Documente Academic

Documente Profesional

Documente Cultură

Watch

Încărcat de

Rohit Mishra0 evaluări0% au considerat acest document util (0 voturi)

44 vizualizări1 paginăwatchkeeping procedure

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentwatchkeeping procedure

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

44 vizualizări1 paginăWatch

Încărcat de

Rohit Mishrawatchkeeping procedure

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

WATCHKEEPING PROCEDURES

Refer to STCW 95 Pt.A-VIII/2

In addition:

At commencement of the watch a full tour of the engine room should be made checking

that current operational parameters of all machinery is correct. That is, check all oil levels

and temperatures are within parameters. Check that there are no unusual noises and that all

machinery is running satisfactory. Check that bilges are empty & oil free.

Ensure that the engine room is in a clean and tidy condition. “Good housekeeping” plays an

important part towards the safety and efficiency of the engine room.

When satisfied that everything is satisfactory, take over the watch.

During the watch ensure that the main propulsion plant and auxiliary systems are kept

under constant surveillance, and operated at maximum efficiency.

Inspections of the machinery, steering gear and adjacent machinery spaces are to be made

at suitable intervals. Check that all machinery is running normally and running within

specified parameters. I.E. correct oil levels & pressures, temperatures, amps etc. Appropriate

action to be made to rectify any defects.

All incidents and any changes to plant conditions are to be recorded in the Engine room log

book.

Alarms must not be canceled without their cause being fully understood and investigated.

The watchkeeping engineer shall ensure that all stand by machinery is instantly available.

The watchkeeping engineer shall ensure that all machinery that is to be worked on shall be

isolated, by passed and made safe to work on.

The Chief Engineer is to be informed of any plant changes which may effect the ships speed,

imminent steering failure, stoppage of the main engine, any alteration in the generation of

electric power or anything else that may effect the safety of the vessel.

The bridge should be notified, where possible, before any operational changes are made to

give maximum possible time to take whatever actions are necessary to avoid a marine casualty.

During the watch the Engineer is to ensure that all bilges and tank tops are kept dry and free

from oil. The regulations regarding the discharge of engine room bilges are to be strictly

adhered to.

The watchkeeping engineer is to handover to the relief engineer all necessary information of

all machinery, together with any specific instructions from the or Chief Engineer.

The watchkeeping engineer is to leave all machinery in good working order, bilges and

tank tops empty and oil free and with all necessary stand by machinery ready for immediate use.

The out going watchkeeping engineer is to sign the engine log book.

S-ar putea să vă placă și

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Chief Engineers Standing OrdersDocument8 paginiChief Engineers Standing Ordersoffshorearmada100% (3)

- Describe EIGHT Actions To Be Taken by The Relieving Engineer Officer of The Watch Before Taking Charge of The WatchDocument26 paginiDescribe EIGHT Actions To Be Taken by The Relieving Engineer Officer of The Watch Before Taking Charge of The WatchAbishek AbiÎncă nu există evaluări

- Unmanned Machinery Space Operations On Board Cargo ShipDocument11 paginiUnmanned Machinery Space Operations On Board Cargo ShipSwarg VibhaÎncă nu există evaluări

- Чек листы и обязанности вахтенногоDocument2 paginiЧек листы и обязанности вахтенногоИлляÎncă nu există evaluări

- Complete Engine Room Watch Keeping - Mfame - GuruDocument8 paginiComplete Engine Room Watch Keeping - Mfame - GuruMetehan YurtseverÎncă nu există evaluări

- WatchkeepingDocument90 paginiWatchkeepingAbdul Hafiz0% (1)

- Без вахтове обслуговування МКВDocument4 paginiБез вахтове обслуговування МКВВалерий РыбалкаÎncă nu există evaluări

- All in One Class4 OralsDocument33 paginiAll in One Class4 OralsSantharam Mariner100% (2)

- How To Prepare For Vetting Inspection in The Engine Room?Document4 paginiHow To Prepare For Vetting Inspection in The Engine Room?saket007iÎncă nu există evaluări

- CHF Eng. Standing-OrdersDocument4 paginiCHF Eng. Standing-OrdersGökhan Ulukuz100% (1)

- CHIEF ENGINEER Standing OrdersDocument3 paginiCHIEF ENGINEER Standing Ordersefendi kaptanÎncă nu există evaluări

- Guidelines For Work in Machinery Spaces ShipsDocument5 paginiGuidelines For Work in Machinery Spaces ShipsNandani ShreyaÎncă nu există evaluări

- Torres - Auto 2 Research June 20, 2022Document16 paginiTorres - Auto 2 Research June 20, 2022Juan Miguel TorresÎncă nu există evaluări

- Chief Engineer's Standing Instructions.Document3 paginiChief Engineer's Standing Instructions.prashant manhasÎncă nu există evaluări

- Oiler ReviewerDocument6 paginiOiler ReviewerJoresol AlorroÎncă nu există evaluări

- How To Prepare For Vetting Inspection in The Engine Room?Document4 paginiHow To Prepare For Vetting Inspection in The Engine Room?Tankcare Marine100% (1)

- CE Standing OrdersDocument4 paginiCE Standing OrdersGaurav MaithilÎncă nu există evaluări

- Function of Diesel EngineDocument16 paginiFunction of Diesel EngineShienna MañiboÎncă nu există evaluări

- 2 Maintenance Theory and Practice in MarDocument11 pagini2 Maintenance Theory and Practice in MarDariusÎncă nu există evaluări

- Handing Over and Taking Over of WatchDocument20 paginiHanding Over and Taking Over of WatchKutty PuthalanÎncă nu există evaluări

- Plant OperationDocument44 paginiPlant OperationKelvinÎncă nu există evaluări

- 9 Engineering Watch (Underway) 1Document41 pagini9 Engineering Watch (Underway) 1Rishav RajÎncă nu există evaluări

- Ums OperationDocument27 paginiUms OperationSwarg Vibha0% (1)

- Expo de InglesDocument4 paginiExpo de InglesleonardoÎncă nu există evaluări

- Taking Over ProceduresDocument3 paginiTaking Over ProceduresTarek AshryÎncă nu există evaluări

- Starting Methods of Diesel Engine-AgonoyDocument4 paginiStarting Methods of Diesel Engine-AgonoyRAE ANGELO AGONOYÎncă nu există evaluări

- Watchkeeping AnswersDocument10 paginiWatchkeeping AnswersAshok Kumar100% (1)

- What Is Watch KeepingDocument2 paginiWhat Is Watch KeepingFahad SailorÎncă nu există evaluări

- Commissioning Activities - Ball MillDocument10 paginiCommissioning Activities - Ball MillVijay Bhan100% (1)

- Overhauling of TransformersDocument9 paginiOverhauling of TransformersVibhor Gaur100% (5)

- Ums System FailureDocument3 paginiUms System Failureaadarsh kumarÎncă nu există evaluări

- Jerwin AssgnmntDocument6 paginiJerwin AssgnmntErmercadoÎncă nu există evaluări

- Description of The UnitDocument8 paginiDescription of The UnitDelshad DuhokiÎncă nu există evaluări

- Watchkeeping and Equipment OperationDocument8 paginiWatchkeeping and Equipment OperationDeepakÎncă nu există evaluări

- Управление маслостанцией PDFDocument12 paginiУправление маслостанцией PDFIvan MaltsevÎncă nu există evaluări

- Amt 643 Lec PrelimsDocument2 paginiAmt 643 Lec PrelimsTyron CastroÎncă nu există evaluări

- Power PlantDocument11 paginiPower Plantarvidkumar87060Încă nu există evaluări

- Cogen ManDocument31 paginiCogen ManircasinagaÎncă nu există evaluări

- Commissioning Procedure: Air Pre HeaterDocument14 paginiCommissioning Procedure: Air Pre Heaterarvidkumar87060Încă nu există evaluări

- 20 Points Engineers Onboard Ship Should Consider While Planning For A Long VoyageDocument4 pagini20 Points Engineers Onboard Ship Should Consider While Planning For A Long VoyageŞtefan Cotruţă100% (1)

- Startup Sequence For SGTDocument22 paginiStartup Sequence For SGTmak6ibitek0% (1)

- Performance of Engine Room Watch Keeping DutiesDocument17 paginiPerformance of Engine Room Watch Keeping DutiesMike Bunoan Dumangeng83% (6)

- Ewk Review Material For MidtermDocument4 paginiEwk Review Material For MidtermJimmy C. Enojo Jr.Încă nu există evaluări

- Deck Equipments: Deck Cranes Mooring Winch Anchor Windlass Lift Boat DavitsDocument9 paginiDeck Equipments: Deck Cranes Mooring Winch Anchor Windlass Lift Boat Davitsnelson nacu50% (2)

- ISM Ship Management SMS Manual - SOM CH 09 Engine Room Operations-Ver03Document48 paginiISM Ship Management SMS Manual - SOM CH 09 Engine Room Operations-Ver03Burak YıldırımÎncă nu există evaluări

- JLL Schedule 1 SowDocument9 paginiJLL Schedule 1 SowRohan BagadiyaÎncă nu există evaluări

- 5 Vetting Check List - Aug 2014Document3 pagini5 Vetting Check List - Aug 2014gulfknot CE100% (1)

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 paginiManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Mgnt-Cms-1e-8 1 1 12Document2 paginiMgnt-Cms-1e-8 1 1 12Marlon Polinar JrÎncă nu există evaluări

- Section 4 PrecommDocument3 paginiSection 4 PrecommMithilesh YadavÎncă nu există evaluări

- Unmanned Machinery Space OperationDocument1 paginăUnmanned Machinery Space OperationcaptaincadenaÎncă nu există evaluări

- Engineroom Manual2Document13 paginiEngineroom Manual2Sarm1s100% (1)

- What Actions Will You Follow To Ensure That The Crank Case Oil of The Main Engine Is Always in Satisfactory Condition?Document16 paginiWhat Actions Will You Follow To Ensure That The Crank Case Oil of The Main Engine Is Always in Satisfactory Condition?arjun singhÎncă nu există evaluări

- Basic Procedures To Be Followed Before OperationDocument3 paginiBasic Procedures To Be Followed Before OperationEdward BolingotÎncă nu există evaluări

- Starting of Main EngineDocument5 paginiStarting of Main EngineAayush Agrawal100% (2)

- SEBU6965-06 Before StartDocument6 paginiSEBU6965-06 Before StartLUIZ GUSTAVOÎncă nu există evaluări

- Pasgt Act 4Document3 paginiPasgt Act 4Ramil SalundagaÎncă nu există evaluări

- Notes Rohit 2Document87 paginiNotes Rohit 2Rohit MishraÎncă nu există evaluări

- Bottem End Bearing RemovalDocument8 paginiBottem End Bearing RemovalRohit Mishra100% (2)

- Notes RohitDocument66 paginiNotes RohitRohit MishraÎncă nu există evaluări

- Laxmi Chalisa HindiDocument3 paginiLaxmi Chalisa HindiM K MishraÎncă nu există evaluări

- Assorted QuestionsDocument17 paginiAssorted QuestionsRohit MishraÎncă nu există evaluări

- OralquesDocument4 paginiOralquesRohit MishraÎncă nu există evaluări

- Sri Hanuman Chalisa in HindiDocument3 paginiSri Hanuman Chalisa in HindiSrivatsa97% (31)

- Eco Bilge Alfa Laval2Document1 paginăEco Bilge Alfa Laval2Rohit MishraÎncă nu există evaluări

- Alfa Laval PureBallast PR 20090601Document3 paginiAlfa Laval PureBallast PR 20090601Rohit MishraÎncă nu există evaluări

- Bilge Water System Alfa LavalDocument2 paginiBilge Water System Alfa LavalOmar MoradiÎncă nu există evaluări

- CO2 ReleaseDocument1 paginăCO2 ReleaseRohit MishraÎncă nu există evaluări

- International Convention For The Safety of Life at Sea (SOLAS), 1974Document24 paginiInternational Convention For The Safety of Life at Sea (SOLAS), 1974Rohit MishraÎncă nu există evaluări

- Comparison Design Between MC Vs MC-CDocument16 paginiComparison Design Between MC Vs MC-Cmaninder_khasria100% (1)

- Main Menu - Emilie MaerskDocument1 paginăMain Menu - Emilie MaerskRohit MishraÎncă nu există evaluări

- Class 2 OralDocument13 paginiClass 2 OralRohit Mishra100% (1)

- Container StressesDocument2 paginiContainer StressesSiddharth SinghÎncă nu există evaluări

- Permit To WorkDocument39 paginiPermit To WorkRohit MishraÎncă nu există evaluări

- Accumulator ChargingDocument1 paginăAccumulator ChargingRohit MishraÎncă nu există evaluări

- Class 2 Oral NotesDocument59 paginiClass 2 Oral NotesRohit Mishra100% (13)

- New Recent OralDocument1 paginăNew Recent OralRohit MishraÎncă nu există evaluări

- TRASSIDocument7 paginiTRASSIRohit Mishra50% (2)

- OralquesDocument4 paginiOralquesRohit MishraÎncă nu există evaluări

- Stormwater Best Management Practices: Reference GuideDocument216 paginiStormwater Best Management Practices: Reference GuideSaydahmadÎncă nu există evaluări

- (Brochure) LZ AT3110Document1 pagină(Brochure) LZ AT3110August PhạmÎncă nu există evaluări

- Copy FM 55-30: Motor Transportation OperationsDocument76 paginiCopy FM 55-30: Motor Transportation OperationsjamesfletcherÎncă nu există evaluări

- GSB (SOURCE - BATHU UNA QUARRY) Grade - IIIDocument27 paginiGSB (SOURCE - BATHU UNA QUARRY) Grade - IIIjitendra100% (1)

- KingAir200 Cockpit LayoutDocument1 paginăKingAir200 Cockpit LayoutRicardo Barros LeãoÎncă nu există evaluări

- Cisco 3504 Wireless Controlller DatasheetDocument6 paginiCisco 3504 Wireless Controlller Datasheethem777Încă nu există evaluări

- Abstract Sheet 23-09-2022Document16 paginiAbstract Sheet 23-09-2022Rajesh Bhat - Estimation Dept. KBP CivilÎncă nu există evaluări

- Acm 200 en PDFDocument6 paginiAcm 200 en PDFAde Indra SiboroÎncă nu există evaluări

- Engine InventoryDocument7 paginiEngine InventoryArif Mulyasyahputra2Încă nu există evaluări

- Siglo XVI HolandaDocument271 paginiSiglo XVI Holandafores2Încă nu există evaluări

- Comm-PC-System Protection and Control Subcommittee SPCS DL-Redundancy - Tech - Ref - 1!14!09Document60 paginiComm-PC-System Protection and Control Subcommittee SPCS DL-Redundancy - Tech - Ref - 1!14!09shabirafzalÎncă nu există evaluări

- Airport Layout and Airport TerminalDocument94 paginiAirport Layout and Airport TerminalChouaib Ben Boubaker80% (10)

- Bicycle and Motorcycle DynamicsDocument28 paginiBicycle and Motorcycle DynamicsSurya PatilÎncă nu există evaluări

- Velocity ProblemsDocument4 paginiVelocity ProblemshevelascoÎncă nu există evaluări

- FINAL Traffic Signal Maintenance Consolidation StudyDocument23 paginiFINAL Traffic Signal Maintenance Consolidation StudyKhairul AnuarÎncă nu există evaluări

- Ocean Reefer Quality Guidelines ReleaseDocument15 paginiOcean Reefer Quality Guidelines ReleaseAnonymous 1gbsuaafddÎncă nu există evaluări

- Powertronic V5Document38 paginiPowertronic V5ARDELTÎncă nu există evaluări

- Grade 12 Eapp Lesson 3 Quarter 1Document12 paginiGrade 12 Eapp Lesson 3 Quarter 1Maria Cecilia Loristo0% (1)

- MICT Terminal Information 2018Document2 paginiMICT Terminal Information 2018Jorwin ButialÎncă nu există evaluări

- Mtoe User GuideDocument28 paginiMtoe User GuidepravinÎncă nu există evaluări

- AR-00 00 000-TOC en A 1 MainDocument14 paginiAR-00 00 000-TOC en A 1 Mainaboamerhhh8Încă nu există evaluări

- Aditya Joshi CVDocument23 paginiAditya Joshi CVAditya JoshiÎncă nu există evaluări

- Case Study Dcc30103Document3 paginiCase Study Dcc30103Muhd MuazÎncă nu există evaluări

- The Economic Impact of The World Cup On BrazilDocument7 paginiThe Economic Impact of The World Cup On Brazileadona15Încă nu există evaluări

- Text-Book of Seamanship - Part 5Document77 paginiText-Book of Seamanship - Part 5Maria VasileÎncă nu există evaluări

- Unit 1 IEN Master 2Document8 paginiUnit 1 IEN Master 2tanny nina maynictaÎncă nu există evaluări

- HM 40 Feb 2023 Edi, Cow, EditableDocument36 paginiHM 40 Feb 2023 Edi, Cow, EditableAung Htet KyawÎncă nu există evaluări

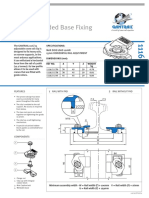

- Gantrail Welded Base Fixing: SpecificationsDocument2 paginiGantrail Welded Base Fixing: SpecificationstobiasÎncă nu există evaluări

- JF015E Calibration Parte3Document4 paginiJF015E Calibration Parte3EdgarditoÎncă nu există evaluări

- Automotive HistoryDocument6 paginiAutomotive HistoryJohn Kheil Oliquino Obina100% (1)