Documente Academic

Documente Profesional

Documente Cultură

073 All Change For Asikoy Copper Mine

Încărcat de

Kenny CasillaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

073 All Change For Asikoy Copper Mine

Încărcat de

Kenny CasillaDrepturi de autor:

Formate disponibile

Kure, Turkey

All change for Asikoy copper mine

Moving ore

production

underground

Copper has been mined for many

years at the Asikoy open pit,

located in Kure county, some

60‑km north of Kastamonu in the

western part of Turkey’s Black

Sea Region. Kure itself is 25 km

from the Black Sea coast, and 300

km from Ankara. A major open

pit operation was established in

the mid-sixties, and production

continues to this day. However,

reserves were diminishing, and,

with the available orebody exten-

sions at depth, a plan for under-

ground mining was evolved. This

required excavation of a conveyor

adit to transport rock from under-

ground to the existing mill, and

a vehicle access adit, together

with a spiral ramp to the base View of Asikoy open pit mining operation.

of the known deposit. Shafts for

backfill and ventilation were also

needed. Production commenced contract by STFA tunnelling division. The sump at the base of the mine

in 2001, when STFA Construction Average advance was 120 m/month. has 2,560 cu m capacity, and there is a

and STFA Tunnelling Corporation The top half of each round was drilled natural water make of 12 lit/sec. Two

Joint Venture took over the under- from the levelled muckpile. The total vertical shafts to surface and one sublevel

ground mining operation as con-

development carried out prior to produc- shaft facilitate ventilation. The exhaust

tractor, using a fleet of Atlas

Copco equipment which includes tion was 1,954 m of ramp drivage, 815 m shaft is equipped with a cover, which

production and development drill of shaft sinking, and 3,331 m of other can be raised in winter to induce natural

rigs, loaders, and trucks. Monthly development. air movement.

ore production is around 45,000 t

at average grade 2% Cu, with cut-

Portal entrance to Asikoy underground mine.

off grade of 0.5%.

Access

The vehicle access adit is horizontal,

and connects with the spiral ramp

developed in the footwall of the

orebody down to the sump level. The

orebody, which dips at between 45 and

60 degrees, is accessed from the ramp,

along levels spaced at 12 m vertical

intervals.

The 20 sq m oval-plan spiral ramp

was driven at 5-7 degrees from 932 m

level to 792 m level by hand between

1998 and 2000 using Atlas Copco BBC

16W pneumatic rock drills with jack-

legs. This work was carried out under

underground mining methods 73

Kure, Turkey

Development

An Atlas Copco Rocket Boomer 282

equipped with COP 1838ME rock drills

is used to develop the ore and waste

drifts.

The Rocket Boomer has one extend-

ing boom to facilitate drilling off the first

rounds in strike drifts at right angles.

Drill hole diameter is 45 mm,

and hole length 3.5 m. The mine has

conducted trials of bits from differ-

ent manufacturers, and has settled

on Secoroc as the most cost-effec-

tive. Around 250 m/month of drivage

is required to keep pace with the

stopes, all of which are mined on the

retreat.

Most development is within the com-

petent footwall rock mass. The orebody

exhibits different rock mass character-

istics. Ground support is by shotcrete, Scooptram ST6C, one of three at Asikoy.

bolting with mesh, mesh reinforced

shotcrete, standard Swellex in 2.4 m The Rocket Boomer 282 handles all Production

and 3.3 m lengths, and cement grouted rockbolt drilling, with 37 mm holes for

bolts in 3 m, 4 m and 6 m lengths. Swellex and 64 mm holes for grouted The mining method is longhole bench

Two manually-controlled Atlas Copco rebar. The mine is working with Atlas stoping with post backfill. The ore is

Scooptram ST6C loaders are used for Copco to increase the use of Swellex, developed by driving strike access drifts

mucking development faces. because of its better controllability. with cross sectional area of 21.68 sq

Line-up of Atlas Copco equipment at Asikoy mine.

74 underground mining methods

Kure, Turkey

m along the footwall contact, or in the

centre of the orebody. Stope preparation

is carried out by driving 7 m-wide x Surface

4.5 m-high sill drifts across the strike, Belt conveyor

to the hangingwall or footwall. These

drifts vary in length, depending on the

thickness of the orebody.

An Atlas Copco Simba H1254 with

top hammer is used for stope drilling.

Blast holes with a diameter of 76 mm

are drilled downwards on several pat-

terns, according to ore and stope type.

The mine prefers downhole drilling as Flexowell

Sill drift development

the most practical for their patterns,

while reducing the safety risk. Stoping

Muckpile

At the end of the sill drifts, a 1.5 m

x 1.5 m drop raise is opened by long-

Ore pass

hole blasting, and this is widened out to

create a free breaking face. Thereafter,

the bench between the sill drifts is Ore

blasted towards the open slot one or two Feeder

rows at a time. The main blasting agent Grizzly Belt conveyor

is ANFO, which may be diluted with

polystyrene beads for the profile holes,

with Powergel primers and Nonel initia- Crusher

tion. The ore is mucked from the lower

sill drift using a remote controlled Atlas Cemented backfill

Copco Scooptram ST6C. After complet-

ing the extraction of the ore between the Production flow from orebody to surface.

sill drifts, the open stope is backfilled

to the floor level of the upper sill drift. Stoping sequence at Asikoy.

Once two adjacent p rimary stopes are

backfilled, the primary pillar can be

mined as a secondary stope.

The production stopes can be up to

60-70 m-long, but average around 30 m- Development Production drilling

long. Currently, 8 m is left between

Production drilling with Simba H1254. HW HW

slot

Blasting and mucking

Filling

HW HW

underground mining methods 75

Kure, Turkey

Rocket Boomer 282 on surface. Unique Flexowell vertical conveyor installation.

sublevels, and the extraction drives are located in Samsun, along the Black Sea There are 140 men on the mine. In total,

4.5 m-high. The latest stope, which lies coast, and to export markets. thirteen engineers have been employed

between 894 m and 912 m levels, has a for production and engineering. Atlas

height of 12 m, and this larger dimen- Training Copco has a maintenance contract for

sion will be increasingly used. its equipment at the mine, and provides

This is the first mining operation where a workshop container manned by a

Rock handling SFTA has been involved and, being the fitter.

only Turkish-operated mechanized

The 2.5 m-diameter main orepasses are mine, the company takes education Acknowledgements

also longhole drilled using the Rocket and training very seriously. Atlas

Boomer 282, or hand drilled. An ore- Copco undertook the training of the Atlas Copco is grateful to the man-

pass system to the 804 level feeds the mine instructors, and SFTA has car- agement of Asikoy copper mine for

underground crusher. Crushed ore sized ried on, giving every man on the mine the opportunity to visit the project.

at –10 cm travels along a conveyor belt specific education, each with a course Particular thanks are due to Kenan

to a feeder, and into a Flexowell verti- every three months. The average age of Ozpulat, project manager, and Serkan

cal conveyor belt system at 792 level. operators is around 30, and most have Yuksel, chief mine engineer, for their

A trunk conveyor at average grade of 8 been with the group for many years. assistance at site and in reading draft.

degrees transfers the ore to the surface

primary crusher. Minetruck MT2000 discharges cemented backfill into a primary stope.

There are four vertical shafts for

backfilling at Asikoy, with three sub-

vertical shafts.

Two types of fill are used for backfill-

ing. These are cemented rock fill (CRF)

and uncemented waste fill (WF). CRF,

with a cement content of 5% by weight,

is used for backfilling of primary stopes.

Secondary stopes are waste filled.

Minetruck MT2000 trucks are used for

both types of backfilling.

SF TA has a ten-yea r contract

to produce 30,000 t/month of ore

grading 2% copper at a fixed price per

tonne, although 414,000 t was produced

over the last year. The ore is concen-

trated to 17% at site, and is trucked to

the port of Inebolu, some 25 km away,

from where it is shipped to a smelter

76 underground mining methods

S-ar putea să vă placă și

- Guia1 Min540Document2 paginiGuia1 Min540Luis Flores Sabando100% (1)

- AVOCA Mining MethodDocument9 paginiAVOCA Mining MethodCarlos A. Espinoza M100% (2)

- Raiseboring RSADocument26 paginiRaiseboring RSAsijuaÎncă nu există evaluări

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- 025 Principles of Raise BoringDocument4 pagini025 Principles of Raise BoringKenny Casilla100% (1)

- Are You Looking For .: WWW - Promining.inDocument27 paginiAre You Looking For .: WWW - Promining.inANKIT DEOGADEÎncă nu există evaluări

- 137 Keeping A Low Profile at PanasqueiraDocument6 pagini137 Keeping A Low Profile at PanasqueiraKenny CasillaÎncă nu există evaluări

- The Development of Drilling and Blasting Practice at Palabora Mining Company LimitedDocument16 paginiThe Development of Drilling and Blasting Practice at Palabora Mining Company LimitedPaul MatshonaÎncă nu există evaluări

- 4th Sem - Mining Engg - Th-01Document19 pagini4th Sem - Mining Engg - Th-01Satyajeet ParidaÎncă nu există evaluări

- (64225) Coiled-Tubing Drilling of Horizontal Sidetrack (实例1)Document5 pagini(64225) Coiled-Tubing Drilling of Horizontal Sidetrack (实例1)samanÎncă nu există evaluări

- 119 Mechanized Mining in Low Headroom at WatervalDocument2 pagini119 Mechanized Mining in Low Headroom at WatervalKenny CasillaÎncă nu există evaluări

- 129 Sub Level Caving For ChromiteDocument4 pagini129 Sub Level Caving For ChromiteKenny CasillaÎncă nu există evaluări

- Cemented Rockfill PDFDocument5 paginiCemented Rockfill PDFvins4u100% (1)

- Ecovery of Broken Ore Stocks Left On The Mine Floor and Other Applications of The Underground Mobile SupersuckerDocument7 paginiEcovery of Broken Ore Stocks Left On The Mine Floor and Other Applications of The Underground Mobile SupersuckergeolukeÎncă nu există evaluări

- Future of Cascade Mining Method in Jungle Lode of Kathpal Chromite Mine, FacorDocument12 paginiFuture of Cascade Mining Method in Jungle Lode of Kathpal Chromite Mine, FacorSantosh KumarÎncă nu există evaluări

- Large Diameter Vertical Raise Drilling and Shaft Boring TechniquesDocument15 paginiLarge Diameter Vertical Raise Drilling and Shaft Boring TechniquesMelissaRicoÎncă nu există evaluări

- Metodos AtlasCopcopage35Document5 paginiMetodos AtlasCopcopage35lautaroi77Încă nu există evaluări

- Mining of Narrow Steeply Dipping VeinsDocument31 paginiMining of Narrow Steeply Dipping Veinstd__1985Încă nu există evaluări

- Design and Installation of Suctıon Anchor PilesDocument13 paginiDesign and Installation of Suctıon Anchor PilesYavuz Selim DEMİRELÎncă nu există evaluări

- Shaft Sinking Part 1Document33 paginiShaft Sinking Part 1dandeashrit100% (1)

- Haulage OptimisationDocument8 paginiHaulage Optimisationnaldo fernandezÎncă nu există evaluări

- MPBT - Pertemuan 12Document31 paginiMPBT - Pertemuan 12Ardiansyah Ay11Încă nu există evaluări

- Are You Looking For .: WWW - Promining.inDocument18 paginiAre You Looking For .: WWW - Promining.inANKIT DEOGADEÎncă nu există evaluări

- BreastDocument2 paginiBreastTinozivasheÎncă nu există evaluări

- Metal Mining (19121066)Document7 paginiMetal Mining (19121066)Shivani ChoudharyÎncă nu există evaluări

- Metal Mining Stoping MethodsDocument51 paginiMetal Mining Stoping MethodsAjeet KumarÎncă nu există evaluări

- Metal Mining Stoping MethodsDocument51 paginiMetal Mining Stoping MethodsSheshu BabuÎncă nu există evaluări

- Extracción de Roca y Arena en TSB Komati MillDocument3 paginiExtracción de Roca y Arena en TSB Komati MillJuan Altamirano RojasÎncă nu există evaluări

- 039 Mining in Flat OrebodiesDocument4 pagini039 Mining in Flat OrebodiesKenny CasillaÎncă nu există evaluări

- Waterval R P South AfricaDocument2 paginiWaterval R P South AfricaJonatan Isaac Huaman AraujoÎncă nu există evaluări

- Shrinkage Stoping (19121066)Document7 paginiShrinkage Stoping (19121066)Shivani ChoudharyÎncă nu există evaluări

- Jack Up Drilling RigDocument2 paginiJack Up Drilling RigMaría MarquinaÎncă nu există evaluări

- Raise-Bored Slot Raises: 18 Underground DrillingDocument2 paginiRaise-Bored Slot Raises: 18 Underground DrillinggeyunboÎncă nu există evaluări

- Stoping MethodDocument51 paginiStoping MethodRathnakar Reddy100% (1)

- Longhole Stoping at The Asikoy Underground Copper Mine in TurkeyDocument7 paginiLonghole Stoping at The Asikoy Underground Copper Mine in TurkeySari Fitria RamadhaniÎncă nu există evaluări

- Mining of NarrowDocument31 paginiMining of NarrowWilliam HinostrozaÎncă nu există evaluări

- Ingles IiDocument8 paginiIngles IiEdwin CondoriÎncă nu există evaluări

- Vertical Crater RetreatDocument30 paginiVertical Crater Retreatyorka25100% (2)

- Allis-Chalmers Manufacturing Company Bulletin 1403Document16 paginiAllis-Chalmers Manufacturing Company Bulletin 1403Mr Thane100% (1)

- Mine LayoutDocument7 paginiMine LayoutRavikumar mahadevÎncă nu există evaluări

- Vertical Crater RetreatDocument3 paginiVertical Crater RetreatvinothkhannaÎncă nu există evaluări

- Well Completion & StimulationDocument50 paginiWell Completion & StimulationShourovjossÎncă nu există evaluări

- Underground Mining-Supported OpeningsDocument13 paginiUnderground Mining-Supported OpeningsPuvanendran GajananÎncă nu există evaluări

- Mining Magazine - Sinking SkilfullyDocument14 paginiMining Magazine - Sinking SkilfullyLehlohonolo MoqekelaÎncă nu există evaluări

- Preprint 04-11: SME Annual Meeting Feb. 23-25, Denver, ColoradoDocument4 paginiPreprint 04-11: SME Annual Meeting Feb. 23-25, Denver, ColoradoluisparedesÎncă nu există evaluări

- 091 Boxhole Boring at El TenienteDocument6 pagini091 Boxhole Boring at El TenienteKenny CasillaÎncă nu există evaluări

- Longwall MiningDocument48 paginiLongwall MiningAjeet Kumar100% (1)

- OpenHole Sidetrack TechniqueDocument8 paginiOpenHole Sidetrack Techniqueamirawan532Încă nu există evaluări

- Coal Mining MethodsDocument2 paginiCoal Mining MethodsIzhar JiskaniÎncă nu există evaluări

- Encargo de Traducción 3Document5 paginiEncargo de Traducción 3Bárbara MuñozÎncă nu există evaluări

- Técnicas en Minería SubterráneaDocument17 paginiTécnicas en Minería SubterráneaHenrry Rosas TorresÎncă nu există evaluări

- Kimberlitic Tubes Underquarry ReservesDocument4 paginiKimberlitic Tubes Underquarry ReservesManuel AragonÎncă nu există evaluări

- BHM For GoldDocument3 paginiBHM For GoldFajar DjihadÎncă nu există evaluări

- Sublevel CavingDocument24 paginiSublevel CavingANSHUL YADAVÎncă nu există evaluări

- Application: Notes On Shrinkage StopingDocument6 paginiApplication: Notes On Shrinkage StopingBharAth ReDdyÎncă nu există evaluări

- (579390026) Caso 8 - Uso de Swellex en Grandes HidroelectricasDocument7 pagini(579390026) Caso 8 - Uso de Swellex en Grandes Hidroelectricaskokolito192Încă nu există evaluări

- 04-2 - Supported - NT DevelopmentDocument39 pagini04-2 - Supported - NT Developmentbonganimduduzi466Încă nu există evaluări

- Chapter 2 Surface MiningDocument90 paginiChapter 2 Surface Miningrishav baishya100% (3)

- Intership Repot Ofsmiore 69Document16 paginiIntership Repot Ofsmiore 69jagan100% (1)

- Report On MinesDocument7 paginiReport On MinesYhaneÎncă nu există evaluări

- Well Drilling - SaiaDocument2 paginiWell Drilling - SaiaAnalis MorenoÎncă nu există evaluări

- 029 Mechanized Bolting and ScreeningDocument4 pagini029 Mechanized Bolting and ScreeningKenny CasillaÎncă nu există evaluări

- 053 Changing Systems at ZinkgruvanDocument6 pagini053 Changing Systems at ZinkgruvanKenny CasillaÎncă nu există evaluări

- 125 Underground Mining of Limestones and GypsumDocument4 pagini125 Underground Mining of Limestones and GypsumKenny CasillaÎncă nu există evaluări

- 021 Underground Mining InfraestructureDocument4 pagini021 Underground Mining InfraestructureKenny CasillaÎncă nu există evaluări

- 133 Getting The Gest For PeñolesDocument4 pagini133 Getting The Gest For PeñolesKenny CasillaÎncă nu există evaluări

- 043 Backfilling For Safety and ProfitDocument3 pagini043 Backfilling For Safety and ProfitKenny CasillaÎncă nu există evaluări

- 017 Finding The Right Balance in Exploration DrillingDocument4 pagini017 Finding The Right Balance in Exploration DrillingKenny CasillaÎncă nu există evaluări

- 047 Innovative Mining at GarpenbergDocument6 pagini047 Innovative Mining at GarpenbergKenny CasillaÎncă nu există evaluări

- 046 Atlas Copco Rock Bolts For MiningDocument1 pagină046 Atlas Copco Rock Bolts For MiningKenny CasillaÎncă nu există evaluări

- 091 Boxhole Boring at El TenienteDocument6 pagini091 Boxhole Boring at El TenienteKenny CasillaÎncă nu există evaluări

- 063 From Surface To Underground at Kemi Chrome MineDocument6 pagini063 From Surface To Underground at Kemi Chrome MineKenny CasillaÎncă nu există evaluări

- 039 Mining in Flat OrebodiesDocument4 pagini039 Mining in Flat OrebodiesKenny CasillaÎncă nu există evaluări

- 109 Sublevel Stoping at Olympic DamDocument6 pagini109 Sublevel Stoping at Olympic DamKenny CasillaÎncă nu există evaluări

- 083 Pioneering Mass Caving at El TenienteDocument8 pagini083 Pioneering Mass Caving at El TenienteKenny CasillaÎncă nu există evaluări

- 033 Mining in Steep OrebodiesDocument6 pagini033 Mining in Steep OrebodiesKenny CasillaÎncă nu există evaluări

- 077 Mining Challenge at El SoldadoDocument6 pagini077 Mining Challenge at El SoldadoKenny CasillaÎncă nu există evaluări

- 068 Mining Magnesite at JelsavaDocument4 pagini068 Mining Magnesite at JelsavaKenny CasillaÎncă nu există evaluări

- 059 Increasing Outputs at LKAB Iron Ore MinesDocument4 pagini059 Increasing Outputs at LKAB Iron Ore MinesKenny CasillaÎncă nu există evaluări

- 121 Large Scale Copper Mining Adapted To Lower SeamsDocument4 pagini121 Large Scale Copper Mining Adapted To Lower SeamsKenny CasillaÎncă nu există evaluări

- 119 Mechanized Mining in Low Headroom at WatervalDocument2 pagini119 Mechanized Mining in Low Headroom at WatervalKenny CasillaÎncă nu există evaluări

- 105 High Speed Haulage at StawellDocument4 pagini105 High Speed Haulage at StawellKenny CasillaÎncă nu există evaluări

- 115 Improved Results at Meisham Iron Ore MineDocument4 pagini115 Improved Results at Meisham Iron Ore MineKenny CasillaÎncă nu există evaluări

- 129 Sub Level Caving For ChromiteDocument4 pagini129 Sub Level Caving For ChromiteKenny CasillaÎncă nu există evaluări

- 097 Modernization at Sierra MirandaDocument8 pagini097 Modernization at Sierra MirandaKenny CasillaÎncă nu există evaluări

- 007 Geology For Underground MiningDocument6 pagini007 Geology For Underground MiningKenny CasillaÎncă nu există evaluări

- 003 Trends in Underground MiningDocument4 pagini003 Trends in Underground MiningKenny CasillaÎncă nu există evaluări

- 013 Mineral Prospecting and ExplorationDocument4 pagini013 Mineral Prospecting and ExplorationKenny CasillaÎncă nu există evaluări

- Underground Coal MineDocument17 paginiUnderground Coal MineFavorSea Industrial Channel Limited100% (1)

- Longwall MiningDocument43 paginiLongwall MiningMeyyer Christopher LumembangÎncă nu există evaluări

- SP16 Start HereDocument2 paginiSP16 Start HereBerg Huaripata GoicocheaÎncă nu există evaluări

- Densidad SlurryDocument1 paginăDensidad SlurryFélix Antonio Peláez PortilloÎncă nu există evaluări

- Mineral Resources of BalochistanDocument23 paginiMineral Resources of Balochistansameerashraf100100% (8)

- Hematite EeDocument2 paginiHematite EeDropić MurisÎncă nu există evaluări

- MINING ENGINEERING 1 Applied Mathematics SolutionsDocument63 paginiMINING ENGINEERING 1 Applied Mathematics SolutionsJordan Taguibulos100% (2)

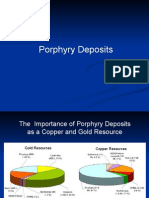

- Porphyry DepositsDocument43 paginiPorphyry DepositsVictor Valdivia100% (2)

- Reporte NI 43-101Document81 paginiReporte NI 43-101Camilo Renato Ríos JaraÎncă nu există evaluări

- Skidoo MillDocument65 paginiSkidoo MillRussell Hartill100% (1)

- Lambpiran ADocument8 paginiLambpiran Ahandryan nandaÎncă nu există evaluări

- A Review of Cassiterite Beneficiation PraticesDocument23 paginiA Review of Cassiterite Beneficiation PraticesLevent ErgunÎncă nu există evaluări

- Ecuador Drilling Rigs : Enap Sipec Enap SipecDocument2 paginiEcuador Drilling Rigs : Enap Sipec Enap SipecCarlo MoivreÎncă nu există evaluări

- Stripping Ratio PDFDocument59 paginiStripping Ratio PDFKeylla Chavez RosasÎncă nu există evaluări

- 71 2012 Marpol Report Oct 2013 PDFDocument7 pagini71 2012 Marpol Report Oct 2013 PDFMehmet ErturkÎncă nu există evaluări

- Overview of Tailings Disposal & Dam Construction Practices in The 21 CenturyDocument53 paginiOverview of Tailings Disposal & Dam Construction Practices in The 21 CenturyGeorgi SavovÎncă nu există evaluări

- Geotechnical Factors Influencing Selection of Mining MethodDocument4 paginiGeotechnical Factors Influencing Selection of Mining MethodMichael AltamiranoÎncă nu există evaluări

- New Afton Presentation1 PDFDocument32 paginiNew Afton Presentation1 PDFOktarianWisnuLusantonoÎncă nu există evaluări

- Berlinite Alpo: Crystal DataDocument1 paginăBerlinite Alpo: Crystal DataEr RutvikÎncă nu există evaluări

- Metallurgical Testwork Interpretation and Process DesignDocument15 paginiMetallurgical Testwork Interpretation and Process Designalinori100% (1)

- Method of Working CoalDocument262 paginiMethod of Working CoalanupamkherÎncă nu există evaluări

- Irrelevant DatabaseDocument44 paginiIrrelevant DatabasearebellionÎncă nu există evaluări

- CILDocument31 paginiCILHemant GaurkarÎncă nu există evaluări

- Narrow Vein Mining CiticorpDocument36 paginiNarrow Vein Mining CiticorpCarlos A. Espinoza MÎncă nu există evaluări

- Germano Dam Closure PlanDocument24 paginiGermano Dam Closure PlanMarcelo LiraÎncă nu există evaluări

- Tin Complex in BelitungDocument16 paginiTin Complex in BelitungFajar SeptiandaruÎncă nu există evaluări

- Autor: Rogobete Marius, Universitatea Din Petroşani Coordonator: Prof - Dr.ing. Cozma Eugen, Universitatea Din PetroşaniDocument4 paginiAutor: Rogobete Marius, Universitatea Din Petroşani Coordonator: Prof - Dr.ing. Cozma Eugen, Universitatea Din Petroşanicobraregala21Încă nu există evaluări

- Case Study - MineSched at SebukuDocument27 paginiCase Study - MineSched at SebukuBlank Kusuma100% (1)

- Deep Mill Freeport IndonesiaDocument16 paginiDeep Mill Freeport Indonesiatenri wijaÎncă nu există evaluări