Documente Academic

Documente Profesional

Documente Cultură

Z

Încărcat de

Sasa MitrovicTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Z

Încărcat de

Sasa MitrovicDrepturi de autor:

Formate disponibile

Measuring Technology Interface

Box MIB

Operating Manual – Version 1.1

BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Contents

Contents

General Safety Instructions........................................... i-1

IMPORTANT SAFETY PRECAUTIONS ............................ i-2

1 General Information....................................... 1-1

1.1 Reason...................................................................1-1

1.2 Safety instructions .................................................1-1

2 Technical properties ...................................... 2-3

2.1 Mechanical properties ...........................................2-3

2.2 Electrical Properties...............................................2-3

3 Technical Data/Environment ......................... 3-5

3.1 Climatic data ..........................................................3-5

3.2 Mechanical data.....................................................3-5

3.3 Electrical protection and safety..............................3-6

3.4 Delivery scope .......................................................3-7

3.4.1 Adapters/cables/connections on front of MIB .......3-7

3.4.2 Adapters/cables/connections on back of MIB .......3-9

4 Installing System ......................................... 4-11

4.1 Overview of components/accessories .................4-11

4.2 Installation of MIB in conjunction with workshop

cart GT1 ...............................................................4-12

4.3 Connection interface on front ..............................4-14

4.3.1 Meaning of LEDs..................................................4-15

4.3.2 Multifunction cable 1 (MFK1) ...............................4-15

4.3.3 Multifunction cable 2 (MFK2) ...............................4-16

4.3.4 Current clip, 50 A/1000 A ....................................4-17

4.3.5 Pressure sensors .................................................4-18

4.3.6 KV adapter ...........................................................4-19

4.3.7 RZV adapter .........................................................4-20

4.4 Connection interface on back ..............................4-21

4.4.1 Table-top power supply unit ................................4-22

4.4.2 Connecting cable from MIB to GT1 .....................4-23

4.4.3 Temperature sensor .............................................4-24

4.4.4 Trigger clip ...........................................................4-25

4.4.5 Stimulus cable 1 ..................................................4-26

4.4.6 Stimulus cable 2 ..................................................4-27

4.4.7 TD cable...............................................................4-28

BMW Group, Measuring Technology Interface Box I-1

Version 1.1, December 2003

Contents

5 Operating MIB on GT1 ................................. 5-29

5.1 Use on vehicle .....................................................5-29

5.2 Preset measurement series .................................5-30

5.2.1 Signal tests ..........................................................5-30

5.2.2 Signal measurements...........................................5-30

5.2.3 Additional measurements ....................................5-30

6 Care and Maintenance of MIB ..................... 6-31

6.1 Visual inspection ..................................................6-31

6.2 General care instructions .....................................6-31

6.3 Cleaning MIB housing..........................................6-32

6.4 Precautionary measures for using cables ............6-32

7 Troubleshooting........................................... 7-33

7.1 Fault reports to Customer Service .......................7-34

7.2 Replacing MIB or components.............................7-34

8 Service Addresses ....................................... 8-35

9 Abbreviations............................................... 9-37

9.1 Definitions ............................................................9-37

9.2 Abbreviations .......................................................9-37

I-2 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

General Safety Instructions

General Safety Instructions

Danger

! means that death, severe personal injury and/or considerable damage

to property will occur if the appropriate precautionary measures are not

taken.

Warning!

! means that death, severe personal injury and/or considerable damage

to property can occur if the appropriate precautionary measures are not

taken.

Caution

! with warning triangle means that slight personal injury and/or damage

to property can occur if the appropriate precautionary measures are not

taken.

Caution

without hazard warning triangle means that damage to property can

occur if the appropriate precautionary measures are not taken.

Important!

means that an undesirable event or state can occur if the relevant

instruction is not observed.

Note

is an important item of information regarding the product itself, its

handling, or that part of the "Operating Manual" to which your attention

is to be drawn in particular.

BMW Group, Measuring Technology Interface Box i-1

Version 1.1, December 2003

IMPORTANT SAFETY PRECAUTIONS

IMPORTANT SAFETY PRECAUTIONS

Important! Read all of the safety precautions:

Warning!

! If the mains cable or the power supply unit is defective or the MIB is

damaged, the MIB may not be used until a qualified expert has

conducted a check.

Warning!

! Mains power cables and measuring cables must not be routed over

tables, benches and cabinets, and they must not become obstacles.

They must not be placed in the vicinity of hot objects or rotating parts.

Warning!

! The mains power cable provided must not be extended. Where

possible, use only the mains power cable supplied.

Warning!

! If you do not use the MIB for a longer time, disconnect it from the power

supply. When you pull the power supply plug, do not pull on the cable,

but instead grasp the power supply plug itself and pull it out of the

power socket.

Warning!

! You may not operate the MIB in the vicinity of open fuel tanks or near

floor level, or in pits or similar, as otherwise there is a danger of

explosion or fire due to gases and/or vapors.

Warning!

! The electrical installation must comply with the requirements specified

in this manual and may only be carried out by qualified personnel.

i-2 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

IMPORTANT SAFETY PRECAUTIONS

Warning!

! Only use the MIB in the manner specified in this manual. Use only the

recommended and approved devices and components with the MIB.

Warning!

! If you open the unit without authorization or perform improper repairs

on it, you may be exposed to considerable danger.

Important!

Fluctuations and deviations in the power supply voltage outside the

permissible tolerance can lead to operating failures.

KEEP THESE

SAFETY PRECAUTIONS

IN A SAFE PLACE!

BMW Group, Measuring Technology Interface Box i-3

Version 1.1, December 2003

IMPORTANT SAFETY PRECAUTIONS

i-4 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

General Information

1 General Information

This documentation contains all information required for operation,

maintenance, care and service for the proper use of the Measuring

Technology Interface Box, referred to in the document at the "MIB".

Knowledge of and technically flawless implementation of the safety in-

structions and warnings contained in this documentation are a prereq-

uisite for safe commissioning and for safety during operation and

maintenance of the MIB.

1.1 Reason

The current power stage of the measuring technology of the Group

Tester One (GT1 basic measuring technology) mainly contains the

functionality of the MoDiCIII, i.e. the multifunction cable 1 and 2, as well

as the current clip, 50 A can be connected to the control unit.

To guarantee the measuring technology scope of the DISplus including

the measuring cables, the MIB is offered. All required measuring and

stimulus cables can be mounted on the MIB.

With these measures and the use of the MIB, the GT1 vehicle diagnosis

system is brought up to measuring technology level identical to that of

the DISPlus.

1.2 Safety instructions

Observe the safety instructions for the MIB. The general safety instruc-

tions are provided following the Table of Contents.

Use in Accordance With Intended Purpose

• The described product has been developed, manufactured, tested

and documented taking account of the relevant safety standards.

• The MIB is used in conjunction with the GT1 for conducting mea-

suring-related actions on the vehicle.

BMW Group, Measuring Technology Interface Box 1-1

Version 1.1, December 2003

General Information

1-2 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Technical properties

2 Technical properties

The MIB GT1 can be used worldwide. It complies with the VDE guide-

lines and all worldwide, country-specific standards and regulatory

works required for use in an automotive workshop.

2.1 Mechanical properties

• Suitable for use in workshops

• Weight of MIB: approx. 1.5 kg

• Housing material: Aluminum, polyamide 15 % glass-bead

reinforced (PA 6 15% GB)

• Housing dimensions: 293 mm x 295 mm x 52 mm

• The materials used are suitable for use the workshop. They have a

limited resistance to gasoline and oil. Brief contact with these

media (splashes or dirty fingers) will not cause the materials to be

attacked. The cable material used for the measuring cables is oil-

resistant.

2.2 Electrical Properties

• Operating voltage 24 V DC via external table-top power supply unit.

• The power supply unit (external) is designed as a table-top unit and

supplies the MIB from the 230 (110) V power system.

- Input range: 100 - 240 V AC

- Output : 24 V DC

BMW Group, Measuring Technology Interface Box 2-3

Version 1.1, December 2003

Technical properties

2-4 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Technical Data/Environment

3 Technical Data/Environment

3.1 Climatic data

Temperature, humidity (testing as per DIN EN 60068-2-1 cold,

2-2 dry heat, 2-3 humidity)

• Operation

- Ambient temperature range: +3°C to +43°C

- Relative humidity at a maximum of +25 °C: 10 to 80 %,

no condensation

• Transport and storage

(MIB and cables packed read for shipping)

- Ambient temperature range: –20 °C to + 60 °C

- Relative humidity at a maximum of +30 °C: 10 to 90 %,

no condensation

Air pressure (testing as per DIN IEC 60068-2-13)

• Operation

- Air pressure/altitude above sea level: up to 70 kPa/3000 m

• Transport and storage (GT1 packed ready for shipping)

- Air pressure/altitude above sea level: up to 54 kPa/5000 m

Degree of soiling 2

overvoltage category I

use in interiors

3.2 Mechanical data

Oscillating load

• Operation (testing as per DIN IEC 680068-2-6 on all 3 axes,

20 cycles each, 1 octave/min)

- 10 to 58 Hz: 0.035 mm

- 58 to 500 Hz: 0.25 g

• Transport (MIB and cables packed ready for shipping, testing

as per DIN IEC 680068-2-6 on all 3 axes, 20 cycles each,

1 octave/min)

- 5 to 8.51 Hz: 2 mm

- 8.51 to 500 Hz: 1

BMW Group, Measuring Technology Interface Box 3-5

Version 1.1, December 2003

Technical Data/Environment

Shock loading

• Operation (testing as per DIN EN 60068-2-27 on all 3 axes,

10 shocks each)

- 50 m/s 2 (5 g), 11 ms half-sine

• Transport (MIB and cables packed ready for shipping, testing as

per DIN EN 60068-2-27 on all 3 axes, 10 shocks each

3.3 Electrical protection and safety

• Safety legislation

- Workshop devices: UL 201

- Measuring equipment: DIN EN 61010-1 (VDE 0411 Part 1),

EN 61010-1, IEC 1010, UL 1950, CSA-C22.2 No. 950

• Resistance to fire

- In accordance with the above safety legislation

• Foreign bodies and water protection

(as per DIN VDE 0470 Part 1) (EN 60529, IEC 529)

- MIB: Housing protection type: IP 40

3-6 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Technical Data/Environment

3.4 Delivery scope

• Measuring Technology Interface Box (MIB)

• Cables/sensors

- (F) Current clip, 1000 A

- (F) Pressure sensor 25 bar

- (F) KV clip

- (F) RZV cable

- (R) Temperature sensor

- (R) Trigger clip

- (R) Stimulus cable 1

- (R) Stimulus cable 2

- (R) TD cable

- (R) Connecting cable from MIB to GT1

• Power supply unit, external

(F) = Connection on front, (R) Connection on back

3.4.1 Adapters/cables/connections on front of MIB

Connections for ODU plugs of various sizes and LED displays for the

operating status are provided on the front of the MIB.

Fig. 3-1 MIB connections on front

BMW Group, Measuring Technology Interface Box 3-7

Version 1.1, December 2003

Technical Data/Environment

Fig. 3-2 Adapters/cables for connection on front

Note

In addition to the adapters/cables shown, connections are also provided for

the multifunction cables MFK1/MFK2.

3-8 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Technical Data/Environment

3.4.2 Adapters/cables/connections on back of MIB

In addition to the power supply-unit connection, plugs for cables with

female connectors and sockets for cables with male connectors are

installed on the back of the MIB.

Fig. 3-3 Cables/adapters for connection on back

Fig. 3-4 Cables/adapters for back

Note

No country-specific connection cables for non-heating apparatuses are includ-

ed in the delivery scope for connection to the power supply unit.

Please obtain a country-specific cable for the connection of the power supply

unit to the power socket. The power supply unit is designed for the conversion

of AC voltage between 100 and 240 V.

BMW Group, Measuring Technology Interface Box 3-9

Version 1.1, December 2003

Technical Data/Environment

3-10 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4 Installing System

4.1 Overview of components/accessories

The MIB is shipped in a carton that contains the MIB itself and the de-

fined connection cables for the measuring technology. A storage case

for the MIB and the cables is not included in the delivery scope.

• MIB

• External power supply unit without connection cable for country-

specific model

• Cables/sensors

- Current clip, 1000 A

- Pressure sensor, 25 bar

- Connecting cable from MIB to GT1

- KV clip

- RZV cable

- Temperature sensor

- Trigger clip

- Stimulus cable 1 and 2

- TD cable

Note

The MFK1, MFK2 and the current clip, 50 A (see below) intended for connec-

tion and operation are not accessories in the delivery scope of the MIB. The

MFK1 and MFK2 are shipped with the GT1, while the current clip, 50 A was

supplied with the DISPlus or is available separately.

BMW Group, Measuring Technology Interface Box 4-11

Version 1.1, December 2003

Installing System

4.2 Installation of MIB in conjunction with workshop

cart GT1

To ensure a high level of mobility of the GT1 and MIB, which can

therefore assume measuring-related measure identical to those of the

DISPlus, a workshop cart was designed.

The concept provides for a fixed location of the GT1 incl. the docking

station and a place for the MIB, the connection cables, a diagnostic

head and an OPPS/OPS.

Two drawers are available for storing various accessories.

Fig. 4-1 Mounting MIB in workshop cart

The compartment below the fold-up surface for the GT1 is used to hold

the MIB. Recesses for the feet of the MIB housing are provided in the

shelf. This already prevents the MIB from sliding. In addition, a retaining

strap is installed via two slots with which the MIB can be secured on the

shelf (Velcro (tm) strip). This secures the MIB on the workshop cart.

In this case, the connection cables for the various measuring

technology measures are connected to the MIB once and hooked into

the cable rack.

Note:

Separate operating instructions "Workshop Cart for the GT1" on the setting

up the workshop cart are provided on the documentation CD.

4-12 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

Fig. 4-2 Front view of GT1 workshop cart

Fig. 4-3 Rear view of workshop cart with cable rack

BMW Group, Measuring Technology Interface Box 4-13

Version 1.1, December 2003

Installing System

4.3 Connection interface on front

Connections are provided on the front on which cables are mounted

that the user may disconnect and interchange during operation.

MFK 1 ODU plug, size 3

MFK 2 ODU plug, size 3

Current clip, 50 A ODU plug, size 2 green

Current clip, 1000 A ODU plug, size 2 green

Pressure sensor, 25 bar ODU plug, size 1 black

KV ODU plug, size 1 red

Ignition distribution clip ODU plug, size 1 red

Fig. 4-4 Connection interface on front

Note

When the MIB is installed in the workshop cart, the defined front of the MIB is

located on the right-hand side seen from the front of the workshop cart.

4-14 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.3.1 Meaning of LEDs

• Power: Power supply unit connected

• Ready: MIB operational

• Ubat: Supply with battery voltage via TD cable OK

Fig. 4-4-1 LED display

4.3.2 Multifunction cable 1 (MFK1)

The MFK 1 is connected to the socket on the front of the MIB marked

with "MFK1". It belongs to the adapters which the user may separate

and connect during operation.

• MFK 1 (ODU plug, size 3), length 3 m

Fig. 4-5 MFK1 (connection on front)

Note

The MFK1 is not included in the delivery scope of the MIB. Please use the

MFK1 included with the GT1.

Only connect the MFK1 to the socket marked with MFK1.

BMW Group, Measuring Technology Interface Box 4-15

Version 1.1, December 2003

Installing System

4.3.3 Multifunction cable 2 (MFK2)

The MFK2 is connected to the socket on the front of the MIB marked

with "MFK2". It belongs to the adapters which the user may separate

and connect during operation.

• MFK 2 (ODU plug, size 3), length 3 m

Fig. 4-6 MFK2 (connection on front)

Note

The MFK2 is not included in the delivery scope of the MIB. Please use the

MFK2 included with the GT1.

Only connect the MFK2 to the socket marked with MFK2.

4-16 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.3.4 Current clip, 50 A/1000 A

The current clips are connected to the sockets on the front of the MIB

marked with SZ 50 or SZ 1000. They belong to the adapters which the

user may separate and connect during operation.

• Current clip, 50 A (ODU plug, size 2, green)

• Current clip, 1000 A (ODU plug, size 2, green)

Fig. 4-7-1 Current clip, 50 A (connection on front)

Note

The current clip, 50 A is not included in the delivery scope of the MIB. Please

use the current clip included with the DISPlus.

This current clip can also be ordered separately.

No photo was available for the current clip, 1000 A at the time of going to press!

Only connect the current clips to the assigned sockets in accordance with the

marking.

BMW Group, Measuring Technology Interface Box 4-17

Version 1.1, December 2003

Installing System

4.3.5 Pressure sensors

A 25 bar pressure sensor is included in the delivery scope of the MIB.

The sensor is connected on the front of the MIB to the sockets marked

with "DR1" or "DR2". The GT1 measuring application determines

which connection is to be used for the pressure sensor. It belongs to

the adapters which the user may separate/interchange and connect

during operation.

Length of pressure sensor = 4 m.

Pressure sensor 25 bar ODU plug, size 1 black

Fig. 4-8 Example of a pressure sensor, 25 bar (connection on front)

Note

Only connect the pressure sensor to the assigned sockets in accordance with

the marking. The ODU plugs are color-coded in black and have a coding, i.e.

they cannot be connected to the ODU socket size 1 (red).

Note

To use the pressure sensor for compression measurement you require optional

test probes (not shown).

The test probes are available in two designs:

Part No. BMW 110235 (supplier Cartool) for M engines

Part No. BMW 110226 (supplier Cartool) all other engines.

The test probes are not included in the delivery scope of the MIB.

Especially in case of changes in the part order numbers and the suppliers,

please observe the information on the BMW information pages on the intranet

(= SERVOLUTION.MUC) or extranet.

4-18 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.3.6 KV adapter

The KV adapter is connected to the socket on the front of the MIB

marked with "KV/RZV". It belongs to the adapters which the user may

separate and connect during operation.

The KV adapter is used for high-voltage measurement (ignition cable,

ignition distributor system).

• KV (ODU plug, size 1, red), length 3.5 m

Fig. 4-9-1 KV (connection on front)

Note

Only connect the KV adapter to the assigned sockets in accordance with the

marking. The ODU plugs are color-coded in red and have a coding, i.e. they

cannot be connected to the black ODU socket size 1.

BMW Group, Measuring Technology Interface Box 4-19

Version 1.1, December 2003

Installing System

4.3.7 RZV adapter

The RZV adapter is connected to the socket on the front of the MIB

marked with "KV/RZV". It belongs to the adapters which the user can

separate and connect during operation.

• RZV (ODU plug, size 1, red), length 3.5 m

Fig. 4-9-2 RZV (connection on front)

Note

Only connect the RZV adapter to the assigned sockets in accordance with the

marking. The ODU plugs are color-coded in red and have a connection lock, i.e.

they cannot be connected to the black ODU socket size 1.

4-20 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.4 Connection interface on back

Connections are provided on the back of the MIB to which cables are

connected that are permanently connected to the MIB and may not be

disconnected during operation.

DC IN 24V Connection for table-top power

supply unit

TEST Only for service purposes of

MIB!

The user may not connect

anything to this connection!

MIB-GT1 Connection between MIB and

GT1

TEMP Temperature sensor

TRZ Trigger clip

STIM1 Stimulus cable 1

STIM2 Stimulus cable 2

TD TD cable

Fig. 4-10 Connection interface on back

Note

When the MIB is installed in the workshop cart, the defined back of the MIB is

located on the left-hand side seen from the front of the workshop cart.

BMW Group, Measuring Technology Interface Box 4-21

Version 1.1, December 2003

Installing System

4.4.1 Table-top power supply unit

A table-top power supply unit is provided for connecting the MIB to the

power supply. The related connection is located on the back of the MIB

(DC IN 24 V), on the left-hand side seen from the workshop cart. Con-

nection to the power supply is made with a standard mains power cable

which, however, is not included in the delivery scope.

Fig. 4-11 Table-top power supply unit (connection on back)

Note

Please obtain a country-specific mains power cable which complies with your

country's regulations for operating the MIB on your power system. The power

supply unit itself is designed for a connection range of 100 - 240 V AC.

The table-top power supply unit cannot be disconnected during opera-

tion!

4-22 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.4.2 Connecting cable from MIB to GT1

A 5 m long cable (with an ODU plug, size 3, on the GT1 side) is included

for connecting the MIB to the GT1. Connect the other end of this cable

to the connection socket (marked MIB – GT1) on the back of the MIB.

The other end with the black ODU plug is connected to the control unit

of the GT1 (upper left).

Length of the MIB-GT1 connecting cable = 5 m.

Fig. 4-12 Cable for connecting MIB to GT1 (connection on back)

Note

Seen from the workshop cart, the MIB-GT1 connection is located on the left-

hand side. Secure the plug by screwing in the threaded screws.

The MIB-GT1 cable cannot be disconnected during operation!

BMW Group, Measuring Technology Interface Box 4-23

Version 1.1, December 2003

Installing System

4.4.3 Temperature sensor

A temperature sensor is included for measuring temperatures

analogous to the DISPlus. Connection to the MIB is made with a

connection plug on the back of the MIB marked "Temp"; the

connection on the cable of the temperature sensor is designed as a

socket.

Length of temperature sensor = 3 m.

Fig. 4-13 Temperature sensor (connection on back)

Note

Seen from the workshop cart, the connection is located on the left-hand side.

Secure the connection by screwing in the threaded screws.

The sensor cable cannot be disconnected during operation!

4-24 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.4.4 Trigger clip

The firing point is determined with the trigger clip via an inductive con-

nection on the ignition cable. Connection to the MIB is made with a

connection plug on the back of the MIB marked "TRZ"; the connection

on the cable of of trigger clip is designed as a socket.

Length of trigger clip = 4 m.

Fig. 4-14 Trigger clip (connection on back)

Note

Seen from the workshop cart, the connection is located on the left-hand side.

Secure the connection by screwing in the threaded screws.

The trigger clip cable cannot be disconnected during operation!

BMW Group, Measuring Technology Interface Box 4-25

Version 1.1, December 2003

Installing System

4.4.5 Stimulus cable 1

Connection to the MIB is made with a connection socket on the back of

the MIB marked "STIM1"; the connection on the cable of the temper-

ature sensor is designed as a socket.

Length of stimulus cable 1 = 3 m.

Possible uses:

• DC stimuli

• Sine-wave generator

• Pulse generator

• R simulator

Fig. 4-15 Stimulus cable 1 (connection on back)

Note

Seen from the workshop cart, the connection is located on the left-hand side.

Secure the connection by screwing in the threaded screws.

The stimulus cable 1 cannot be disconnected during operation!

4-26 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Installing System

4.4.6 Stimulus cable 2

Connection to the MIB is made with a connection socket on the back of

the MIB marked "STIM2"; the connection on the cable of the temper-

ature sensor is designed as a socket.

Length of stimulus cable 2 = 3 m.

Fig. 4-16 Stimulus cable 2 (connection on back)

Note

Seen from the workshop cart, the connection is located on the left-hand side.

Secure the connection by screwing in the threaded screws.

The stimulus cable 2 cannot be disconnected during operation!

BMW Group, Measuring Technology Interface Box 4-27

Version 1.1, December 2003

Installing System

4.4.7 TD cable

Connection to the MIB is made with a connection socket on the back of

the MIB marked "TD"; the connection on the cable of the temperature

sensor is designed as a socket.

A connection is made between the MIB and the diagnostic head with

the TD cable (brown ODU plug, size 1 with corresponding connection

socket on the diagnostic head).

Length of TD cable = 8 m.

Use:

The engine speed signal (TD) is fed into the MIB via the diagnostic head

and the TD cable. With the TD cable the signals Ter. 1 and TD can be

measured via the diagnostic head. In addition, the pulse generator

(stimuli) is supplied with battery voltage (TER. 30, TER. 31) via the TD

cable.

Fig. 4-17 TD cable (connection on back)

Note

Seen from the workshop cart, the connection is located on the left-hand side.

Secure the connection by screwing in the threaded screws.

The TD cable is equipped with a brown ODU plug, size 1 and secured against

incorrect connection (e.g. to the ).

The TD cable cannot be disconnected during operation!

4-28 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Operating MIB on GT1

5 Operating MIB on GT1

5.1 Use on vehicle

The following photo shows the use of the MIB connected to the GT1

and used with a workshop cart.

Fig. 5-1 MIB in use on vehicle

Note

When using the workshop cart, make sure that sufficient space is maintained

between the individual vehicles!

Always set the brake of the workshop cart before beginning work.

Make sure the cables used do not cause people to trip.

BMW Group, Measuring Technology Interface Box 5-29

Version 1.1, December 2003

Operating MIB on GT1

5.2 Preset measurement series

In the following the measurements are listed that can be preset with the

software and carried out with the GT1 and the MIB.

These measurements are conducted analogously to the procedure for

measurements with the DISPlus diagnosis system.

Note

The measurements conducted with the GT1 and the MIB are supported by the

DIS application from program CD version 36.

5.2.1 Signal tests

• Wire test

• Potentiometer test

5.2.2 Signal measurements

• Status of diagnosis socket

• Status of OBD socket

• Engine-speed sensor signal

• Engine speed signal (TD)

• ti injection signal

• Primary ignition signal (Ter. 1 signal)

• Secondary ignition signal

• Diesel NBF signal

• Diesel engine-speed sensor signal (6 pin)

• Terminal 4a signal

• Lambda signal

• Idle actuator signals

• Throttle potentiometer signal

• Camshaft sensor signal

5.2.3 Additional measurements

• Alternator test

• Absolute compression

• Relative compression

• Pressure distribution

• Smooth running

• Xenon headlight test up to 8/1998

• Xenon headlight test from 9/1998

5-30 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Care and Maintenance of MIB

6 Care and Maintenance of MIB

6.1 Visual inspection

So that the MIB can be used to optimum effect, it is required that you

keep it in perfect condition.

Perform regular visual inspections of the MIB. Check all components

for damage (e.g. breaks) and soiling.

Regularly check all cables for damage.

Check the pins of the ODU plug or the multi-pin connection plug for

bending.

Warning!

! Damaged connection cables must be replaced in all cases.

6.2 General care instructions

Observe the following instructions for care of the MIB:

• Make sure that your MIB is securely set up, i.e. either in the direct

vicinity of the GT1 docking station location or preferably as a

diagnosis unit together with the GT1 on the workshop cart

designed for this purpose.

• Protect the MIB from moisture, exposure to direct sunlight and

extreme temperatures.

• Further information on the recommended operating temperature

and relative humidity range for the MIB is contained in Chapter 3 of

this manual.

• Protect the MIB from the penetration of liquids.

• Disconnect the MIB from the external power supply unit before you

conduct the maintenance work listed below.

BMW Group, Measuring Technology Interface Box 6-31

Version 1.1, December 2003

Care and Maintenance of MIB

6.3 Cleaning MIB housing

Wipe the housing of the MIB with a soft cloth slightly moistened with

water. If you use cleaning agents, the coating may be discolored or

damaged.

6.4 Precautionary measures for using cables

Above all make sure that the cables do not become kinked.

Carefully connect cables to the MIB and secure than with the threaded

screws on the plug if necessary.

Only connect adapters/cables to the properly marked connection

sockets on the MIB.

Make sure the cables do not cause people to trip.

If you use the workshop cart, hang the cables/adapters in the intended

positions on the cable rack again after use.

6-32 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Troubleshooting

7 Troubleshooting

The Measuring Technology Interface Box is a product of SIEMENS. It

was inspected before it left the factory. Carefully selected components

and maintenance of numerous quality controls guarantee high

resistance of the MIB. Should a fault occur in spite of this, please

consult the instructions in this chapter before contacting the Customer

Service responsible.

Faults that can occur on the MIB can be divided into the following

groups:

• Faults caused by environmental influences: ambient temperature,

(aggressive) moisture, dust, soot, grease, flying sparks, mains

supply, transformers, large electric motors, radio-control systems,

vibration.

• Faults in the cable connections to the GT1/vehicle.

• Faults in the power supply via the power supply unit.

• Faults on the GT1 that can affect the operation of the MIB.

Please attempt to determine the fault and localize it as precisely as

possible.

Note

Via the telephone or fax numbers familiar for inquiries on the DISPlus and GT1,

SIEMENS also assumes hotline responsibilities for the MIB and carries out the

agreed upon full range of service.

BMW Group, Measuring Technology Interface Box 7-33

Version 1.1, December 2003

Troubleshooting

7.1 Fault reports to Customer Service

If the fault cannot be remedied, please contact SIEMENS Service

(see Chapter 8).

Note

You can best send your fault report to SIEMENS Service with a FAX report. The

two-page fault report (see the documentation of the workshop systems under

"GT1/Form") must be filled out completely and faxed to the support center

responsible for your country (see Chapter 8).

Describe the fault pattern as precisely as possible (report etc.), when and after

which action the fault occurred, what you have done to pinpoint the fault, and

what the result of this was.

7.2 Replacing MIB or components

During the warranty period or the three-year term of your Service

Agreement, the MIB will be repaired by replacing the entire unit if a fault

occurs. If a fault occurs in the related cables/sensors, they will be

replaced free of charge within the one-year warranty period.

7-34 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Service Addresses

8 Service Addresses

The list of addresses with the service centers for the specific countries

and the Hotline telephone and fax numbers is continually updated.

If no center is specified as responsible for your country, please contact

the SIEMENS office in Germany.

The service addresses are located in a central document "SERVICE

ADDRESSES" applicable for all workshop systems on the documenta-

tion CD.

Note

Please only report a hardware or software fault to one of the responsi-

ble SIEMENS Hotlines in accordance with the specifications in the doc-

ument "SERVICE ADDRESSES".

BMW Group, Measuring Technology Interface Box 8-35

Version 1.1, December 2003

Service Addresses

8-36 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

Abbreviations

9 Abbreviations

9.1 Definitions

Term Explanation

Access Point A device integrated in a workshop network with which

communication between the network subscribers is

possible via radio waves and access to the workshop

network is enables.

Diagnostic head Device via which the connection between a vehicle

and a tester or an SSS can be established.

Table 9-1 Terms and Explanations

9.2 Abbreviations

Abbreviation Explanation

AP Access Point

CU GT1 control unit

CIP Coding Individualizing Programming

DISPlus BMW tester with TFT touchscreen

DH Diagnostic head

DMM Digital Multimeter

DSO Digital Memory Oscilloscope

LAN Local Area Network

MIB Measuring Technology Interface Box

MUX Multiplexer

MW Measured value

OPPS Optical Testing and Programming System

OPS Optical Programming System

Ri Internal resistance

SSS Software Service Station (also Triple-S)

Table 9-2 Abbreviations

BMW Group, Measuring Technology Interface Box 9-37

Version 1.1, December 2003

Abbreviations

9-38 BMW Group, Measuring Technology Interface Box

Version 1.1, December 2003

We have checked to ensure that the content of the printed matter Transfer or duplication of this document, as well as use or

matches the hardware and software described. Nonetheless, communication of its content are not permitted unless express

deviations cannot be excluded and we are unable to provide a consent is granted. Violations give rise to claims for damages.

guarantee that the match is complete. However, the information All rights reserved, in particular pending patent rights.

provided in this printed matter is checked regularly, and necessary

corrections are included in subsequent issues. We are grateful for

all suggested improvements.

Copyright © BMW AG 2003 All Rights Reserved

The right to make changes of a technical nature is reserved.

BMW Aktiengesellschaft US-EN / Printed in Germany

S-ar putea să vă placă și

- ltr-5 Scheda enDocument1 paginăltr-5 Scheda enDimitris ThanasopoulosÎncă nu există evaluări

- Inbound 8511313797200267098Document10 paginiInbound 8511313797200267098phan42Încă nu există evaluări

- Service Manual: RefrigeratorDocument50 paginiService Manual: RefrigeratorMarcos E Sanchez DÎncă nu există evaluări

- NGSL+1 01+by+bandDocument181 paginiNGSL+1 01+by+bandSasa MitrovicÎncă nu există evaluări

- ErrnoDocument3 paginiErrnoSasa MitrovicÎncă nu există evaluări

- ErrnoDocument3 paginiErrnoSasa MitrovicÎncă nu există evaluări

- Tempfet BTS 132: FeaturesDocument11 paginiTempfet BTS 132: FeaturesSasa MitrovicÎncă nu există evaluări

- Can (M) G VW t5 03Document2 paginiCan (M) G VW t5 03Sasa MitrovicÎncă nu există evaluări

- HRDocument5 paginiHRSasa MitrovicÎncă nu există evaluări

- T5 Pin Connector Assignments Selected Connections PDFDocument10 paginiT5 Pin Connector Assignments Selected Connections PDFSasa MitrovicÎncă nu există evaluări

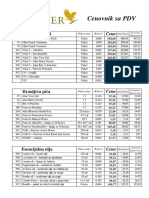

- Cenovnik Sa PDV: Forever PaketiDocument4 paginiCenovnik Sa PDV: Forever PaketiSasa MitrovicÎncă nu există evaluări

- T5 Pin Connector Assignments Selected Connections PDFDocument10 paginiT5 Pin Connector Assignments Selected Connections PDFSasa MitrovicÎncă nu există evaluări

- TH3122 004 PDFDocument14 paginiTH3122 004 PDFSasa MitrovicÎncă nu există evaluări

- Form of The Future Progressive TenseDocument2 paginiForm of The Future Progressive TenseSasa MitrovicÎncă nu există evaluări

- BC846ALT1G Series, SBC846ALT1G Series General Purpose TransistorsDocument13 paginiBC846ALT1G Series, SBC846ALT1G Series General Purpose TransistorsSasa MitrovicÎncă nu există evaluări

- Log TMBAG6NEXD0028904 210446km 130765miDocument6 paginiLog TMBAG6NEXD0028904 210446km 130765miSasa MitrovicÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Three Phase Load CalculatorDocument1 paginăThree Phase Load CalculatorErdincÎncă nu există evaluări

- 20AF46 Toshiba BoletinDocument6 pagini20AF46 Toshiba BoletinparascoliÎncă nu există evaluări

- 08y HydraulicCloggingIndicator PressureFilter CP101 103Document2 pagini08y HydraulicCloggingIndicator PressureFilter CP101 103msalem73Încă nu există evaluări

- SMPS Charge Pump Power Supply Documentation 1.1Document5 paginiSMPS Charge Pump Power Supply Documentation 1.1moma52Încă nu există evaluări

- Tim Mellow 25w OTL Tube Amplifier PDFDocument6 paginiTim Mellow 25w OTL Tube Amplifier PDFpravin jadav100% (3)

- Inverex Nitrox 6kW Hybrid Inverter Datasheet SpecificationsDocument2 paginiInverex Nitrox 6kW Hybrid Inverter Datasheet Specifications1saad116Încă nu există evaluări

- En 60204 1 Enquiry Form For The Electrical Equipment of MachinesDocument4 paginiEn 60204 1 Enquiry Form For The Electrical Equipment of MachinesalbatsÎncă nu există evaluări

- DST2600 Is A Compact and Rugged Automatic Gen-Set Control Panel For Engines With Power Up To 40kVA MaxDocument4 paginiDST2600 Is A Compact and Rugged Automatic Gen-Set Control Panel For Engines With Power Up To 40kVA Maxmuhammad arifÎncă nu există evaluări

- AC/DC Voltage Power Supply: Testing The Minimum Trip Voltage of A BreakerDocument3 paginiAC/DC Voltage Power Supply: Testing The Minimum Trip Voltage of A BreakerRicardo Cabrera OsinagaÎncă nu există evaluări

- ID-3LA-LP ID-12LA-LP ID-20LA-LP RFID Reader Modules Low Power - Micro Power 125khz LFDocument20 paginiID-3LA-LP ID-12LA-LP ID-20LA-LP RFID Reader Modules Low Power - Micro Power 125khz LFAbleIDLtdÎncă nu există evaluări

- Questbank1 AnswersDocument8 paginiQuestbank1 Answersjay garciaÎncă nu există evaluări

- Solar Panel Electric Energy Efficiency CalculationDocument6 paginiSolar Panel Electric Energy Efficiency CalculationKaustabha DasÎncă nu există evaluări

- KVPS RAO - Sub-Station ExperienceDocument18 paginiKVPS RAO - Sub-Station ExperienceADE MRTÎncă nu există evaluări

- Electrical Machines - IIIDocument9 paginiElectrical Machines - IIILourence Adriel DimaunahanÎncă nu există evaluări

- SMK0965F: Switching Regulator ApplicationsDocument8 paginiSMK0965F: Switching Regulator ApplicationsFale MensÎncă nu există evaluări

- Manual Da Vida JamerDocument5 paginiManual Da Vida JamerVladimir CorreiaÎncă nu există evaluări

- 6800+ Series: Safety Instructions and Standards (For Use With FR6800+MB)Document18 pagini6800+ Series: Safety Instructions and Standards (For Use With FR6800+MB)Techne PhobosÎncă nu există evaluări

- Schneider-Electric Monitor Relay Rm35ua13mwDocument2 paginiSchneider-Electric Monitor Relay Rm35ua13mwIsmet KoracÎncă nu există evaluări

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDocument2 paginiHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- RC820 (2E RELAY) Instruction Manual: ToshibaDocument25 paginiRC820 (2E RELAY) Instruction Manual: Toshibaiam_sutat5147Încă nu există evaluări

- Applimotion ULT Motor Kits DatasheetDocument2 paginiApplimotion ULT Motor Kits DatasheetElectromateÎncă nu există evaluări

- Sunpower - Solar Panel - 225WDocument2 paginiSunpower - Solar Panel - 225Wankur yadavÎncă nu există evaluări

- CR 55 AaaehqqeDocument7 paginiCR 55 AaaehqqesigithvacÎncă nu există evaluări

- 7ut512 513 PDFDocument2 pagini7ut512 513 PDFHaračić DinoÎncă nu există evaluări

- Mosfet: IPP50R380CEDocument13 paginiMosfet: IPP50R380CEFernando GuerreroÎncă nu există evaluări

- Cummins: Fault Code: 135 PID: P100 SPN: 100 FMI: 3Document5 paginiCummins: Fault Code: 135 PID: P100 SPN: 100 FMI: 3Enrrique LaraÎncă nu există evaluări

- Apc sc1500 ManualDocument16 paginiApc sc1500 ManualClaudia WallaceÎncă nu există evaluări

- Semiconductors: Thyristor Modules Thyristor/Diode ModulesDocument4 paginiSemiconductors: Thyristor Modules Thyristor/Diode ModulesTeknotama Inti Medindo PTÎncă nu există evaluări

- Tariff, Power Factor and Power Factor ImprovementDocument12 paginiTariff, Power Factor and Power Factor ImprovementnurliyanaÎncă nu există evaluări

- ACS800-04 HW ManualDocument132 paginiACS800-04 HW Manualmodelador3dÎncă nu există evaluări