Documente Academic

Documente Profesional

Documente Cultură

Desand Sluice Gate

Încărcat de

Ichwan RachmantoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Desand Sluice Gate

Încărcat de

Ichwan RachmantoDrepturi de autor:

Formate disponibile

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

PLTM PUSAKA 1

DESAND SLUICE GATE

Calculation Sheet of Water Gate and Screen

DESAND SLUICE GATE Sheet No. 1 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

DESIGN DATA

( Perhitungan didasarkan pada kondisi Abnormal / Banjir )

Abnormal Elevation

1,60 m = D Clear Height

2,00 m = L Clear Width

1,70 m = Hs Sealing Height Normal Elevation

2,16 m = B Sealing Width

1,00 tf/m³ = W₀

h₃

- m = Bottom Elevation

h₂

h₀

- m = h₀ h₁ - Hs

- m = h₁ Normal Elevation

h₁

Normal head

6,31 m = h₂ Abnormal elevation

Abnormal head ( in Flood Condition )

Hs

4,61 m = h₃ h₂ - Hs Bottom Elevation

DESIGN LOAD

20,060 tf = P abnormal ½ * ( h₂² - h₃² ) * B * W₀

227,00 cm = L Effective Span ( Effective Span is distance between center of wheel to wheel at top view )

SS 400 = Material

2.400,00 kgf/cm² = σy Yield Strength

1.296,00 kgf/cm² = σy' 0,6 * σy * c

0,90 = c Duty Factor

2.100.000 kgf/cm² = E Modulus Elasticity

CALCULATIONS OF GIRDER

Division & Design Load ( Based on Abnormal Condition )

Abnormal Condition

Space of Z I

Girder Force Load P M S

Girder

tf/m ² tf kgf kgfcm kgf cm³ cm ⁴

1 4,61 3,39 3.390,43 100.865,17 1.695,21 77,83 778,28

0,65

2 5,26 6,17 6.173,24 183.654,01 3.086,62 141,71 1.417,08

0,45

3 5,71 5,88 5.878,64 174.889,48 2.939,32 134,95 1.349,46

0,50

4 6,21 4,62 4.617,83 137.380,38 2.308,91 106,00 1.060,03

0,10

6,31

1,70 20,06

P = Load

M = Bending Moment P/8*(2*L-B)

S = Shearing Force P/2

Z = Section Modulus M / σy'

I = Moment of Inertia M * a / 2 * σy'

DESAND SLUICE GATE Sheet No. 2 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

CALCULATIONS OF GIRDER

PROPERTY APPLICATION

Girder 1, 2 & 3 menggunakan IWF 200 x 100 x 5,5 x 8

20,00 cm = a Length of Flange

18,40 cm = b Clear distance between upper & lower flanges

10,00 cm = c Width of Flange

0,80 cm = d Thickness of Flange

0,55 cm = e Thickness of Web

10,00 cm = f

10,12 cm² = Aw Sectional Area of Web

8,00 cm² = Ac Sectional Area of Compression Flange

1.840,00 cm⁴ = I > Imin = 1.417,08 cm⁴ SAFE! M * a / 2 * σy'

275,80 cm³ = Zc > Zmin = 141,71 cm⁴ SAFE! M / σy'

275,80 cm³ = Zt > Zmin = 141,71 cm⁴ SAFE!

Girder 4 menggunakan UNP 200 x 75 x 8,5

20,00 cm = a Length of Flange

15,00 cm = b Clear distance between upper & lower flanges

8,00 cm = c Width of Flange

2,50 cm = d Thickness of Flange

0,75 cm = e Thickness of Web

11,25 cm² = Aw Sectional Area of Web

20,00 cm² = Ac Sectional Area of Compression Flange

1.950,00 cm⁴ = I > Imin = 1.060,03 cm⁴ SAFE! M * a / 2 * σy'

195,00 cm³ = Zc > Zmin = 106,00 cm⁴ SAFE! M / σy'

195,00 cm³ = Zt > Zmin = 106,00 cm⁴ SAFE!

STRESSED on GIRDER

BENDING STRESS σt = M / Zt

Girder M Zt (cm³) σt (kgf/cm²) σta (kgf/cm²) σc = M / Zc

kgfcm Zc (cm³) σc (kgf/cm²) σca (kgf/cm²)

275,80 365,72 1.296,00 SAFE!

1 100.865,17

275,80 365,72 1.296,00 SAFE!

275,80 665,90 1.296,00 SAFE!

2 183.654,01

275,80 665,90 1.296,00 SAFE!

275,80 634,12 1.296,00 SAFE!

3 174.889,48

275,80 634,12 1.296,00 SAFE!

195,00 704,51 1.296,00 SAFE!

4 137.380,38

195,00 704,51 1.296,00 SAFE!

SHEARING STRESS ζ = S / Aw

Girder S ζa = 0,6 * σta

Aw (cm²) ζ (kgf/cm²) ζa (kgf/cm²)

kgfcm

1 1.695,21 10,12 167,51 777,60 SAFE!

2 3.086,62 10,12 305,00 777,60 SAFE!

3 2.939,32 10,12 290,45 777,60 SAFE!

4 2.308,91 11,25 205,24 777,60 SAFE!

DESAND SLUICE GATE Sheet No. 3 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

CALCULATIONS OF GIRDER

ALLOWABLE STRESS

Allowable Bending Stress AT TENSION SIDE Aw

k = 3 +

1.296,00 kgf/cm² = σta 0,6 * σy * c 2 * Ac

Aw

, however < 2

Allowable Bending Stress AT COMPRESSION SIDE Ac

Aw Ac I b σca → k = 2

GIRDER k q/k I/b

cm ³ cm ³ cm cm kgf/cm²

1 10,12 8,00 1,91 4,72 57,00 10,00 5,70 1.296,00 l q

<

2 10,12 8,00 1,91 4,72 57,00 10,00 5,70 1.296,00 b k

3 10,12 8,00 1,91 4,72 57,00 10,00 5,70 1.296,00 q l

< < 30

4 11,25 20,00 1,81 4,97 57,00 8,00 7,13 1.296,00 k b

I = Flange Supporting Length b = Width of Flange

Allowable Shearing Stress d = Max. Distance of Vertical Stiffener

777,60 kgf/cm² = ζa 0,6 * σta tw

d = 3200 x

PROPERTY OF SECTION VERIFICATIONS S

Web Thickness A

b Tw

GIRDER b / Tw

cm cm l so in Case Vertical Stiffener will

if < 70

1 18,40 0,55 33,45 Not use Stiffener Tw not to be Arranged

2 18,40 0,55 33,45 Not use Stiffener

3 18,40 0,55 33,45 Not use Stiffener l so in Case Vertical Stiffener will be

if < 152

4 15,00 0,75 20,00 Not use Stiffener Tw Arranged

T w = Thickness of Web b = Clear distance between upper & lower flanges

Flange Width

COMPRESSION SIDE TENSION SIDE

GIRDER

bfc tfc bfc / tfc bft tft bft / tft bfc

< 24

1 10,00 0,80 12,50 10,00 0,80 12,50 TRUE tfc

2 10,00 0,80 12,50 10,00 0,80 12,50 TRUE

3 10,00 0,80 12,50 10,00 0,80 12,50 TRUE bft

< 30

4 8,00 2,50 3,20 8,00 2,50 3,20 TRUE tft

bfc , bft = Width of Flange (cm) tfc tft = Thickness of Flange (cm)

Deflection on Girder

P I δ 1/λ Where ,

GIRDER

kgf cm ⁴ cm bft / tft P L * B² B³

1 3.390,43 1.840,00 0,14 0,00062 SAFE

δ =

48 * E * I

( L³ - 2

+

8

)

2 6.173,24 1.840,00 0,25 0,00112 SAFE

3 5.878,64 1.840,00 0,24 0,00107 SAFE 1 δ

= < 180

4 4.617,83 1.950,00 0,18 0,00079 SAFE λ L

DESAND SLUICE GATE Sheet No. 4 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

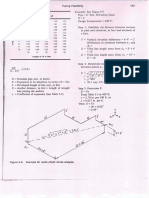

CALCULATIONS OF STRINGER

Modeling and Drafting

761,95

565 570

5687

6237

650

A B 0,5687 kgf/cm²

6712

0,6237 kgf/cm²

450

C D

500

E F 0,6712 kgf/cm²

754,89

bottom

100

P

m

L

P = Water Pressure ( kgf / cm² )

L

M = Bending Moment ( kgf.cm )

P * m * L²

=

8

S = Shearing Force ( kgf )

P*m*L

=

2

DESAND SLUICE GATE Sheet No. 5 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

CALCULATIONS OF STRINGER

Division & Design Load ( Based on Abnormal Condition )

SECTIONAL FORCE

P m L M S Zmin Imin

STRINGER

kgf/cm² cm cm kgfcm kgf cm ³ cm ⁴

A 0,5687 56,50 65,00 16.969,47 1.044,28 13,09 130,94

B 0,5687 57,00 65,00 17.119,65 1.053,52 13,21 132,10

C 0,6237 56,50 45,00 8.919,88 792,88 6,88 68,83

D 0,6237 57,00 45,00 8.998,82 799,90 6,94 69,44

E 0,6712 56,50 50,00 11.850,88 948,07 9,14 91,44

F 0,6712 57,00 50,00 11.955,75 956,46 9,23 92,25

PROPERTY APPLICATION Stringer A, B, C, E, F

I, Xt , Xc , are calculated by Autocad Mechanical

20,00 cm = a Flange

18,30 cm = b

7,50 cm = c

0,85 cm = d Flange Thickness

1,15 cm = e Web Thickness

21,05 cm² = Aw Sectional Area of Web

6,38 cm² = Ac Sectional Area of Compression Flange

15,00 cm = Xt

15,00 cm = Xc

1.950,00 cm⁴ = I > Imin = 132,10 cm⁴ SAFE! M * a / 2 * σy'

130,00 cm³ = Zt > Zmin = 13,21 cm⁴ SAFE! I / Xt

130,00 cm³ = Zc > Zmin = 13,21 cm⁴ SAFE! I / Xc

STRESS

BENDING STRESS SHEARING STRESS

Stringer M Zt (cm³) σt σta (kgf/cm²) S Aw ζ ζa

kgfcm Zc (cm³) σc σca (kgf/cm²) kgfcm cm ² kgf/cm ² kgf/cm ²

130,00 130,53 1.296,00 SAFE!

A 16.969,47 1.044,28 21,05 49,62 777,60 SAFE!

130,00 130,53 1.296,00 SAFE!

130,00 131,69 1.296,00 SAFE!

B 17.119,65 1.053,52 21,05 50,06 777,60 SAFE!

130,00 131,69 1.296,00 SAFE!

130,00 68,61 1.296,00 SAFE!

C 8.919,88 792,88 21,05 37,68 777,60 SAFE!

130,00 68,61 1.296,00 SAFE!

130,00 69,22 1.296,00 SAFE!

D 8.998,82 799,90 21,05 38,01 777,60 SAFE!

130,00 69,22 1.296,00 SAFE!

130,00 91,16 1.296,00 SAFE!

E 11.850,88 948,07 21,05 45,05 777,60 SAFE!

130,00 91,16 1.296,00 SAFE!

130,00 91,97 1.296,00 SAFE!

F 11.955,75 956,46 21,05 45,45 777,60 SAFE!

130,00 91,97 1.296,00 SAFE!

σt = M / Zt ζ = S / Aw

σc = M / Zc ζa = 0,6 * σta

DESAND SLUICE GATE Sheet No. 6 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

CALCULATIONS OF STRINGER

Division & Design Load ( Based on Abnormal Condition )

ALLOWABLE STRESS

Allowable Bending Stress AT TENSION SIDE Aw

k = 3 +

1.296,00 kgf/cm² = σta 0,6 * σy * c 2 * Ac

Aw

, however < 2

Allowable Bending Stress AT COMPRESSION SIDE Ac

Aw Ac I b σca → k = 2

Stringer k q/k I/b

cm ³ cm ³ cm cm kgf/cm²

A 21,05 6,38 2,16 4,17 53,00 7,50 7,07 1.296,00

B 21,05 6,38 2,16 4,17 53,00 7,50 7,07 1.296,00

C 21,05 6,38 2,16 4,17 37,50 7,50 5,00 1.296,00 l q

<

D 21,05 6,38 2,16 4,17 37,50 7,50 5,00 1.296,00 b k

E 21,05 6,38 2,16 4,17 15,50 7,50 2,07 1.296,00 q l

< < 30

F 21,05 6,38 2,16 4,17 15,50 7,50 2,07 1.296,00 k b

I = Flange Supporting Length b = Width of Flange

Allowable Shearing Stress d = Max. Distance of Vertical Stiffener

777,60 kgf/cm² = ζa 0,6 * σta tw

d = 3200 x

PROPERTY OF SECTION VERIFICATIONS S

Web Thickness A

b Tw

Stringer b / Tw

cm cm

A 18,30 1,15 15,91 Not use Stiffener

B 18,30 1,15 15,91 Not use Stiffener l so in Case Vertical Stiffener will

if < 70

C 18,30 1,15 15,91 Not use Stiffener Tw not to be Arranged

D 18,30 1,15 15,91 Not use Stiffener

E 18,30 1,15 15,91 Not use Stiffener l so in Case Vertical Stiffener will be

if < 152

F 18,30 1,15 15,91 Not use Stiffener Tw Arranged

T w = Thickness of Web b = Clear distance between upper & lower flanges

Flange Width

COMPRESSION SIDE TENSION SIDE

Stringer

bfc tfc bfc / tfc bft tft bft / tft

A 7,50 0,85 8,82 7,50 0,85 8,82 TRUE

B 7,50 0,85 8,82 7,50 0,85 8,82 TRUE bfc

< 24

C 7,50 0,85 8,82 7,50 0,85 8,82 TRUE tfc

D 7,50 0,85 8,82 7,50 0,85 8,82 TRUE

E 7,50 0,85 8,82 7,50 0,85 8,82 TRUE bft

< 30

F 7,50 0,85 8,82 7,50 0,85 8,82 TRUE tft

bfc , bft = Width of Flange (cm) tfc tft = Thickness of Flange (cm)

DESAND SLUICE GATE Sheet No. 7 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

CALCULATIONS OF LIFTING HOIST

PIN HOIST W

47,00 mm = L₁ Distance A B

47,00 mm = L₂ Distance

94,00 mm = L₃ Total Distance L₁ L₂

10.110,00 mm = W Weight

5.055,00 mm = Weight per Pin L₃

SECTIONAL FORCE

11.879,25 kgcm = M Bending Moment ( W * L₁ * L₂ ) / L₃

5.055,00 kg = S Shearing Force ( W * L₁ ) / L₃

PROPERTY OF SECTION

S 45 C ( N ) = Material

4,40 cm = d

8,36 kgcm = Z ( π / 32 ) * d³

15,21 kg = A ( π / 4 ) * d²

STRESS σb < σba --------------------→ SAFE!

3.500,00 kg/cm² = σy Yield Strength

1.890,00 kg/cm² = σba Allowable Bending Stress 0,6 * σy * c

1.420,47 kg/cm² = σb Bending Stress M*Z

1.134,00 kg/cm² = ζa Allowable Shearing Stress 0,6 * σba

332,45 kg/cm² = ζ Shearing Stress S/A

B t

DESIGN OF MATERIAL SUPPORTING PLATE

SS 400 = Material E

17,73 mm = t

66,00 mm = B

d

2.400,00 kg/cm² = σy Yield Strength

1.296,00 kg/cm² = σy' Allowable Stress 0,6 * σy * c

777,60 kg/cm² = ζa Allowable Shearing Stress 0,6 * σy'

789,84 kg/cm² = σ

Checking for Normal Stress σ < σy' --------------------→ SAFE!

SKIN PLATE

Coefficient Table of Skin Plate base on DIN 19704

b/a 1,00 1,25 1,50 1,75 2,00 2,50 3,00 > 3,00

σ₁ 30,9 40,3 45,5 48,4 49,9 50,0 50,0 50,0

No. a b P t ε σ Allowable Stress

b/a k₁

Division cm cm kgf/cm² cm cm kgf/cm² kgf/cm²

A 56,5 65 1,15 36,5 0,5687 1,0 0,1 818,96 1.296,00 SAFE!

B 57,0 65 1,14 36,4 0,5687 1,0 0,1 831,24 1.296,00 SAFE!

C 56,5 45 0,80 27,0 0,6237 1,0 0,1 663,67 1.296,00 SAFE!

D 57,0 45 0,79 26,5 0,6237 1,0 0,1 662,96 1.296,00 SAFE!

E 56,5 50 0,88 28,5 0,6712 1,0 0,1 753,89 1.296,00 SAFE!

F 57,0 50 0,88 28,5 0,6712 1,0 0,1 767,29 1.296,00 SAFE!

a = Short Side of Subdivision P = Mean Water Pressure of Subdivision σ = Bending Stress of skin plate

b = Long Side of Subdivision t = Used Thinkness of Plate

k = Coefficient based on b/a ε = Corrosion Allowance

DESAND SLUICE GATE Sheet No. 8 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

DESIGN DATA OF WHEEL

Based on INDIAN STANDARD 4622 : 2003

54.610,50 N = Wheel Load NORMAL

65.532,60 N = P Wheel Load MAXIMUM ( Safety Factor = 1,2 )

60,00 mm = t Wheel Thickness

220,00 mm = Ø Wheel Diameter

2.500,00 mm = R₁ Wheel Radius Crowning

110,00 mm = R₂ Wheel Diameter

0,29 mm = µ Poisson's Ratio

229,00 BHN = Wheel Material

686,00 N/mm² = UTS

205.000,00 N/mm² = E Modulus Elasticity

DESIGN LOAD OF WHEEL

23,53 N/mm² = Critical Stress ( of Projected Area ) ( 0,169 x BHN ) - 15,174

7,84 N/mm² = Allowable Stess ( of Projected Area for Normal Load ) ( Safety Factor = 3 )

11,76 N/mm² = or Allowable Stess ( of Projected Area for Maximum Load ) ( Safety Factor = 2 )

6.963,55 mm² = Projected Area Required ( for Normal Load )

5.570,84 mm² = or Projected Area Required ( for Maximum Load )

CALCULATIONS OF WHEEL

Check for Maximum Shear Stress

22,73 = B/A ( 1 / ( 2 * R₂ ) ) - ( 1 / ( 2 * R₁ ) ) = R₁ / R₂

Mean of Reciprocals of Radius in x - Direction = 1 / ( 2 * R₁ )

0,00475 = B+A ½ * ( ( 1 / R₁ ) + ( 1 / R₂ ) )

Mean of Reciprocals of Radius in y - Direction = 1 / ( 2 * R₂ )

From Curves for Determine of Stresses in Wheels INDIAN STANDARD

0,78 = k

0,72 = ( A₁ * p ) / a³

0,39 = Z₁ / a

0,35 = ( A₁ / a ) * ( ₁Z z - ₁Y y )

0,00188 = A₁ Evaluation of Elastic Property and Shape Property ( 2 * ( 1 - µ² ) ) / ( E * ( A + B ) )

5,55 = a Semi-Mayor Axis of Ellipse of Contact 3 √ ( ( A * P ) / 0,72 )

=

( ₁Z z - ₁Y y ) 0,35 * ( a / A₁ )

1.030,70 N/mm² = Maximum Differential of Stress Components

515,35 N/mm² = Maximum Shear Stress ½ * ( ₁Z z - ₁Y y )

551,89 N/mm² = Allowable Shear Stress 2,41 * BHN

515,35 < 551,89 --------------------→ SAFE !

DESAND SLUICE GATE Sheet No. 9 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

CALCULATIONS OF WHEEL

Check for Contact Stress

2,16 mm = Z₁ Depth to Point of Maximum Stress Difference or Point at Which Maximum 0,39 * a

Shearing Stress Occurs

4,33 mm = b Semi-Minor Axis of Ellipse of Contact k*a

CONTACT STRESS

1.304,61 N/mm² = Actual Stress ( 3/2 ) * ( p / ( π * a * b ) )

1.646,40 N/mm² = Allowable Stress ( if used on CREST GATE ) 2,4 * UTS

--------------------→ SAFE !

1.440,60 N/mm² = Allowable Stress ( if used on SLUICE GATE ) 2,1 * UTS

--------------------→ SAFE !

0,00 = Z₁ / a

0,39 * a = Z₁

2,16 mm = Z₁

4,33 mm = Minimum Depth of Penetration of Hardness Required 2 * Z₁

DESAND SLUICE GATE Sheet No. 10 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

DESIGN DATA OF SHAFT

10,85 cm = Ls₁ Ls1

19,75 cm = Ls₂ Ls2 Ls3

3,40 cm = Ls₃

6,00 cm = d

7,00 cm = d₁

d1

d

4.865,00 kgf = Pactual

5.838,00 kgf = Pw ( Safety Factor = 1,2 )

CALCULATIONS OF SHAFT

SECTIONAL FORCE

19.849,20 kgf.cm = Msa Bending Moment Point - a Pw * Ls₃

63.342,30 kgf.cm = Msb Bending Moment Point - b Pw * Ls₁

REACTION FORCE

9.045,21 kgf = Rsb Reaction Force Point - b Pw * ( ( Ls₁ + Ls₂ ) / Ls₂ )

3.207,21 kgf = Rsc Reaction Force Point - c Pw * ( Ls₁ / Ls₂ )

SHEARING FORCE

5.838,00 kgf = Sba = Pw Shearing Force b to a

3.207,21 kgf = Sbc = Rsc Shearing Force b to c

PROPERTY OF SECTION

S 45 C ( N ) = Material

3.497,64 kgf/cm² = σy Yield Strength

0,90 = c Duty Factor

POINT - a d = 6,00 cm

28,27 cm² = Aa ( π / 4 ) * d²

21,21 cm² = Za ( π / 32 ) * d³

POINT - b d₁ = 7,00 cm

38,48 cm² = Ab ( π / 4 ) * d₁²

33,67 cm² = Zb ( π / 32 ) * d₁³

STRESS

Bending Stress

1.888,73 kgf/cm² = σa Allowable Bending Stress

936,03 kgf/cm² = σsa Bending Stress Point - a Msa / Zb

--------------------→ SAFE !

1.881,05 kgf/cm² = σsb Bending Stress Point - b Msb / Zb

--------------------→ SAFE !

Shearing Stress

1.133,24 kgf/cm² = δa Allowable Shearing Stress

275,30 kgf/cm² = δsa Shearing Stress Point - a ( 4 * Sba / 3 * Aa )

--------------------→ SAFE !

202,26 kgf/cm² = σsb Shearing Stress Point - b ( 4 * Sba / 3 * Ab )

--------------------→ SAFE !

DESAND SLUICE GATE Sheet No. 11 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

PLTM PUSAKA 1 / CIANJUR - WEST JAVA

DESIGN DATA OF BUSHING

d

Bushing (Oilless)

L

5.838,00 kgf = Pw

6,00 cm = d

7,00 cm = L

1,17 cm = L/d L / d = should be in between 0,5 - 2,0

CALCULATIONS OF BUSHING

600,00 kgf/cm² = Pba Minimum Allowable Bearing Stress

BRONZE

Allowable Bearing Stress of 150 - 600 kgf/cm²

139,00 kgf/cm² = Pb Bearing Stress Pw / ( d * L )

--------------------→ SAFE !

DESAND SLUICE GATE Sheet No. 12 of 12

This document and its attachment are stictly confidential and property of SALFACON and shall not be traced, photographed, copied or produced in any manners, not used

for any purposes whatsoever written permission of SALFACON©

S-ar putea să vă placă și

- Weir Intake Gate PDFDocument12 paginiWeir Intake Gate PDFIchwan RachmantoÎncă nu există evaluări

- Hydro Dynamic ForcesDocument34 paginiHydro Dynamic Forcesvikasgahlyan100% (1)

- Spherical Valve Foundation ForceDocument1 paginăSpherical Valve Foundation ForceRakesh SapkotaÎncă nu există evaluări

- Quick Reference: General Use Standard Size Range (Inches) Maximum Normal (FEET) Seating (FACE) Unseating (BACK)Document21 paginiQuick Reference: General Use Standard Size Range (Inches) Maximum Normal (FEET) Seating (FACE) Unseating (BACK)graceÎncă nu există evaluări

- Hydraulics and Design of TrashrackDocument25 paginiHydraulics and Design of TrashracksapkotamonishÎncă nu există evaluări

- Design of Slide Gate Size 1.6 X 2 MDocument4 paginiDesign of Slide Gate Size 1.6 X 2 MTarunPatraÎncă nu există evaluări

- Silt Gravel Removal GateDocument16 paginiSilt Gravel Removal GateRaja SinghÎncă nu există evaluări

- Sluice GateDocument24 paginiSluice GateEldhoThomas100% (1)

- Radial GatesDocument12 paginiRadial GatesCHEL TAKÎncă nu există evaluări

- Sluice GateDocument2 paginiSluice GateMadusha TisseraÎncă nu există evaluări

- Trashrack DesignDocument4 paginiTrashrack DesignpicottÎncă nu există evaluări

- A New Improved Formula For Calculating Trashrack LossesDocument8 paginiA New Improved Formula For Calculating Trashrack LossesNikom KraitudÎncă nu există evaluări

- Asce Epri Guides 1989Document59 paginiAsce Epri Guides 1989david_rosemberg50% (2)

- Design of Dogging BeamDocument1 paginăDesign of Dogging BeamSujeet KumarÎncă nu există evaluări

- Downpull ForceDocument49 paginiDownpull ForceDavid RodriguezÎncă nu există evaluări

- Gate Slot LossesDocument13 paginiGate Slot LossesRex ImperialÎncă nu există evaluări

- Gate and Hoist DesignDocument15 paginiGate and Hoist DesignRajivÎncă nu există evaluări

- Structural Design of Radial GatesDocument24 paginiStructural Design of Radial Gateschandwanivinay100% (1)

- Penstock Presentation - PpsDocument42 paginiPenstock Presentation - PpsGourav KhudasiaÎncă nu există evaluări

- GatesDocument49 paginiGatesPrem Singh RawatÎncă nu există evaluări

- Air Demand Behind Emergency Closure GatesDocument12 paginiAir Demand Behind Emergency Closure GatesSandeep JoshiÎncă nu există evaluări

- Hydrodynamic Effects During Earthquakes On Dams and Retaining WallsDocument6 paginiHydrodynamic Effects During Earthquakes On Dams and Retaining WallsAndres CaroÎncă nu există evaluări

- 16 Screw Hoist For Sluice Gate PDFDocument10 pagini16 Screw Hoist For Sluice Gate PDFsamÎncă nu există evaluări

- Surge Shaft - Design ConceptDocument65 paginiSurge Shaft - Design Conceptpankaj100% (2)

- Rubberdamnew 140214103433 Phpapp02Document24 paginiRubberdamnew 140214103433 Phpapp02Mukhlish AkhatarÎncă nu există evaluări

- 4.10 - Desilting Basin - Flushing Sluice Gate and HydraulicDocument4 pagini4.10 - Desilting Basin - Flushing Sluice Gate and Hydraulicsrigirisetty208Încă nu există evaluări

- Spillway Energy Dissipaters Rosh GolDocument4 paginiSpillway Energy Dissipaters Rosh GolNaimat RasoolÎncă nu există evaluări

- Steel Structure ST 37Document11 paginiSteel Structure ST 37aliÎncă nu există evaluări

- HydromechanicalDocument31 paginiHydromechanicalJennifer HudsonÎncă nu există evaluări

- Desilting Basin - TCSDocument4 paginiDesilting Basin - TCSManojPatne0% (1)

- Key Elevation (Not To Scale) Detail A Scale - A: Units Engineering Consultancy Pvt. Ltd. Padam Khola Small Hydro ProjectDocument2 paginiKey Elevation (Not To Scale) Detail A Scale - A: Units Engineering Consultancy Pvt. Ltd. Padam Khola Small Hydro ProjectManjil PuriÎncă nu există evaluări

- Sluice Gate ManufacturerDocument2 paginiSluice Gate ManufacturerVed PrakashÎncă nu există evaluări

- Radial Gate-Design CheckDocument5 paginiRadial Gate-Design Checksuranga dadallage100% (1)

- Design of Hydraulics Structures 89Document6 paginiDesign of Hydraulics Structures 89Jhon Sebastian BolañosÎncă nu există evaluări

- Design of Radial GatesDocument23 paginiDesign of Radial GatesWilliam MataÎncă nu există evaluări

- Prediction of Downpull On Closing High H PDFDocument11 paginiPrediction of Downpull On Closing High H PDFSumit SharmaÎncă nu există evaluări

- Sample Calculation - CR GateDocument5 paginiSample Calculation - CR GateRose Mary100% (1)

- Guidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousesDocument17 paginiGuidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousessubasratnaÎncă nu există evaluări

- Voulume III - Technical AnnexDocument140 paginiVoulume III - Technical AnnexyeyenÎncă nu există evaluări

- Vertical GatesDocument243 paginiVertical GatesSannyBombeoJomocÎncă nu există evaluări

- Gate Lip HydraulicsDocument7 paginiGate Lip HydraulicsDaniela E. WagnerÎncă nu există evaluări

- Pen StockDocument59 paginiPen Stockdandewjanger100% (1)

- Indian Standard Radial GateDocument8 paginiIndian Standard Radial GateMirza FadlulahÎncă nu există evaluări

- Design Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDocument12 paginiDesign Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDavid DelgadoÎncă nu există evaluări

- SpillwayDocument68 paginiSpillwayYogesh KavadÎncă nu există evaluări

- KT Penstock PDFDocument24 paginiKT Penstock PDFKmi GutierrezÎncă nu există evaluări

- Radial Gates Drawing Design - 2pgsDocument2 paginiRadial Gates Drawing Design - 2pgsPaolo AfidchaoÎncă nu există evaluări

- Sickle PlateDocument26 paginiSickle PlateSambhav Poddar100% (1)

- Radial+Gate+With+Arm+ +6+m.+++Haji+ShaherDocument65 paginiRadial+Gate+With+Arm+ +6+m.+++Haji+ShaherMuhammed Wahid100% (3)

- Hydropower Intake Design and CriteriaDocument6 paginiHydropower Intake Design and CriteriaManikandanÎncă nu există evaluări

- Ebook1183 EbookDocument99 paginiEbook1183 Ebookranendra sarma100% (1)

- Radial GatesDocument26 paginiRadial Gatesrs2operÎncă nu există evaluări

- Design of Intake Stoplog R0Document25 paginiDesign of Intake Stoplog R0Sujeet Kumar50% (2)

- Gate Diversion TarbelaDocument89 paginiGate Diversion TarbelaAMIAMIÎncă nu există evaluări

- De SiltingDocument6 paginiDe Siltingtarang001Încă nu există evaluări

- Corbel Pier 1Document3 paginiCorbel Pier 1Phani PitchikaÎncă nu există evaluări

- 568 - CMS Food Court PitchedDocument3 pagini568 - CMS Food Court PitchedEr S Thirumarai NathanÎncă nu există evaluări

- Qdoc - Tips Helicoidal Stair Design Spreadsheet by OlusegunverDocument2 paginiQdoc - Tips Helicoidal Stair Design Spreadsheet by OlusegunverZaw Hlaing AungÎncă nu există evaluări

- Air Conditioning Calculation - R0Document28 paginiAir Conditioning Calculation - R0harikrishnanpd3327Încă nu există evaluări

- Stress Predictions at Elbow Ends Under Internal Pressure and System MomentsDocument9 paginiStress Predictions at Elbow Ends Under Internal Pressure and System MomentsGaurav BedseÎncă nu există evaluări

- Nu Rick 1976Document7 paginiNu Rick 1976XinDa ZhuÎncă nu există evaluări

- FCE 411 - Geotechnical EngineeringDocument7 paginiFCE 411 - Geotechnical EngineeringKen MutuiÎncă nu există evaluări

- Assignment2 Answer-KeyDocument11 paginiAssignment2 Answer-KeyRed Crazy0% (1)

- 1 Prelim Met O1Document44 pagini1 Prelim Met O1Kurt Ivan NapalingaÎncă nu există evaluări

- Heat Exchanger Heat 4e Chap11 LectureDocument52 paginiHeat Exchanger Heat 4e Chap11 LecturewasdasbyomdeÎncă nu există evaluări

- Traffic Flow TheoryDocument108 paginiTraffic Flow TheorySasana SanÎncă nu există evaluări

- Pipe Line Flexibility Manual CalculationDocument20 paginiPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- (Old and New) Theories On The Glass TransitionDocument25 pagini(Old and New) Theories On The Glass TransitionRawlinsonÎncă nu există evaluări

- Aerodynamics of Wind TurbinesDocument4 paginiAerodynamics of Wind TurbinesIoanna KaloÎncă nu există evaluări

- Hydraulic Calculations Adjusted FlowDocument9 paginiHydraulic Calculations Adjusted FlowMd Shaidur Rahman100% (1)

- Airlift EquationsDocument1 paginăAirlift EquationsAlejandro Enrique RodriguezÎncă nu există evaluări

- Rumus Perhitungan Turbin UapDocument17 paginiRumus Perhitungan Turbin Uapricki yusufÎncă nu există evaluări

- Week 6, Deep Foundation Part 2Document38 paginiWeek 6, Deep Foundation Part 2Aw Ting HuiÎncă nu există evaluări

- Forces On Immersed Bodies 10Document19 paginiForces On Immersed Bodies 10Sunil BagadeÎncă nu există evaluări

- Archimedes Number: WhereDocument39 paginiArchimedes Number: WhereZain UlabideenÎncă nu există evaluări

- Plastic Shrinkage CrackingDocument11 paginiPlastic Shrinkage CrackingRubsoneproÎncă nu există evaluări

- TE - Mech - RAC - Chapter 4 - VCC Cycles-1Document98 paginiTE - Mech - RAC - Chapter 4 - VCC Cycles-1Aniket MandalÎncă nu există evaluări

- Ensayo A TraccionDocument11 paginiEnsayo A TraccionRock JorgeÎncă nu există evaluări

- CRSI Manual To Design RC Diaphragms - Part21Document4 paginiCRSI Manual To Design RC Diaphragms - Part21Adam Michael GreenÎncă nu există evaluări

- Sheet 4 - ME 211TDocument3 paginiSheet 4 - ME 211Tsophia haniÎncă nu există evaluări

- Bab 5 Kurva-Kurva Prestasi Dan Kavitasi PompaDocument9 paginiBab 5 Kurva-Kurva Prestasi Dan Kavitasi PompaMuhammad Khoirul AnwarÎncă nu există evaluări

- 01 Session 01 Lecture 001 Elasticity Plasticity Stress StrainDocument20 pagini01 Session 01 Lecture 001 Elasticity Plasticity Stress Strainyoeuy zeodyÎncă nu există evaluări

- Ass 4Document2 paginiAss 4Puneet MeenaÎncă nu există evaluări

- Assignment 4Document3 paginiAssignment 4Shripad PachputeÎncă nu există evaluări

- Radial Pump Impeller Design ExampleDocument16 paginiRadial Pump Impeller Design ExampleDon Poul JoseÎncă nu există evaluări

- Heat Transfer Through Nano Fluids 2-4Document25 paginiHeat Transfer Through Nano Fluids 2-4Lizzi JohnsonÎncă nu există evaluări

- Boundary Layers Integral Approach 2Document14 paginiBoundary Layers Integral Approach 2Yash JainÎncă nu există evaluări

- York Ducted InverterDocument2 paginiYork Ducted InverterjABU100% (1)