Documente Academic

Documente Profesional

Documente Cultură

MEK-2500 Installation Preparation Guide

Încărcat de

cuongDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MEK-2500 Installation Preparation Guide

Încărcat de

cuongDrepturi de autor:

Formate disponibile

1.

1 - Process Site Selection

1 Installation Preparation Guide

1.1 Process Site Selection

Careful siting of the transmitter is essential for optimum performance and ease

of maintenance.

The transmitter can be installed in a vertical, horizontal or inclined pipe. If

installed in a horizontal or inclined pipe, the location should be carefully

selected so that it does not measure large bubbles trapped in the pulp.

Measuring vessels for use in low pressure installations may be of left-hand or

right-hand design.

Your BTG sales engineer can help you select the location that will give the

best results in line with your specific control strategy.

MEK-2500 Installation Preparation Guide 1

© BTG 2008

1.1 - Process Site Selection

Fig 1 Recommended minimum

calming length - distance

between pump/pipe elbow/

shut-off valve and

consistency transmitter

The minimum distance the

transmitter should be located

downstream of a pump, bend or

LU LU

elbow is the greater of two

numbers:

Upstream the transmitter LU:

1 m (3 ft.), or the diameter of the

pipe multiplied by 3 where

consistency is <8%; and 0.5 m (1.5

ft.), or the diameter of the pipe

multiplied by 1.5 where

Ld

consistency is >8%.

Downstream the transmitter Ld:

For all consistencies, the minimum

distance between the transmitter

and a pump, bend or elbow located

downstream is similarly the greater

of two numbers:

0.5 m (1.5 ft.), or the diameter of LU

the pipe multiplied by 1.5

Ld

NOTE!

Always choose the largest of the 1.5

LUx

values calculated above.

NOTE!

In order to obtain the best measuring results, it is strongly recommended that

the transmitter is mounted in relation to the piping and other equipment as

shown in the figures above.

2 MEK-2500 Installation Preparation Guide

© BTG 2008

1.1 - Process Site Selection

Fig 2 Installation of the

transmitter near a

pipe elbow

NOTE!

Alt. A is the most suitable. Avoid

using alt. C.

Important recommendations:

1. to ensure minimum time lag, install the transmitter as close as possible to

the point where dilution water is injected.

2. Install the transmitter at a height where it will be difficult to reach, build a

platform that will make it more easily accessible for service and inspection.

3. It is important to choose a location with sufficient room for insertion and re-

moval of the transmitter and opening its covers. The overall length of the

transmitter is 464 mm (18.8 inches). Remember to leave sufficient room for

insertion and removal.

4. Install the transmitter so that it is protected from direct mechanical damage.

Install under a roof if there is any risk of frequent water or pulp spray.

5. Protect the transmitter from heavy vibration such as cavitation or unbal-

anced pumps. One method is to install a rubber bellows in the line.

MEK-2500 Installation Preparation Guide 3

© BTG 2008

1.1 - Process Site Selection

4 MEK-2500 Installation Preparation Guide

© BTG 2008

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- TMX600Document74 paginiTMX600cuongÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Documentation CFC Templates Motor - Rev.01Document11 paginiDocumentation CFC Templates Motor - Rev.01cuongÎncă nu există evaluări

- TMX1000ADocument74 paginiTMX1000AcuongÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- TMX800SDocument71 paginiTMX800ScuongÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- TMX800Document74 paginiTMX800cuongÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Safety Regulations - Small Drums - 2005Document15 paginiSafety Regulations - Small Drums - 2005cuongÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- ModuScreenC4R Part ListDocument6 paginiModuScreenC4R Part ListcuongÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- TMX600ADocument20 paginiTMX600AcuongÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- TMX800SDocument21 paginiTMX800ScuongÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- AhlCleaner RB 300 HD - en EOMDocument24 paginiAhlCleaner RB 300 HD - en EOMcuongÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- JM JTManualDocument23 paginiJM JTManualcuongÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- LT-600HOC HCP-1000 Manual With Universal Backbox Jun 3 PDFDocument80 paginiLT-600HOC HCP-1000 Manual With Universal Backbox Jun 3 PDFdiejuanÎncă nu există evaluări

- TMX1000ADocument20 paginiTMX1000AcuongÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Technical DocumentationDocument29 paginiTechnical DocumentationcuongÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- CPF2023LS Parts ListDocument87 paginiCPF2023LS Parts ListcuongÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Wika Pressure TransmiterDocument4 paginiWika Pressure TransmitercuongÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- ModuScreen C4R EOMDocument70 paginiModuScreen C4R EOMcuongÎncă nu există evaluări

- DF3805-04 Parts BookDocument70 paginiDF3805-04 Parts BookcuongÎncă nu există evaluări

- ModuScreen T2C EOMDocument69 paginiModuScreen T2C EOMcuongÎncă nu există evaluări

- ModuScreen T2C PARTLISTDocument11 paginiModuScreen T2C PARTLISTcuongÎncă nu există evaluări

- Erection Work, Operating and Maintenance Instructions: Belt Press CPF2023 SLDocument73 paginiErection Work, Operating and Maintenance Instructions: Belt Press CPF2023 SLcuongÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- CDI0 Part ListDocument61 paginiCDI0 Part ListcuongÎncă nu există evaluări

- Cdi0 EomDocument95 paginiCdi0 EomcuongÎncă nu există evaluări

- ModuScreen F EOMDocument67 paginiModuScreen F EOMcuongÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- DF3805-04 EomDocument98 paginiDF3805-04 EomcuongÎncă nu există evaluări

- 6100E Series User GuideDocument208 pagini6100E Series User GuideniketannaikÎncă nu există evaluări

- Configuration of Class 210 Transmitters by KeypadDocument24 paginiConfiguration of Class 210 Transmitters by KeypadcuongÎncă nu există evaluări

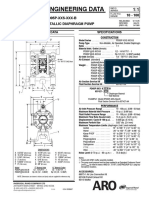

- Sales & Engineering Data: 10 - 100 PD05P-XXS-XXX-B 1/2" Non-Metallic Diaphragm PumpDocument2 paginiSales & Engineering Data: 10 - 100 PD05P-XXS-XXX-B 1/2" Non-Metallic Diaphragm PumpcuongÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- BT RRDocument456 paginiBT RRslawny7794% (17)

- Burkert General Catalogue Rev2Document44 paginiBurkert General Catalogue Rev2cuongÎncă nu există evaluări

- Presentation On CmsDocument14 paginiPresentation On Cmsjanu0% (1)

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 paginiRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandÎncă nu există evaluări

- Pressure Test REPORTDocument6 paginiPressure Test REPORTMANIMARAN QCÎncă nu există evaluări

- LV-110120-110220 35-35112 3in ANSI 300Document12 paginiLV-110120-110220 35-35112 3in ANSI 300mggz_15Încă nu există evaluări

- Coil Tubing ESP APCDocument6 paginiCoil Tubing ESP APCJhon Doe100% (1)

- ANDRITZ PumpsDocument2 paginiANDRITZ Pumpsventaseh 2019100% (1)

- Mechanical Boiler Inspection ReportDocument1 paginăMechanical Boiler Inspection ReportAfzal pathanÎncă nu există evaluări

- 18 - Section-13 Shutdown SystemsDocument19 pagini18 - Section-13 Shutdown Systemsavula43Încă nu există evaluări

- Um Ga250al Ga400al Eng 0350941Document40 paginiUm Ga250al Ga400al Eng 0350941jackyt09Încă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- SPG en ProductCatalogue VFTDocument34 paginiSPG en ProductCatalogue VFTRoo FaÎncă nu există evaluări

- 750-263 5 2015Document456 pagini750-263 5 2015weweqweqwÎncă nu există evaluări

- TVL Smaw11 Q1 M 8Document10 paginiTVL Smaw11 Q1 M 8Earl Christian BonaobraÎncă nu există evaluări

- BHEL SupercriticalDocument40 paginiBHEL SupercriticalSam100% (2)

- Fire Pumps in Accordance EN 12845+A2 GuideDocument30 paginiFire Pumps in Accordance EN 12845+A2 GuideNajaf HussainÎncă nu există evaluări

- CHE504 - Lab Report On Gas Absorption L8 PDFDocument23 paginiCHE504 - Lab Report On Gas Absorption L8 PDFRakesh KumarÎncă nu există evaluări

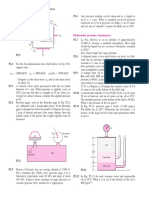

- Tuto Chap 3Document3 paginiTuto Chap 3Zakiyah Mohamed Razi50% (2)

- Paper - 2 - SetB - QADocument14 paginiPaper - 2 - SetB - QANataraj Singh SardarÎncă nu există evaluări

- Mitigation Plan Tiein ScheduleDocument1 paginăMitigation Plan Tiein ScheduleThirukkumaranBalasubramanianÎncă nu există evaluări

- Heat Loss From Oil Filled Tanks and Pipe LinesDocument2 paginiHeat Loss From Oil Filled Tanks and Pipe LinesAs'adÎncă nu există evaluări

- Print FrankDocument17 paginiPrint FrankAnagha NandaÎncă nu există evaluări

- SHELL FUEL KnowledgeDocument39 paginiSHELL FUEL KnowledgeVincent Ferrer NironÎncă nu există evaluări

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocument20 paginiBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelÎncă nu există evaluări

- Welcome To: MMUP Engineers Registration Exam Preparation CourseDocument101 paginiWelcome To: MMUP Engineers Registration Exam Preparation CourseHanda Bin AdiÎncă nu există evaluări

- of PCV ValveDocument7 paginiof PCV ValveDevesh JaiswalÎncă nu există evaluări

- Total 215 234 449: Consolidated School Nutritional Status Report by Grade LevelDocument3 paginiTotal 215 234 449: Consolidated School Nutritional Status Report by Grade LevelAnonymous xlKXtUNuÎncă nu există evaluări

- 06 Applied Thermodynamics - Jet Propulsion CyclesDocument38 pagini06 Applied Thermodynamics - Jet Propulsion CyclesahmedÎncă nu există evaluări

- UNICEL Vertical Gas Flotation PDFDocument2 paginiUNICEL Vertical Gas Flotation PDFJessika LópezÎncă nu există evaluări

- Reduce Hazards-Vaccum SystemDocument7 paginiReduce Hazards-Vaccum SystemChem.EnggÎncă nu există evaluări

- Chapter 1Document68 paginiChapter 1khurramÎncă nu există evaluări

- Sentry - Spiral Tube Heat Exchangers - 2016Document2 paginiSentry - Spiral Tube Heat Exchangers - 2016Victor PomboÎncă nu există evaluări