încărcat de

Fakhreddine EzzahiDrepturi de autor:

Formate disponibile

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

For Review and

0 29-08-2019 CM QA/QC PD

Approval

Rev Date Purpose Prepared by Reviewed by Approved

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 1 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

METHOD STATEMENT FOR INSTALLATION OF

TSE PUMPS IN PUMPING STATION

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 2 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

Table of Contents

1. PURPOSE..................................................................................................................... 4

2. SCOPE ......................................................................................................................... 4

3. REFERENCE ................................................................................................................ 4

4. DEFINITION .................................................................................................................. 4

5. RESOURCES ............................................................................................................... 4

5.1 Equipment and Tools .............................................................................................. 4

5.2 Manpower ............................................................................................................... 5

6. RESPONSIBILITIES ..................................................................................................... 5

7. PERMITS and LICENSE............................................................................................... 7

8. WORK SEQUENCE ...................................................................................................... 7

8.1 Pre-requisites ........................................................................................................ 7

8.2 Work Methodology................................................................................................ 8

8.2.1 Pump Installation ................................................................................................. 8

9. QUALITY CONTROL & QUALITY ASSURANCE ....................................................... 10

10. HEALTH SAFETY & ENVIRONMENT ........................................................................ 10

11. ATTACHMENTS ......................................................................................................... 10

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 3 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

1. PURPOSE

The purpose of this Method Statement is to outline the general requirements which should be

taken into consideration for installation of TSE Pumps for Construction of D Line TSE Pumping

Station and Transmission Main project.

2. SCOPE

This Method Statement identifies the general steps & arrangements which should be followed

during installation of TSE Pumps in Pumping Station Building.

3. REFERENCE

Project Specification

Project Drawings

QCS 2014

4. DEFINITION

Client - ASHGHAL (Public Works Authority)

Consultant - CDM Smith Qatar

JEC - Al Jaber Engineering W.L.L.

QCS - Qatar Construction Specifications

HSE - Health, Safety & Environment

PQP - Project Quality Plan

ITP - Inspection Test Plan

PPE - Personal Protective Equipment

IR - Inspection Request

5. RESOURCES

5.1 Equipment and Tools

Mobile crane

Crane truck/flatbed trailer

Full set of metric tools for mechanical assembly

Strand Jacks and Chain Blocks

Ventilation fan

Grinding machine

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 4 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

Drilling machines

Welding machines and consumables

Fitter regular tools (i.e., square, spirit level, hammer, clamps, etc.)

Fork lift

Lifting tools and tackles (i.e., nylon belt slings, D shackles, etc.)

Set of spanners

5.2 Manpower

a. Site Engineer

b. Surveyor

c. Foreman

d. Safety Officer

e. Electrician

f. Pipe Fitter

g. Operator

h. Skilled Worker

i. Labor

6. RESPONSIBILITIES

Project Construction Manager (PCD)

Responsible for controlling the Project entire activities & for the overall coordination with

the Consultant/Client.

Coordinating and following up the planning, progress, resource in adherence with Quality

and HSE requirements.

Monitor the Project progress and financial performance and advice concern of the

corrective and preventive action in case of slippage or violation.

Construction Manager

Organize the site so that work is carried out to the required specifications with a minimum

risk to men, equipment and materials.

Adhere to the Project Specific Quality Management Program and HSE Requirements.

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 5 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

QA/QC Manager

Identify the Projects Specific Quality Requirements, Develop the Project Specific Quality

Assurance Program (Project Quality Plan), Inspection and Test Plan (ITP), Operational and

Control procedures, Mechanism and Forms and ensure effective implementation of the

same.

Ensure compliance with applicable Standards as well as relevant statutory requirements.

QA/QC Engineer

Responsible for the work entire Quality Assurance, Quality Control & inspection programs.

Produce all Quality related documents & necessary quality reports as requested.

Provide written procedures & to coordinate in formalizing the Method Statements with the

Construction Manager/Site Engineers to describe the job specific work for each stage of

activity.

Site HSE Manager

Responsible for entire HSE matters and preparing Risk Assessment (RA) in line with Method

statements for particular activity.

Liaison with Client/Consultant Representative for HSE issues.

Monitoring the HSE requirements as per Project Specifications and Consultant

requirements.

Safety Engineer

Ensure that all workers have a safe place of work, advice safe system of work and provide

adequate instructions, training and supervision to enable employees to work in safety.

Carry out site surveillance on daily basis to ensure that the HSE Methods of working are in

operation & that all regulations are being observed.

Report, determine & analyze the cause of any accident or dangerous occurrence and

recommend measures for preventing recurrence.

Chief Surveyor/Surveyor

Chief Surveyor: Chief surveyor will be in-charge of the Topographic survey. He will lead the

survey team and will coordinate with all the concerned parties and ensure survey works is

in time and with proper quality.

Surveyors: The surveyor will be responsible for all survey work and will report to chief

surveyor.

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 6 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

Site Engineer

Adheres to the Project specific method statements, procedures, inspection programs & HSE

instructions to get the activities performed to Engineer’s Representative satisfaction with

full coordination with the HSE & Quality personnel.

7. PERMITS and LICENSE

Obtained relevant permit/license shall be approved and available at site prior to start any

activities.

8. WORK SEQUENCE

8.1 Pre-requisites

Ensure General Arrangement drawing is approved.

Ensure the materials inspection approval prior for installation.

Materials shall be check visually for any damages and defects prior for installation.

All lifting equipment to be used shall have allowable lifting capacities and valid SWL

certification from approved third party and to be available at site.

Warning signs shall be set all around the site as necessary. Signs must be clearly visible to

the workforce and drivers by both day and night.

All necessary work permits shall be obtained from the authorities, prior to the

commencement of any activity at site and shall remain valid throughout the entire

duration of operation.

Ensure that the persons involved with the works are adequately trained & equipped with

the required PPE against the work hazards.

Ensure having adequate number & suitable type of equipment and trained & experienced

operators that enable the work to be done smoothly in relation with the HSE, Quality &

Client requirements.

Pumps shall be lifted in accordance with the pump manufacturer’s specifications and as

per approved method statement.

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 7 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

8.2 Work Methodology

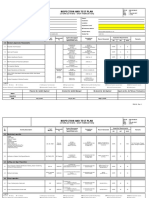

Sewerage water pump schedule – TSE Pumping Station

Unit Type Motor (kW) Speed (rpm) Capacity Qty

8.2.1 Pump Installation

8.2.1.1 Preparation

General recommendations:

Check local codes and requirements before installation. Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

RECEIVING:

Upon receiving the pump, it should be inspected for damage or shortages. If damage has occurred, file a claim

immediately with the company that delivered the pump. If the manual is removed from the crating, do not lose or

misplace.

STORAGE:

Short Term - Pumps are manufactured for efficient performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as factory assembled, in a dry atmosphere with constant

Temperatures for up to six (6) months.

Long Term - Any length of time exceeding six (6) months, but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed over walled enclosure that provides protection from the

elements (rain, snow, wind-blown dust, etc..), and whose temperature can be maintained between +40 deg. F and

+120 deg. F. Pump should be stored in its original shipping container and before initial startup, rotate impeller by

hand to assure seal and impeller rotate freely.

8.2.1.2 Rigging, Crane Selection and Lifting Method

8.2.1.3 Installation

FOUNDATION

The pump foundation should be sufficiently substantial to form a level, rigid support for the combined weight of the

pump and driver and maintain alignment of the installed unit. Foundation bolts, of the proper size, should be

imbedded in the concrete. A pipe sleeve, about 2½” diameters larger than the bolt, should be used to allow for final

positioning of the bolts. See Figure 1.

FOUNDATION FOR HSC PUMP

Foundation should be sufficiently substantial to absorb any vibration and to form a permanent, rigid support for the

base plate.

Foundation bolts of suitable size should be embedded in the concrete located by a drawing or template.

Place pumping unit on foundation with wedges under base plate leaving approximately 3/4” space for grouting.

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 8 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

Carefully level the unit by adjusting the wedges until shafts of pump and driver are leveled, recreating factory

alignment.

Check coupling faces as well as suction and discharge flanges of pump for horizontal or vertical position with a

level.

Slight misalignment at this point may be corrected by adjusting the wedges.

MOUNTING:

Horizontal mounted pumps and drivers that are received from the factory with both machines mounted on a

common baseplate, were accurately aligned before shipment. Vertical mounted pumps were accurately aligned

before shipment.

Figure 1. Foundation Bolt Location and Anchorage

Position unit on foundation and level the baseplate, using rectangular metal blocks and shims, or wedges having

a small taper as shown in Figure 2. A gap of 3/4” to 1½” should be allowed between the baseplate and foundation

for grouting.

Figure 2. Adjusting Wedges for Mounting

8.2.1.4 Pump Alignment

A flexible coupling should not be used to compensate for misalignment of the pump and driver shafts. The

purpose of the flexible coupling is to compensate for temperature changes and to permit end movement of the

shafts without interference with each other, while transmitting power from the driver to the pump.

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 9 of 10

CONSTRUCTION OF D LINE TSE PUMPING STATION & TRANSMISSION MAIN DS105– C762

PROJECT ID: IA 2018 C 011 G

METHOD STATEMENT FOR INSTALLATION OF TSE PUMPS IN PUMPING STATION

Document Reference C762-MEC-MS-00049 Rev. 0 Date: 29-8-2019

Figure. Angular misalignment.

8.2.1.5 Pump Connection - Mechanical

8.2.1.6 Pump Connection – Electrical

8.2.1.7 Testing

9. QUALITY CONTROL & QUALITY ASSURANCE

Activity inspection will be carried as per the approved ITP.

Ensure approved Shop drawing is being used at site.

10. HEALTH SAFETY & ENVIRONMENT

HSE induction courses shall be provided to all personnel prior to site attendance.

All manpower to use the required PPE during execution of all the works.

Regular tool box meeting shall be conducted to explain the nature of works and associated

risks.

Continuous on-site supervision will be conducted to ensure safe environment at all times.

11. ATTACHMENTS

Risk Assessment (RA)

Doc. Ref.: C762-MEC-MS-00049 Rev.0 Page 10 of 10

S-ar putea să vă placă și

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 paginiMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHÎncă nu există evaluări

- Mandrelling Test / Checklist: Pmqs Construction Solutions, IncDocument1 paginăMandrelling Test / Checklist: Pmqs Construction Solutions, IncAbnar KumplishaÎncă nu există evaluări

- Water Tank ItpDocument5 paginiWater Tank Itptuan mai vanÎncă nu există evaluări

- Method Statement of Installation of SS Puddle FlangesDocument7 paginiMethod Statement of Installation of SS Puddle Flangessarmad spectrumÎncă nu există evaluări

- PT Prospera Brillar Indonesia: Hse Organization ChartDocument1 paginăPT Prospera Brillar Indonesia: Hse Organization ChartTadaya KasaharaÎncă nu există evaluări

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 paginiProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhÎncă nu există evaluări

- Method Statement For Dewatering (Using Submersible Pumps) : Document TitleDocument6 paginiMethod Statement For Dewatering (Using Submersible Pumps) : Document TitleMidhunRameshThuvasseryÎncă nu există evaluări

- Method Statement For Installation of Puddle Flange DN 500Document8 paginiMethod Statement For Installation of Puddle Flange DN 500Ahmed ImranÎncă nu există evaluări

- Painting Procedure For Firefighting Piping NetworkDocument6 paginiPainting Procedure For Firefighting Piping NetworkWahid HusainÎncă nu există evaluări

- BCB Solutions Business ProfileDocument9 paginiBCB Solutions Business ProfileJacaranda FM NewsÎncă nu există evaluări

- PMPT Itp 010Document3 paginiPMPT Itp 010hz135874Încă nu există evaluări

- Excavation and Fill SpecificationsDocument35 paginiExcavation and Fill SpecificationsMohamedOmar83Încă nu există evaluări

- 439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water LineDocument16 pagini439 20140827 Method Statement of Tie-Ins For Portable Water and Sanitary Waste Water Linearshad iqbalÎncă nu există evaluări

- Method Statement For Foundation ExcavatiDocument6 paginiMethod Statement For Foundation ExcavatiArianne Mae De Vera GallonÎncă nu există evaluări

- 5.9 Plans For Erecting Large EquipmentDocument7 pagini5.9 Plans For Erecting Large EquipmentAmeerHamzaWarraichÎncă nu există evaluări

- Field Mechanical EngineerDocument2 paginiField Mechanical EngineerArt JamesÎncă nu există evaluări

- QCDFSS-6.7 - Fire Pumps - Arabic Version of Rev ADocument4 paginiQCDFSS-6.7 - Fire Pumps - Arabic Version of Rev AAnoirÎncă nu există evaluări

- Bid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRDocument7 paginiBid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRFrancis Nano FerrerÎncă nu există evaluări

- Civil Demolition Work East of PL3 Rev01Document30 paginiCivil Demolition Work East of PL3 Rev01Venkadesh PeriathambiÎncă nu există evaluări

- 1 - Underground Piping InstallationDocument6 pagini1 - Underground Piping InstallationYusufÎncă nu există evaluări

- Checklist Underground FF Piping InstallationDocument1 paginăChecklist Underground FF Piping Installationbeho2000Încă nu există evaluări

- Method Statement For Installatio of Water Booster PumpsDocument9 paginiMethod Statement For Installatio of Water Booster PumpsDiana Abu Hassan Hatoum100% (1)

- Pipe Testing PresentationDocument36 paginiPipe Testing PresentationsudhialakkalÎncă nu există evaluări

- WQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers WorksDocument68 paginiWQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers Worksmuhammad.younisÎncă nu există evaluări

- Method Statement of Bored Piles 21Document40 paginiMethod Statement of Bored Piles 21Dharma Pratap LamgadeÎncă nu există evaluări

- Installation Guide - Pressure Pipe - 6.26.15Document12 paginiInstallation Guide - Pressure Pipe - 6.26.15MazenÎncă nu există evaluări

- Compliance Statement for 4 Residential Building ProjectDocument1 paginăCompliance Statement for 4 Residential Building ProjectAhmed HelmyÎncă nu există evaluări

- 4.M.S Pump InstallationDocument12 pagini4.M.S Pump Installationarshad iqbalÎncă nu există evaluări

- Excavation and Fill Method Statement SummaryDocument12 paginiExcavation and Fill Method Statement Summary한상호Încă nu există evaluări

- HDPE Pipe Installation MethodDocument13 paginiHDPE Pipe Installation MethodABAID ULLAHÎncă nu există evaluări

- MEthdstatemet For GRP Pipe Puddle Flange Installation (Complete)Document13 paginiMEthdstatemet For GRP Pipe Puddle Flange Installation (Complete)Mdubdt100% (1)

- Oman-India Fertilizer Project OIFDocument24 paginiOman-India Fertilizer Project OIFBassam Dahham83% (6)

- BK91-1320-BSC-000-CNS-CMM-0003 - B - Method Statement For Geotechnical Investigation - C2Document9 paginiBK91-1320-BSC-000-CNS-CMM-0003 - B - Method Statement For Geotechnical Investigation - C2Berry UmpolaÎncă nu există evaluări

- Method For Installation of PEHD ManholesDocument14 paginiMethod For Installation of PEHD ManholesPipeline EngineerÎncă nu există evaluări

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 paginiCV-0013-005 - Method Statement For Concrete Work (Revised)한상호Încă nu există evaluări

- Op-3-27. Checklist For Information Required Before Cpt/Cptu TestsDocument5 paginiOp-3-27. Checklist For Information Required Before Cpt/Cptu Testsjinwook75Încă nu există evaluări

- MOS Air Handling Units AHUDocument5 paginiMOS Air Handling Units AHUSuban Hari100% (1)

- Method Statement Striking FormworkDocument3 paginiMethod Statement Striking FormworkSurya HeriwijayaÎncă nu există evaluări

- METHOD OF STATEMENT - ALKHOMRA PROJECT - MarbleDocument9 paginiMETHOD OF STATEMENT - ALKHOMRA PROJECT - Marbleahmed samirÎncă nu există evaluări

- Guidelines for Scope Change ProcessDocument3 paginiGuidelines for Scope Change ProcessgauravÎncă nu există evaluări

- Site Organisation Chart: Plant OperatorsDocument1 paginăSite Organisation Chart: Plant OperatorsPatrick SipatelaÎncă nu există evaluări

- PMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Document3 paginiPMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Emmanuel TamayoÎncă nu există evaluări

- XXXXXXXXXXXXXXXXXXXXXXXXXXXXXX: Method Statement: Construstion of ManholeDocument10 paginiXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX: Method Statement: Construstion of ManholeJunaid MirÎncă nu există evaluări

- Method Statement Submission: For: LPG System Work Installation, Testing & CommissioningDocument5 paginiMethod Statement Submission: For: LPG System Work Installation, Testing & CommissioningMd ShahinÎncă nu există evaluări

- Salalah Free Zone Drainage InstallationDocument10 paginiSalalah Free Zone Drainage InstallationShahzaib ShahidÎncă nu există evaluări

- Perfect Manhole Installation GuideDocument9 paginiPerfect Manhole Installation Guidechienthan21Încă nu există evaluări

- Anchr Bolt RefDocument9 paginiAnchr Bolt ReferleosÎncă nu există evaluări

- Interconnecting the Permeate Pipe to the Existing PipelineDocument20 paginiInterconnecting the Permeate Pipe to the Existing PipelinegregÎncă nu există evaluări

- Lesson 10 Project Quality PlanningDocument51 paginiLesson 10 Project Quality PlanningDevjit MandalÎncă nu există evaluări

- Method of Statement For Installation of Wires and Cables PDF FreeDocument6 paginiMethod of Statement For Installation of Wires and Cables PDF Freetristan guarinoÎncă nu există evaluări

- Static Equipment Erection ProcedureDocument10 paginiStatic Equipment Erection ProcedureputrasejahtraÎncă nu există evaluări

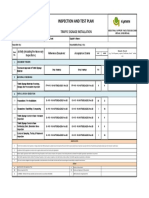

- Traffic Signage Installation ITPDocument1 paginăTraffic Signage Installation ITPmoytabura96Încă nu există evaluări

- 4 AM-IsP-I16021-MS-PL-001 Installation of Waterline Pipes and FittingsDocument11 pagini4 AM-IsP-I16021-MS-PL-001 Installation of Waterline Pipes and Fittingsgangadharan000Încă nu există evaluări

- Fence InstallationDocument10 paginiFence InstallationanoopyohÎncă nu există evaluări

- PMF-007-INT-001 - 02 Project Management PlanDocument56 paginiPMF-007-INT-001 - 02 Project Management PlanEng hassan hussienÎncă nu există evaluări

- Dewatering Method StatementDocument6 paginiDewatering Method StatementMohsen KeramatiÎncă nu există evaluări

- 1.method Statement - INSTALLATION OF GRP WATER TANKSDocument11 pagini1.method Statement - INSTALLATION OF GRP WATER TANKSsarmad spectrumÎncă nu există evaluări

- Flushing and Disinfection Method StatementDocument6 paginiFlushing and Disinfection Method StatementburereyÎncă nu există evaluări

- MS For AIR CURTIANDocument12 paginiMS For AIR CURTIANlike saddamÎncă nu există evaluări

- MP2019 186 Mec 002Document17 paginiMP2019 186 Mec 002puwe qiheÎncă nu există evaluări

- VAPT7.E37780 - Solenoids For Use in Hazardous Locations Certified For Canada - UL Product IqDocument2 paginiVAPT7.E37780 - Solenoids For Use in Hazardous Locations Certified For Canada - UL Product IqFakhreddine EzzahiÎncă nu există evaluări

- IELTS WritingDocument3 paginiIELTS WritingmichalakisÎncă nu există evaluări

- Fortive Corp CCPA Public Facing Privacy NoticeDocument9 paginiFortive Corp CCPA Public Facing Privacy NoticeFakhreddine EzzahiÎncă nu există evaluări

- UL Certification For Solenoid Operators Used in Hazardous LocationsDocument1 paginăUL Certification For Solenoid Operators Used in Hazardous LocationsFakhreddine EzzahiÎncă nu există evaluări

- 4.6 IELTS Writing Task 1Document12 pagini4.6 IELTS Writing Task 1Fakhreddine EzzahiÎncă nu există evaluări

- Appendix A-3 Annual ChecklistDocument10 paginiAppendix A-3 Annual ChecklistFakhreddine EzzahiÎncă nu există evaluări

- A Guide To Gland Packing, Selection of Gland Packing, Standard SizesDocument15 paginiA Guide To Gland Packing, Selection of Gland Packing, Standard SizesFakhreddine ZahiÎncă nu există evaluări

- 577013-727 - PLLD - WPLLD Alarm Quick HelpDocument20 pagini577013-727 - PLLD - WPLLD Alarm Quick HelpFakhreddine EzzahiÎncă nu există evaluări

- Troubleshooting: No Liquid DeliveryDocument4 paginiTroubleshooting: No Liquid DeliveryFakhreddine ZahiÎncă nu există evaluări

- Appendix A-2 Monthly ChecklistDocument2 paginiAppendix A-2 Monthly ChecklistFakhreddine EzzahiÎncă nu există evaluări

- Appendix A-3 Annual ChecklistDocument10 paginiAppendix A-3 Annual ChecklistFakhreddine EzzahiÎncă nu există evaluări

- 4.7 IELTS Task 1 TipsDocument3 pagini4.7 IELTS Task 1 TipsFakhreddine EzzahiÎncă nu există evaluări

- Useful Information On Pump Shaft SealsDocument9 paginiUseful Information On Pump Shaft SealsFakhreddine EzzahiÎncă nu există evaluări

- Appendix A-2 Monthly ChecklistDocument2 paginiAppendix A-2 Monthly ChecklistFakhreddine EzzahiÎncă nu există evaluări

- Appendix A-1 Daily ChecklistDocument1 paginăAppendix A-1 Daily ChecklistFakhreddine EzzahiÎncă nu există evaluări

- Appendix A-4 Sample Site PlanDocument1 paginăAppendix A-4 Sample Site PlanFakhreddine EzzahiÎncă nu există evaluări

- IELTS Map VocabularyDocument13 paginiIELTS Map VocabularyDeen Turja0% (1)

- Sti Sp001 Standard For Inspection of Aboveground Storage Tanks-ChevronDocument7 paginiSti Sp001 Standard For Inspection of Aboveground Storage Tanks-Chevrononin007Încă nu există evaluări

- 26.3 IELTS Listening Spelling ListDocument32 pagini26.3 IELTS Listening Spelling ListRao SÎncă nu există evaluări

- Commonly Used Words in IELTS Listening Test11 PDFDocument4 paginiCommonly Used Words in IELTS Listening Test11 PDFreema198777% (26)

- Academic Writing Sample Candidate Responses and Examiner CommentsDocument5 paginiAcademic Writing Sample Candidate Responses and Examiner CommentsFazÎncă nu există evaluări

- IELTS Task 1 Writing Band DescriptorsDocument2 paginiIELTS Task 1 Writing Band Descriptorspelosa12345Încă nu există evaluări

- IELTS Map VocabularyDocument13 paginiIELTS Map VocabularyDeen Turja0% (1)

- 2.1 Avoid These Answer Sheet MistakesDocument1 pagină2.1 Avoid These Answer Sheet MistakesDeen TurjaÎncă nu există evaluări

- IELTS Map VocabularyDocument13 paginiIELTS Map VocabularyDeen Turja0% (1)

- Lectures and Conversations To Improve ListeningDocument4 paginiLectures and Conversations To Improve ListeningmobileÎncă nu există evaluări

- Commonly Used Words in IELTS Listening Test11 PDFDocument4 paginiCommonly Used Words in IELTS Listening Test11 PDFreema198777% (26)

- 2.1 Avoid These Answer Sheet MistakesDocument1 pagină2.1 Avoid These Answer Sheet MistakesDeen TurjaÎncă nu există evaluări

- 26.3 IELTS Listening Spelling ListDocument32 pagini26.3 IELTS Listening Spelling ListRao SÎncă nu există evaluări

- Lectures and Conversations To Improve ListeningDocument4 paginiLectures and Conversations To Improve ListeningmobileÎncă nu există evaluări

- EPA - Regulatory Impact AnalysisDocument822 paginiEPA - Regulatory Impact AnalysisSugarcaneBlogÎncă nu există evaluări

- COKE MidtermDocument46 paginiCOKE MidtermKomal SharmaÎncă nu există evaluări

- Corvette Stingray - Papercraft Sports Car: Food Living Outside Play Technology WorkshopDocument22 paginiCorvette Stingray - Papercraft Sports Car: Food Living Outside Play Technology WorkshopStylus ClearingÎncă nu există evaluări

- SS Corrosion SlidesDocument36 paginiSS Corrosion SlidesNathanianÎncă nu există evaluări

- Science Q4 Lesson BDA EarthquakeDocument41 paginiScience Q4 Lesson BDA EarthquakeAnaLizaD.SebastianÎncă nu există evaluări

- E85001-0646 - Intelligent Smoke DetectorDocument4 paginiE85001-0646 - Intelligent Smoke Detectorsamiao90Încă nu există evaluări

- 2019-03-30 New Scientist PDFDocument60 pagini2019-03-30 New Scientist PDFthoma leongÎncă nu există evaluări

- Ies RP 7 2001Document88 paginiIes RP 7 2001Donald Gabriel100% (3)

- Financial Audit NotesDocument11 paginiFinancial Audit NotesMamunoor RashidÎncă nu există evaluări

- (DO-CYT-T1-16) - KASSAHUN ComparisionDocument126 pagini(DO-CYT-T1-16) - KASSAHUN ComparisionMohammed AdaneÎncă nu există evaluări

- Zaranda Finlay 684 Manual Parts CatalogDocument405 paginiZaranda Finlay 684 Manual Parts CatalogRicky Vil100% (2)

- AXIS Camera Station Installation and Migration Guide: User ManualDocument7 paginiAXIS Camera Station Installation and Migration Guide: User ManualCORAL ALONSOÎncă nu există evaluări

- Superelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDocument7 paginiSuperelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDavid C HouserÎncă nu există evaluări

- Market & Industry Analysis CheckDocument2 paginiMarket & Industry Analysis CheckAndhika FarrasÎncă nu există evaluări

- BS en 12951-2004Document26 paginiBS en 12951-2004Mokhammad Fahmi IzdiharrudinÎncă nu există evaluări

- Example Italy ItenararyDocument35 paginiExample Italy ItenararyHafshary D. ThanialÎncă nu există evaluări

- Group Assignment: Consumer Buying Behaviour Towards ChipsDocument3 paginiGroup Assignment: Consumer Buying Behaviour Towards ChipsvikasÎncă nu există evaluări

- E4PA OmronDocument8 paginiE4PA OmronCong NguyenÎncă nu există evaluări

- OrcaSecurity Solution OverviewDocument2 paginiOrcaSecurity Solution Overviewandini eldanantyÎncă nu există evaluări

- $$TR Sas 114 AllDocument384 pagini$$TR Sas 114 Allctudose4282Încă nu există evaluări

- Final Year Project - Developing A Plastic Bottle Solar CollectorDocument78 paginiFinal Year Project - Developing A Plastic Bottle Solar CollectorLegendaryN0% (1)

- Social Vulnerability Index Helps Emergency ManagementDocument24 paginiSocial Vulnerability Index Helps Emergency ManagementDeden IstiawanÎncă nu există evaluări

- Variant Configuration Step by Step ConfigDocument18 paginiVariant Configuration Step by Step Configraghava_83100% (1)

- DBM CSC Form No. 1 Position Description Forms 1feb.222019Document2 paginiDBM CSC Form No. 1 Position Description Forms 1feb.222019Jemazel Ignacio87% (30)

- Math30.CA U1l1 PolynomialFunctionsDocument20 paginiMath30.CA U1l1 PolynomialFunctionsUnozxcv Doszxc100% (1)

- UE Capability Information (UL-DCCH) - Part2Document51 paginiUE Capability Information (UL-DCCH) - Part2AhmedÎncă nu există evaluări

- Operations Management For Competitive Advantage 11Th Edition Solutions Manual PDFDocument2 paginiOperations Management For Competitive Advantage 11Th Edition Solutions Manual PDFLouis DodsonÎncă nu există evaluări

- Auditing For Managers - The Ultimate Risk Management ToolDocument369 paginiAuditing For Managers - The Ultimate Risk Management ToolJason SpringerÎncă nu există evaluări

- Cold Fear manual_englishDocument10 paginiCold Fear manual_englishHelmi IsmunandarÎncă nu există evaluări

- FINAL Session 3 Specific GuidelinesDocument54 paginiFINAL Session 3 Specific GuidelinesBovelyn Autida-masingÎncă nu există evaluări