Documente Academic

Documente Profesional

Documente Cultură

Pressure Test Equation

Încărcat de

Mohamed ElsayedDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pressure Test Equation

Încărcat de

Mohamed ElsayedDrepturi de autor:

Formate disponibile

ASME B31.

3-2012

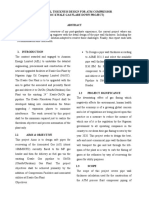

for use at pressure–temperature ratings in accordance Table 304.1.1 Values of Coefficient Y for t < D/6

with para. 302.2.1 or para. 302.2.2, as applicable. The Temperature, °C (°F)

rules in para. 304 are intended for pressure design of

≤ 482 ≥ 621

components not covered in Table 326.1, but may be used

(900 510 538 566 593 (1,150

for a special or more-rigorous design of such compo- Materials & Lower) (950) (1,000) (1,050) (1,100) & Up)

nents, or to satisfy requirements of para. 302.2.2. Designs

shall be checked for adequacy of mechanical strength Ferritic 0.4 0.5 0.7 0.7 0.7 0.7

as described in para. 302.5. steels

Austenitic 0.4 0.4 0.4 0.4 0.5 0.7

steels

304 PRESSURE DESIGN OF COMPONENTS

Other ductile 0.4 0.4 0.4 0.4 0.4 0.4

304.1 Straight Pipe metals

Cast iron 0.0 ... ... ... ... ...

304.1.1 General

(a) The required thickness of straight sections of pipe

shall be determined in accordance with eq. (2):

d + 2c

Yp

tm p t + c (2) D + d + 2c

304.1.2 Straight Pipe Under Internal Pressure

The minimum thickness, T, for the pipe selected, con- (a) For t < D/6, the internal pressure design thickness

sidering manufacturer’s minus tolerance, shall be not for straight pipe shall be not less than that calculated

less than tm . in accordance with either eq. (3a) or eq. (3b):

(b) The following nomenclature is used in the equa-

tions for pressure design of straight pipe: PD

tp (3a)

c p sum of the mechanical allowances (thread or 2共SEW + PY 兲

groove depth) plus corrosion and erosion P 共d + 2c兲

allowances. For threaded components, the tp (3b)

2关SEW − P 共1 − Y 兲兴

nominal thread depth (dimension h of

ASME B1.20.1, or equivalent) shall apply. For (b) For t ≥ D/6 or for P/SE > 0.385, calculation of

machined surfaces or grooves where the toler- pressure design thickness for straight pipe requires spe-

ance is not specified, the tolerance shall be cial consideration of factors such as theory of failure,

assumed to be 0.5 mm (0.02 in.) in addition to effects of fatigue, and thermal stress.

the specified depth of the cut.

D p outside diameter of pipe as listed in tables of

304.1.3 Straight Pipe Under External Pressure. To

determine wall thickness and stiffening requirements

standards or specifications or as measured

for straight pipe under external pressure, the procedure

d p inside diameter of pipe. For pressure design

outlined in the BPV Code, Section VIII, Division 1, UG-28

calculation, the inside diameter of the pipe is

through UG-30 shall be followed, using as the design

the maximum value allowable under the pur-

--``,,,`,```,``,``,,,```,,,,``-`-`,,`,,`,`,,`---

length, L, the running centerline length between any

chase specification.

two sections stiffened in accordance with UG-29. As an

E p quality factor from Table A-1A or A-1B

exception, for pipe with Do /t < 10, the value of S to be

P p internal design gage pressure

used in determining Pa2 shall be the lesser of the follow-

S p stress value for material from Table A-1 ing values for pipe material at design temperature:

T p pipe wall thickness (measured or minimum in (a) 1.5 times the stress value from Table A-1 of this

accordance with the purchase specification) Code, or

t p pressure design thickness, as calculated in (b) 0.9 times the yield strength tabulated in Section II,

accordance with para. 304.1.2 for internal pres- Part D, Table Y-1 for materials listed therein

sure or as determined in accordance with

(The symbol Do in Section VIII is equivalent to D in this

para. 304.1.3 for external pressure

Code.)

tm p minimum required thickness, including

mechanical, corrosion, and erosion allowances 304.2 Curved and Mitered Segments of Pipe

W p weld joint strength reduction factor in accor-

304.2.1 Pipe Bends. The minimum required thick-

dance with para. 302.3.5(e)

ness, tm, of a bend, after bending, in its finished form,

Y p coefficient from Table 304.1.1, valid for t < D/6

shall be determined in accordance with eqs. (2) and (3c)

and for materials shown. The value of Y may

be interpolated for intermediate temperatures. PD

tp (3c)

For t ≥ D/6, 2[(SEW/I) + PY]

20

Copyright ASME International

Provided by IHS under license with ASME Licensee=Shell Global Solutions International B.V. Main/5924979112, User=ABASS,

No reproduction or networking permitted without license from IHS Not for Resale, 09/26/2013 08:45:05 MDT

S-ar putea să vă placă și

- Joint FactorDocument8 paginiJoint FactorMohamed ElsayedÎncă nu există evaluări

- Asme B31.3 Wall THK Equation - y ValuesDocument1 paginăAsme B31.3 Wall THK Equation - y Valuesjoaquin torrano veraÎncă nu există evaluări

- A - Minimum Required Thickness or Pressure Design Thickness ASME B31.3 304.1.1 and 304.1.2Document4 paginiA - Minimum Required Thickness or Pressure Design Thickness ASME B31.3 304.1.1 and 304.1.2edisjdavÎncă nu există evaluări

- b31 3Document1 paginăb31 3Hugo OrtegaÎncă nu există evaluări

- Asme B31.3 2018 30PDocument7 paginiAsme B31.3 2018 30PKim JungdaeÎncă nu există evaluări

- Pages From ASME B31.3-2014-2Document1 paginăPages From ASME B31.3-2014-2Godwin A.udo-akanÎncă nu există evaluări

- Pipe Wall Thickness CalculationDocument8 paginiPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- ASME B 31.3 Table 304.1.1 Coefficient (Y)Document1 paginăASME B 31.3 Table 304.1.1 Coefficient (Y)groshan20Încă nu există evaluări

- B - Minimum Required Thickness Permanent Blank ASME 304.5.3Document2 paginiB - Minimum Required Thickness Permanent Blank ASME 304.5.3edisjdavÎncă nu există evaluări

- Table 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018Document32 paginiTable 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018GabrielÎncă nu există evaluări

- Pipe Thickness CalculationDocument4 paginiPipe Thickness CalculationHarryÎncă nu există evaluări

- SPREADSHEETS SERIES No. 0009S - 2Document4 paginiSPREADSHEETS SERIES No. 0009S - 2Emma DÎncă nu există evaluări

- Pipe Thickness Calculation AS Per ASME 31.3Document11 paginiPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRÎncă nu există evaluări

- Asme B31.3Document69 paginiAsme B31.39440864459100% (4)

- Astm A381 1996 PDFDocument7 paginiAstm A381 1996 PDFMauricio Rincón OrtizÎncă nu există evaluări

- Reinforcement Pad CalculationDocument5 paginiReinforcement Pad Calculationsada siva100% (1)

- SPREADSHEETS SERIES No. 0003S - 2Document2 paginiSPREADSHEETS SERIES No. 0003S - 2Emma DÎncă nu există evaluări

- Asme B31.8Document14 paginiAsme B31.8omar equihua100% (1)

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 paginiDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012Încă nu există evaluări

- Metal-Arc-Welded Steel Pipe For Use With High-Pressure Transmission SystemsDocument5 paginiMetal-Arc-Welded Steel Pipe For Use With High-Pressure Transmission Systemsrohit kumarÎncă nu există evaluări

- Hdpe Pipe Wall Thickness CalculationsDocument1 paginăHdpe Pipe Wall Thickness CalculationsTsouki TsoukiÎncă nu există evaluări

- Cong Thuc Tinh Toan Piping ThicknessDocument108 paginiCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonÎncă nu există evaluări

- ASME B31.4-Wall Thickness CalDocument2 paginiASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Pipe Thickness Calculation For Internal PressureDocument12 paginiPipe Thickness Calculation For Internal PressurefsijestÎncă nu există evaluări

- Part-Ii: Chapter - 2. Design of Piping ComponentsDocument4 paginiPart-Ii: Chapter - 2. Design of Piping ComponentsAshish PatelÎncă nu există evaluări

- SampleCalculationspipingB3132008 PDFDocument13 paginiSampleCalculationspipingB3132008 PDFsosatlantiqueÎncă nu există evaluări

- ASME B31 8 Riser CalcDocument12 paginiASME B31 8 Riser CalcEmmanuel LawrenceÎncă nu există evaluări

- Technical Notes - B31.3Document36 paginiTechnical Notes - B31.3Amit Pandey100% (1)

- Blind CalculationDocument2 paginiBlind CalculationwidhiyogaÎncă nu există evaluări

- SB 241Document24 paginiSB 241JolettitoÎncă nu există evaluări

- A 381 Â " 96 - QTM4MS05NGDocument5 paginiA 381 Â " 96 - QTM4MS05NGhÎncă nu există evaluări

- Caepipe Version 5 Bcte A Power Piping Asme b311 2016 Allowable PressureDocument51 paginiCaepipe Version 5 Bcte A Power Piping Asme b311 2016 Allowable PressureAtanasioÎncă nu există evaluări

- Engineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardDocument9 paginiEngineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardGabbar SinghÎncă nu există evaluări

- 307 Valves and Specialty Components: ASME B31.3-2018Document4 pagini307 Valves and Specialty Components: ASME B31.3-2018gigiphi1Încă nu există evaluări

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 paginiPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeÎncă nu există evaluări

- Steel Sheet, Aluminum-Coated (Type 2) For Corrugated Steel PipeDocument3 paginiSteel Sheet, Aluminum-Coated (Type 2) For Corrugated Steel PipeFRANZ RICHARD SARDINAS MALLCOÎncă nu există evaluări

- 331 Heat Treatment: ASME B31.3-2012Document4 pagini331 Heat Treatment: ASME B31.3-2012Stephen RajÎncă nu există evaluări

- 1.reference ASME B31.3: Blind CalculationDocument2 pagini1.reference ASME B31.3: Blind CalculationwidhiyogaÎncă nu există evaluări

- ASME B31.8 Riser CalcDocument12 paginiASME B31.8 Riser CalcSalz EngineeringÎncă nu există evaluări

- ASME B31.4-Wall Thickness Calc For 6 InchDocument2 paginiASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoÎncă nu există evaluări

- Astm A178 A178m-02 PDFDocument4 paginiAstm A178 A178m-02 PDFZaida Isadora Torres Vera100% (1)

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pagini2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Diagram Illustrating Application of 831.3 Piping at EquipmentDocument1 paginăDiagram Illustrating Application of 831.3 Piping at EquipmentMechanicalÎncă nu există evaluări

- ASME B31.8 Riser CalcDocument23 paginiASME B31.8 Riser Calcisrar khan100% (2)

- ASME B31.5-Refrigeration-PipingDocument11 paginiASME B31.5-Refrigeration-PipingJai100% (2)

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Document27 paginiCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinÎncă nu există evaluări

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 paginiASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- Plate CalculationDocument7 paginiPlate CalculationminhthanhmosÎncă nu există evaluări

- Pipe Thickness Calculator As Per ASME B31.3Document3 paginiPipe Thickness Calculator As Per ASME B31.3anh thoÎncă nu există evaluări

- ASME B31.3 Key ChangesDocument2 paginiASME B31.3 Key ChangessssÎncă nu există evaluări

- Sa 31Document4 paginiSa 31Wagner Renato AraújoÎncă nu există evaluări

- Pipe Wall Thickness Calculation Technical ReportDocument4 paginiPipe Wall Thickness Calculation Technical ReportImalah UgoachanumÎncă nu există evaluări

- Calculation of Pipe Reinforcement Asme b31 3Document3 paginiCalculation of Pipe Reinforcement Asme b31 3KomedianTunggalÎncă nu există evaluări

- Brance Pipe CALDocument6 paginiBrance Pipe CALKlaikangwol AnuwarnÎncă nu există evaluări

- Case 2290 PDFDocument90 paginiCase 2290 PDFDarioÎncă nu există evaluări

- Idoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318Document9 paginiIdoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318GEMSL MOÎncă nu există evaluări

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsDe la EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsÎncă nu există evaluări

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Document8 paginiHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedÎncă nu există evaluări

- 312 Flanged Joints: ASME B31.3-2012Document2 pagini312 Flanged Joints: ASME B31.3-2012Mohamed ElsayedÎncă nu există evaluări

- Questions CswipDocument63 paginiQuestions CswipMohamed ElsayedÎncă nu există evaluări

- Section 2 Calculations B31.3 New Piping CalculationsDocument36 paginiSection 2 Calculations B31.3 New Piping CalculationsMohamed ElsayedÎncă nu există evaluări

- Section 6 B31.3 330 Preheating: Haward Technology Middle East 1 Section 6Document37 paginiSection 6 B31.3 330 Preheating: Haward Technology Middle East 1 Section 6Mohamed ElsayedÎncă nu există evaluări

- Table A-1 Basic Allowable Stresses in Tension For MetalsDocument28 paginiTable A-1 Basic Allowable Stresses in Tension For MetalsMohamed ElsayedÎncă nu există evaluări

- E Joint Factor 2 PDFDocument1 paginăE Joint Factor 2 PDFMohamed ElsayedÎncă nu există evaluări

- Asme 16.5 OgsDocument13 paginiAsme 16.5 OgsMohamed ElsayedÎncă nu există evaluări

- QC Questions InterviewsDocument23 paginiQC Questions InterviewsMohamed ElsayedÎncă nu există evaluări

- TWW Tool Guide PDFDocument8 paginiTWW Tool Guide PDFVictor GrigorasÎncă nu există evaluări

- Travelling Itinerary: MS 2614 Economy 03 Jul 18 CAI - Cairo Intl Arpt KWI - Kuwait 2030 2359 Confirmed Nb8SsuDocument1 paginăTravelling Itinerary: MS 2614 Economy 03 Jul 18 CAI - Cairo Intl Arpt KWI - Kuwait 2030 2359 Confirmed Nb8SsuMohamed ElsayedÎncă nu există evaluări

- Caliper Test (Anayet)Document4 paginiCaliper Test (Anayet)Ali RazuÎncă nu există evaluări

- Ultimate Yielding State of Web Plate in Pure Bending: CR CR CR T CR CR T T T TDocument1 paginăUltimate Yielding State of Web Plate in Pure Bending: CR CR CR T CR CR T T T TardabiliÎncă nu există evaluări

- Sandvik 2RE10 - The Risk Reducer in Nitric Acid Production - Sandvik Materials TechnologyDocument5 paginiSandvik 2RE10 - The Risk Reducer in Nitric Acid Production - Sandvik Materials TechnologyAnonymous 5odj1IcÎncă nu există evaluări

- Aluminum CorrosionDocument1 paginăAluminum CorrosionthanhnguyenhhvnÎncă nu există evaluări

- Laser Writer - Overview of Different Process Steps at IISc CeNSEDocument14 paginiLaser Writer - Overview of Different Process Steps at IISc CeNSEprashant_scribdÎncă nu există evaluări

- Flashing Systems 10 Book 0 - 1 CompressedDocument26 paginiFlashing Systems 10 Book 0 - 1 CompressedSam SÎncă nu există evaluări

- 2007 Minnesota Building CodeDocument441 pagini2007 Minnesota Building CodeSteve EkmanÎncă nu există evaluări

- Design Application & Installation Information: Service ConditionsDocument10 paginiDesign Application & Installation Information: Service ConditionsjoechengshÎncă nu există evaluări

- DSR 2020 Civil 2Document150 paginiDSR 2020 Civil 2Santosh K SatiÎncă nu există evaluări

- Government of India Ministry of RailwaysDocument56 paginiGovernment of India Ministry of RailwaysSalim KhanÎncă nu există evaluări

- Meachanically Fastened Roofing Single Ply Membranes PDFDocument32 paginiMeachanically Fastened Roofing Single Ply Membranes PDFclaitonborgesÎncă nu există evaluări

- Design of Slab FormsDocument27 paginiDesign of Slab FormsZevanyaRolandTualaka100% (1)

- Prediction of Pressure Drop in Vertical Pneumatic ConveyorsDocument9 paginiPrediction of Pressure Drop in Vertical Pneumatic ConveyorshendrobamaÎncă nu există evaluări

- 2102 - Vol - 2BDocument7 pagini2102 - Vol - 2BSoumen KarÎncă nu există evaluări

- 11 Underwood SSRspecificationpresentation PDFDocument37 pagini11 Underwood SSRspecificationpresentation PDFYasin AykanatÎncă nu există evaluări

- Hydro TestingDocument26 paginiHydro TestingMahaveer SinghÎncă nu există evaluări

- Duct RsesDocument18 paginiDuct RsesSameer AbdullahÎncă nu există evaluări

- J IntegralDocument11 paginiJ IntegralmohsenjunÎncă nu există evaluări

- Technical Folder Filtercel Cfa-W: SpecificationsDocument1 paginăTechnical Folder Filtercel Cfa-W: SpecificationsmehrezÎncă nu există evaluări

- ADWEA - Vendor's ListDocument312 paginiADWEA - Vendor's ListClark HonradoÎncă nu există evaluări

- Data Sheet - ATS - 40Document1 paginăData Sheet - ATS - 40HhelenaaÎncă nu există evaluări

- Fresh Water ModuleDocument24 paginiFresh Water Moduleanon_411130333Încă nu există evaluări

- Hydrolic Transportation Tailing SlurryDocument7 paginiHydrolic Transportation Tailing SlurryBagus Tjahjoko Nugroho100% (1)

- 03-09 RconDocument1 pagină03-09 RconManojÎncă nu există evaluări

- Fire Safety of BuildingsDocument55 paginiFire Safety of BuildingsRayanÎncă nu există evaluări

- Oil Seal NAK - CatalogDocument170 paginiOil Seal NAK - CatalogPhạm Hoài AnhÎncă nu există evaluări

- Report No. (Số báo cáo) : MRIR-P-PP5-002 Page (Trang) : 10 of 10 Inspection Date (Ngày kiểm tra) :9/29/2020 Material Receiving Inspection Report For Pipe MaterialsDocument20 paginiReport No. (Số báo cáo) : MRIR-P-PP5-002 Page (Trang) : 10 of 10 Inspection Date (Ngày kiểm tra) :9/29/2020 Material Receiving Inspection Report For Pipe Materialsnguyenquocbao1990Încă nu există evaluări

- MSC Topic 3B - C21Document40 paginiMSC Topic 3B - C21myint phyoÎncă nu există evaluări

- Uc Booking W.E.F. 01.01.2019 To 30.09.2019 EE (B) - II-WZDocument34 paginiUc Booking W.E.F. 01.01.2019 To 30.09.2019 EE (B) - II-WZBALAJI ASSOCIATESÎncă nu există evaluări

- Orifice Plate For Flow MeasurementDocument3 paginiOrifice Plate For Flow Measurementcinema bizarreÎncă nu există evaluări