Documente Academic

Documente Profesional

Documente Cultură

ST 6m1 Electronicautomation

Încărcat de

Boddapalli sureshTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ST 6m1 Electronicautomation

Încărcat de

Boddapalli sureshDrepturi de autor:

Formate disponibile

www.DataSheet.co.

kr

Quick Reference Guide

Sequential Timers

ST-10/ST-10M1/ST-6M1/ST-10M2

ELECTRONIC AUTOMATION (P) LTD

P. B. # 6414, Yelahanka, Bangalore - 560064

Phones: 0091 - 080 - 8567561 / 8567562

Fax : 080 - 8567129

E-mail : eaplindia@vsnl.com URL : www.eaplindia.com

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

Thank you for purchasing EAPL’S Sequential Timer. This instruction manual describes every

aspect of installation, set-up, and operation of the Sequential Timer. If you run into difficulties and

need technical assistance, feel free to call our technical support at (080) 8567561 available

between 9 AM – 5:30PM IST or visit our web site at www.eaplindia.com.

EAPL, an ISO 9001 company, leaders in Timer Technology Brings to you a new range of micro

controller based programmable timers. High reliability, accuracy, compactness are some of the

striking design features.

Uncompromising quality with cost effectiveness has been the watchword at EAPL.

For Customer Use

Enter below the serial Number which is located on the timer cabinet. Retain this information for

future reference.

Model No:

Serial No:

Batch No:

Date of Purchase:

Purchase Point:

Accessories

Sequential Timer - 1 no.

Quick reference guide

Note: Please acknowledge that we reserve the right to make changes in product performance or

specifications without prior notice. Also please note that we bear no responsibility for mistakes,

misprints or omissions of the instruction manual Specifications.

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

Salient Features

State of the art microcontroller design

User friendly programming for On/Off time selection up to 99 hrs 59 mins.

7 segment display indication for channel & timing operation.

Multiple units can be cascaded to obtain more channels.

Program & process value retention incase of power failure.

External contacts for timing initiation & timing pause.

O r d e r i n g I n f o r m a t i o n

* OLP=On line programming

Model Function Output Source Voltage Time Range

Sequential switching with OLP Relay 110V AC

ST-10 0.1 sec to 99 hrs 59 mins

Relay Output 240V AC

Sequential switching without OLP Relay 110V AC

ST-10M1 0.1 sec to 99 hrs 59 mins

Relay Output 240V AC

6-channel Sequential switching without Relay

110V AC

ST-6M1 OLP 0.1 sec to 99 hrs 59 mins

240V AC

Relay Output

Sequential switching without OLP Triac 110V AC

ST-10M2 0.01 sec to 99 hrs 59 mins

Triac Output 240V AC

Specia l Features

HOLD: When the slide switch on the front panel is kept in the hold position, the Timing data is

retained in case of power failure. Upon resumption of power the timing continues from the point

where it has stopped.

RESTART: When the slide switch is kept in the restart position, the timer resets in case of power

failure and starts from beginning upon power resumption.

EXTERNAL START: By shorting terminals S1 and S2 for minimum period of 120

milliseconds (potential free shorting) or by keeping S1 and S2 permanently shorted, the timer

sequence is initiated.

SINGLE CYCLE OPERATION: By keeping the terminals C1 and C2 shorted (potential

Free) on the front panel, the sequential switching of output is executed for one Cycle and stops.

CYCLIC OPERATION: By keeping the terminals C1 and C2 on the front panel open, the

Sequential switching of outputs keeps repeating after the end of each cycle.

INHIBIT: By shorting terminals I1 and I2 (potential free) on the front panel, status of relays/triac

output (ON or OFF) is maintained irrespective of the program timing. By removing the short, the

programmed timing continues and relay / triac respond as per the preprogrammed timings.

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

CYCLE COMPLETE OUTPUT: This feature namely an opto coupled output signal from

terminals O1 and O2 is available at the end of one switching sequence. This signal is intended for

cascading one or more units to increase the number of output channels.

ONLINE PROGRAMMING: This facility is provided only in model ST10 wherein it permits

the user to change the program online by setting the switches in “PROG” position making the

required changes in timing and implementing the same, for the cycle in progress.

Specifications

Operating Voltage Range - 15% to + 10% of rated voltage

Rated frequency 50 Hz 5%

Power consumption 15V A / 3W ac approx.

10 (RLYO –RLY9)

Number of channels 10(OP0 – OP9) for ST-10M2

6 (RLYO –RLY5) for ST-6M1

0.1 sec to 99hrs 59mins. For each channel

ON / OFF time range

0.01 secs to 99hrs 59mins. In ST 10 M2

NO relay contacts rated for 10A@ 250V AC/28V DC

Resistive for ST 10 M1, ST 6M1

Control output

For ST-10M2 10 triac output (OP0 - OP9) rated 500mA

@ 250V AC resistive

0.1% max w.r.t setting 50msecs.

Setting Accuracy 0.2% max w.r.t setting 20msecs for ST-10M2

0.05% max 50msecs.

Repeat Accuracy

0.3% max. 20msecs for ST-10M2

Recovery Time 2 secs min

Variation due to voltage change 1% max 50msecs.

Variation due to temp. change 2% max 50msecs.

Variation due to freq. change 1% max 50msecs.

Operating: - 10 C to + 55 C

Ambient Temperature

Storage : - 25 C to + 80 C

Humidity Max. 85% RH @ 40 C

Electrical Life 105 Operations min. with full load

Rated frequency of operation 1800 5% operations per hour max.

Insulation resistance >100M ohms @ 500 VDC

Connections Screw type terminals with self lifting clamps

Dimensions 200 x 130 x 45 mm [W x H x D]

Operating Instructions

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

Potential free contacts should be used to short terminals C1 & C2 ,I1 & I2, S1&S2.Applying

power to these points will damage the timer permanently.

When more than one unit is used in cascade, output O1 & O2 should be connected to S1

& S2 respectively of next timer.

Do not connect O1& O2 to S1 & S2 of the same timer. Use C1 & C2 for cyclic or single

cycle mode operation.

Programming is not possible if terminals I1 & I2 are shorted.

Apply Rated voltage to the timer to avoid permanent damage

Front Panel

1 SEQUENCE

This button is used to select the required output / channel to program the timing.

2 ON / OFF

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

This button is used to select the ON time and OFF time for particular output / channel

3 RANGE

This button is used to select the desired time range (SEC/SEC, MIN/SEC, and HRS/MIN)

4, 5 ADV

This buttons is used to increment the time range digits

6 PROG/RUN

This switch is used to select the mode of operation (for programming PROG mode& for

running timer RUN mode)

7 RESTART/HOLD

This switch is used to select the RESTART or HOLD mode.

8 DISPLAY

It displays the relay number which is in function.

9, 14 INDICATOR

It is the indicator for ON time and OFF time.

10, 11 & 12 INDICATORS

It indicates the different time combinations

13 DISPLAYS

It displays the time combination.

15 INDICATORS

It indicates the relay on function.

Terminal Details

A1, A2 : Power

S1, S2 : External Start

C1, C2 : Single Cycle or Cyclic operation selection terminal (SHORT

single cycle, OPEN for Cyclic operation)

O1, O2 : Output for cascade mode operation

I1, I2 : Inhibit terminals

RLY0 TO RLY9 : Normally open relay contacts (for ST10, ST10- M1)

RLY0 TO RLY5 : Normally open relays contacts (for ST6-M1)

OP0 TO OP9 : Triac outputs (for ST10-M2)

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

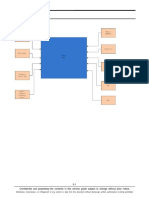

Connection Diagram

NOTE: In the above figure relay 9 is connected to the load, similarly other relays can be connected

to load.

Timing Diagram

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

www.DataSheet.co.kr

Programming theTimer

Keep the PROG/RUN slide switch in the “PROG” position.

Apply rated voltage across A1 and A2.

By using the “SEQUENCE” button, select the required output, to program the timer.

By using the “ON / OFF” button, select the “ON “and “OFF” time for particular output.

By using the “RANGE “button, select the desired time range (sec/sec or min/sec or

hrs/min) as per requirement.

Set the required time by using “ADV” button.

After programming the timer, keep the ”RUN/PROG” slide switch in “RUN“ position and the

unit is ready for operation.

Initiating a Sequence

By shorting the S1 and S2 terminals on the front panel for a minimum period of 150

milliseconds, the timing is initiated.

The sequence starts with closure of “RLY0/OP1”as the case may be.

S1 and S2 can be kept permanently shorted to start the sequence when in HOLD mode.

In case of restart mode start signal is required every time a sequence has to be initiated.

Timer Cascading

Short C1 and C2 of all the timers to be cascaded.

Connect O1 and O2 of the first timer to S1 and S2 respectively of the second timer and so

on. (O1S1 – O2S2 and so on….)

Sequential Timer Quick Reference Guide

Datasheet pdf - http://www.DataSheet4U.net/

S-ar putea să vă placă și

- SQL TimerDocument8 paginiSQL TimerNikhilesh BabuÎncă nu există evaluări

- Automatic Transfer SwitchDocument2 paginiAutomatic Transfer Switchmuhamad cholishÎncă nu există evaluări

- Manual Soft Starter PSD370 5309699-1Document22 paginiManual Soft Starter PSD370 5309699-1Marcos AldrovandiÎncă nu există evaluări

- F M Din T M: UJI Iniature Imer AnualDocument2 paginiF M Din T M: UJI Iniature Imer AnualtharngalÎncă nu există evaluări

- SG6105A Power Supply Supervisor + Regulator + PWM: Features DescriptionDocument18 paginiSG6105A Power Supply Supervisor + Regulator + PWM: Features DescriptionTrâm QuỳnhÎncă nu există evaluări

- El Programador Subestándar - Modo Router en Modem SENDTEL MS8-8817 CANTVDocument17 paginiEl Programador Subestándar - Modo Router en Modem SENDTEL MS8-8817 CANTVMalfo10Încă nu există evaluări

- IGFR-4: Ground Fault Relay With Adjustable Time Delay Part Number: 1100-0104Document4 paginiIGFR-4: Ground Fault Relay With Adjustable Time Delay Part Number: 1100-0104Brandon Bryan Gomez RodriguezÎncă nu există evaluări

- Type SSM 1kV - Manual - Rev1Document60 paginiType SSM 1kV - Manual - Rev1Carlos AnibalÎncă nu există evaluări

- E+ E-0V 110 Volt Pot 1K: Installation and MaintenanceDocument12 paginiE+ E-0V 110 Volt Pot 1K: Installation and MaintenanceRonald Gomez tapiaÎncă nu există evaluări

- Can D500Document12 paginiCan D500Khaleel KhanÎncă nu există evaluări

- Switch On To The Best: Cam Operated Rotary SwitchesDocument32 paginiSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- Ffs 0674 Single Phase Controller Sci DatasheetDocument2 paginiFfs 0674 Single Phase Controller Sci DatasheetDavid ProsperoÎncă nu există evaluări

- Three-Phase Inverter Reference Design For 200-480 VAC Drives With Opto-Emulated Input Gate DriversDocument39 paginiThree-Phase Inverter Reference Design For 200-480 VAC Drives With Opto-Emulated Input Gate DriversM. T.Încă nu există evaluări

- Sf-Ac: Possible To Create The Highest Level Safety SystemDocument6 paginiSf-Ac: Possible To Create The Highest Level Safety SystemMelyssa Motta da SilvaÎncă nu există evaluări

- CMXC 007 Service Manual 003038-9Document9 paginiCMXC 007 Service Manual 003038-9Siding BarroÎncă nu există evaluări

- Three Phase ACCL CG Catalogue 1.1Document12 paginiThree Phase ACCL CG Catalogue 1.1Ravindra JadhavÎncă nu există evaluări

- L010939 - ProNet Series Users Manual - V2.02 PDFDocument182 paginiL010939 - ProNet Series Users Manual - V2.02 PDFJair PinhoÎncă nu există evaluări

- STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDDocument18 paginiSTR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDBertrand Soppo YokiÎncă nu există evaluări

- Alstom All-In-One Programmable Static Industrial Timer Relay Type RQT 0002 095 (TimEE 2)Document2 paginiAlstom All-In-One Programmable Static Industrial Timer Relay Type RQT 0002 095 (TimEE 2)AONLAÎncă nu există evaluări

- IGFR-5: Ground Fault Relay With Adjustable Time Delay Part Number: 1100-0105Document4 paginiIGFR-5: Ground Fault Relay With Adjustable Time Delay Part Number: 1100-0105Brandon Bryan Gomez RodriguezÎncă nu există evaluări

- Agilent Models 6690A-6692A System DC Power Supply: Data SheetDocument5 paginiAgilent Models 6690A-6692A System DC Power Supply: Data Sheetdhavala2858Încă nu există evaluări

- SamusngDocument57 paginiSamusngHelvRod RodríguezÎncă nu există evaluări

- Voltage Regulators: Página 1 de 10 C15 Standby Generator Set C5H00001-UP (SEBP4325 - 14) - Document StructureDocument10 paginiVoltage Regulators: Página 1 de 10 C15 Standby Generator Set C5H00001-UP (SEBP4325 - 14) - Document StructureErika DiazÎncă nu există evaluări

- Manual L510Document102 paginiManual L510JoseManuelNuñezÎncă nu există evaluări

- Kana - Bfc-10-Ch-Std-Ga-Ec-110 VacDocument6 paginiKana - Bfc-10-Ch-Std-Ga-Ec-110 VacJiyaul HaqueÎncă nu există evaluări

- BLDC 5015aDocument5 paginiBLDC 5015aroozbehxoxÎncă nu există evaluări

- Product Guide: Protection and ControlDocument16 paginiProduct Guide: Protection and Controljorge664Încă nu există evaluări

- Green-Mode PWM Controller With High Voltage Startup Circuit: Preliminary GR8875 SeriesDocument14 paginiGreen-Mode PWM Controller With High Voltage Startup Circuit: Preliminary GR8875 SeriesaliÎncă nu există evaluări

- ATS420 ATS Controller User Manual V1.0Document29 paginiATS420 ATS Controller User Manual V1.0Arturo HerreraÎncă nu există evaluări

- Omogoye .O.S, Ogundare .A.B, Ojo .F.Epage 1Document7 paginiOmogoye .O.S, Ogundare .A.B, Ojo .F.Epage 1kalu chimdiÎncă nu există evaluări

- FICHA TECNICA Smart-EvoDocument4 paginiFICHA TECNICA Smart-EvoClaudio A.Încă nu există evaluări

- Static Voltage Stabilizer PDFDocument17 paginiStatic Voltage Stabilizer PDFFlo Mirca100% (3)

- Taylor Contactor Open Transition Tech DataDocument17 paginiTaylor Contactor Open Transition Tech DataAdewunmi AdeoluwaÎncă nu există evaluări

- Dual Band Transceiver: S-15120XZ-C1 March 2015Document55 paginiDual Band Transceiver: S-15120XZ-C1 March 2015wahyunugieÎncă nu există evaluări

- Nitel LT Industrial AvrDocument2 paginiNitel LT Industrial AvrDhamodaran PandiyanÎncă nu există evaluări

- Hipotronics - 880pl 10ma A & BDocument21 paginiHipotronics - 880pl 10ma A & BGabrielÎncă nu există evaluări

- Op XC200NX-XC1200 Op185-V02Document3 paginiOp XC200NX-XC1200 Op185-V02Gab SotÎncă nu există evaluări

- ZLAC706-CAN Specification 1 - 3 Special For Hub Motor - 1 PDFDocument39 paginiZLAC706-CAN Specification 1 - 3 Special For Hub Motor - 1 PDFDÎncă nu există evaluări

- MAGNAVALVE Mod ACDocument25 paginiMAGNAVALVE Mod ACdahora13Încă nu există evaluări

- M40FA640A/A - Mark I: User ManualDocument17 paginiM40FA640A/A - Mark I: User Manualflorensius suparyantoÎncă nu există evaluări

- Arrancadores Suaves Media TensiónDocument118 paginiArrancadores Suaves Media Tensión15265562Încă nu există evaluări

- 3WA11 DatashDocument9 pagini3WA11 DatashsuadÎncă nu există evaluări

- Model: Avr - 102: Micro Controller Based Automatic Voltage Regulating RelayDocument2 paginiModel: Avr - 102: Micro Controller Based Automatic Voltage Regulating RelayMohar Singh/UPBG/PantnagarÎncă nu există evaluări

- Inst Ext GB Asm-01 UDocument2 paginiInst Ext GB Asm-01 UabdiÎncă nu există evaluări

- Adr111e 05Document17 paginiAdr111e 05Vishwanath TodurkarÎncă nu există evaluări

- Series NMV Leaflet English Ed06!04!680868Document2 paginiSeries NMV Leaflet English Ed06!04!680868mahesh reddy mÎncă nu există evaluări

- Acs800 Starter Hardware ManualDocument193 paginiAcs800 Starter Hardware Manualویرا محاسب پاسارگادÎncă nu există evaluări

- IRPT1061A DatasheetzDocument12 paginiIRPT1061A DatasheetzMarcelo FagundesÎncă nu există evaluări

- Zenith ZTG Transfer Switch: Spec SheetDocument15 paginiZenith ZTG Transfer Switch: Spec SheetDomenico SarcinaÎncă nu există evaluări

- Product Bulletin: GE Consumer & IndustrialDocument8 paginiProduct Bulletin: GE Consumer & IndustrialChristian VaÎncă nu există evaluări

- Datasheet PDFDocument15 paginiDatasheet PDFDhiran NishantÎncă nu există evaluări

- 205 UserDocument18 pagini205 UserAbukar Ali MahdiÎncă nu există evaluări

- R220 Manual Macfarlane GeneratorsDocument7 paginiR220 Manual Macfarlane Generatorsabuzer1981Încă nu există evaluări

- HLP-SK100 Series English Operating Manual V2015-01Document147 paginiHLP-SK100 Series English Operating Manual V2015-01Uhule PeterÎncă nu există evaluări

- EM Overcurrent Relay PDFDocument2 paginiEM Overcurrent Relay PDFRafin AqsaÎncă nu există evaluări

- Digital Power Electronics and ApplicationsDe la EverandDigital Power Electronics and ApplicationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- 8 Fuel AnswersDocument6 pagini8 Fuel AnswersSatyam ShuklaÎncă nu există evaluări

- Panasonic SCPM25 UputstvoDocument29 paginiPanasonic SCPM25 UputstvoВладимир СтајићÎncă nu există evaluări

- Altronics de 3000 IOI 9 08Document85 paginiAltronics de 3000 IOI 9 08Felix ZavalaÎncă nu există evaluări

- Smart Ato ManualDocument6 paginiSmart Ato ManualPerran TrevanÎncă nu există evaluări

- Öhlins Fork Manual and RepairDocument16 paginiÖhlins Fork Manual and Repairstefan1968Încă nu există evaluări

- Air Dryer - FushengDocument44 paginiAir Dryer - Fushengrema irma100% (1)

- Catalogue Industrie UkDocument100 paginiCatalogue Industrie UkAgustin SanchezÎncă nu există evaluări

- 7W Amplifier Circuit TDA2003Document7 pagini7W Amplifier Circuit TDA2003Mar EscÎncă nu există evaluări

- Fan From DeltaDocument38 paginiFan From DeltaJeff SunÎncă nu există evaluări

- Bomba KWP BlocDocument28 paginiBomba KWP BlocKevin OchoaÎncă nu există evaluări

- Hino 700 Exhaust Brake-Engine Retarder WireingDocument2 paginiHino 700 Exhaust Brake-Engine Retarder Wireingg.shien5150100% (1)

- cMT-G03 Datasheet ENG PDFDocument2 paginicMT-G03 Datasheet ENG PDFAshutosh Vivek ParabÎncă nu există evaluări

- X320 Select Series Tractor IntroductionDocument7 paginiX320 Select Series Tractor IntroductionYeison NavasÎncă nu există evaluări

- 2018,2017,2016,15,14 Cheverolet Z06, Stingray, Grand Touring Engine PartsDocument18 pagini2018,2017,2016,15,14 Cheverolet Z06, Stingray, Grand Touring Engine PartsMike FinazziÎncă nu există evaluări

- 3 Amigos - SVS-Fault - Test & Mod - SierraferyDocument11 pagini3 Amigos - SVS-Fault - Test & Mod - Sierraferydeadlydecor tattoosÎncă nu există evaluări

- MecanicaDocument18 paginiMecanicawilson claveriaÎncă nu există evaluări

- Lecture - 6 - DC To DC (Choppers) - W2017 PDFDocument47 paginiLecture - 6 - DC To DC (Choppers) - W2017 PDFAhmad AliÎncă nu există evaluări

- Krve 80 PP - 20220725Document5 paginiKrve 80 PP - 20220725Baris YeltekinÎncă nu există evaluări

- Preventative Maintenance Guide For Mt3300 Mt3400 TwtaDocument12 paginiPreventative Maintenance Guide For Mt3300 Mt3400 Twtamohkal1168Încă nu există evaluări

- Smart Anchor PricelistDocument25 paginiSmart Anchor PricelistAjay MedikondaÎncă nu există evaluări

- Vol02 Tab01Document128 paginiVol02 Tab01jonathanÎncă nu există evaluări

- Gemini-BPM500 PreampDocument12 paginiGemini-BPM500 PreampAristoteles CarreñoÎncă nu există evaluări

- Network Termination Unit STU2: Always Up-To-DateDocument2 paginiNetwork Termination Unit STU2: Always Up-To-DateНатальяÎncă nu există evaluări

- Smart String Inverter: Efficient Safe Reliable SmartDocument2 paginiSmart String Inverter: Efficient Safe Reliable SmartRamon OrellanaÎncă nu există evaluări

- Wood - Magazine - 267 - May 2020Document88 paginiWood - Magazine - 267 - May 2020Adam Niddrie100% (1)

- PDF Operator39s Manual Moba Matic 1 Can and Moba Mini Matic DLDocument73 paginiPDF Operator39s Manual Moba Matic 1 Can and Moba Mini Matic DLVitalii KrasnokutskiyÎncă nu există evaluări

- VG Cables For Marine Engineering 02Document24 paginiVG Cables For Marine Engineering 02SyazieliKamaruzamanÎncă nu există evaluări

- Bugera Bvv3000 Infinium: Service ManualDocument31 paginiBugera Bvv3000 Infinium: Service Manualne0bot100% (3)

- Baker - 690981 PDFDocument24 paginiBaker - 690981 PDFAsep SuhermanÎncă nu există evaluări

- Microondas Manual Americano en EspañolDocument52 paginiMicroondas Manual Americano en EspañolAlan SotoÎncă nu există evaluări