Documente Academic

Documente Profesional

Documente Cultură

Well Foundation Obsolete NBMCW 2010

Încărcat de

Joel Junias0 evaluări0% au considerat acest document util (0 voturi)

27 vizualizări9 paginiThis is the research paper on well foundation

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis is the research paper on well foundation

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

27 vizualizări9 paginiWell Foundation Obsolete NBMCW 2010

Încărcat de

Joel JuniasThis is the research paper on well foundation

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 9

Well Foundations

for Bridges are Obsolete!!!

S.A.Reddi, Fellow Indian National Academy of Engineering

Introduction Pre-cast RC bored piles of to bouldery strata Despite best

2.5m diameter was first successfully efforts, the well only went down by

Bridge foundations are the most

realized in India for the old Thana 35.25 m after three seasons and at

complicated and difficult to

Creek Bridge constructed in 1960s. extra cost! The well was plugged at

construct. Unexpected difficulties

For the 13 Km long Saudi–Baharain RL 32.075 m and 5 nos 1.5 m dia

cause delays, extra costs and

Causeway large diameter pre-cast RCC bored piles (25-35m) were

revision of designs due to altered

pre-stressed bored piles were provided to anchor the well, one in

situations. Loss of human lives was

adopted. By 2005, piles of 2-3 m the middle through the dredge hole

normal rather than exception. In the

dia, upto 120m deep are extensively and 4 outside at the four corners.

Sixties, more than 50 lives were

used in the rest of the world. These Further a launching apron of crated

lost due to the accident during

new techniques eliminate boulder 3 m thick was laid making

pneumatic sinking operations for

complicated weather-dependent a circle of 60 m dia around the

well foundations of Mahanadi bridge

and risky operations in water. They well, at RL 61.00. These extra works

in Orissa. For Kali Bridge at Karwar

have reduced the delays caused further delay in the comp-

in Karnataka, pneumatic sinking

considerably and minimized the letion of the substructure works.

was required for inspection of the

technical and financial risks. The

founding surface of the wells. Apart Well foundations on

development of modern techniques

from delays and extra costs, large sloping rock:

has considerably reduced quantities

number of workers suffered caisson

disease. Due to difficulties in well

of materials used for foundations Brahmaputra Bridge at

as well as energy consumption and

sinking, two contractors left the job Jogighopa (2.28 km)

environmental impacts.

and the third took more than 5 The wells of main span were 11 m

years to complete the well Well Foundation x 17 m double ‘D’ type. Foundations

foundations. Alternative construction 17 & 18 were resting on hard rock

techniques and equipments have Problems at at steep incline of almost 1:1 slope.

emerged. With the introduction of It was not possible to rest the

advanced piling equipment, large

Brahmaputra Bridge

foundations partially on two types

diameter piles up to 3.5 m dia are at Tezpur of strata. Hence to found these

easily realized at a fast rate, with a The bridge was more than 3 km wells, 1500 mm dia anchor piles,

significant reduction in cost and long with 26 spans of 120 m and 2 12 nos for each foundation were

material quantities. Bridges shore spans of 70 m each, founded provided through the body of the

elsewhere are now constructed with on 12m dia Wells. Sinking well No.2 steining, extending to about 10 m

pile foundations. to full depth was not possible due below the cutting edge.

148 NBM&CW SEPTEMBER 2010

Additional cost was several The calculated maximum scour

crores. Effective use of Pile depth was 36 m below water level.

Foundations - Jamuna River The soil strata were sandy up to

Bridge in Bangladesh (figs.2 about 30 m followed by hard stiff

&3). clay. During construction, the wells

A 4.8 km long, four lane started tilting and the problems

road bridge with 100 m spans continued right through the sinking.

was constructed in the 1990s Despite extensive chiseling, the rate

on the Jamuna river of sinking was painfully slow.

(Brahmaputra in India). The Well 2 - The founding level was

foundation design was 64.7 m below the water level.

challenging. Very deep wells The rate of sinking through clay

are extremely slow to construct, was about 1.5 - 2 cm/hr. 3500

costly, increasing the total cost. crane hours were used to sink

Various alternatives were the well.

considered including caissons, Well 17 - The well shifted by 1.86

driven precast piles and driven m. The piers were to be retained

steel tubular piles. The only at the original position; resulting

viable option was large in excessive moments in the well.

Figure 1: Brahmaputra bridge foundations

No. 17 & 18 diameter tubular steel piles To counter the moments

driven at a rake (fig.2). The counterweight was provided in the

piles were fabricated in Korea, form of a dummy well sunk to a

shipped to site and installed depth of 20 m in the adjacent

by hydraulic hammer. The area and connected to the main

diameter of the piles ranged well through a common well cap.

between 2.5 and 3.15 m and Well 32 - The well shifted by

the steel tubes were filled with 1150 mm. A similar solution as in

concrete. Maximum pile length well 17 was adopted.

was 72 m below bed level. Well 4 - During concreting of

During one working season curb, sand leaked from the island

from October 1995 to June and the entire curb tilted and sank

1996 all the 121 main work by 4.5 m. A new sheet pile

piles plus two full scale trial cofferdam had to be erected and

piles were driven. a new well curb was cast. The

Figure 2: Pile foundations for Jamuna bridge

This optimization resulted total delay was one month.

in overall reduction in the Well 9 - the total height of the

bridge costs by more than steining except last 2 m was

50%. This solution also completed with 7.5 m balance

reduced the use of resources sinking. Due to presence of stiff

(concrete and steel) clay, 8 m sump was made to

considerably and was facilitate sinking. After several

beneficial to environmental weeks, the well suddenly jumped

Figure 3: Completed view of the Jamuna bridge

impact. The piles were by about 9 m with the top of

installed in 8 months; the well steining below water level. Work

Due to the steep incline, part of

foundations of three bridges across resumed after monsoon. A

the cutting edge was resting on the

the same river constructed in India temporary RC cofferdam was

rock while the other parts were

have taken 3-5 years each to constructed and the sunk well

overhanging. In order to contain the

complete. dewatered to expose and build

bottom plug, two rows of jet grouted up further steining. Time loss:

piles were introduced around the Damages During about 6 months.

periphery of the well steining which

Construction - Ganga Wells 3 & 4 -Wells were sunk by

acted as curtain wall (fig.1). 1500

about 44 and 37 m before the

dia piles also driven up to hard Bridge at Bhagalpur (4.6

monsoon season in 1996. The

rock along the periphery through km) wells were toppled due to scour

the steining. The completion of the The well foundations consist of and disappeared during the

project was extended by 3 years. single circular wells 11.6 m dia. floods. Based on a number of

150 NBM&CW SEPTEMBER 2010

trial bores well No.3 was found total height of steining except last 2 An Expensive

tilted along the bridge axis. Well m was concreted. The well was in

No.4 was found on the upstream the final stages of steining, with Solution Indeed !!

side along the direction of current. about 7.5 m to reach the founding The completion was delayed by

These wells weighing up to level. As the well was stuck up in more than one season as the

9900 t could not be restored and stiff clay, efforts were made to sink solution was based on an Expert

were abandoned. New wells were the well by creating a sump of about Committee investigation and report.

cast and sunk by changing the 8 m below the cutting edge. All of a This led to delay in finalization of

span arrangement. Floating sudden the well sank suddenly by the designs and drawings for the

caissons were used. about 9 m and the top of steining foundation well and necessity of

Extra cost and time - The cost on was below the water level by about issuing variation orders to cover the

completion was Rs.106 cr against 3.5 m. Rectification measures were items of cut-off walls and bed

accepted tender cost of Rs.55 cr! very expensive and time consuming. protection works which were not

The time overrun was 5 years! Ganga bridge at Varanasi: Very envisaged in the original contract.

stiff clay was encountered at 25 m

Tilts and Shifts in Well below and sinking of well Ganga Bridge, Patna

Foundations - Vasai foundations No. 3 and 5 was very The 5.6 km long bridge comprises

Creek Bridges Near difficult, did not move for three of 46 spans of 120 m each resting

months. Then well No.3 jumped by on 56 m deep well foundations

Mumbai several meters without any warning (12m dia.). Two of the wells in the

Bassein Creek road bridge near when two workers and one midstream (Nos. 41 and 45)

Mumbai (1970) faced problems of supervisor were taking sump encountered artesian conditions

heavy tilting of the well foundations. sounding. The tragic accident killed during the final stages of sinking

Two of the foundations no.4 & 6 all the three people. The well No.5 There was continuous sand

tilted very heavily and all attempt to also jumped by about 5 m and blowing filling the dredge hole to 5-

correct the tile failed. The was submerged in the water by 6 m above the cutting edge. Months

foundations were abandoned and 1m. of efforts to sink the well proved

the design of the bridge was futile. A technical advisory committee

changed to accommodate new Artesian Conditions took about a year for arriving at a

foundations and longer spans. The During Construction of solution. Temporary steel cofferdam

project was delayed by six years

with termination of the first contract,

Well Foundations was built enveloping the well and

an artificial head of about 6 m of

arbitration, litigation. Nepal Bridge (Kohalpur / water was created to counter act

Despite previous histories of Mahakali Section ) the sand bubbling. Delay: two years

two bridges built across the same Artesian conditions were

creek that faced problems with well Cracking of Well Steining

encountered during soil

foundations, the same were again investigations for the Shivganga During Construction

adopted for another Vasai Creek bridge (8 spans of 32 m). At Cracking of well steining is one of

Bridge. During construction, heavy locations P-4 and P-5 artesian head the serious problems faced many

tilting of wells was observed. The of about 4.3 m was encountered at times in the construction of well

corrective measures for one well about 17 m below ground level. foundations, resulting in time and

alone took almost two years The well was redesigned with cost overruns. The causes are

delaying completion of the foundation terminating above the usually:

foundations; costing about Rs. 2 artesian layer, resulting in shallow 1. Blasting, Dewatering

crores. foundations resting on clay. Due to 2. Insufficient steining thickness

founding the wells at shallow depth, 3. Jumping due to excessive sump

Sudden Jumping of Wells

it was necessary to provide 4. Sand blows

During Sinking adequate bed protection so as to 5. Surcharge due to dumping

Sometimes the well sinks suddenly prevent scour. The bed protection dredge material close to well.

due to excessive sump or weak consisted of : 6. Failure of cutting edges.

soil layer and the steining Upstream and downstream When such cracking occurs, at

disappears below water level, aprons least one season is lost for the

making it difficult to continue further Cut-off walls, upstream & investigation, developing remedial

work on the well steining. downstream measures, approvals of the same

In one of the well foundations Concrete floor etc. In the last 45 years, the author

in a bridge across river Ganga, the is aware of more then 200 cases

152 NBM&CW SEPTEMBER 2010

Analysis by the Federal

Highway Administration

(FHWA), USA

More than 100,000 bridges would

be constructed during the next two

decades. Foundations represent

about 30% or more of the cost of

the highway bridges. The

predominant type of foundation

Figure 5: Pasighat Bridge, Boulder system used for the highway

Figure 4: Pasighat Bridge, AP

dredged during well sinking

bridges in the US is pile. Many

bridges can tolerate significant

of bridges constructed by various beginning of sinking. After 15 years magnitudes of a total and differential

construction agencies, where the of struggle to pneumatically sink vertical settlement without becoming

dredge hole of well has to be filled the wells to RL – 50 m, the seriously over-stressed

with concrete due to cracks in designed founding level was

steining. drastically raised by 22m in 2002. Appreciation

During well sinking of Tapi The Indian Bridge Engineers are by

Major Bridges and large mentally tuned to

Bridge, Maharashtra, hard strata

was met. Due to blasting, extensive (Worldwide) on Pile providing well foundations for

bridges as a reflect action; whereas

cracks developed in steinings New Foundations

steinings had to be constructed it is very necessary to analyze the

Su Tong Bridge, China : The 6 km

inside the wells. The original comparative merits and demerits,

long Cable-stay bridge crosses

contract period was four years. construction time frame and cost of

Yangtze river near Shangai will carry

Attempts were made for five years construction of bridges with well/

a six lane highway with emergency

to sink the wells. Work was pile foundations before finally

lanes, with a record 1088 m main

suspended for five years for want choosing the type of foundation. An

span and 300 m high concrete

of decision to revise the founding analysis of the history of well

pylons. Each tower is supported on

level. An expert committee ultimately foundations during the last five

131 cast-in-situ bored piles 120 m

recommended raising the decades indicates innumerable

long and 2.7 m diameter. Due to

foundation level of wells by more difficulties, delays and cost overruns

strong currents, significant scour is

than 20m The bridge was in a majority of the cases.

expected around the foundations,

completed after fourteen years. The Realization of well foundations

and suitable scour protection is

contractor suffered losses due to requires special skills and

provided around the pylons. The

the delays. The owner suffered experience which are gradually

central span has a clearance of 62

substantial losses due to time dwindling.

m for container ships to pass

overrun. Delay: 10 years. Developments have taken place

through. The bridge used 200,000 t

in respect of large diameter pile

Extraordinary Delays in of steel, 1 million cum of concrete.

foundations as well as equipment

Stonecutters Bridge, Hong

Construction of Well Kong: The 1600 m long

for the same. The time and cost

Foundations Pasighat advantages of opting for pile

Stonecutters Bridge Hong Kong with

foundations have been amply

Bidge, Arunachal cable-stay span of 1018 m is one

demonstrated worldwide and to a

of the longest in the world. The

Pradesh, 703 m long bridge is founded on 3.0 m dia

limited extent in India. Piles up to a

The project started in 1987 and the diameter of 3m and depth of up to

piles, up to 90 m deep, socketted

construction of well foundations 120m have been realized for a

into rock. Bandra Worli Sea Link

continued for the next 20 years! As number of major bridges

Mumbai: The sea link consists of

per the design, based on worldwide, with cost saving of up to

5.6 km long, 8-laned bridge with

misleading soil data, six wells were 40% when compared to well

cable stayed portion of 600 m. The

to be sunk to about 50 m below foundations.

bridge is founded on 1.5 m

bed. The actual strata met with There is currently no restriction

diameter bored piles. Concrete for

during sinking were hard in the IRC Code regarding use of

the piles is M50 grade and for pile

conglomerate with densely pile foundation. However, many

caps is M60. Silica fume and fly

compacted and very large boulders Owners impose restrictions in the

ash are used for concrete

(fig.6) were found right from the tender documents, without any

preparation.

154 NBM&CW SEPTEMBER 2010

segments. This was made

possible by an high early strength

concrete which enabled pre-

stressing at 60 hours after

concreting. Fe500 steel

reinforcement bars were used for

the first time in India in a cantilever

construction bridge. The huge

Bearings with anchors were located

among highly congested

reinforcement; normal concrete

Figure 6: Chenab Bridge at Akhnoor-Longest Span Cantilever PSC Bridge,

eliminated wells

placement, vibration was

impossible. Special Conbextra

justification. The example cited sunk wells and go for a scheme Grout replaced normal High

above concerning the problems of with longer central span, eliminating Strength Concrete below bearings.

well foundations amply justifies a the water foundations altogether. Self–compacting concrete (S.C.C)

second look on the choice of With a 160m central span, both the was used for the first time for

foundations. In fact, the use of well main pier foundations were located concrete below the bearings.

foundations for bridges should be in the dry on the banks, resting on Segments on both sides of the

an exception rather than the rule. raft foundations. These foundations Pier were concreted simultaneously

were completed in months instead balancing the weights. When the

Chenab River Bridge at of decades earlier in unsuccessful 22nd segments were facing each

Akhnoor Near Jammu attempts to sink wells in water. The other and the shuttering of the 23rd

abutments consist of hollow box segment i.e. the linking segment

The project was started in the early

and piers consist of hollow was to have been placed there was

Seventies. A .scheme for a 231m

rectangular section on raft no level difference and the levels

long bridge with 5 spans

foundations. matched on both tips to the nearest

(3x46+2x46.5) upstream of existing

The superstructure was millimeter both in plan (centre line)

steel bridge was originally

designed and constructed as a as well as in elevation. This was

conceived. The scheme involved

continuous cantilever of 280m possible because every day the

construction of five well foundations

length, with a central span of 160m levels were maintained by a team

in the volatile Chenab River, to be

(longest in India at the time). Two of surveyors with the help of total

sunk through difficult strata – hard

pairs of cantilever gantries were station. These levels were sent to

conglomerate, in spite of

deployed. The bridge with the new the Design consultant who

insurmountable difficulties

layout eliminating well foundations monitored these personally. In fact,

elsewhere under similar

was completed in 20 months after the concreting of each pair of

circumstances. Two successive

Other Records: The Chenab segments the levels as actually

contracts and 30 years later, the

bridge deck was constructed with measured and as envisaged by the

impossibility of sinking wells

the shortest time cycle of 6 days designer fitted almost like a ‘T’.

through such strata was realized.

consistently achieved for the This proves that the parameters

Based on lateral thinking, it

construction of each pair of fixed by the Design consultant and

was decided to abandon the partly

the parameters as actually achieved

during execution were

complimenting each other. The

cables were so placed that almost

all the cables were straight and

without any curve. Thus

prestressing results were exactly as

shown in approved drawings both

in terms of extension and gauge

pressure.

Figure 7: Chenab Bridge, Giant Figure 8: Chenab Bridge Hydraulic Earthquake The author was Value

Bearings Dampers Engineering Consultant for the Fast

Track Project.

158 NBM&CW SEPTEMBER 2010

S-ar putea să vă placă și

- Well Foundations For Bridges Are ObsoleteDocument8 paginiWell Foundations For Bridges Are Obsoletesa_reddiÎncă nu există evaluări

- Well FoundationDocument56 paginiWell FoundationSriram Nandipati67% (3)

- Teesta-III Cut-Off WallDocument7 paginiTeesta-III Cut-Off WallAnil KumarÎncă nu există evaluări

- Engineering Geology For Weak Rocks of Abu Hamour Surface and Ground Water Drainage Tunnel Phase-1 Doha, QatarDocument6 paginiEngineering Geology For Weak Rocks of Abu Hamour Surface and Ground Water Drainage Tunnel Phase-1 Doha, Qatarsebastian titusÎncă nu există evaluări

- Landfall and Shore Approach PDFDocument7 paginiLandfall and Shore Approach PDFvpandya1981100% (1)

- TBM1Document9 paginiTBM1REDDYGAARI ABBAYIÎncă nu există evaluări

- Dam HRT Surge TankDocument27 paginiDam HRT Surge Tankjitendra15496Încă nu există evaluări

- Extreme Excavation in Fault Zones and Squeezing Ground at The Kargi HEPP in TurkeyDocument11 paginiExtreme Excavation in Fault Zones and Squeezing Ground at The Kargi HEPP in TurkeynishantÎncă nu există evaluări

- Hoover Dam (USA) : Problem Technology/ EquipmentDocument8 paginiHoover Dam (USA) : Problem Technology/ EquipmentEdence PuahÎncă nu există evaluări

- Tunnel Boring Machines Used For Irrigation in Andhra Boring Machines Used ForDocument8 paginiTunnel Boring Machines Used For Irrigation in Andhra Boring Machines Used ForEE MI NandyalÎncă nu există evaluări

- Construction of Large Span Shallow Tunnels: A Case Study From The New M5 - PublishedDocument6 paginiConstruction of Large Span Shallow Tunnels: A Case Study From The New M5 - Publisheddafo407Încă nu există evaluări

- Group Members:: Aditya Chauhan Maninder Pal Singh Abhishek Sonkhla Abhishek Sharma Mohit RanaDocument60 paginiGroup Members:: Aditya Chauhan Maninder Pal Singh Abhishek Sonkhla Abhishek Sharma Mohit RanaManinderSachdevaÎncă nu există evaluări

- Eg Unit 5Document20 paginiEg Unit 5Shifranth VarmaÎncă nu există evaluări

- A Review Study On Methods of Tunneling I PDFDocument5 paginiA Review Study On Methods of Tunneling I PDFpaÎncă nu există evaluări

- Difficulty in Sinking Well FoundationDocument22 paginiDifficulty in Sinking Well Foundationhussain9000100% (1)

- CIGRE Engineering Solutions To Mitigate Construction Challenges of New Overhead LinesDocument11 paginiCIGRE Engineering Solutions To Mitigate Construction Challenges of New Overhead LinesMalik Shoaib khalidÎncă nu există evaluări

- Overcoming Squeezing in The Yacambu - Quibor Tunnel, VenezuelaDocument30 paginiOvercoming Squeezing in The Yacambu - Quibor Tunnel, VenezuelaFelipe UribeÎncă nu există evaluări

- Padma Bridge-Design For Severe Earthquake and Deep Riverbed ScourDocument2 paginiPadma Bridge-Design For Severe Earthquake and Deep Riverbed ScourShekh Muhsen Uddin AhmedÎncă nu există evaluări

- Foundations Failures of Bridges and Geotechnical InvestigationsDocument5 paginiFoundations Failures of Bridges and Geotechnical InvestigationsWilhelm WesselsÎncă nu există evaluări

- Unit 8 TunnelsDocument11 paginiUnit 8 TunnelsPrakash PatelÎncă nu există evaluări

- Centenial Bridge, Panama - Medellin 10-18-17 v04Document126 paginiCentenial Bridge, Panama - Medellin 10-18-17 v04Miguel MasmelaÎncă nu există evaluări

- Malpasset (Var) France: Burst of A Dam 2 December 1959Document7 paginiMalpasset (Var) France: Burst of A Dam 2 December 1959Yuvraj M. SinghÎncă nu există evaluări

- Cho S M Et Al 2008 Geotextile Tube Application As The Cofferdam at The Foreshore With Large Tidal Range For Incheon Bridge Project PDFDocument6 paginiCho S M Et Al 2008 Geotextile Tube Application As The Cofferdam at The Foreshore With Large Tidal Range For Incheon Bridge Project PDFMuhammad Rizki AnwarÎncă nu există evaluări

- A Study On Construction Challenges of Bridges in The Hilly Areas of TamilnaduDocument29 paginiA Study On Construction Challenges of Bridges in The Hilly Areas of TamilnaduShraman GuptaÎncă nu există evaluări

- Well FoundationDocument9 paginiWell FoundationManmeet SinghÎncă nu există evaluări

- Class 9 DamsDocument46 paginiClass 9 DamsVikaas SagerÎncă nu există evaluări

- Bi 012008 EngDocument3 paginiBi 012008 EngSivaramanÎncă nu există evaluări

- 6-5 Pro 2020Document9 pagini6-5 Pro 2020vishal koushalÎncă nu există evaluări

- P2270107 - Section IIDocument5 paginiP2270107 - Section IIAniruddha ChakrabortyÎncă nu există evaluări

- 4 The Yamuna Cable Stayed Bridge at Allagabad, India - Design and Constuction AspectsDocument9 pagini4 The Yamuna Cable Stayed Bridge at Allagabad, India - Design and Constuction AspectsIndra MishraÎncă nu există evaluări

- Dagachhu HEP February 2014Document5 paginiDagachhu HEP February 2014Gaddam Padmaja Reddy0% (1)

- Srisailam Boillaert MasonDocument8 paginiSrisailam Boillaert MasonzuenboÎncă nu există evaluări

- Curve Jacking - Paper Bangkok T-1ThorenDocument10 paginiCurve Jacking - Paper Bangkok T-1ThorenCheng KimHuaÎncă nu există evaluări

- Published Tunnelling Article in Construction TimesDocument6 paginiPublished Tunnelling Article in Construction TimesDEBASIS BARMANÎncă nu există evaluări

- Eddie Wong Aecom PDFDocument79 paginiEddie Wong Aecom PDFAishwarya Kumar100% (1)

- 4 Design and Construction of The Millennium Dome, UKDocument5 pagini4 Design and Construction of The Millennium Dome, UKDiannisa Rachmawati100% (2)

- IJABR V7I1 2016 18 Yousef ParishDocument8 paginiIJABR V7I1 2016 18 Yousef ParishMukhlish AkhatarÎncă nu există evaluări

- The Hong Kong-Zhuhai-Macao BridgeDocument5 paginiThe Hong Kong-Zhuhai-Macao BridgeNtongwe ClovisÎncă nu există evaluări

- Design Optimization of Light Metal Irrigation Channels: Honggang ZHENGDocument5 paginiDesign Optimization of Light Metal Irrigation Channels: Honggang ZHENGAbdullah MangatongÎncă nu există evaluări

- 2B Basics of Tunnelling PDFDocument1 pagină2B Basics of Tunnelling PDFBIRUK FEKADUÎncă nu există evaluări

- Bhavani Type Stilling BasinDocument4 paginiBhavani Type Stilling BasinRaju Kumar MishraÎncă nu există evaluări

- Po 37Document7 paginiPo 37Harold TaylorÎncă nu există evaluări

- Taney Bridge Paper 21-01-03Document35 paginiTaney Bridge Paper 21-01-03Doug WeirÎncă nu există evaluări

- Pipe Jacked TunnelsDocument10 paginiPipe Jacked Tunnelsretk0801Încă nu există evaluări

- Tunnel LiningDocument29 paginiTunnel LiningAkash akshayÎncă nu există evaluări

- Dewatering Hydraulic Failure and Subsequent Analysis of A SheeteDocument6 paginiDewatering Hydraulic Failure and Subsequent Analysis of A Sheetefarel nandaÎncă nu există evaluări

- Civil Construction Project Development in The Himalayas Solving Geotechnical Challenges - HydroWorldDocument7 paginiCivil Construction Project Development in The Himalayas Solving Geotechnical Challenges - HydroWorldWkÎncă nu există evaluări

- 10 - Tunnelling and Underground SpaceDocument119 pagini10 - Tunnelling and Underground SpaceHassanÎncă nu există evaluări

- Ramboda Pass TunnelDocument11 paginiRamboda Pass Tunnelnandasoma100% (1)

- Pubb-0584-L-Settlements Induced by Jet-GroutingDocument9 paginiPubb-0584-L-Settlements Induced by Jet-GroutingMarco Dos Santos NevesÎncă nu există evaluări

- Construction of The Seikan Undersea Tunnel - IIDocument7 paginiConstruction of The Seikan Undersea Tunnel - IIAbdelali SolÎncă nu există evaluări

- Geological Criteria For Dams: Deeptesh Karmalkar ES16BTECH11013Document4 paginiGeological Criteria For Dams: Deeptesh Karmalkar ES16BTECH11013Deeptesh KarmalkarÎncă nu există evaluări

- Sardar Sarovar Project - The Engineering MarvelDocument15 paginiSardar Sarovar Project - The Engineering MarvelJ TÎncă nu există evaluări

- Bridges, Cofferdams and Caissons A Bridge: Is A Structure Which Provides Passage Facilities Over An ObstacleDocument23 paginiBridges, Cofferdams and Caissons A Bridge: Is A Structure Which Provides Passage Facilities Over An ObstacleJoseph EzekielÎncă nu există evaluări

- Th16 766Document4 paginiTh16 766Soumen BoseÎncă nu există evaluări

- Transactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159De la EverandTransactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159Încă nu există evaluări

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionDe la EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionÎncă nu există evaluări

- EVehicle - Vehicle ServicesDocument1 paginăEVehicle - Vehicle Servicesgoodgirl11Încă nu există evaluări

- Warehouse KPIs TypesDocument19 paginiWarehouse KPIs TypesIldefonso OchoaÎncă nu există evaluări

- Full Download Brock Biology of Microorganisms 15th Edition Madigan Test BankDocument35 paginiFull Download Brock Biology of Microorganisms 15th Edition Madigan Test Bankbeizatikeorar100% (20)

- Eu-Listed Yards Can Handle Recycling Demand of Eu-Flagged Ships - DataDocument8 paginiEu-Listed Yards Can Handle Recycling Demand of Eu-Flagged Ships - Datapepe cruzÎncă nu există evaluări

- Case Study ThirteenDocument6 paginiCase Study ThirteenDiljot SinghÎncă nu există evaluări

- Vessels PDFDocument24 paginiVessels PDFtoshugoÎncă nu există evaluări

- LFV Wall Chart 2015 FinalDocument2 paginiLFV Wall Chart 2015 FinalKarunya GoliÎncă nu există evaluări

- Swift Society for Worldwide Interbank Financial Telecommunication 環球銀行財務電信協會Document7 paginiSwift Society for Worldwide Interbank Financial Telecommunication 環球銀行財務電信協會Florencia PaisÎncă nu există evaluări

- Svetsaren 1 2009Document72 paginiSvetsaren 1 2009João Diego FeitosaÎncă nu există evaluări

- Wireless Sensor Networks For Civil Infrastructure MonitoringDocument22 paginiWireless Sensor Networks For Civil Infrastructure MonitoringTruc PhanÎncă nu există evaluări

- Product Guide: FeaturesDocument16 paginiProduct Guide: FeaturesJavier Ignacio MacíasÎncă nu există evaluări

- Fact Sheet - VolvoDocument2 paginiFact Sheet - VolvoMihai AncutaÎncă nu există evaluări

- Cimc Flat Rack ManualDocument14 paginiCimc Flat Rack Manualjuan.vargas.calle6904Încă nu există evaluări

- Mobileye Smartphone App User Guide v0.1Document14 paginiMobileye Smartphone App User Guide v0.1Janio MachadoÎncă nu există evaluări

- Xt600e 3tb-3uw 90-95Document46 paginiXt600e 3tb-3uw 90-95Kenneth SynnesÎncă nu există evaluări

- Crown SP 3500 Stock Picker Lift Truck Operator's Manual PDFDocument22 paginiCrown SP 3500 Stock Picker Lift Truck Operator's Manual PDFVüsal 1Încă nu există evaluări

- Logistic NotesDocument16 paginiLogistic NotesFatima AliÎncă nu există evaluări

- 2012 40' Azimut 40S - Sample Survey ReportDocument53 pagini2012 40' Azimut 40S - Sample Survey ReportSuenos Azules67% (3)

- ProcessDocument29 paginiProcessAnkit VermaÎncă nu există evaluări

- Project 5 Sem Final ReportDocument41 paginiProject 5 Sem Final Reportvijay shindeÎncă nu există evaluări

- TMG Hold & Check Points 16.11.17Document54 paginiTMG Hold & Check Points 16.11.17anjnaÎncă nu există evaluări

- ComunicationDocument220 paginiComunicationmathivananÎncă nu există evaluări

- October Optimized 10Document84 paginiOctober Optimized 10Saksham PatelÎncă nu există evaluări

- List of Pin Codes of MaharashtraDocument459 paginiList of Pin Codes of MaharashtraAbhishek KumarÎncă nu există evaluări

- S AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Document17 paginiS AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Mohammad Al JedyÎncă nu există evaluări

- CP Rider JenfijrkvefDocument36 paginiCP Rider JenfijrkvefEnriqueÎncă nu există evaluări

- Cerritos Station TOD District Final Report WebDocument106 paginiCerritos Station TOD District Final Report WebradengembullÎncă nu există evaluări

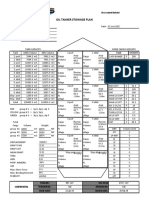

- Group 4 RDF 027 Oil Tanker Stowage Plan Rev 1.0 EditableDocument1 paginăGroup 4 RDF 027 Oil Tanker Stowage Plan Rev 1.0 Editablegidjuns abs100% (1)

- Caustic Soda ManualDocument63 paginiCaustic Soda ManualFarhan Zafar Khan100% (1)

- 03 - Par A - BridgesDocument109 pagini03 - Par A - BridgesDhrubajyoti DattaÎncă nu există evaluări