Documente Academic

Documente Profesional

Documente Cultură

Spiral Jet Technical Document

Încărcat de

ykozeDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Spiral Jet Technical Document

Încărcat de

ykozeDrepturi de autor:

Formate disponibile

SPRAY NOZZLES

COMPACT, ONE PIECE, LARGE FLOW RATE

FULL CONE SPRAY NOZZLES

HHSJ HHSJ HHSJ

threaded/hex threaded/flats threaded/round

1⁄4)-2) NPT or BSPT (M) 1⁄4)-4) NPT or BSPT (M) 1⁄4)-4) NPT or BSPT (M)

C

36

GENERAL PURPOSE

Flow capacity at 40 psi (3 bar) in flats design only. They can

DESIGN FEATURES ranges from 1.4 to 1050 gpm also be produced from a wide

The Type HHSJ is a Full Cone (5.5 to 4140 l/min). variety of other materials for

spray nozzle available for spray specific applications.

Sizes 1⁄4) to 2) are available in

angles ranging from 60° to 170°.

brass, cast 316 stainless steel,

These compact nozzles permit ACCESSORIES

and TEFLON or PVC materials.

maximum liquid throughput for a

Brass version is available with

COMMON APPLICATIONS given pipe size and the free

hex design. Stainless steel with Adjustable Ball Fittings

ⓦ Flue gas scrubbing passage design minimizes

flats. TEFLON and PVC nozzles

clogging. The compact size can

ⓦ Gas cooling with rounded design. In the

be installed or retrofitted on most

larger 3) and 4) sizes, both brass

ⓦ Washing & rinsing processes pipe systems. Available in NPT

and stainless steel are available

or BSPT (M) threads.

ⓦ Fire supression & prevention

FULL CONE

PERFORMANCE DATA DIMENSIONS

Free CAPACITY Nozzle Nozzle Length Spray Angle

Pipe Size Spray Angle at 0.7 bar Orifice

Capacity Passage (liters per minute) Inlet Conn. mm

NPT or Diam.

Size Diam. 0.7 1.5 3 7 25** /

14 53.9 60°, 150° & 170°

BSPT (M) 60° 90° 120° 150° 170° mm

mm bar bar bar bar bar

/

14 47.6 90° & 120°

ⓦ ⓦ ⓦ 07 2.4 2.4 2.6 3.9 5.5 8.4 16 3/8 60.3 60° 150° & 170°

1/4 ⓦ ⓦ ⓦ ⓦ ⓦ 13 3.2 3.2 4.9 7.3 10.3 15.7 30 3/8 47.6 90° & 120°

ⓦ ⓦ ⓦ ⓦ ⓦ 20 4.0 3.2 7.6 11.2 15.8 24 46

1/2 79.4 60°, 150° & 170°

ⓦ 07 2.4 2.4 2.6 3.9 5.5 8.4 16

1/2 63.5 90° & 120°

ⓦ 13 3.2 3.2 4.9 7.3 10.3 15.7 30

ⓦ 20 4.0 3.2 7.6 11.2 15.8 24 46 3/4 87.3 60°, 150° & 170°

3/8 ⓦ ⓦ ⓦ ⓦ ⓦ 30 4.8 3.2 11.4 16.7 24 36 68 3/4 69.9 90° & 120°

ⓦ ⓦ ⓦ ⓦ ⓦ 40 5.6 3.2 15.1 22 32 48 91

ⓦ ⓦ ⓦ

1 116 60°, 150° & 170°

ⓦ ⓦ 53 6.4 3.2 20 30 42 64 121

ⓦ ⓦ ⓦ ⓦ ⓦ 82 7.9 3.2 31 46 65 99 187 1 92.1 90° & 120°

ⓦ ⓦ ⓦ ⓦ ⓦ 120 9.5 4.8 45 67 95 145 270 11/2 171 60°, 150° & 170°

1/2

ⓦ ⓦ ⓦ ⓦ ⓦ 164 11.1 4.8 62 92 129 198 370 11/2 111 90° & 120°

3/4 ⓦ ⓦ ⓦ ⓦ ⓦ 210 12.7 4.8 80 117 166 255 480 2 175 60° thru 170°

ⓦ ⓦ ⓦ ⓦ ⓦ 340 15.9 6.4 130 190 270 410 775 3 302 60°

1

ⓦ ⓦ ⓦ ⓦ ⓦ 470 19.1 6.4 179 260 370 565 1070

3 203 90° & 120°

ⓦ ⓦ ⓦ ⓦ ⓦ 640 22.2 7.9 245 355 505 770 1460

4 229 60°, 90° & 120°

1-1/2 ⓦ ⓦ ⓦ ⓦ ⓦ 820 25.4 7.9 310 455 645 990 1870

ⓦ ⓦ ⓦ ⓦ ⓦ 960 28.6 7.9 365 535 755 1160 2190

ⓦ ⓦ ⓦ ⓦ ⓦ 1400 34.9 11.1 535 780 1105 1690 3190

2

ⓦ ⓦ ⓦ ⓦ ⓦ 1780 38.1 11.1 680 995 1405 2150 4060

ⓦ ⓦ ⓦ 2560 44.5 14.3 980 1430 2020 3090 5830

ORDERING INFORMATION

3

ⓦ ⓦ ⓦ 3360 50.8 14.3 1280 1880 2650 4050 7660 COMPLETE NOZZLE

4 ⓦ ⓦ ⓦ 5250 63.5 15.9 2000 2930 4140 6330 11960 NUMBER

**At higher pressures, Brass and Cast

316 Stainless Steel nozzles are required.

Material Material Code 1/4 HHSJ - SS 120 07

Q no material code = Brass

Q SS = Cast 316 Stainless Steel Pipe Nozzle Material Spray Capac–

Size Type Code Angle ity

Q TEF = TEFLON Size

Q PVC = Polyvinyl Chloride

SPRAY NOZZLES

FULL CONE FLANGE-TYPE NOZZLES

HFSJ

2), 3) & 4) sizes

C

37

GENERAL PURPOSE

These larger capacity nozzles They are designed with precision

DESIGN FEATURES are size efficient…for maximum impact blade angles that

Type HFSJ (full cone) flange-type throughput for a given pipe size distribute the spray droplets for

nozzles provide good coverage and the large free passage excellent coverage. The flange-

for a variety of applications from resists clogging. type nozzles can be custom-

flue gas desulphurization and sized for your installation and

Flow capacities at 10 psi (.7 bar)

dust suppression to gas cooling. are available in several

range from 140 to 525 gpm (530

They are available with reaction- abrasion-resistant materials.

to 2020 l/min). These full cone

bonded silicon carbide tips on nozzles are available with 2), 3)

FRP flanges and up to 4) size

FULL CONE

and 4) flange mountings and

flange connections. spray angles from 60° to 170°.

PERFORMANCE DATA

Standard Material

Free CAPACITY Reaction-bonded Silicon Carbide with

Spray Angle at 0.7 bar Orifice

Connection Capacity Passage (liters per minute) F.R.P. Flange.

Diam.

Size Size Diam. 0.7 1.5 3 7 25 Material Code

60° 90° 120° 150° 170° mm

mm bar bar bar bar bar SILCRB = Reaction-bonded

Silicon Carbide

2) ⓦ ⓦ ⓦ ⓦ ⓦ 1400 34.9 11.1 535 780 1105 1690 3190

Flange ⓦ ⓦ ⓦ ⓦ ⓦ 1780 38.1 11.1 680 995 1405 2150 4060

3) ⓦ ⓦ ⓦ 2560 44.5 14.3 980 1430 2020 3090 5830

Flange ⓦ ⓦ ⓦ 3360 50.8 14.3 1280 1880 2650 4050 7660

4) Flange ⓦ ⓦ ⓦ 5250 63.5 15.9 2000 2930 4140 6330 11960

COMMON APPLICATIONS ORDERING INFORMATION

ⓦ Flue gas desulphurization COMPLETE NOZZLE

NUMBER

ⓦ Dust supression

ⓦ Gas cooling 3 HFSJ-SILCRB 60 2560

Flange Nozzle Material Spray Capac-

Inlet Type Code Angle ity

Conn. Size

Size

SPRAY NOZZLES

EXTRA LARGE FREE PASSAGE

HHSJX HHSJX HHSJX

threaded/hex threaded/flats threaded/round

3⁄8"-2" NPT or BSPT (M) 3⁄8"-2" NPT or BSPT (M) 3⁄8"-2" NPT or BSPT (M)

C

38

GENERAL PURPOSE

COMMON APPLICATIONS DESIGN FEATURES

ⓦ Flue gas scrubbing Maximum free passage SpiralJet Maximum free passage SpiralJet nozzle is available in threaded

nozzles minimize the possibility nozzles are available in brass, hex, threaded round, and

ⓦ Gas cooling

of plugging in high-flow pollution 316SS, and polypropylene. threaded flats. Maximum

ⓦ Washing & rinsing processes control applications. With a Additional materials such as operating pressure depends on

FULL CONE

ⓦ Fire suppression & prevention simple one-piece design, the TEFLON, silicon carbide, material, size and application.

inlet orifice is the smallest ceramic, and PVC are available

opening that liquid passes upon request.

through. The outlet helix orifice Type HHSJX SpiralJet nozzles ACCESSORIES

is proportionately larger than the are available with either 90° or

inlet opening. This virtually Adjustable Ball Fittings

120° spray angle with full-cone

eliminates plugging and allows spray patterns. The HHSJX

for maximum liquid throughput.

PERFORMANCE DATA

Free CAPACITY Nozzle Length

Pipe Size Spray Angle at 0.7 bar Orifice

Capacity Passage (liters per minute) (mm)

NPT or Diam. Split-Eyelet Connector

Size Diam. 0.7 1.5 3 7 25

BSPT (M) 90° 120° mm 90° & 120°

mm bar bar bar bar bar

P P 30 4.8 4.8 11.4 16.7 24 36 68

P P 40 5.6 5.6 15.1 22 32 48 91

3/8 69

P P 53 6.4 6.4 20 30 42 64 121

P P 82 7.9 7.9 31 46 65 99 187

1/2 P P 120 9.5 9.5 45 67 95 145 270

85

P P 164 11.1 11.1 62 92 129 198 370

Other Accessories

3/4 P P 210 12.7 12.7 80 117 166 255 480 117 ⓦ Pressure Regulators

P P 340 15.9 15.9 130 190 270 410 775 ⓦ Control Valves

1 130

P P 470 19.1 19.1 179 260 370 565 1070 ⓦ Solenoid Valves

ⓦ Swivel Connectors

P P 640 22.2 22.2 245 355 505 770 1460

1-1/2 P P 820 25.4 25.4 310 455 645 990 1870 171 SEE SECTION G FOR

COMPLETE INFORMATION.

P P 960 28.6 28.6 365 535 755 1160 2190

2 P P 1400 34.9 34.9 535 780 1105 1690 3190

279

P P 1780 38.1 38.1 680 995 1405 2150 4060 ORDERING INFORMATION

Material Material Code Additional materials upon request. COMPLETE NOZZLE

Q no material code = Brass ASSEMBLY

Q SS = Cast 316 Stainless Steel 3/8 HHSJX-SS 120 30

Q PP = Polypropylene

Pipe Nozzle Material Spray Capac-

Size Type Code Angle ity

Size

S-ar putea să vă placă și

- 24.2 The Core Assumptions of MindfulnessDocument9 pagini24.2 The Core Assumptions of Mindfulnessale alvarezÎncă nu există evaluări

- Orbinox VG08 Knife Gate ValveDocument8 paginiOrbinox VG08 Knife Gate ValveYorkistÎncă nu există evaluări

- Legg Calve Perthes Disease: SynonymsDocument35 paginiLegg Calve Perthes Disease: SynonymsAsad ChaudharyÎncă nu există evaluări

- Mailam India Limited Qw-482: Welding Procedure Specification (WPS)Document2 paginiMailam India Limited Qw-482: Welding Procedure Specification (WPS)Asad Bin Ala QatariÎncă nu există evaluări

- 1.transformer Maintenance Inspection Checklist - 001 - Uo - TSCDocument3 pagini1.transformer Maintenance Inspection Checklist - 001 - Uo - TSCAnonymous mNQq7ojÎncă nu există evaluări

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Document5 paginiSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarÎncă nu există evaluări

- Gate & Globe PDFDocument0 paginiGate & Globe PDFZoebairÎncă nu există evaluări

- Test & Repair Equipment Engineered Solutions Valve AcademyDocument44 paginiTest & Repair Equipment Engineered Solutions Valve AcademyBouzaida Maher100% (1)

- E25NAFLON Expansion BellowsDocument22 paginiE25NAFLON Expansion BellowsRezza Octova GochirÎncă nu există evaluări

- P02-S01 Rev 5 Sep 2021 Piping Material Specifications For Process FluidsDocument21 paginiP02-S01 Rev 5 Sep 2021 Piping Material Specifications For Process FluidsMohamed AdelÎncă nu există evaluări

- c3175492 Pavan Kumarvasudha Signed OfferletterDocument6 paginic3175492 Pavan Kumarvasudha Signed OfferletterPavan Kumar Vasudha100% (1)

- Issued For Construction: Piping Isometric DrawingDocument1 paginăIssued For Construction: Piping Isometric Drawing86tejasÎncă nu există evaluări

- Card Board BurstingDocument3 paginiCard Board BurstingParthiban Karuna100% (1)

- RF Return Line FilterDocument8 paginiRF Return Line Filterboobalan_shriÎncă nu există evaluări

- Test Pack Clearance FormatDocument2 paginiTest Pack Clearance FormatKarthikÎncă nu există evaluări

- Spirajet Spray NozzleDocument2 paginiSpirajet Spray NozzleykozeÎncă nu există evaluări

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 paginiWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedÎncă nu există evaluări

- PulpectomyDocument3 paginiPulpectomyWafa Nabilah Kamal100% (1)

- Me N Mine Science X Ist TermDocument101 paginiMe N Mine Science X Ist Termneelanshujain68% (19)

- Pro HYdrant Test KItDocument1 paginăPro HYdrant Test KItNos GoteÎncă nu există evaluări

- MCQ Homework: PeriodonticsDocument4 paginiMCQ Homework: Periodonticsفراس الموسويÎncă nu există evaluări

- Model 210 Digital Electro-Hydraulic Set StopDocument4 paginiModel 210 Digital Electro-Hydraulic Set StopykozeÎncă nu există evaluări

- Tds of Eterset 2844Document2 paginiTds of Eterset 2844Nandkumar PawarÎncă nu există evaluări

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 pagină4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- 800D SeriesDocument3 pagini800D Seriesvkeie0206Încă nu există evaluări

- Schematic Diagram For Hydrotest.Document1 paginăSchematic Diagram For Hydrotest.vsÎncă nu există evaluări

- Foam InductorDocument6 paginiFoam InductorDipanjan Chakrabarti100% (1)

- FRM IPSCO OEM Catalog Aug 2015Document1 paginăFRM IPSCO OEM Catalog Aug 2015Andres Navarro100% (1)

- Technical Compliance Sheet Butterfly ValveDocument5 paginiTechnical Compliance Sheet Butterfly Valvebiswasdipankar05Încă nu există evaluări

- HRSG HydrotestDocument7 paginiHRSG Hydrotestshubham raj bhawsarÎncă nu există evaluări

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerDocument118 paginiTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenÎncă nu există evaluări

- Is 11006 2011 PDFDocument16 paginiIs 11006 2011 PDFAnantha NarayananÎncă nu există evaluări

- Butterfly ValveDocument4 paginiButterfly ValveghjtyuÎncă nu există evaluări

- Seal CoolerDocument2 paginiSeal CoolerJulio Adolfo López Portocarrero100% (1)

- Tai PresentationDocument43 paginiTai PresentationusamafalakÎncă nu există evaluări

- C C CCCCCCCCCCCC C CDocument62 paginiC C CCCCCCCCCCCC C CGaurav VashishtÎncă nu există evaluări

- Catálogo Pietro FiorentiniDocument32 paginiCatálogo Pietro FiorentiniEdilsonÎncă nu există evaluări

- Cameron Scanner 2000 Data SheetDocument12 paginiCameron Scanner 2000 Data SheetHendryTriyono100% (1)

- MS For Fabrication of Above-Ground Storage TankDocument8 paginiMS For Fabrication of Above-Ground Storage Tankdadz mingiÎncă nu există evaluări

- KSB Etanorm LDocument40 paginiKSB Etanorm LhaseitoÎncă nu există evaluări

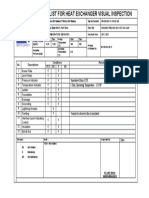

- Checklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSDocument1 paginăChecklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSRizqiÎncă nu există evaluări

- Trav L Cutter ManualDocument46 paginiTrav L Cutter ManualullwnÎncă nu există evaluări

- PSX - 60 Structural Adhesive Kit: Epoxy Siloxane Electrically Conductive Adhesive For Bonding Fiberglass Pipe and FittingsDocument2 paginiPSX - 60 Structural Adhesive Kit: Epoxy Siloxane Electrically Conductive Adhesive For Bonding Fiberglass Pipe and FittingsmusÎncă nu există evaluări

- Job Procedure For Hot Insulation Work of Piping & Equipment1Document13 paginiJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- Bangladesh MGI 300TD Continuous Polyester Production Line Bottle FlakeDocument44 paginiBangladesh MGI 300TD Continuous Polyester Production Line Bottle Flakeswapon kumar shillÎncă nu există evaluări

- Steam BoilerDocument3 paginiSteam BoilerMohammad AzlanÎncă nu există evaluări

- CFX Multiphase 12.0 WS00 TOCDocument3 paginiCFX Multiphase 12.0 WS00 TOCMaher ShehabÎncă nu există evaluări

- Gantrail Welded Base Fixing: SpecificationsDocument2 paginiGantrail Welded Base Fixing: Specificationsaandueza_1Încă nu există evaluări

- Klinger Marine Valves & GasketsDocument279 paginiKlinger Marine Valves & GasketsAndy Luthor100% (1)

- 175 170200Document2 pagini175 170200Vijay BhaleraoÎncă nu există evaluări

- Of ANSI/AGMA 9005-E02.: ISBN: 1-55589-973-8 Pages: 33Document1 paginăOf ANSI/AGMA 9005-E02.: ISBN: 1-55589-973-8 Pages: 33gioÎncă nu există evaluări

- WPS Sa 517Document2 paginiWPS Sa 517DHANANNJAI SINGH -Încă nu există evaluări

- PIPE SUPPORT-STR - Welding Inspection ReportDocument1 paginăPIPE SUPPORT-STR - Welding Inspection ReportBWQÎncă nu există evaluări

- Swagelok Fitting AssyDocument2 paginiSwagelok Fitting AssygustavoespinosamÎncă nu există evaluări

- Static Pressure Calculation SheetDocument24 paginiStatic Pressure Calculation SheetMuhammad ZubairÎncă nu există evaluări

- Keranol Fu 320Document2 paginiKeranol Fu 320shankarkl100% (1)

- InstructionManual200 300Document4 paginiInstructionManual200 300manish kumarÎncă nu există evaluări

- Installation Manual OXYFLEX® MF1100 October 2014 PDFDocument8 paginiInstallation Manual OXYFLEX® MF1100 October 2014 PDFRomuel PioquintoÎncă nu există evaluări

- Sikadur®-52 LP: Product Data SheetDocument3 paginiSikadur®-52 LP: Product Data SheetMuamer Jasna ĐulovićÎncă nu există evaluări

- QAP For Conical StrainerDocument2 paginiQAP For Conical StrainersatishchidrewarÎncă nu există evaluări

- Bondstrand Fiberglass Flanges Assembly Instructions - AmeronDocument8 paginiBondstrand Fiberglass Flanges Assembly Instructions - AmeronFabio SilvaÎncă nu există evaluări

- 300 Copy Gas Cutting Daily Check ListDocument3 pagini300 Copy Gas Cutting Daily Check ListDeepu ChandranÎncă nu există evaluări

- 1-Check List CF PumpDocument2 pagini1-Check List CF PumpStarla HillÎncă nu există evaluări

- Made in Italy - EuropeDocument8 paginiMade in Italy - EuropeenenickÎncă nu există evaluări

- CXS1919B 14 CondenserDocument1 paginăCXS1919B 14 CondenserairlanggaputraÎncă nu există evaluări

- GL5603Document2 paginiGL5603Yairton Vargas MuñozÎncă nu există evaluări

- Enchlor Catalog 2013Document8 paginiEnchlor Catalog 2013Pablo NavasÎncă nu există evaluări

- Compact, One Piece, Large Flow Rate Full Cone Spray Nozzles Spray NozzlesDocument1 paginăCompact, One Piece, Large Flow Rate Full Cone Spray Nozzles Spray NozzlesJUAN CARLOSÎncă nu există evaluări

- 3 PM Project Execution 2015Document81 pagini3 PM Project Execution 2015ykozeÎncă nu există evaluări

- Smith Meter MicroLoadnet Installation ManualDocument46 paginiSmith Meter MicroLoadnet Installation ManualykozeÎncă nu există evaluări

- Alfa 50 RegulatorDocument2 paginiAlfa 50 Regulatorykoze100% (1)

- HAZOP TemplateDocument1 paginăHAZOP TemplateykozeÎncă nu există evaluări

- Buss 37 ZemaljaDocument50 paginiBuss 37 ZemaljaOlga KovacevicÎncă nu există evaluări

- Essay 31 - Permissive ParentingDocument2 paginiEssay 31 - Permissive Parentingqbich37Încă nu există evaluări

- Boeco BM-800 - User ManualDocument21 paginiBoeco BM-800 - User ManualJuan Carlos CrespoÎncă nu există evaluări

- Probni Test 1. Godina - Ina KlipaDocument4 paginiProbni Test 1. Godina - Ina KlipaMickoÎncă nu există evaluări

- Kingdom of AnimaliaDocument6 paginiKingdom of AnimaliaBen ZerepÎncă nu există evaluări

- Universal ING - LA.Boschi Plants Private LimitedDocument23 paginiUniversal ING - LA.Boschi Plants Private LimitedAlvaro Mendoza MaytaÎncă nu există evaluări

- Test On QuantifiersDocument1 paginăTest On Quantifiersvassoula35Încă nu există evaluări

- 2015 12 17 - Parenting in America - FINALDocument105 pagini2015 12 17 - Parenting in America - FINALKeaneÎncă nu există evaluări

- Free Higher Education Application Form 1st Semester, SY 2021-2022Document1 paginăFree Higher Education Application Form 1st Semester, SY 2021-2022Wheng NaragÎncă nu există evaluări

- FSSC 22000 V6 Guidance Document Environmental MonitoringDocument10 paginiFSSC 22000 V6 Guidance Document Environmental Monitoringjessica.ramirezÎncă nu există evaluări

- Hamraki Rag April 2010 IssueDocument20 paginiHamraki Rag April 2010 IssueHamraki RagÎncă nu există evaluări

- Week5 6 2Document2 paginiWeek5 6 2SAMANIEGO BERMEO DAVID SEBASTIANÎncă nu există evaluări

- Pyq of KTGDocument8 paginiPyq of KTG18A Kashish PatelÎncă nu există evaluări

- Chomp Excersie 3Document5 paginiChomp Excersie 3Omahri24Încă nu există evaluări

- Unknown Facts About Physicians Email List - AverickMediaDocument13 paginiUnknown Facts About Physicians Email List - AverickMediaJames AndersonÎncă nu există evaluări

- Abfraction, Abrasion, Biocorrosion, and The Enigma of Noncarious Cervical Lesions: A 20-Year PerspectivejerdDocument14 paginiAbfraction, Abrasion, Biocorrosion, and The Enigma of Noncarious Cervical Lesions: A 20-Year PerspectivejerdLucianoÎncă nu există evaluări

- General Session Two - Work Life BalanceDocument35 paginiGeneral Session Two - Work Life BalanceHiba AfandiÎncă nu există evaluări

- Measurement of Bioreactor K ADocument18 paginiMeasurement of Bioreactor K AAtif MehfoozÎncă nu există evaluări

- Missoula County Fairgrounds Phase 2Document10 paginiMissoula County Fairgrounds Phase 2Olivia IversonÎncă nu există evaluări

- Bitumen BasicsDocument25 paginiBitumen BasicsMILON KUMAR HOREÎncă nu există evaluări

- ContinueDocument2 paginiContinueNeal ReppÎncă nu există evaluări

- Sol. Mock Test CBSE BiologyDocument3 paginiSol. Mock Test CBSE BiologysbarathiÎncă nu există evaluări

- SSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemDocument56 paginiSSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemJose Ramón Orenes ClementeÎncă nu există evaluări

- Amul Amul AmulDocument7 paginiAmul Amul Amulravikumarverma28Încă nu există evaluări