Documente Academic

Documente Profesional

Documente Cultură

077 Mining Challenge at El Soldado

Încărcat de

Kenny CasillaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

077 Mining Challenge at El Soldado

Încărcat de

Kenny CasillaDrepturi de autor:

Formate disponibile

El Soldado, Chile

Mining challenge at El Soldado

Integrated operation

El Soldado is a tightly integrated

operation consisting of an under-

ground and open pit copper mine,

a concentrator and an oxide plant.

In order to increase production

underground, El Soldado intro-

duced a variation to its standard

sublevel open stoping mining

method in 1983. Six years later,

the open pit section of the mine

was started, posing an additional

complication for the geotech-

nical and mine design teams.

These days, the engineers enjoy

the challenge of an underground

mine, which features a com-

plex layout and problematic rock

conditions with numerous open

cavities, irregular orebodies of Atlas Copco ROC L8 crawlers at El Soldado open pit.

variable dimensions and in situ

stresses that vary in magnitude as

well as in orientation. Extraction Inés de Collahuasi and Mantos Blancos Of these, 24 technicians are employed

of the reserves must also follow a mines. in maintenance. The mine operates

sequence that minimizes impacts El Soldado mine is located 132 km Monday to Friday in three shifts of 8 h.

on the overlying surface opera- northwest of Santiago, on the western Mining at El Soldado started in 1842.

tions. A committed user of Atlas

Copco drill rigs, the mine depends slopes of the Coastal range, at about Since 1978, when Exxon Minerals ac-

upon Rocket Boomer M2 Cs for 830 m asl. El Soldado produces around quired the operation, about 70 million t

development and Simba M6 Cs 64,000 t copper in concentrate and of ore containing 1.8% copper have

for production, all featuring a high 5,000 t copper cathode, and its reserves been mined by the underground sub-

level of computerization. are estimated to be 115 million t grad- level open stoping method. In 1989, the

ing 1.0% copper. El Morro open pit commenced produc-

History The total workforce of El Soldado is tion to increase output to the present

under 280 people, of which one third 18,000 t/day. Today, the underground

The El Soldado and Los Bronces copper are employed in the underground mine. mine provides less than 30% of the

mines and the Chagres smelter, all lo-

cated in Chile, are operated by Compañía El Soldado location in central Chile.

Minera Disputada de las Condes.

In addition to its record as a success-

71°

71° 70°

70°

ful mining company, Disputada's oper-

ations achieved recognition in 1999 EL

ELSOLDADO

SOLDADO

when it became the first industrial CHAGRES

CHAGRES LOS

LOSANDES

ANDES

company to receive Chile’s National QUILLOTA

QUILLOTA

Environment Award, recognizing its SOUTH

SOUTH AMERICA

AMERICA

NAA

SOUTH

SOUTH AMERICA

AMERICA

leadership in environmental practices 33°

N TTIIN

VALPARAISO

VALPARAISO 33°

LOS

LOS BRONCES

and its high standards in environmental

BRONCES

GEEN

management.

ARRG

Disputada produces around 250,000 t/

CCH

HILI

ELE

SANTIAGO

SANTIAGO

A

year of copper. When, in 2002, Anglo SAN

SANANTONIO

ANTONIO

American plc agreed to purchase Dis-

putada from Exxon Mobil, it substan- EL

ELTENIENTE

TENIENTE 34°

34°

tially enhanced the quality of its base RANCAGUA

RANCAGUA

metals portfolio, in addition to offering

significant synergies with its other

Chilean copper operations, the Doña El

El Soldado's

El Soldado's

Soldado deposites

deposites

deposits

underground mining methods 77

El Soldado, Chile

Development

Boomer drilling

DTH Drilling 5½" Simba

DTH drilling

Raise

Simba

drilling

2½"Simba

radial drilling

Ore-pass

Extraction level

Transport level

Scooptram

loading

El Soldado underground mining schematic overview.

total concentrator feed, but rather more Problematical geology numerous isolated orebodies, with a

of the contained copper. strong structural control, located through-

The sulphide plant's current capac- The El Soldado deposit is located in the out an area 1,800 m-long by 800 m-

ity is 6.5 million t/year, of which the Lower Cretaceous Lo Prado formation, wide. The lateral limits of the orebodies

underground mine supplied 2 million t and is thought to be of epigenetic origin. are characterized by abrupt variations

in 2006. This is expected to decrease to The main host rocks are trachytes, fol- in the copper grade. The transition from

1.6 million t in 2007 as open pit output lowed in importance by andesites and high-grade mineralization of 1.2%

increases. tuffs. Copper mineralization occurs as to 2% Cu to low grade areas of 0.5%

Section of El Soldado mine and plant process.

78 underground mining methods

El Soldado, Chile

Extraction level layout

10.0 m Ventilation

shaft immediately above the underground

mine. An integral mine plan is there-

Shaft 10.0 m

Shaft B

= 1.5 m 2.5 x 2.5 m

fore required, in which the sequence

+ + +

++ + + Shaft

++ + + +

Ventilation 17 E

to

of extraction, both in the open pit and

22

Max 15.0 m

shaft m

m m

22 22 +

Max 15.0 m

underground, needs to satisfy safety

Max 15.0 m

Max 15.0 m

to to ++

10.0 m 17 17 ++

50.0 m

o

Shaft 40-50

and efficiency criteria. In particular,

o

40-50

2.5 x 2.5 m

40-50o

40-50o the design and extraction sequence of

17

Max. transport distance

underground stopes have to be managed

Max. transport distance

to

2

2m

18.0 to 20.0 m

Max 15.0 m

in such a way that they do not affect

150.0 m

18.0 to 20.0 m

150.0 m

Ventilation

shaft 18.0 to 20.0 m the open pit operations, and minimize

OP

OP

disturbance to unmined areas, enabling

maximum resource recovery. This has

18.0 to 20.0 m

to be balanced with the need to main-

tain high-grade feed, and the selectivity

Extraction level layout.

that comes with underground mining.

There has been a large amount of de-

to 1.2% Cu takes place within a few The nature of the major structures, velopment in the underground mine,

metres. Orebodies typically exhibit an and the inherent condition of the rock creating a large number of stopes, and

outer pyrite-rich halo, followed inwards mass, play a critical role in determin- a complex layout.

by an abundant chalcopyrite and bor- ing the extent of any likely instability Because of all the aspects that need

nite core, with minor chalcocite and surrounding excavations at El Soldado to be taken into account before mining

hematite. The main gangue minerals mine. Seven main fault systems, and a can start, extensive geotechnical moni-

are calcite, quartz, chlorite, epidote system of bed contacts, have been de- toring is applied to rock conditions, to

and albite. fined within the ore deposit limits as detect and identify failures and insta-

The orebodies are of tabular shape, being significant in geotechnical terms. bilities, to collect data for mine plan-

with dimensions that vary from 100 to The induced state of stress after excava- ning and stope design, and for ongoing

200 m in length, 30 to 150 m in width, tion is a significant mine design crite- assessment of mine stability. Over the

and 80 to 350 m in height. The ground ria, and a monitoring objective. In an longer term, the collected data provides

conditions are classified as competent, attempt to obtain information on the in- control points to update the geotechni-

with an intact rock strength greater than situ stress in critical areas of the mine, cal database, and to verify the assump-

200 Mpa, in a moderate stress regime measurements have been carried out. tions made in the design.

ranging from 15 to 30 Mpa. These geo-

technical conditions facilitate the devel- Mine stability Underground layout

opment of large open cavities, normally

as large as the orebodies, with dimen- Mine stability is a matter of prime im- The access points to the orebodies are

sions from 40 to 90 m width, 50 to 290 portance in the planning process, particu- located on the slope of the Chilean coa-

m length, and up to 300 m height. larly as the El Morro open pit is situated stal range hosting the mine, several

Rocket Boomer M2 C underground . Surface workshop at El Soldado.

underground mining methods 79

El Soldado, Chile

the surface. If it is decided to fill a stope,

then waste rock from development is

used.

Production stopes

Production block access is provided by

developing sublevels, with a pattern of

5.0 m x 3.7 m LHD drawpoints at the

base of the stope. Block undercutting is

accomplished with a fan pattern of 60 to

75 mm-diameter holes up to 25 m-long

loaded with ANFO and HE boosters.

Uphole production drilling pattern. Slots are made by enlarging a 2.5 x 2.5

m blast hole slot raise, at one end, or in

hundred metres above the valley floor. increase in production rates. Nominal the middle, of the stope. Blast holes of

Today, the main entry is located at -100 stope dimensions are 30 to 60 m- 165 mm-diameter and up to 80 m-long

level (730 m asl) and the haulage level is wide, 50 to 100 m-long, and up to 100 are drilled with an underhand pattern.

at 300 m below datum (530 m asl). The m-high, though large orebodies are Blast size and blasting sequence is

mine has been developed by a network divided into several units, leaving rib defined for each stope, according to

of sublevels, providing access to the and crown pillars as temporary sup- major structural features and the prox-

tops and bottoms of the mining areas. port structures. Rib pillars are 30 to 50 m- imity of existing cavities. Dilution con-

Sublevels are linked by ramps, with a wide, and crown pillars 25 to 40 m- thick. trol is improved, and blast hole losses

maximum slope of 15%. Ore is loaded The stopes are mined progressively down- avoided, by carefully considering the

directly into ore passes with an overall wards by a traditional SBOS method, particular geometries created by the in-

capacity of 10,000 to 30,000 t, which and are left unfilled. Pillars are subse- tersection of major discontinuities and

connect sub levels with the haulage quently recovered by a mass blast tech- the free faces of the planned excavation.

level. This ore is transported to a crush- nique, and are sometimes designed Often, faults present geometries which

er located on surface, near the concen- to break more than 1 million t of ore generate wedges that can slide into the

trator, using 50 t-capacity, highway-type each. cavity, affecting fragmentation and gen-

trucks. Some ore is mined below the main The rock is very competent, and the erating oversize rock at drawpoints. The

haulage level, and this material is trans- stope cavities can be left open, sometimes presence of cavities, or simultaneous

ported directly to the surface crusher standing for 5 or 10 years, depending mining in nearby locations, also impose

using trucks and ramps. on the sector and the rock structure. restrictions in the mining sequence and

Historically, the massive, but irregular, Smaller stope cavities normally have size of blast.

orebodies and the competent ground stable geometries, with less than 5% Production ore from stopes is loaded

conditions made sublevel open stoping dilution from back extension or wall out with 10 cu yd LHDs. One-way dis-

the preferred mining method. However, failure. However, three large open sto- tances of 100 to 150 m are maintained

in 1983, fully mechanized sublevel and pes, the Santa Clara, California and to orepass tips, which are not equipped

large-diameter blast hole open stope Valdivia Sur stopes, have experienced with grizzlies as oversize rock is drilled

(SBOS) was introduced as a variation controlled structural caving, filling the and blasted in place at the drawpoints.

of the standard method, enabling an existing void and breaking through to Orepasses terminate in hydraulically-

controlled chutes at the –300 haulage

level, where the 50 t trucks are loaded

Downhole production drilling pattern.

with run-of-mine ore or development

waste.

Parallel hole drilling Radial hole drilling A square pattern of 1.90 m x 1.7 m

split set bolts, 2.05 m-long, in combina-

C tion with wire mesh, is used to maintain

adp 450

working areas free of rock fall, and to

50 to 75 m protect personnel and equipment. This

approach to ground control is not in-

50 to 75 m A

Nonel

tended for heavy rock loads or massive

stress-induced instabilities, though

B

Á is adequate for local support. Where

45° needed, cable bolting is used to sup-

port unfavourable geometries, such as

45° C´

large wedges or low dip bedding layers,

80 underground mining methods

El Soldado, Chile

Copco DC carriers in co-operation with

Dyno Nobel, are used for both face and

long hole charging. A fourth unit, a

Rocmec DC 11 built on an Atlas Copco

carrier, is equipped with an Atlas Copco

GA 11 compressor and an ANOL CC

type of charging vessel.

For loading and transportation, three

Atlas Copco Scooptram ST8B loaders

are employed. The mine also has three

13 cu yd Scooptram ST1810 loaders

equipped with monitoring systems which

are employed on waste haulage.

Rock reinforcement is carried out

with an Atlas Copco Boltec H335 bolting

machine.

El Soldado has installed a computer-

based system to monitor the condition of

its mobile equipment. The underground

leaky feeder communication system is

linked to the loaders and drill rigs.

Both the open pit and the under-

ground areas have equipment mainte-

Simba M6 C drilling radial holes.

nance workshops. A preventive mainte-

nance workshop located on the surface

further serves the underground area,

and also to support drawpoints and ore three Atlas Copco Boomer H127s and field maintenance is carried out on

passes where the rock conditions have equipped with COP 1032 rock drills have the Simbas.

changed dramatically. Occasionally, been replaced by new Rocket Boomer

cable bolts are used to minimize or pre- M2 C units featuring Advanced Boom Outlook

vent caving in the sublevel stopes. Control (ABC) system. These work al-

Development headings average 18.5 ongside the remaining Boomer H127 El Soldado's main objective is to con-

sq m cross section, in which the intro- unit drilling 43 mm holes. The old ma- tinue with its tradition of excellence in

duction of the Rocket Boomer M2 Cs chines have been rebuilt, one as a secon- safety and cost competitiveness. The

has increased the incremental advance dary drill rig, and the other as a scaler. underground mine production is being

from 3.9 to 4.2 m/round. The number For production, El Soldado employs reduced as open pit output increases,

of holes/round has meanwhile been de- three Atlas Copco Simba 264 rigs equip- and variants of the exploitation method

creased by changing from 45 mm to 51 ped with the COP 64 DTH rock drill will be introduced to recover minor

mm-diameter bits and a 5 in cut hole. for 5.5 in holes. There are also an Atlas volume reserves using automated radial

Large-diameter blast hole open stop- Copco Simba H221 and a Simba H252, drilling to over 40 m depth.

ing has worked well at El Soldado. The both used for radial drilling of DTH El Soldado's mining plan is intrinsi-

mine drills up to 53,000 m/year using holes ranging between 65-75 mm. The cally linked to its geotechnical and geo-

DTH, and 32,000 m/year with topham- Simba H252 drills the 75 mm-diameter metric conditions, and so improvements

mer drilling. The current method allows upholes for the undercut. to the monitoring and data-collection

the exploitation of larger units, reducing The Simba 264 machines are being systems, in order to obtain more precise

preparation costs and improving pro- replaced by the new generation Simba geotechnical engineering, are constantly

ductivity costs. Another advantage of M6 C DTH drill rigs, which along with being studied.

the method is that it is selective, allow- the Rocket Boomer M2 C units, feature

ing extraction of only the mineral. The the ABC Regular, which will be up- Acknowledgements

current cost distribution is: development graded to ABC Total in due course.

32%; service and other 28%; drilling El Soldado obtains 20% to 30% more This article is based on interviews with

and blasting 17%; extraction 12%; and drilling capacity per hour with the new Nelson Torres, Mine Superintendent at

transport 11%. Simba M6 C machines, on account of El Soldado, and extracts from the fol-

mechanized tube handling and better lowing paper: Contador N and Glavic

Equipment maintenance control of drilling parameters. M, Sublevel Open Stoping at El Soldado

The robust design offers better utili- Mine: A Geomechanical Challenge.

El Soldado has been through a phase zation and lower maitenance. Three

of equipment replacement. Two of the PT-61 ANFO chargers, built on Atlas

underground mining methods 81

A winning combination

The Rocket Boomer E-series. A new face drilling rig that

features the super-fast, prize-winning COP 3038 rock drill. It

also introduces the BUT 45, a superb new boom that reduces

hole deviation, provides extra large coverage area and slashes

positioning time between holes by 50%. The result?

A winning combination that significantly cuts tunnelling

costs and leads to real operational economy.

Committed to your superior productivity.

Atlas Copco Rock Drills AB

Fax: +46-(0)19 6707393

www.atlascopco.com

S-ar putea să vă placă și

- 129 Sub Level Caving For ChromiteDocument4 pagini129 Sub Level Caving For ChromiteKenny CasillaÎncă nu există evaluări

- Scooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityDocument5 paginiScooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacitySebastian CortesÎncă nu există evaluări

- Use of Machine Learning Algorithm Models To Optimize The Fleet Management System in Opencast MinesDocument9 paginiUse of Machine Learning Algorithm Models To Optimize The Fleet Management System in Opencast MinesInternational Journal of Innovative Science and Research Technology100% (1)

- Addressing The Challenges and Future of Cave Mining PDFDocument20 paginiAddressing The Challenges and Future of Cave Mining PDFDiego Ignacio VelizÎncă nu există evaluări

- Tren ScoopDocument16 paginiTren ScoopHugoRamosMamaniÎncă nu există evaluări

- Short-Term Underground Mine Scheduling PDFDocument95 paginiShort-Term Underground Mine Scheduling PDFDavid HalomoanÎncă nu există evaluări

- Innovative Cave Establishment Practices at Ridgeway DeepsDocument15 paginiInnovative Cave Establishment Practices at Ridgeway Deepsalvaroaac4Încă nu există evaluări

- Pre Conditioning Cadia East A Catalan G DunstanDocument15 paginiPre Conditioning Cadia East A Catalan G DunstanMatías Ignacio Fuentes Bustamante100% (1)

- Simulacion de Eventos Discretos en SubteraneoDocument16 paginiSimulacion de Eventos Discretos en SubteraneoAnthony Job Rosales LuisÎncă nu există evaluări

- Ranking of Geometry/Grade Distribution For Diferent Mining MethodDocument8 paginiRanking of Geometry/Grade Distribution For Diferent Mining MethodVictor QuispeÎncă nu există evaluări

- Design of The Second Block Cave at Northparkes E26 MineDocument12 paginiDesign of The Second Block Cave at Northparkes E26 MineYojan Ccoa CcopaÎncă nu există evaluări

- Understanding and Assessment of Mining Equipment EffectivenessDocument6 paginiUnderstanding and Assessment of Mining Equipment EffectivenessFelipe JimenezÎncă nu există evaluări

- Optimization of Mining Method and EquipmentDocument6 paginiOptimization of Mining Method and EquipmentkullieÎncă nu există evaluări

- MC 100 Cargador de ExplosivosDocument8 paginiMC 100 Cargador de ExplosivosWiwa Hernandez Donoso100% (1)

- Full Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineDocument10 paginiFull Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineandresmaureiravÎncă nu există evaluări

- Lecture - 4 - Open - Pit - Mining - Presentation PDFDocument18 paginiLecture - 4 - Open - Pit - Mining - Presentation PDFRahat fahimÎncă nu există evaluări

- El Soldado - BoricDocument22 paginiEl Soldado - BoricvasaminÎncă nu există evaluări

- Friction Hoisting ArrangementDocument2 paginiFriction Hoisting ArrangementAnonymous ntE0hG2TPÎncă nu există evaluări

- 2.3.2.3 Avoca MethodDocument67 pagini2.3.2.3 Avoca Methoddewin lizarazoÎncă nu există evaluări

- Calculating Stripping Ratios and Break Even Limits for Surface Coal MinesDocument11 paginiCalculating Stripping Ratios and Break Even Limits for Surface Coal MinespriyankaÎncă nu există evaluări

- Lab4 MIN277Document29 paginiLab4 MIN277Jhordy Romero GabrielÎncă nu există evaluări

- Full Text 01Document199 paginiFull Text 01huberÎncă nu există evaluări

- MME 2010 Contents and Introduction PDFDocument13 paginiMME 2010 Contents and Introduction PDFAmaraaZoyaÎncă nu există evaluări

- Chapter 2 - Surface Mining MethodsDocument14 paginiChapter 2 - Surface Mining Methodsdaniel_tavares_9Încă nu există evaluări

- Laubscher Planning Mass Mining OperationsDocument16 paginiLaubscher Planning Mass Mining OperationsScott Downs100% (2)

- Automation at Northparkes Rio TintoDocument30 paginiAutomation at Northparkes Rio TintoAmilton filhoÎncă nu există evaluări

- Underground ExpansionDocument48 paginiUnderground ExpansionChristian TewodrosÎncă nu există evaluări

- MINERA PLANIFICACIÓN PROCESO INTRODUCCIÓNDocument35 paginiMINERA PLANIFICACIÓN PROCESO INTRODUCCIÓNGustavo Salazar Fernandez100% (1)

- KGHM International Vibration and Airblast Presentation PDFDocument26 paginiKGHM International Vibration and Airblast Presentation PDFCahaya TambunanÎncă nu există evaluări

- Mass Underground Mining and The Role of PDFDocument5 paginiMass Underground Mining and The Role of PDFThiago Pires SampaioÎncă nu există evaluări

- Case Study Model For Economic Lifetime of Drilling Machines in The Swedish Mining IndustryDocument18 paginiCase Study Model For Economic Lifetime of Drilling Machines in The Swedish Mining IndustryBerat HasolliÎncă nu există evaluări

- Underground Mining Methods (Alumnos)Document50 paginiUnderground Mining Methods (Alumnos)Arturo Erick Anticona GarcíaÎncă nu există evaluări

- DSI Underground Systems Cable Bolts USDocument14 paginiDSI Underground Systems Cable Bolts USDonald Culqui ValleÎncă nu există evaluări

- Mine Power PDFDocument10 paginiMine Power PDFzahidÎncă nu există evaluări

- Block CavingDocument19 paginiBlock CavingmanikantaÎncă nu există evaluări

- Drawpoint Spacing at Panel Caving PDFDocument6 paginiDrawpoint Spacing at Panel Caving PDFDiegoÎncă nu există evaluări

- Vertical Crater RetreatDocument30 paginiVertical Crater Retreatyorka25100% (2)

- LECTURE 5 Cheat Sheet PythonDocument12 paginiLECTURE 5 Cheat Sheet Pythondhanhicha botonÎncă nu există evaluări

- Ventilation InnovationDocument2 paginiVentilation InnovationAnang Ma'rupÎncă nu există evaluări

- Preconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsDocument16 paginiPreconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsFernando RicardoÎncă nu există evaluări

- Global Iron Ore DataDocument4 paginiGlobal Iron Ore DatabogdanberchiÎncă nu există evaluări

- PIO Antamina PDFDocument7 paginiPIO Antamina PDFJC AlemanÎncă nu există evaluări

- Boltec DS411Document4 paginiBoltec DS411fabian castroÎncă nu există evaluări

- 007 Smooth BlastingDocument49 pagini007 Smooth Blastinghendrawan ari sudrajatÎncă nu există evaluări

- KODA-LoftExtended 29.04.2020Document4 paginiKODA-LoftExtended 29.04.2020Leon ZieglerÎncă nu există evaluări

- RecMin Help US PDFDocument196 paginiRecMin Help US PDFsoloserjÎncă nu există evaluări

- Maptek Vulcan Open Cut Drill BlastDocument1 paginăMaptek Vulcan Open Cut Drill BlastMario Andrés Rojas GamboaÎncă nu există evaluări

- Fanel: Sistemas de IniciaciónDocument2 paginiFanel: Sistemas de IniciaciónyersonÎncă nu există evaluări

- Surface and UGDocument26 paginiSurface and UGsunilsinghmÎncă nu există evaluări

- Deswik - So v2018.1 What S NewDocument28 paginiDeswik - So v2018.1 What S NewCarlos Joaquin BarreraÎncă nu există evaluări

- Codelco - El Teniente Final Paper DeepMining07 PreconditioningDocument10 paginiCodelco - El Teniente Final Paper DeepMining07 PreconditioningFernando RicardoÎncă nu există evaluări

- Factors Affecting Mining-UpdatedDocument12 paginiFactors Affecting Mining-UpdatedFaryal KhanÎncă nu există evaluări

- Answer MiningDocument3 paginiAnswer Miningrichkyutama0% (1)

- Practical Implementation of VOD at The Henderson Mine: R. Dave Brokering, D.M. Loring, C.J. RutterDocument8 paginiPractical Implementation of VOD at The Henderson Mine: R. Dave Brokering, D.M. Loring, C.J. RutterCARLOS OSIEL SEBASTIÁN VALDÉSÎncă nu există evaluări

- Zaldivar MMS PDFDocument114 paginiZaldivar MMS PDFsebastian sougarretÎncă nu există evaluări

- Sorting of Alluvial DiamondsDocument8 paginiSorting of Alluvial DiamondsNooraÎncă nu există evaluări

- Otc 6267 MSDocument16 paginiOtc 6267 MSnandani sudamaÎncă nu există evaluări

- Korte 2000Document5 paginiKorte 2000Javier R. AmayaÎncă nu există evaluări

- 083 Pioneering Mass Caving at El TenienteDocument8 pagini083 Pioneering Mass Caving at El TenienteKenny CasillaÎncă nu există evaluări

- Read On.: Excavator Operating Weight Class 120 TonnesDocument4 paginiRead On.: Excavator Operating Weight Class 120 Tonnesedgar lopezÎncă nu există evaluări

- 125 Underground Mining of Limestones and GypsumDocument4 pagini125 Underground Mining of Limestones and GypsumKenny CasillaÎncă nu există evaluări

- 133 Getting The Gest For PeñolesDocument4 pagini133 Getting The Gest For PeñolesKenny CasillaÎncă nu există evaluări

- 053 Changing Systems at ZinkgruvanDocument6 pagini053 Changing Systems at ZinkgruvanKenny CasillaÎncă nu există evaluări

- 137 Keeping A Low Profile at PanasqueiraDocument6 pagini137 Keeping A Low Profile at PanasqueiraKenny CasillaÎncă nu există evaluări

- 029 Mechanized Bolting and ScreeningDocument4 pagini029 Mechanized Bolting and ScreeningKenny CasillaÎncă nu există evaluări

- 047 Innovative Mining at GarpenbergDocument6 pagini047 Innovative Mining at GarpenbergKenny CasillaÎncă nu există evaluări

- 063 From Surface To Underground at Kemi Chrome MineDocument6 pagini063 From Surface To Underground at Kemi Chrome MineKenny CasillaÎncă nu există evaluări

- 017 Finding The Right Balance in Exploration DrillingDocument4 pagini017 Finding The Right Balance in Exploration DrillingKenny CasillaÎncă nu există evaluări

- 039 Mining in Flat OrebodiesDocument4 pagini039 Mining in Flat OrebodiesKenny CasillaÎncă nu există evaluări

- 021 Underground Mining InfraestructureDocument4 pagini021 Underground Mining InfraestructureKenny CasillaÎncă nu există evaluări

- 046 Atlas Copco Rock Bolts For MiningDocument1 pagină046 Atlas Copco Rock Bolts For MiningKenny CasillaÎncă nu există evaluări

- 025 Principles of Raise BoringDocument4 pagini025 Principles of Raise BoringKenny Casilla100% (1)

- 043 Backfilling For Safety and ProfitDocument3 pagini043 Backfilling For Safety and ProfitKenny CasillaÎncă nu există evaluări

- 115 Improved Results at Meisham Iron Ore MineDocument4 pagini115 Improved Results at Meisham Iron Ore MineKenny CasillaÎncă nu există evaluări

- 083 Pioneering Mass Caving at El TenienteDocument8 pagini083 Pioneering Mass Caving at El TenienteKenny CasillaÎncă nu există evaluări

- 059 Increasing Outputs at LKAB Iron Ore MinesDocument4 pagini059 Increasing Outputs at LKAB Iron Ore MinesKenny CasillaÎncă nu există evaluări

- 097 Modernization at Sierra MirandaDocument8 pagini097 Modernization at Sierra MirandaKenny CasillaÎncă nu există evaluări

- 033 Mining in Steep OrebodiesDocument6 pagini033 Mining in Steep OrebodiesKenny CasillaÎncă nu există evaluări

- 121 Large Scale Copper Mining Adapted To Lower SeamsDocument4 pagini121 Large Scale Copper Mining Adapted To Lower SeamsKenny CasillaÎncă nu există evaluări

- 105 High Speed Haulage at StawellDocument4 pagini105 High Speed Haulage at StawellKenny CasillaÎncă nu există evaluări

- 068 Mining Magnesite at JelsavaDocument4 pagini068 Mining Magnesite at JelsavaKenny CasillaÎncă nu există evaluări

- 073 All Change For Asikoy Copper MineDocument4 pagini073 All Change For Asikoy Copper MineKenny Casilla0% (1)

- 007 Geology For Underground MiningDocument6 pagini007 Geology For Underground MiningKenny CasillaÎncă nu există evaluări

- 109 Sublevel Stoping at Olympic DamDocument6 pagini109 Sublevel Stoping at Olympic DamKenny CasillaÎncă nu există evaluări

- 119 Mechanized Mining in Low Headroom at WatervalDocument2 pagini119 Mechanized Mining in Low Headroom at WatervalKenny CasillaÎncă nu există evaluări

- 091 Boxhole Boring at El TenienteDocument6 pagini091 Boxhole Boring at El TenienteKenny CasillaÎncă nu există evaluări

- 013 Mineral Prospecting and ExplorationDocument4 pagini013 Mineral Prospecting and ExplorationKenny CasillaÎncă nu există evaluări

- 003 Trends in Underground MiningDocument4 pagini003 Trends in Underground MiningKenny CasillaÎncă nu există evaluări

- International Market SegmentationDocument9 paginiInternational Market SegmentationYashodara Ranawaka ArachchigeÎncă nu există evaluări

- Chapter 11 AnswerDocument16 paginiChapter 11 AnswerKathy WongÎncă nu există evaluări

- Indigo by Louis FischerDocument6 paginiIndigo by Louis Fischermitasha_saini100% (5)

- SAARC - Successes and Challenges PDFDocument6 paginiSAARC - Successes and Challenges PDFalam amarÎncă nu există evaluări

- F Business Taxation 671079211Document4 paginiF Business Taxation 671079211anand0% (1)

- The Role of Ideology in International RelationsDocument8 paginiThe Role of Ideology in International RelationsVinay JohnÎncă nu există evaluări

- Microeconomia: Preferenze Lessicografiche (Dimostrazioni Delle Proprietà)Document3 paginiMicroeconomia: Preferenze Lessicografiche (Dimostrazioni Delle Proprietà)maslsl daimondÎncă nu există evaluări

- A Presentation ON Amul DairyDocument12 paginiA Presentation ON Amul DairyChirag PanchalÎncă nu există evaluări

- Briefing Note: "2011 - 2014 Budget and Taxpayer Savings"Document6 paginiBriefing Note: "2011 - 2014 Budget and Taxpayer Savings"Jonathan Goldsbie100% (1)

- Break EvenAnalysisDocument24 paginiBreak EvenAnalysisDlsu Amphi-CatÎncă nu există evaluări

- Emissions TradingDocument22 paginiEmissions Tradingasofos100% (1)

- HNIDocument5 paginiHNIAmrita MishraÎncă nu există evaluări

- Strike On MRFDocument5 paginiStrike On MRFMegha YmtÎncă nu există evaluări

- Account statement for Naresh Seervi from 28 June to 18 July 2019Document3 paginiAccount statement for Naresh Seervi from 28 June to 18 July 2019Naresh SeerviÎncă nu există evaluări

- PRQNP 11 FBND 275 HXDocument2 paginiPRQNP 11 FBND 275 HXjeevan gowdaÎncă nu există evaluări

- Final Presentation On Ambuja Cements LTDDocument25 paginiFinal Presentation On Ambuja Cements LTDRocky SyalÎncă nu există evaluări

- Companies From Deal CurryDocument5 paginiCompanies From Deal CurryHemantÎncă nu există evaluări

- DR Winston McCalla, Lessons From The Caribbean Region Experience, Presentation, 2-2012Document21 paginiDR Winston McCalla, Lessons From The Caribbean Region Experience, Presentation, 2-2012Detlef LoyÎncă nu există evaluări

- Microeconomics Chapter 1 IntroDocument28 paginiMicroeconomics Chapter 1 IntroMc NierraÎncă nu există evaluări

- Regional Acceptance Ach Draft Form-OneDocument2 paginiRegional Acceptance Ach Draft Form-Onejohnlove720% (1)

- Tony Tan Caktiong – Jollibee founderDocument6 paginiTony Tan Caktiong – Jollibee founderRose Ann0% (1)

- Indian Economy Classified by 3 Main Sectors: Primary, Secondary and TertiaryDocument5 paginiIndian Economy Classified by 3 Main Sectors: Primary, Secondary and TertiaryRounak BasuÎncă nu există evaluări

- Management of Environmental Quality: An International JournalDocument21 paginiManagement of Environmental Quality: An International Journalmadonna rustomÎncă nu există evaluări

- Annual Review Pitch Deck by SlidesgoDocument7 paginiAnnual Review Pitch Deck by SlidesgoALJOHARA KHALID HAMAD ALSULIMANÎncă nu există evaluări

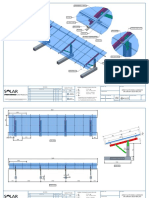

- Array 5x2 On Concrete Block Ballast-01Document2 paginiArray 5x2 On Concrete Block Ballast-01Wisnu WicaksonoÎncă nu există evaluări

- FLYFokker Fokker 70 Leaflet - 1Document4 paginiFLYFokker Fokker 70 Leaflet - 1FredyBrizuelaÎncă nu există evaluări

- Formulación Matemática Del Sistema RicardianoDocument22 paginiFormulación Matemática Del Sistema RicardianoPili BarrosÎncă nu există evaluări

- AcpcDocument21 paginiAcpcapi-293268314Încă nu există evaluări

- Product Highlight Sheet-Retire SmartDocument3 paginiProduct Highlight Sheet-Retire SmartLU HERRERAÎncă nu există evaluări

- Shaking Tables Around The WorldDocument15 paginiShaking Tables Around The Worlddjani_ip100% (1)