Documente Academic

Documente Profesional

Documente Cultură

Electrode Booklet F Web 106

Încărcat de

satnamDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Electrode Booklet F Web 106

Încărcat de

satnamDrepturi de autor:

Formate disponibile

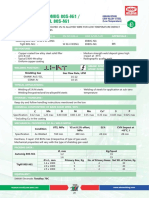

BETANOX 318 PLUS

STAINLESS STEEL (Austenitic Steel)

Stabilized 18/13/2 Mo type stainless steel Electrode

CLASSIFICATION : EN 1600 AWS A/SFA 5.4 IS 5206

E 19 12 3 Nb R 13 E 318-17 E 19.12.2 Nb R36

KEY FEATURES :

• Acid-Rutile based electrode • Good corrosion resistance to Sulphuric

• Low carbon 18/13/Mo/Nb stabilized and organic acids

weld deposit • Working temperatures upto 400°C

• Controlled ferrite prevent fissuring • Easy strike and re-striking

• Resistant to stress corrosion and inter- • Easy slag removal

crystalline corrosion cracking • Radiographic quality welds

WELDING POSITION : AC (70 OCV) /DCEP

TYPICAL APPLICATIONS :

• Welding of Nb and Ti stabilized SS such as AISI • Suitable for materials AISI 316L, 316Ti,

316, 318 and equivalent grades 316Cb, 1.4301, 1.4401, 1.4404, 1.4435,

• Welding of equipments in chemical, paper and 1.4436, 1.4437, 1.4541, 1.4550, 1.4571,

pulp, paint and dye industries 1.4580, 1.4581, 1.4583

REDRYING CONDITION : 250-300OC for minimum 1 hr. (Also available in vacuum packed condition)

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si Cr Ni Mo Nb S P

Typical 0.04 1.9 0.5 18.3 12.8 2.2 0.4 0.02 0.02

Specification 0.08 max 1.0-2.5 1.0 max 17.0-20.0 11.0-14.0 2.0-2.5 6xC-1.0 0.03 max 0.03 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

Condition UTS, MPa EL% Ferrite No.

Typical 615 36 5

As Welded

Specification 560-660 30-40 4-8

PARAMETERS - PACKING DATA :

Ø x L, mm Amperage, A Wt./Carton, Kg Cartons/Box Net wt./Box, Kg

2.5 x 350 50-75 2 5 10

3.15 x 350 80-100 2 5 10

4.0 x 350 110-140 2 5 10

5.0 x 350 150-180 2 5 10

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

106

S-ar putea să vă placă și

- Electrode Booklet F Web 105Document1 paginăElectrode Booklet F Web 105satnamÎncă nu există evaluări

- Electrode Booklet F Web 104Document1 paginăElectrode Booklet F Web 104satnamÎncă nu există evaluări

- Electrode Booklet F Web 101Document1 paginăElectrode Booklet F Web 101satnamÎncă nu există evaluări

- Electrode Booklet F Web 120Document1 paginăElectrode Booklet F Web 120satnamÎncă nu există evaluări

- Electrode Booklet F Web 97Document1 paginăElectrode Booklet F Web 97satnamÎncă nu există evaluări

- Betanox 308 Plus: STAINLESS STEEL (Austenitic Steel)Document1 paginăBetanox 308 Plus: STAINLESS STEEL (Austenitic Steel)satnamÎncă nu există evaluări

- Electrode Booklet F Web 110Document1 paginăElectrode Booklet F Web 110satnamÎncă nu există evaluări

- Electrode Booklet F Web 100Document1 paginăElectrode Booklet F Web 100satnamÎncă nu există evaluări

- Betachrome 17cr Welding ElectrodeDocument1 paginăBetachrome 17cr Welding ElectrodeSatyendra SinghÎncă nu există evaluări

- Electrode Booklet F Web 96Document1 paginăElectrode Booklet F Web 96satnamÎncă nu există evaluări

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 paginăNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelÎncă nu există evaluări

- Metalbond: Mild Steel General Purpose (MSGP)Document1 paginăMetalbond: Mild Steel General Purpose (MSGP)satnamÎncă nu există evaluări

- Electrode Booklet F Web 85Document1 paginăElectrode Booklet F Web 85satnamÎncă nu există evaluări

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 paginăNimoten: LOW ALLOY STEEL (Nimoten Series)satnamÎncă nu există evaluări

- Electrode Booklet F Web 8Document1 paginăElectrode Booklet F Web 8satnamÎncă nu există evaluări

- Electrode Booklet F Web 93Document1 paginăElectrode Booklet F Web 93satnamÎncă nu există evaluări

- Electrode Booklet F Web 9Document1 paginăElectrode Booklet F Web 9satnamÎncă nu există evaluări

- Celwel - 70P (Ador Electrodes)Document1 paginăCelwel - 70P (Ador Electrodes)Harish KandollaÎncă nu există evaluări

- Electrode Booklet F Web 13Document1 paginăElectrode Booklet F Web 13satnamÎncă nu există evaluări

- Electrode Booklet F Web 24Document1 paginăElectrode Booklet F Web 24satnamÎncă nu există evaluări

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Document1 paginăNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnamÎncă nu există evaluări

- Ador Welding Cromoten D For c5 & f5 WeldingDocument1 paginăAdor Welding Cromoten D For c5 & f5 WeldingShar MathewÎncă nu există evaluări

- Betanox D Welding ElectrodeDocument1 paginăBetanox D Welding ElectrodearavindpeetaÎncă nu există evaluări

- Electrode Booklet F Web 121Document1 paginăElectrode Booklet F Web 121satnamÎncă nu există evaluări

- Carbo 4370 Mpr-E307Document1 paginăCarbo 4370 Mpr-E307ali torabiÎncă nu există evaluări

- Electrode Booklet F Web 23Document1 paginăElectrode Booklet F Web 23satnamÎncă nu există evaluări

- Electrode Booklet F Web 90Document1 paginăElectrode Booklet F Web 90satnamÎncă nu există evaluări

- Tenalloy Z PlusDocument1 paginăTenalloy Z Plushemal ChauhanÎncă nu există evaluări

- Ebondm: Mild Steel General Purpose (MSGP)Document1 paginăEbondm: Mild Steel General Purpose (MSGP)satnamÎncă nu există evaluări

- Electrode Booklet F Web 22Document1 paginăElectrode Booklet F Web 22satnamÎncă nu există evaluări

- Electrode Booklet F Web 73Document1 paginăElectrode Booklet F Web 73satnamÎncă nu există evaluări

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 paginăTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiÎncă nu există evaluări

- Kingbond S: Mild Steel General Purpose (MSGP)Document1 paginăKingbond S: Mild Steel General Purpose (MSGP)satnamÎncă nu există evaluări

- Electrode Booklet F Web 20Document1 paginăElectrode Booklet F Web 20satnamÎncă nu există evaluări

- Electrode Booklet F Web 14Document1 paginăElectrode Booklet F Web 14satnamÎncă nu există evaluări

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 paginăTenalloy 125: LOW ALLOY STEEL (High Strength)satnamÎncă nu există evaluări

- Electrode Booklet F Web 21Document1 paginăElectrode Booklet F Web 21satnamÎncă nu există evaluări

- Nicalloy Fe 3 Basic Coated Nickel Based ElectrodeDocument1 paginăNicalloy Fe 3 Basic Coated Nickel Based ElectroderravibharathÎncă nu există evaluări

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 paginăX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainÎncă nu există evaluări

- Tenalloy 70D11Document1 paginăTenalloy 70D11pach-thÎncă nu există evaluări

- Hardfacing Electrodes: Brand ISDocument13 paginiHardfacing Electrodes: Brand ISashwini shuklaÎncă nu există evaluări

- Acfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmDocument1 paginăAcfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmdodoÎncă nu există evaluări

- Standards Approvals & Certificates: Rutil-Bazik Örtülü Elektrod - Non Alloyed SteelsDocument1 paginăStandards Approvals & Certificates: Rutil-Bazik Örtülü Elektrod - Non Alloyed SteelsBeshoy RedaÎncă nu există evaluări

- Tiginox 385: Classification: en Iso 14343-ADocument1 paginăTiginox 385: Classification: en Iso 14343-AJagannath SahuÎncă nu există evaluări

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 paginăTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamÎncă nu există evaluări

- E 7016 Product-SheetDocument1 paginăE 7016 Product-SheetAlireza TakrimiÎncă nu există evaluări

- Celwel - 60 (Adore Electrodes)Document1 paginăCelwel - 60 (Adore Electrodes)Harish KandollaÎncă nu există evaluări

- Böhler Fox Dcms KB: Classifi CationsDocument1 paginăBöhler Fox Dcms KB: Classifi CationsBranko FerenčakÎncă nu există evaluări

- Electrode Booklet F Web 18Document1 paginăElectrode Booklet F Web 18satnamÎncă nu există evaluări

- Stoody Super 20Document1 paginăStoody Super 20JUAN DAVID ESPITIAÎncă nu există evaluări

- Section 4: Specification ClassificationDocument1 paginăSection 4: Specification ClassificationTheo AnggaraÎncă nu există evaluări

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 paginăAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamÎncă nu există evaluări

- FPO22001 ASME Filer Metal Data SheetDocument5 paginiFPO22001 ASME Filer Metal Data Sheetyousab creator2Încă nu există evaluări

- Carbocast 1 - eDocument1 paginăCarbocast 1 - eali torabiÎncă nu există evaluări

- Böhler Fox CM 5 KB: Classifi CationsDocument1 paginăBöhler Fox CM 5 KB: Classifi CationsBranko FerenčakÎncă nu există evaluări

- ISO 3506 2 Mechanical Properties PDFDocument2 paginiISO 3506 2 Mechanical Properties PDFp2pcreep100% (1)

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 paginăTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaÎncă nu există evaluări

- Böhler Fox CN 13/4 Supra: Classifi CationsDocument1 paginăBöhler Fox CN 13/4 Supra: Classifi CationsBranko FerenčakÎncă nu există evaluări

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 paginăAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamÎncă nu există evaluări

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 paginăAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamÎncă nu există evaluări

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 paginăAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamÎncă nu există evaluări

- Tigfil Cuni: Classification: ApprovalsDocument1 paginăTigfil Cuni: Classification: ApprovalssatnamÎncă nu există evaluări

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 paginăAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamÎncă nu există evaluări

- CWC-BookletF1 59Document1 paginăCWC-BookletF1 59satnamÎncă nu există evaluări

- CWC-BookletF1 36 PDFDocument1 paginăCWC-BookletF1 36 PDFJagannath SahuÎncă nu există evaluări

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 paginăAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamÎncă nu există evaluări

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 paginăAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamÎncă nu există evaluări

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 paginăMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuÎncă nu există evaluări

- Tiginox 385: Classification: en Iso 14343-ADocument1 paginăTiginox 385: Classification: en Iso 14343-AJagannath SahuÎncă nu există evaluări

- CWC-BookletF1 9Document1 paginăCWC-BookletF1 9satnamÎncă nu există evaluări

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 paginăAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamÎncă nu există evaluări

- CWC-BookletF1 38 PDFDocument1 paginăCWC-BookletF1 38 PDFsatnamÎncă nu există evaluări

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 paginăAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamÎncă nu există evaluări

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 paginăAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamÎncă nu există evaluări

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 paginăAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamÎncă nu există evaluări

- CWC-BookletF1 15Document1 paginăCWC-BookletF1 15satnamÎncă nu există evaluări

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 paginăTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamÎncă nu există evaluări

- CWC-BookletF1 17Document1 paginăCWC-BookletF1 17satnamÎncă nu există evaluări

- CWC-BookletF1 12Document1 paginăCWC-BookletF1 12satnamÎncă nu există evaluări

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 paginăAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamÎncă nu există evaluări

- CWC-BookletF1 10Document1 paginăCWC-BookletF1 10satnamÎncă nu există evaluări

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 paginăAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamÎncă nu există evaluări

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 paginăTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamÎncă nu există evaluări

- CWC-BookletF1 9Document1 paginăCWC-BookletF1 9satnamÎncă nu există evaluări

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 paginăTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamÎncă nu există evaluări

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 paginăAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamÎncă nu există evaluări

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 paginăTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamÎncă nu există evaluări

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 paginăTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamÎncă nu există evaluări

- B670 07Document4 paginiB670 07Srinivasan KrishnamoorthyÎncă nu există evaluări

- Methanol PresentationDocument29 paginiMethanol PresentationCristina OzarciucÎncă nu există evaluări

- Sedar Perkasa SDN BHD - Company Profile 2023Document48 paginiSedar Perkasa SDN BHD - Company Profile 2023choong chloeÎncă nu există evaluări

- CountryProfile ProductMetadataforSectorDocument232 paginiCountryProfile ProductMetadataforSectorMeenakshi JaikrishnanÎncă nu există evaluări

- MOJAVE Single Wide 2015Document16 paginiMOJAVE Single Wide 2015Donnarose DiBenedettoÎncă nu există evaluări

- Electrical Actuator 21 31 42 Datasheet English PDFDocument4 paginiElectrical Actuator 21 31 42 Datasheet English PDFHeru Purwanto HeruÎncă nu există evaluări

- 3M™ Wrap Film Series 1380: Application On Substrates With RecessesDocument9 pagini3M™ Wrap Film Series 1380: Application On Substrates With RecessesAnonymous OCKxWxsjlÎncă nu există evaluări

- HES Casing Accessories CatDocument23 paginiHES Casing Accessories CatJoan Corso100% (1)

- Case 9Document2 paginiCase 9Chechaa PerezÎncă nu există evaluări

- Draka 2Document260 paginiDraka 2Sakinah Cik KinoÎncă nu există evaluări

- 2 Medición Correcta de Flujo en Biogas Húmedo - B200Document45 pagini2 Medición Correcta de Flujo en Biogas Húmedo - B200ChemicalProgrammerÎncă nu există evaluări

- Diploma Sittr 21 Revision Syllabus Strength of MaterialsDocument2 paginiDiploma Sittr 21 Revision Syllabus Strength of MaterialsYaduthilak YktÎncă nu există evaluări

- K 5 Premium Full Control Plus: Operating InstructionsDocument84 paginiK 5 Premium Full Control Plus: Operating Instructionsronald DÎncă nu există evaluări

- Identify The Following: Cien 3090 Construction Materials & Testing Midterm ExamDocument1 paginăIdentify The Following: Cien 3090 Construction Materials & Testing Midterm Examacurvz2005Încă nu există evaluări

- EZ Clean 1500Document4 paginiEZ Clean 1500sebasalinashjÎncă nu există evaluări

- Windsor Steampac WT Boiler Brochure 2019Document2 paginiWindsor Steampac WT Boiler Brochure 2019AnthonyÎncă nu există evaluări

- Pipe Standrad ASTMDocument4 paginiPipe Standrad ASTMTrà Nguyễn100% (1)

- 3 Methods of Determining Workability of ConcreteDocument4 pagini3 Methods of Determining Workability of Concretesuryakantame100% (1)

- MFC Hubli Final Bill Jan 2013Document12 paginiMFC Hubli Final Bill Jan 2013Nagaraj PatilÎncă nu există evaluări

- Equipment List Corn Oil Update Terbaru 01-10-2011Document8 paginiEquipment List Corn Oil Update Terbaru 01-10-2011ayiep1202Încă nu există evaluări

- E SN752Document3 paginiE SN752hasan_676489616Încă nu există evaluări

- Not For Sale: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationDocument24 paginiNot For Sale: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationEmiÎncă nu există evaluări

- Lighting: Tef 2440 Obstruction Light Low Intensity, Type ADocument2 paginiLighting: Tef 2440 Obstruction Light Low Intensity, Type Apramod_tryÎncă nu există evaluări

- 1995 R129-Owners-Manual PDFDocument148 pagini1995 R129-Owners-Manual PDFMarvin ChuaÎncă nu există evaluări

- NCH Tech Sheet Deox ThailandDocument1 paginăNCH Tech Sheet Deox Thailandson.brbÎncă nu există evaluări

- Bill No 1: Preliminary & GeneralDocument8 paginiBill No 1: Preliminary & GeneralOluwaseyi AyediranÎncă nu există evaluări

- Chapter 1 Basic DC TerminologyDocument9 paginiChapter 1 Basic DC TerminologyFahmi PrayogiÎncă nu există evaluări

- 2 - Conservation and The Use of Secondary and Recycled Materials PDFDocument16 pagini2 - Conservation and The Use of Secondary and Recycled Materials PDFfa_fa67Încă nu există evaluări

- 500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGDocument7 pagini500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGbinstartedÎncă nu există evaluări

- Elements - turbine-Turbo-TOC KaydonDocument3 paginiElements - turbine-Turbo-TOC KaydonnguyenanhtuanbÎncă nu există evaluări