Documente Academic

Documente Profesional

Documente Cultură

Environmental standards for waste facilities

Încărcat de

federicoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Environmental standards for waste facilities

Încărcat de

federicoDrepturi de autor:

Formate disponibile

Environmental Standards

Storage and Material Reclamation Facilities –

Design and Operation

KSA Presidency of Meteorology and Environment PME Reference

Kingdom of Saudi Arabia National Environmental Standard

Storage and Material Reclamation Facilities – Design and Operation

Article I – Preliminary

‘material reclamation facility (MRF)’ refers to a

site for the reclamation and recovery of waste

materials for beneficial use, whether for

1) Definitions

recycling/reuse, composting or energy recovery.

‘authorisation process’ refers to the ‘mechanical biological treatment (MBT)’ refers to

determination of all applications for the the mechanical sorting/separation technologies

development of a new waste facility by the used in conjunction with biological treatment

Competent Agency up to the point where processes, such as composting or anaerobic

permission is granted to proceed with facility digestion.

development.

‘parameter’ shall refer to a chemical, physical or

‘biodegradable’ means capable of being degraded biological measurement factors as determined at

by plants and animals. the specific article within this document and

associated published Waste Management

‘bunds’ are systems which contain waste in an standards.

embankment or secondary container to prevent the

waste from travelling or escaping. ‘PME’ refers to the Presidency of Meteorology and

Environment who are designated as the

‘Competent Agency’ where referenced, refers to responsible authority for the protection of the

the Presidency of Meteorology and Environment or environment and the development of environmental

its designated representative. protection standards in the Kingdom of Saudi

Arabia.

‘construction quality assurance plan’ (CQA)

refers to the documentation to be provided outlining ‘quarantine area’ refers to a location within the

the successful construction of the facility and site which is set aside for the temporary storage of

providing evidence that all design performance potentially unacceptable waste materials pending

specifications have been met. final confirmation.

‘disposal’ means the discharge, deposit, injection, ‘recycling’ is the separation and collection of

dumping, spilling, leaking, or placing of any waste wastes materials for the subsequent transformation

into or on any land or water so that such waste or or remanufacture into usable or marketable

any constituent thereof may enter the environment products or materials.

or be emitted into the air or discharged into any

waters, including ground waters. ‘risk assessment’ is the process of identifying and

quantifying a risk and assessing the significance of

‘emission’ means the direct or indirect release of that risk in relation to other risks.

substances, vibrations, heat or noise from

individual or diffuse sources in the plant into the air, ‘site identification number’ means the number

water or soil. assigned by the Competent Agency to each TSD

facility operator of hazardous waste.

‘feedstock’ refers to the raw material required for

the process. ‘site manager’ refers to the individual with overall

responsibility for the operation and management of

‘generator’ is a commercial or industrial a waste management facility.

organisation which produces or stores trackable

waste and arranges for this waste to be sent for ‘storage’ means all operations intended to keep or

storage, recycling, treatment or disposal at another contain wastes and other hazardous, toxic or

location via an authorised transporter. radioactive substances for the purpose of

treatment, transportation or disposal, but excluding

‘GER’ refers to the Kingdom of Saudi Arabia’s those sites where the waste is originally produced

General Environmental Regulations. such as households, or commercial premises, or

where the waste is produced during construction

‘hazardous waste’ is a waste with properties that activities pending reuse or removal.

make it dangerous or capable of having a harmful

effect on human health and the environment. ‘tanks’ are stationary devices, as opposed to

portable containers, used to store or treat waste.

‘KSA’ refers to the Kingdom of Saudi Arabia. Tanks can be open topped or completely enclosed,

and may be constructed of materials including

steel, plastic, fibreglass, and concrete.

Kingdom of Saudi Arabia Page 1 of 18

KSA Presidency of Meteorology and Environment PME Reference

‘tipping area’ is the designated area within which 3) 3) Timescales for implementation

the unloading of vehicles occurs prior to .

reclamation of waste materials. a) The effective date of this standard is

01/05/1433H corresponds to 24/03/2012G.

‘transporter’ means a person engaged in the off-

site transportation of waste by air, rail, highway or

water and is anyone who transports the trackable

waste from its place of production or storage to

another location. 4) Purpose

‘treatment’ is any means or technique of altering a) The Standard for Storage and Material

the physical, chemical or biological properties of Reclamation Facilities Design and Operation has

wastes used to neutralize such wastes; utilize effect for purposes connected with the regulation of

substances or energy contained therein or released waste and hazardous waste, and in particular for

by them; and transform the hazardous wastes into the purposes of the:

wastes that are non-hazardous, less hazardous or

safer when transported, stored, disposed of, i) design of new Storage and Material

prepared for storage, or reduced in volume. Reclamation Facilities which accept

waste of all types from across the KSA

‘TSD Facility’ refers to a treatment, storage and/or whether a material or substance is inert,

a disposal facility. non-hazardous or a hazardous waste,

as the case may be;

‘WAC’ refers to Waste Acceptance Criteria.

ii) operation of Storage and Material

‘waste facility’ is a site for recycling, storing, Reclamation Facilities to ensure that the

treating or disposing of waste. site is managed in a manner which will

have least possible impact upon the

‘waste handler’ is a generator, transporter and neighbouring environment or human

receiver of waste who has waste responsibilities. health;

‘waste receiver’ is any person operating a facility and accordingly the Storage and Material

to whom waste is transported for recycling, storage, Reclamation Facilities Design and Operation

treatment or disposal. Standard shall be recognised and used for those

purposes.

‘waste receiving area’ is a pre-determined area of

the site which has been set aside for the delivery of b) The Standard guides those developing and

waste by the general public and which is located operating Storage and Material Reclamation

outside the normal field of on-site operations for Facilities to:

health and safety purposes.

i) understand the best practice

‘waste tracking’ is the recording of information requirements with respect to Storage

from the waste generator about the quantity and and Material Reclamation Facility (MRF)

type of waste produced; recording information design and operation;

about who transported the waste and when;

recording information from the waste receiver ii) develop new storage and MRF sites

about the quantity and type of waste received; and with due regard to international best

matching information about the waste from both the practice; and

generator and the receiver.

iii) understand the necessary site

‘working plan’ is the operational plan developed development requirements for storage

prior to the acceptance of waste which sets out the and MRF sites dealing with different

operational methods to be used on site and waste types.

demonstrates how environmental and human

health impacts will be managed and controlled. c) The Standard is intended for use as a default

position for Storage and MRF design and operation.

2) Citation The Standard applies to all new Storage and MRFs

pre-development. However, existing storage and

MRF operators must, as far as practicable,

a) This document may be cited as the National

implement the relevant best practice measures

Storage and material reclamation facilities – Design

contained within this Standard.

and Operation Standard for KSA. This standard

revises the current General Standards for the

Environment (specifically document number 1409- 5) Scope

01) issued by the Presidency of Meteorology and

Environment (PME). a) This Standard sets out the design parameters

and operational requirements for Storage and

MRFs in the Kingdom of Saudi Arabia.

Kingdom of Saudi Arabia Page 2 of 18

KSA Presidency of Meteorology and Environment PME Reference

b) This Standard does not apply to the: d) The Competent Agency or appointed individual

for the purpose of storage and material reclamation

i) management of Radioactive waste; facilities regulation may:

ii) management of liquid wastes; or i) Enter any premises for the purpose of

carrying out any investigation.

iii) management of sludges, including

sewage sludges and sludges from ii) carry out such inspections, measurements

dredging operations. and tests on premises entered, articles or

records found on any such premises, and

c) This Standard does not provide detailed take away such samples or articles, as may

information or guidance on the operation of different be considered appropriate for the purpose of

facilities, but instead concentrates on setting out the enabling such investigation; or

Standards for the design and operation of generic

Material Reclamation Facilities (MRFs), Storage iii) at any reasonable time require any

(TSD) Facilities and Mechanical/Biological relevant party to supply him with copies of, or

Treatment (MBT) Plants. of extracts from, any records kept for the

purpose of demonstrating compliance with

6) Exemptions storage and material reclamation facilities

standards.

a) Specific exemptions may be specified within this

e) This standard enables the issue of regulations

standard at any point where relevant to the Article

and technical memoranda which are enforceable by

that they are common to.

the Competent Agency who hold delegated

authority under the General Environmental

Regulations.

7) Powers of Authority

a) Within the scope of these standards the 8) Enforcement procedures

Competent Agency may:

a) Failure to comply with the requirements of these

standards may lead to prosecution by the

i) prescribe specific storage and material Competent Agency and those convicted of such

reclamation facility requirements at any failure may be subject to fines or periods of

time; imprisonment as laid out in the General

Environmental Regulations.

ii) authorise such relaxations or departures

from, the storage and material b) It is anticipated that the requirements of this

reclamation facility standards and make standard will be enforced nationally with inspections

any such authorisation subject to the taking place to verify their implementation at a

prescribed conditions, and to modify or regional and local level.

revoke any such authorisation or

condition; and 9) Penalty fines

iii) authorise a local Concerned Agency to a) Maximum fines that may be imposed for

exercise any power conferred by these exceeding the applicable standard, breach of permit

regulations by paragraphs i) - iii) above. and failure to comply with an abatement notice are

set out in the General Environmental Regulations.

b) The Competent Agency may, for the purposes of

this Standard, appoint persons to act on their 10) Appeals

behalf as technical assessors and monitors in

relation to the powers and duties conferred on him a) A right of appeal exists for any organisation or

by this standard and/or its subsequent individual who is required to take action as a

amendments. consequence of the implementation of the revised

standard.

c) In addition to the responsibilities conferred by

other sections contained within this standard, it b) The right of appeal against conviction or

shall be the duty of a relevant party; sentence is available through the appropriate

judicial system as set out in the General

i) to give the Competent Agency all such Environmental Regulations.

assistance; and

c) All appeals should be fully supported with a

ii) to provide the Competent Agency with all documented case containing as a minimum, the

such information, as that may reasonably be information required under the appeals process of

required for the purpose of carrying out an the General Environmental Regulations.

investigation

11) Periodic Review

Kingdom of Saudi Arabia Page 3 of 18

KSA Presidency of Meteorology and Environment PME Reference

Reclamation Facilities including specific

requirements for site location, tipping floor

a) As a minimum, the Competent Agency shall requirements, liquid management, odour control,

undertake a periodic review of this standard every Construction Quality Assurance (CQA) of the

5 years. design parameters, litter and pest/vermin control,

and closure.

b) Where new information suggests that

adjustments are required to this standard, all b) These provisions are generic for all Storage and

changes will be subject to the appropriate Material Reclamation Facilities detailed in Article II

consultation and will be notified to facilities by the of this Standard, unless otherwise stated.

Competent Agency. Appropriate implementation

time will be allowed. c) Where risk assessments and investigations

identify that a specific provision or requirement is

required then this justification will be taken into

account during the Authorisation Process. The

Article II – Storage and Material Reclamation Facility minimum information required for authorisation

Classification purposes is outlined in Appendix A in the Pre-

Design Report Requirements for Authorisation.

a) The classification of storage facilities and MRFs

are based upon the type of wastes which they are 1) Environmental Assessment

permitted to accept through their gates. There are

more stringent requirements placed upon wastes

a) A full Environmental Assessment will not

which have the potential to cause harm to human

normally be required for new Class 2 and Class 3

health or the environment.

storage and MRFs prior to their development,

unless there are likely to be locally sensitive

b) For the purposes of this Standard, storage receptors to the development.

facilities are classified as sites for the temporary

storage of waste at dedicated waste storage sites, b) An Environmental Assessment is necessary for

where waste is delivered to the site by waste the siting and location of all new storage and MRFs

transporters. The waste is then stored after receipt dealing with Class 1 waste types (or those which

prior to onward transfer for treatment or disposal. can accept both Class 1 and Class 2 wastes). This

will be necessary to gain a thorough understanding

of the environment where the facility is to be sited in

order to design the site to minimise impacts on the

environment.

2) Storage and Material Reclamation Facility

Types c) As a minimum requirement, where required, the

Environmental Assessment must include the items

a) There are three types of classification of storage outlined in Appendix B.

and MRFs according to their potential impact on

human health or the wider environment. These are: d) An Environmental Assessment will not be

required at existing operational sites, except where

i) Class 1 Storage and MRFs – sites there are proposals for a major increase in

permitted to accept only hazardous capacity, or where there is a desire to upgrade an

wastes which satisfy site specific existing facility to accept hazardous waste in the

acceptance criteria; future.

ii) Class 2 Storage and MRFs - sites 2) Site Location

permitted to accept only non-hazardous

materials from municipal, commercial a) When locating a storage facility or MRF

and industrial origins; and consideration must be given to the following:

iii) Class 3 Storage and MRFs - sites i) the facility must be located in close

permitted to accept only inert materials. proximity to population centres and the

collection sources;

b) Existing sites, and those sites proposed for

handling both hazardous and non-hazardous ii) the facility or site for a proposed facility

wastes will fall within the Class 1 classification with must be located adjacent to major

due regard to best environmental practice. highways or other transportation

arterials, and provide for easy

access/egress to the facility;

Article III – General Provisions iii) distance from the site boundary to

sensitive receptors such as residential

a) The following outlines the requirements with properties, recreation areas, coastal

respect to the design of Storage and Material water resources and agricultural areas;

Kingdom of Saudi Arabia Page 4 of 18

KSA Presidency of Meteorology and Environment PME Reference

written report has been prepared in accordance

iv) presence of groundwater, surface water, with Appendix A.

coastal water or nature conservation

zones; 4) Site Layout

v) geological and hydrogeological

a) Storage and MRFs must be designed to:

conditions underlying the site; and

i) minimise potential environmental

vi) other undetermined local factors which

impacts;

could be impacted by a proposed facility

and which will be identified at the local

ii) minimise health and safety risks for

level during the site selection process.

operators and the public;

b) The active waste handling area of a storage

iii) encourage waste recovery; and

facility or MRF must not be located within thirty

(30) metres of any neighbouring property line.

iv) use onsite resources efficiently.

c) The active waste handling area of a storage

b) To assist in meeting these requirements a

facility or MRF must not be located within one

detailed site layout plan must be provided to the

hundred (100) metres of any surface water

Competent Agency as part of the Working Plan for

excluding drainage ditches and sedimentation

the site prior to site development to provide

ponds.

evidence that key concerns have been considered

and addressed prior to the development works.

d) The active waste handling area of a MRF must

not be located within one hundred (100) metres

c) Where there is general access to the public for

of any residence, school, hospital or recreational

the drop off of wastes a suitable set aside Waste

park area.

Receiving Area with recycling and drop-off points

must be provided to reduce the need for the public

e) The active waste handling area of a storage

to unload their vehicles close to the main working

facility or MRF must not be located within thirty

areas within the site to minimise safety risks.

(30) metres of a drinking water well.

d) All wastes delivered to the site must be

subjected to review against site specific Waste

3) Site Specific Design Considerations Acceptance Criteria to confirm their suitability for

receipt at the site. A Quarantine Area must be

a) All storage and MRF sites must be designed with provided for the temporary storage of suspect

the desire for the least possible local impact and wastes brought onto the site pending confirmation

where possible they must blend in with the local of their suitability.

surroundings.

b) Site factors which affect facility design include

(but are not limited to): Article IV – Site Infrastructure Requirements

i) topography; 1) Roads and Internal Pavements

ii) size and shape of the property area;

a) Local infrastructure must be able to sustain the

operation of a storage facility and MRF as these

iii) subsurface geological and

sites require the transportation of waste. The

hydrogeological conditions;

capacity of the road network to cope safely with any

increased traffic load and with a minimum of

iv) surrounding land use;

disturbance to the local community must be

examined as part of pre-development requirements.

v) local ecological aspects;

b) Access to the site will be from permanent roads

vi) seismic considerations; and

from the main highway.

vii) access and ease of transport to the site.

c) The on-site roadway system must minimise the

number of traffic intersections and merges. To the

c) A detailed pre-construction plan must be

extent possible keep personal vehicle traffic,

provided to the Competent Agency. Details of the

material delivery traffic, and tractor-trailer traffic

requirements for this plan are provided in Appendix

separate.

A.

d) Permanent roads must be designed with due

e) A new facility must not be established by any

regard to the estimated volume of traffic. Where

person, nor an increase in the incoming volume of

possible, two lane traffic, (minimum total road width

waste to an existing facility be exercised, unless a

Kingdom of Saudi Arabia Page 5 of 18

KSA Presidency of Meteorology and Environment PME Reference

of 7.5 metres), must be provided to allow efficient d) Any solids or oils collected in the interceptor

entrance and exit from the site. must be removed at appropriate intervals to

maintain the capacity of the solids interceptor.

e) Permanent roads and yard areas must be

constructed of ground supported reinforced e) The drainage systems must be inspected at

concrete to a specification and depth capable of annual intervals throughout the operational life of

withstanding the rigors of large goods vehicle traffic the facility to ensure their integrity.

over a prolonged period, being easily cleaned to

reduce mud and debris and coping with surface f) The solids interceptor must be inspected at

water arisings. monthly intervals and will be subject to periodic

maintenance to remove any accumulated silt and

f) Impermeable pavements must be provided in maintain capacity.

relation to the waste reception and storage areas to

provide containment of any drainage or liquids g) The main waste treatment building must be

generated within those areas. designed to prevent the ingress of rainwater and

surface water. All roof drains will discharge into the

g) Specifications for the design and construction of surface water drainage system.

these areas must ensure that the surface provides

an impermeable, durable and easily maintained 3) Utilities and Facilities

surface capable of preventing the transmission of

any fluids through the pavement, or any joints

a) Electricity, water, sanitation and communications

within the pavement and ensuring the collection of

facilities must be provided at all storage facilities

any fluids into the sealed drainage system (where

and MRFs to ensure the health and safety of on-

required).

site personnel, and to enable control of operations

on site (such as dust control, vehicle washing and

h) The surfaces must be inspected at monthly

fire fighting).

intervals throughout the operational life of the

facility and a record kept of the results of each

b) As a minimum temporary structures must be

inspection.

located on site providing accommodation to on site

personnel. Such structures must be designed to

i) In the event that action becomes necessary to

provide:

maintain the cleanliness of these areas, the surface

must be cleaned by any manual or mechanical

i) office space for general site

means available to the site management. Cleaning

management duties and records

may include, but not be limited to; hosing down,

storage;

manually sweeping or shovelling, or mechanical

sweepers.

ii) sanitation facilities for site staff and

visitors;

j) All necessary repairs will be made to any defects

in the surface to ensure that it remains even, does

iii) storage space for site equipment and for

not become rutted or subject to differential

maintenance purposes; and

settlement and remains free draining and free from

standing water.

iv) first Aid area, fully stocked for minor

accidents.

k) The external roads and paved yard areas will be

constructed to provide an even surface that falls to

c) All structures must be located in a suitable area

ensure that drainage is directed towards the

of the site to allow control of day to day activities

surface water drainage systems.

whilst also taking account of health and safety

aspects.

2) Surface Water Drainage

4) Fencing and Security

a) Surface water caused by run off of entrained

water from the waste mass or by storm water

a) A fence must be constructed around the

events must be adequately controlled through the

perimeter of the facility to:

construction of interlinked drainage channels

across the site between the operating areas and

i) reduce onsite trespass, especially from

the surrounding areas of the site.

vulnerable members of the population,

and animals;

b) The design of the drainage system must be

taken into account pre-development.

ii) provide a screen for the site;

c) Surface water drainage must be discharged via

iii) delineate the property lines; and

an interceptor into a runoff water attenuation

lagoon.

iv) provide a control for litter blow.

Kingdom of Saudi Arabia Page 6 of 18

KSA Presidency of Meteorology and Environment PME Reference

b) Fences must be a minimum of 2 metres tall

around the entire perimeter of the site, with lockable vii) the words “NO UNAUTHORISED

gates provided at the site entrance. Appropriate TIPPING”.

signage to discourage trespassers must be erected

at the site entrance.

c) Maintenance and inspection of the site fencing Article V – Storage and Material Reclamation Facility

and gates along the site boundary must be Design Standards

undertaken on a routine basis and temporary

repairs will be implemented either upon

identification during the inspection or by the end of 1) Building Requirements

the day that the defect is found. A note of the

inspection and repairs will be kept on site and a

a) Local building codes must be carefully followed

record kept of the results of each inspection.

when designing a storage facility or MRF. Basics

such as the number of bathrooms, minimal working

d) Permanent repairs to the fencing and gates must

space per employee, and other requirements may

be completed within seven working days and a note

be specified. Working condition rules such as

will be made in the site diary to this effect.

minimum and maximum temperatures, air changes,

and required ventilation may also influence design.

5) Unacceptable Load Quarantine Area b) The outside walls of the building must be

designed to allow safe and easy access for

a) An area of the site must be made available to incoming and outgoing vehicles. It is important to

allow for the temporary segregation of suspect, design doors wide and high enough to

burning or unacceptable waste loads which enter accommodate vehicles unloading inside the

the site. This area should be located away from the building, and to minimise potential for open trucks

main areas frequented by personnel. Water must backing out to cause structural damage.

be available in case of burning waste loads.

c) The number of doors provided for vehicular

b) This area must be clearly marked with reference entrance into the facility must provide scope to

to its required purpose to ensure that there is no accommodate the expected number of trucks at

inadvertent mixing of waste materials. normal peak times. The same is true for loading

areas where reclaimed materials will be loaded

c) A paved surface area of 10 metres by 10 metres onto trailers for transport to markets.

minimum must be provided, with its own linked

drainage collection system. All drainage from this d) The building must have as few interior columns

part of the site must be collected and held in as possible to allow the maximum flexibility for

segregation until laboratory testing proves that it is placing equipment and accommodating future

suitable for discharge into the onsite surface needs to rearrange the layout.

drainage system. Where unsuitable, this water

must be transported for off-site treatment at a e) The floor must be strong enough in all places to

suitable water treatment facility. accommodate both vehicles and heavy, stationary

processing equipment.

6) Site Identification Board f) The floor must also be designed to allow for the

anchoring of equipment such as separation plant

and conveyors to assist in assurance of health and

a) An identification board of durable material and

safety for on site personnel.

approximate size 1 metre by 1 metre must be

erected and maintained in a prominent position at

g) The ceiling must be high enough to

the site entrance. The board must display the

accommodate equipment specifications. Conveying

following information:

lines, air classifiers, shredders, and other

processing equipment can be as tall as 15 metres.

i) site name and address;

h) Exhaust removal systems shall be installed in

ii) operator name;

enclosed areas and operated to provide adequate

ventilation within the facility.

iii) waste management licence number;

iv) site identification number, where

relevant; 2) Tipping Area and Storage Areas

v) emergency contact name and telephone a) The waste tipping or storage areas must be

number; designed to accommodate at least two days’

expected volume of material, although more space

vi) days and hours site is open to receive may be required for larger Material Reclamation

waste; and Facilities in case of unexpected downtime.

Kingdom of Saudi Arabia Page 7 of 18

KSA Presidency of Meteorology and Environment PME Reference

b) Where both mixed and source separated e) Repairs must be organised to any defects found

materials are accepted within the facility, separate within one week, in order to maintain the integrity of

tipping areas must be provided to assist in more the surface and prevent transmission of fluids, other

efficient processing and greater recovery of than via the engineered systems.

materials. Signs should clearly indicate to each

driver the proper location for material delivery.

4) Construction Quality Assurance (CQA)

c) The tipping area floor must be designed to:

a) The technical specifications for all aspects of

i) handle heavy weights;

engineered containment and drainage must be

derived from engineering and environmental risk

ii) withstand the wear caused by pushing

assessments and will ensure all pollution

and moving recyclables; and

prevention and control measures will be designed

to meet with best practice.

iii) provide efficient drainage for liquids

brought in by trucks

b) All aspects of the construction of engineered

containment and drainage will be submitted to the

iv) be free from asphalt, especially where

Competent Agency for approval prior to

there is a need to control fire.

commencing construction works.

d) The area needed for the tipping or unloading

c) All aspects of the construction of engineered

floor must be estimated based upon the character

containment and drainage shall be subject to

of the materials to be received at the site due to

Construction Quality Assurance to ensure

differences in density of such materials. Appendix

construction is compliant with the required technical

C provides a table of basic conversion factors for

specification as laid out in the Construction Quality

different recoverable waste types. By adding up

Assurance Plan.

the expected daily volumes of the commodities to

be processed, the daily throughput for the facility

d) The CQA plan must be able to verify:

can be estimated.

i) that materials used comply with site

e) Adequate space within the building must be

specific specifications; and

available to design a process layout/materials flow

that is logical, efficient, and minimizes backtracking

ii) that the method of construction and

or multiple handling of materials.

installation is appropriate and design

requirements have been met.

f) Adequate space should be designed in to cover

for seasonal variations in the quantities of incoming

c) The CQA plan must contain the:

materials delivered to the facility for receiving,

storage, sorting and processing during these high

i) material and construction specifications

volume periods.

laid out for the proposed buildings and

pavement areas;

3) Fuel Storage Tanks for Vehicles ii) testing methods used to confirm

compliance;

a) Where present, specifications for the design and

construction of fuel oil tanks and associated bunds iii) testing frequency;

will ensure an external containment capacity of

110% of the total volume of the storage tanks. The iv) corrective action to be taken where

bund walls and bases must be impermeable to the necessary; and

fuel types that may be contained within them.

v) appropriate documentation procedures

b) Any water accumulating in the bunded area must which outline what has been done.

be removed at intervals and disposed of in a

manner appropriate to the quality of the water d) The CQA must be provided for:

removed.

i) all elements of basal containment

c) The impermeable pavements and associated engineering, including internal floor

bunded areas must be cleaned at regular intervals slabs, external pavement areas and

to remove any accumulated debris. bunded areas; and

d) The impermeable pavements and associated ii) surface water and groundwater

bunded areas must be inspected at monthly management systems.

intervals throughout the operational life of the

facility and a record kept of the results of each e) The production of the CQA plan, and all testing

inspection. and reporting must be completed under the control

Kingdom of Saudi Arabia Page 8 of 18

KSA Presidency of Meteorology and Environment PME Reference

of a suitably qualified Chartered Engineer. On

completion, a validation report must be produced Transfer and Material MBT

and submitted to the Competent Agency which Storage Reclamation Facility

must include: Facility Facility

i) demonstration of CQA compliance Capacity ‘000 Up to 100 Up to 150 Up to

throughout the construction period; tonne/yr 250

ii) justifications for any changes or

Buildings 0.05 to 0.1 0.05 to 0.1 0.05 to

deviations from the agreed plan;

m2/tonne/ year 0.1

iii) the results of all testing - this must

include the records of any failed tests Building <20m <20m <20m

with a written explanation, and details of Height

the remedial action taken, referenced to

the appropriate secondary testing;

Article VI - Operations

iv) plans showing the location of all tests;

a) The actual plant operation of storage facilities

v) "as-built" plans and sections of the and MRFs will differ between technology providers

works; and the process employed. Provisions in this

Standard relating to specific processes must be met

vi) copies of the site engineer’s daily in addition to generic operational considerations

records; which are applicable to all types of storage and

MRFs.

vii) records of any problems or non-

compliances and the solution applied; 1) Working Plan

and

a) A Site Specific Working Plan, required in

viii) any other site specific information

accordance with the site specific waste

considered relevant to proving the

management licence application must be

integrity of the facility construction.

developed and forwarded to the Competent Agency

for review and agreement prior to operations

5) Plant Size Considerations commencing on the site for all sites which intend to

handle waste.

a) Storage and MRFs can be built for a wide range

of capacities. The chosen scale will reflect the b) The Working Plan will constitute the

tonnage necessary to meet local waste strategy documentary procedures which will be used to

targets and make the facility profitable within the control all aspects of work on site. Issues to be

conditions of the contract. considered and included within the Working Plan

are outlined below in the following sections.

b) Most Material Reclamation Facilities in this

context will be associated with MBT plant and the

capacities of which may range anywhere from 2) Waste Handling

15,000 tonnes per annum to 500,000 tonnes per

annum.

a) Waste delivered to the facility by waste

transporters must be managed in accordance with

c) The scale of the process must take into account

the requirements in the Waste Classification

the total material throughput of the process.

Standard, the Waste Handling and Storage

Standard and the Waste Regulatory Control and

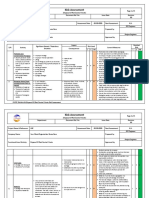

d) The parameters detailed in Table 1 must be

Compliance Standard.

taken into consideration during the design stage of

a storage facility and MRF and in deciding site

b) All labelling must be resilient enough to stay

location and infrastructure requirements.

attached and legible throughout the whole time of

storage at the installation.

Table 1: Storage and Material Reclamation

c) A daily inspection of the condition of containers

Facility Design Parameters

and pallets must be undertaken and written records

kept of these inspections. If a container is found to

be damaged, leaking or in a state of deterioration, it

must immediately be over-drummed or the contents

transferred to another container or processed.

d) Containers must be stored in such a manner that

leaks and spillages could not escape over

bunds/edge of the sealed drainage area.

Kingdom of Saudi Arabia Page 9 of 18

KSA Presidency of Meteorology and Environment PME Reference

place), or (where there is no weighbridge) a volume

e) The operator of the facility must take all or unit estimation will be made, and a record kept

necessary precautions concerning the delivery and detailing the following:

reception of waste in order to prevent or to limit as

far as practicable negative effects on the i) date of removal of each container/skip;

environment, in particular the pollution of air, soil,

surface water and groundwater as well as odours ii) type of waste/product removed;

and noise, and direct risks to human health.

iii) weight of waste/product removed; and

3) Waste Acceptance iv) destination site removed to.

a) Waste will only be accepted at a facility which is

duly authorised to accept that waste in accordance 6) Operations and Maintenance

with the requirements laid out in the .

a) As a minimum, effective operational and

maintenance systems must be employed on all

4) Unacceptable Loads aspects of the site where failure could impact on

the environment. There must be:

a) All operational sites must make provision of an

area suitable for the storage of suspect wastes

i) documented procedures to control

operations that may have an adverse

pending confirmation that they are suitable for

impact on the environment;

acceptance at the facility.

ii) a defined procedure for identifying,

b) Full details of all materials held within the

reviewing and prioritising items of plant

quarantine area must be kept. As a minimum the

for which a preventative maintenance

following records must be held for each and every

regime is appropriate;

load:

iii) documented procedures for monitoring

(i) Date of arrival;

emissions or impacts; and

(ii) Details of the source of the waste and iv) a preventative maintenance programme

the company bringing the waste to the covering all plant, whose failure could

site; lead to impact on the environment.

(iii) A copy of the Waste Tracking Form (see

b) The maintenance system must include auditing

Regulatory Control and Compliance

of performance against requirements arising from

Standard provisions);

the above and reporting the result of audits to

senior management.

(iv) Where relevant, the accompanying

Hazardous Waste Code.

c) All labelling must be resilient enough to stay 7) Competence and Training

attached and legible throughout the whole time of

storage at the installation. a) The Technical Competence and training of

operatives involved in managing storage facilities

d) A daily inspection of the condition of containers and MRFs must be undertaken in accordance with

and pallets must be undertaken and written records the Waste Training and Assessment of Technical

kept of these inspections. If a container is found to Competence of Operators Standard.

be damaged, leaking or in a state of deterioration, it

must immediately be over-drummed or the contents b) Additional training must be provided to all staff

transferred to another container or processed. working within the confines of the treatment facility

with respect to:

e) All spillages of hazardous wastes must be

logged. Where spillages are greater than 200 litres i) health and Safety and the individual

the Competent Agency must be informed. responsibilities that all have for the

safety of others; and

f) Containers must be stored in such a manner that

leaks and spillages could not escape over ii) understanding of the environmental

bunds/edge of the sealed drainage area. impacts that their work could have and

provision of instructions to assist in

reducing these impacts.

5) Waste Despatch

Wastes and process products removed from site

will be weighed at the weighbridge (where one is in

Kingdom of Saudi Arabia Page 10 of 18

KSA Presidency of Meteorology and Environment PME Reference

8) Accident Plans

i) vehicle movements/manoeuvring;

a) An Accident Plan must be put in place by the

Operators (reviewed at least once every three ii) traffic noise on the local road networks;

years, or in the event of an accident) which

identifies: iii) mechanical processing such as waste

preparation;

i) the likelihood and consequence of

accidents; and iv) air extraction fans and ventilation

systems; and

ii) actions to prevent accidents and

mitigate any consequences. v) air cooled condenser units.

b) The Accident Plan will: b) Measures must be taken to minimise the

nuisance arising from the treatment facility in

i) identify the potential on-site accident relation to noise pollution.

hazards;

c) Where noise issues are likely to be relevant, the

ii) provide an assessment of the risks; Operator must provide information on the following:

iii) identify necessary risk management i) the main sources of noise and vibration

measures; that will fall within the installation and

also on infrequent sources of noise and

iv) include contingency actions to be vibration;

undertaken in the event of an accident

to mitigate consequences; and ii) operating timescales of the treatment

facility;

v) make provision for the hazards

displayed by any hazardous wastes iii) the nearest noise-sensitive sites;

accepted at the facility.

iv) conditions/limits imposed under other

regimes;

9) Compliance Reporting

v) the local noise environment;

a) Written procedures must be in place for handling, vi) any environmental noise measurement

investigating, communicating and reporting actual surveys, modelling or any other noise

or potential non-compliance with operating measurements; and

procedures or emission limits.

vii) any specific local issues and proposals

b) There must be written procedures for handling, for improvements.

investigating, communicating and reporting

environmental complaints and implementation of d) Where there are sensitive receptors present, a

appropriate actions. Noise Management Plan must be developed which

provides details on how noise will be managed

c) There must be written procedures for within the site and the measures to be adopted to

investigating incidents, (and near misses) including reduce those noise impacts.

identifying suitable corrective action and follow up.

12) Control of Air-borne Nuisance

10) Site Security

a) Measures must be put in place to minimise the

a) The facility must be secured to prevent free nuisance arising from the facility in relation to:

access to the site.

(i) emissions of dust;

b) The gates of the facility must be locked outside

operating hours. (ii) wind-blown materials; and

c) Access to each facility must be controlled by (iii) the formation of aerosols.

systems to detect and discourage illegal dumping at

the facility.

b) Site operations must have due regard to the

need to control dirt originating from the site being

11) Noise dispersed onto public roads and the surrounding

land.

a) The main contributors to noise associated with

storage facilities and MRFs are likely to be:

Kingdom of Saudi Arabia Page 11 of 18

KSA Presidency of Meteorology and Environment PME Reference

c) All of the potential impacts of a treatment facility f) A regular odour impact assessment must be

must be identified during conceptual model undertaken by the Operator. The impact

development and refined during the Authorisation assessment must cover a range of reasonably

Process. Detailed measures to mitigate the foreseeable odour generation and receptor

impacts must be included in the design of the exposure scenarios and the effect of different

facility and set out in the Working Plan. mitigation options.

d) As a minimum, procedures must be in place to

deal with particulate matter arising from: 14) Control of Pests, Vermin and Birds

i) the placement of wastes;

a) Storage and MRFs are unlikely to attract pests,

vermin and birds due to the majority of waste

ii) traffic on site roads;

throughput and operations being conducted in

enclosed buildings or containers. However, during

iii) site preparation and restoration

hot weather it is possible that flies could

activities;

accumulate, especially if they have been brought in

during delivery of the waste.

iv) surface emissions; and

v) carriage of dust/mud onto the highway. b) Insect infestations commonly arise from waste

which has been awaiting collection for some time.

e) Dust suppression must be provided including the Procedures must be put in place to prevent or limit

availability of bowsers and water supplies. the acceptance of such wastes. The Operator must

reduce the risk of infestation by prompt treatment or

onward removal of such wastes.

13) Odour

c) Where wastes are to be stored outside a building

pending treatment or off site removal, the Operator

a) As one of the most conspicuous potential must provide for adequate measures to deal with

emissions of any putrescible waste receiving or any pest infestation.

treatment facility, odour needs extremely careful

consideration.

15) Litter

b) Operational measures must be put in place to

minimise the nuisance arising from the treatment

plant in relation to emissions of dust and odour a) Any waste which contains plastics and paper is

which may be attributed to the following activities: more likely to lead to litter problems. Litter problems

can be minimised as long as good working

i) delivery of feedstock, which may have practices are adhered to, vehicles use covers and

been stored for long periods, and/or reception and processing are undertaken indoors.

contained in air-tight bags trapping

odour build-up;

16) Control of Leaks and Spillages

ii) feedstock shredding;

a) Where spillages of dry wastes occur, these must

iii) exhaust air from enclosed systems; be cleared by either manual or mechanical means,

for example handpicking, sweeping or shovelling,

iv) anaerobic conditions in decomposing depending on the size and location of the spillage.

putrescible materials;

b) Minor spillages of liquid must be contained using

v) untreated pools of leachate (nutrient-rich spillage kits or any suitable readily available

high organic content liquids produced absorbent material. This material must be disposed

from decomposing materials, and run-off of in a manner appropriate to the type of material

during rainfall); and absorbed.

vi) fresh and partially composted materials c) A record must be maintained in the site diary of

that are left untreated without aeration any spillages so treated.

for periods of time causing anaerobic

decomposition; anaerobic conditions d) In the event of a major spillage the site drains

must therefore be kept to a minimum. must be sealed off where possible and a specialist

contractor brought on site to clear the spillage.

e) Dust and odour emissions must be minimised by

performing all operations under controlled e) The Competent Agency must be informed of any

conditions indoors where practical. Good working major spillage event and a record made in the site

practices and effective management undertaken for diary.

dust suppression from vehicle movements.

Kingdom of Saudi Arabia Page 12 of 18

KSA Presidency of Meteorology and Environment PME Reference

f) Spillage kits and other emergency equipment

must be stored in the appropriate areas of the site. b) A summary of the types and quantities of wastes

The Competent Agency must be informed of the deposited at the site and waste residues removed

location and content of this equipment prior to the from the site must be provided to the Competent

commencement of waste treatment operations at Agency at an agreed frequency and in an agreed

the site. format.

17) Fire Prevention and Control 2) Records of Significant Events

a) All fires on site must be treated as a potential a) The following significant events must be

emergency and dealt with accordingly. Fires may recorded, on site:

occur due to plant failure or combustible material

within stored wastes or process products being i) the start and finish of any construction

ignited (potentially through vandalism). and engineering works undertaken on

site;

b) Small fires may, if possible, be safely brought

under control using fire-fighting equipment present ii) start and finish of waste management

on site. processes carried out on site;

c) In the event of a fire that cannot be easily or iii) maintenance;

safely brought under control then the site Fire

Emergency Procedure will be put into action. This iv) breakdowns;

procedure will be developed with the local Fire

Authority and will be in place prior to any wastes v) emergencies;

being treated at the site.

vi) problems with waste received and

d) Fire fighting equipment of a suitable type shall be action taken;

kept at appropriate locations as advised by the

Company Health and Safety Department and/or the vii) site inspections;

local Fire Authority.

viii) attendance of technically competent

e) The locations of fire fighting equipment and management on site;

materials will be detailed in the Fire Emergency

Plan. ix) despatch of records to the Competent

Agency;

f) All fire fighting equipment must be kept in good

condition, unobstructed and maintained to a x) severe weather conditions;

standard as required by the local Fire Authority.

xi) complaints; and

g) Any fire arising on site must be reported to the

Competent Agency as soon as possible, having xii) pest or vermin incidents.

due regard firstly to any steps necessary to tackle

the fire and its immediate consequences. A record b) The Site Manager or nominated person must

of the occurrence of a fire must also be maintained maintain a record of the above information in the

in the site diary, along with any actions taken. site diary as required.

h) Following approval by the Fire Authority and/or c) The site diary must be kept in the site control

site manager the residues from the fire will be office at all times and made available for inspection

disposed of accordingly at a suitable licensed waste at all reasonable times by any officer of the

management facility. Competent Agency.

i) Any contaminated water arising from fire fighting

within the waste treatment building or bunded areas 3) Format of Records

must be collected and disposed of to an appropriate

facility.

a) The terms Record, Log Book and Site Diary may

be kept as, but not limited to:

Part VII – Record Keeping

i) hand generated log;

1) Waste Movement Records ii) computer generated hard copies;

a) A record of the types and quantities (in tonnes) iii) floppy Disc;

of wastes received at the site, and wastes/process

products removed from the site must be maintained iv) on an unalterable disk or similar format.

and kept in the site office.

Kingdom of Saudi Arabia Page 13 of 18

KSA Presidency of Meteorology and Environment PME Reference

4) Security of Records

a) To ensure the security of records they must be

housed in either locked containers or kept in offices

that shall be locked when not attended.

5) Archiving of Records

a) Copies of all records relating to wastes

movements and product sales must be kept by the

Site Manager for at least 2 years, before archiving.

Kingdom of Saudi Arabia Page 14 of 18

KSA Presidency of Meteorology and Environment PME Reference

Appendix A

Pre-Design Report Requirements for Authorisation

The report must describe the design parameters of the (xii) Detailed plans, specifications and

Storage and Material Reclamation Facility site and must descriptions of the contaminant attenuation

contain as a minimum details of the following: zone, if one is necessary

(xiii) Details of any facilities intended to control or

(i) Legal details for ownership of the site change the contaminating life span of the

(ii) An up to date plan and description of the site site

and the area within 500 metres of the site (xiv) A summary of the main characteristics of the

that covers: site, including the maximum daily quantity of

a. all property and property boundaries waste that will be accepted, the estimated

b. all buildings, roads and utility corridors annual average quantity of waste that will be

c. land contours, surface water drainage, accepted, the working area of the site, the

water bodies, rights-of-way and other total waste receiving volume, the estimated

easements, waste receiving and reclamation capacity in

d. forested areas, tonnes, any subcategories of waste that are

e. land uses and land use designations, not expected to be received or that will not

and be accepted for disposal, and the estimated

f. property conditions not otherwise date of site closure.

covered in subclauses (a) to (e)

(iii) Details of the total waste volume acceptable

at any one time

(iv) A full hydrogeological assessment of the

suitability of the site for the keeping of

municipal waste or other waste that

considers the geologic and hydrogeologic

conditions of the site, the design of the site

and the monitoring and contingency plans

(v) A full geotechnical assessment of the

suitability of the site for the storage of

municipal waste or other waste

(vi) A detailed assessment of the potential

impacts on surface water features that may

be caused by the site or operations at the

site

(vii) Detailed plans, specifications and

descriptions of the system for collecting,

directing and discharging surface water,

including details of any sediment control or

other features and including construction,

quality assurance and quality control

procedures for the system components and

system installation

(viii) Detailed plans, specifications and

descriptions of monitoring facilities for

leachate, ground water, and surface water

(ix) An assessment of potential noise impacts

due to operations at the site and to local

trucking related to operations at the site,

including an evaluation of any proposed

noise control measures

(x) An assessment of potential visual impacts on

nearby properties due to the site and site

operations

(xi) Detailed plans, specifications and

descriptions of the buffer area and ancillary

facilities, including any screening,

landscaping, fencing, weigh scales,

buildings, structures, access roads, internal

roads, holding areas for rejected waste or

materials for recycling, and other holding

areas

Kingdom of Saudi Arabia Page 15 of 18

KSA Presidency of Meteorology and Environment PME Reference

Appendix B

Environmental Assessment Requirements

An environmental assessment of the site proposed for

c. stormwater diversion banks and/or cut-

waste storage or reclamation is required to gain a

off drains and storage dams

thorough understanding of the existing environment at the

d. fire-fighting equipment and water supply

site in order to develop a sound facility design. This

e. wheel washes.

assessment must examine the impact of the proposed

facility on the air, groundwater, surface water and noise

environments, and should be based on at least two to

three years of data.

If, following an environmental assessment, the site is

identified as unsuitable for a waste facility, the proposal

must not proceed any further. For the purposes of siting a

waste management facility, an environmental assessment

would contain:

(i) Meteorological data, including monthly

rainfall, monthly evaporation, seasonal wind

strength and direction

(ii) Hydrogeological assessment in accordance

with EPA Publication Hydrogeological

Assessments (Groundwater Quality), which

includes:

a. local and regional geology

b. spatial distribution of groundwater (local

and regional if watertable is artificially

depressed)

c. depth to groundwater (current and after

any rebound if the watertable is

artificially depressed) and watertable

elevation (mAHD)

d. groundwater gradient and flow direction

e. description of groundwater interaction

with

f. local surface waters

g. aquifer physical properties:

i. permeability

ii. aquifer thickness

iii. saturated thickness

iv. porosity.

h. aquifer chemical properties:

i. mineralogy

ii. cation exchange and sorption

capacity.

i. groundwater quality (local and regional if

aquifer is likely to have been impacted

on by previous activities)

j. beneficial uses of groundwater to be

protected

k. groundwater use in the surrounding

area

l. predicted extent and degree of impacts

on groundwater quality during and after

the operation

m. verification that beneficial uses are not

adversely impacted at the site, or at the

boundary of an attenuation zone where

designated.

(iii) Water Management, including:

a. water balance for the site and estimated

volume of leachate to be generated

b. leachate collection, storage facilities,

treatment and disposal

Kingdom of Saudi Arabia Page 16 of 18

KSA Presidency of Meteorology and Environment PME Reference

Appendix C

Sample Weight to Volume Conversion Factors for Recyclables

Material Volume Mass (in Kilograms)

Newsprint, loose One cubic metre 160 to 360

Newsprint, compacted One cubic metre 330 to 450

Glass, whole bottles One cubic metre 270 to 450

Glass, semi-crushed One cubic metre 450 to 820

Glass, fully crushed One cubic metre 360 to 1220

PET Bottles, whole, loose One cubic metre 14 to 18

PET Bottles, baled One cubic metre 27 to 36

HDPE Bottles, whole, loose One cubic metre 11

HDPE Bottles, baled One cubic metre 30

Mixed Plastic Bottles, loose One cubic metre 14

Aluminium Cans, whole One cubic metre 23 to 34

Aluminium Cans, flattened One cubic metre 115

Ferrous Cans, whole One cubic metre 68

Ferrous Cans, flattened One cubic metre 390

Wood Chips One cubic metre 230

Grass Clippings One cubic metre 180 to 680

Used Motor Oil One Gallon 3

Post-consumer Tyre, Car One (number) 5.5

Tyre, Truck One (number) 27

Food waste, solid and liquid fats 55 Gallon Drum 180

Municipal Solid Waste, One cubic metre 90

uncompacted

Municipal Solid Waste, truck One cubic metre 340

compacted

Commercial and Industrial Waste, One cubic metre 200

uncompacted

Kingdom of Saudi Arabia Page 17 of 18

S-ar putea să vă placă și

- Hazardous Waste Management1Document38 paginiHazardous Waste Management1Ibrahim Azam IbrahimÎncă nu există evaluări

- Royal Commission Public Health Code 2005 overviewDocument188 paginiRoyal Commission Public Health Code 2005 overviewRoy Cicero ManalotoÎncă nu există evaluări

- Cipero & Guaracara River Water Quality Site VisitsDocument76 paginiCipero & Guaracara River Water Quality Site VisitsBrandon Atwell79% (29)

- CESMPDocument338 paginiCESMPAsim ZiaÎncă nu există evaluări

- AsbestosDocument4 paginiAsbestoskoketsoÎncă nu există evaluări

- Erosion and Sediment Control Plan PDFDocument2 paginiErosion and Sediment Control Plan PDFDanielÎncă nu există evaluări

- RA - 9 - For Slab On Grade ConstructionDocument23 paginiRA - 9 - For Slab On Grade ConstructionIbrahim EsmatÎncă nu există evaluări

- Answers 19521Document845 paginiAnswers 19521docerick87Încă nu există evaluări

- Flood Mitigation PlanningDocument14 paginiFlood Mitigation PlanningJingÎncă nu există evaluări

- QHSE Plan - Construction Phase: Client: ProjectDocument83 paginiQHSE Plan - Construction Phase: Client: ProjectEdoÎncă nu există evaluări

- MANAGEMENT OF TEMP WORKSDocument14 paginiMANAGEMENT OF TEMP WORKSezzularab100% (1)

- En EnvStand15 Waste TransportationDocument19 paginiEn EnvStand15 Waste TransportationWellfro100% (1)

- Abu Dhabi Parking StandardsDocument2 paginiAbu Dhabi Parking StandardsAshimolowo Babatunde0% (1)

- En EnvStand16 Landfill-Design & OperationDocument27 paginiEn EnvStand16 Landfill-Design & OperationWellfroÎncă nu există evaluări

- Safety Interview Study Guide Updated VersionDocument24 paginiSafety Interview Study Guide Updated VersionakasalihseÎncă nu există evaluări

- En EnvStand19 Ambient Air QualityDocument6 paginiEn EnvStand19 Ambient Air QualityWellfroÎncă nu există evaluări

- Snake Control 101: The Basics of Keeping Snakes AwayDocument8 paginiSnake Control 101: The Basics of Keeping Snakes AwaynayakyaÎncă nu există evaluări

- Week 1 Day 1Document2 paginiWeek 1 Day 1arens100% (1)

- Abu Dhabi - Waste Water DisposalDocument122 paginiAbu Dhabi - Waste Water Disposalchemserv100% (1)

- HIRA Cage Ladder InstallationDocument9 paginiHIRA Cage Ladder InstallationR. Ayyanuperumal AyyanuperumalÎncă nu există evaluări

- Principles of Health AdminDocument42 paginiPrinciples of Health AdminAnne BattulayanÎncă nu există evaluări

- En - EnvStand12 - Waste Regulatory Control and ComplianceDocument22 paginiEn - EnvStand12 - Waste Regulatory Control and ComplianceWellfroÎncă nu există evaluări

- En EnvStand8 Waste Acceptance CriteriaDocument14 paginiEn EnvStand8 Waste Acceptance CriteriaWellfroÎncă nu există evaluări

- Risk Management: Construction ProjectsDocument33 paginiRisk Management: Construction ProjectsvenkaatramÎncă nu există evaluări

- GoodHousekeepingPractices HazardousWasteManagementDocument4 paginiGoodHousekeepingPractices HazardousWasteManagementNuragus Hariyadi100% (1)

- Native Plants Landscaping SummitDocument30 paginiNative Plants Landscaping SummitelmerbarrerasÎncă nu există evaluări

- Diuretics MOA, Examples, Effects, and Nursing ConsiderationsDocument1 paginăDiuretics MOA, Examples, Effects, and Nursing ConsiderationsGrace ButlerÎncă nu există evaluări

- Construction Air Quality Management Plan: (Type Project Name)Document21 paginiConstruction Air Quality Management Plan: (Type Project Name)Calvien MaitÎncă nu există evaluări

- Disposal of Pest Control Waste Risk AssessmentDocument5 paginiDisposal of Pest Control Waste Risk AssessmentLawrence adeleke Omisakin100% (1)

- 6-National Environmental Standards-Best Practicable Environmental Option For Waste Disposal PDFDocument19 pagini6-National Environmental Standards-Best Practicable Environmental Option For Waste Disposal PDFfedericoÎncă nu există evaluări

- Health Safety Dignity of Sanitation WorkersDocument61 paginiHealth Safety Dignity of Sanitation WorkersWallpe iithÎncă nu există evaluări

- Environmental Impact Assessment Study For A Development Touristic ProjectDocument20 paginiEnvironmental Impact Assessment Study For A Development Touristic ProjectnoveÎncă nu există evaluări

- Inspection Checklist For Concrete Pump: Name of Site: Id NoDocument2 paginiInspection Checklist For Concrete Pump: Name of Site: Id NoJithin M Krishna EzhuthachanÎncă nu există evaluări

- Emergency PLANDocument20 paginiEmergency PLANShariq AhmedÎncă nu există evaluări

- PMF-007-INT-001 - 02 Project Management PlanDocument56 paginiPMF-007-INT-001 - 02 Project Management PlanEng hassan hussienÎncă nu există evaluări

- Landscaping works specificationDocument4 paginiLandscaping works specificationkatepol8264Încă nu există evaluări

- KSA Environmental Guidance on Material Recovery and RecyclingDocument13 paginiKSA Environmental Guidance on Material Recovery and RecyclingBabu Veeraraghavan100% (1)

- 10-National Environmental Standards-Landfill - Design and Operation PDFDocument27 pagini10-National Environmental Standards-Landfill - Design and Operation PDFfedericoÎncă nu există evaluări

- P-LUS-OCEMP-000: Overall Construction Environment Management PlanDocument158 paginiP-LUS-OCEMP-000: Overall Construction Environment Management PlanRafzeena100% (1)

- CPT Environmental PresentationDocument108 paginiCPT Environmental PresentationJason LingÎncă nu există evaluări

- 02 Vetonit Masonry Mortar - Group 180821Document2 pagini02 Vetonit Masonry Mortar - Group 180821Maha MuflehÎncă nu există evaluări

- 7-National Environmental Standards-Biological Treatment - Design and OperationDocument18 pagini7-National Environmental Standards-Biological Treatment - Design and OperationfedericoÎncă nu există evaluări

- National Water Co manual handling guideDocument14 paginiNational Water Co manual handling guidemerinofalÎncă nu există evaluări

- KSA Environmental Standards for Biological TreatmentDocument18 paginiKSA Environmental Standards for Biological TreatmentWellfroÎncă nu există evaluări

- En - EnvStand5 - Prevention of Major AccidentsDocument15 paginiEn - EnvStand5 - Prevention of Major AccidentsWellfroÎncă nu există evaluări

- Saudi Wastewater Reuse Standards For AgriculturalDocument8 paginiSaudi Wastewater Reuse Standards For AgriculturalShamma DamaniÎncă nu există evaluări

- 3 LT Credit 2 Sensitive Land Protection HandoutDocument2 pagini3 LT Credit 2 Sensitive Land Protection HandoutAnkit SinghaiÎncă nu există evaluări

- Install HVAC Duct SystemDocument16 paginiInstall HVAC Duct SystemLouis ClarkÎncă nu există evaluări

- CEMP Audit ChecklistDocument6 paginiCEMP Audit ChecklistNash C. UsopÎncă nu există evaluări

- Construction Procedure Concrete Form WorkDocument12 paginiConstruction Procedure Concrete Form WorkDimas DzununÎncă nu există evaluări

- Demolition Work Audit Checklist: Los Angeles Community College DistrictDocument6 paginiDemolition Work Audit Checklist: Los Angeles Community College DistrictJaycee PagadorÎncă nu există evaluări

- 8.0 - General Workplace Amenities v3.1 EnglishDocument14 pagini8.0 - General Workplace Amenities v3.1 EnglishjbdejhiuhwÎncă nu există evaluări

- LEED For New Construction and Major Renovations (v4) : Location & TransportationDocument1 paginăLEED For New Construction and Major Renovations (v4) : Location & TransportationAnupama ChettyÎncă nu există evaluări

- Excavation and LiftingDocument4 paginiExcavation and LiftingRapha RachoÎncă nu există evaluări

- 1.1 Buildings and FloorsDocument4 pagini1.1 Buildings and FloorsMohamed Mouner100% (1)

- Standard Construction Specs for Roads and Pavement MarkingsDocument3 paginiStandard Construction Specs for Roads and Pavement MarkingsRolando de GuzmanÎncă nu există evaluări

- Environmental Impact Matrix AnalysisDocument15 paginiEnvironmental Impact Matrix AnalysisdebryaniÎncă nu există evaluări

- Construction Phase Plan Church Field Primary SchoolDocument72 paginiConstruction Phase Plan Church Field Primary SchoolGregor SchwarbÎncă nu există evaluări

- AtkinsDocument20 paginiAtkinssyedatifmalikÎncă nu există evaluări

- Apmr Series: Packaged Air ConditionersDocument32 paginiApmr Series: Packaged Air ConditionersOmair FarooqÎncă nu există evaluări

- Social Management PlanDocument46 paginiSocial Management PlanNilamSanjeev Kumar SinghÎncă nu există evaluări

- En EnvStand20 Ambient Water QualityDocument13 paginiEn EnvStand20 Ambient Water QualityWellfroÎncă nu există evaluări

- Waste - Waste Transportaion PDFDocument19 paginiWaste - Waste Transportaion PDFR. P. SinghÎncă nu există evaluări

- Republic Act No. 9003 Ecological Solid Waste Management ActDocument50 paginiRepublic Act No. 9003 Ecological Solid Waste Management ActEchoÎncă nu există evaluări

- BU3-ENV-SOP-010 (01) Waste ManagementDocument25 paginiBU3-ENV-SOP-010 (01) Waste ManagementJoel Osteen RondonuwuÎncă nu există evaluări

- Environment Economic Survey (Industry) 2017 HighlightsDocument61 paginiEnvironment Economic Survey (Industry) 2017 HighlightsfedericoÎncă nu există evaluări

- Claims Management ProcedureDocument28 paginiClaims Management ProcedurefedericoÎncă nu există evaluări

- Comprehensive Waste Management Strategy For ArRiyadh City PDFDocument40 paginiComprehensive Waste Management Strategy For ArRiyadh City PDFfedericoÎncă nu există evaluări

- Sustainable Development Goals Sdgs in Ksa - enDocument145 paginiSustainable Development Goals Sdgs in Ksa - enfedericoÎncă nu există evaluări

- Riyadh Unveils New Waste Management and Recycling Plan: July 14, 2019Document3 paginiRiyadh Unveils New Waste Management and Recycling Plan: July 14, 2019federicoÎncă nu există evaluări

- Sample - First Aid ProcedureDocument16 paginiSample - First Aid ProcedurefedericoÎncă nu există evaluări

- Comprehensive Waste Management Strategy For ArRiyadh City PDFDocument40 paginiComprehensive Waste Management Strategy For ArRiyadh City PDFfedericoÎncă nu există evaluări

- Sample - First Aid ProcedureDocument16 paginiSample - First Aid ProcedurefedericoÎncă nu există evaluări

- 5-National Environmental Standards-Ambient Water Quality PDFDocument13 pagini5-National Environmental Standards-Ambient Water Quality PDFfedericoÎncă nu există evaluări

- 5-National Environmental Standards-Ambient Water Quality PDFDocument13 pagini5-National Environmental Standards-Ambient Water Quality PDFfedericoÎncă nu există evaluări

- The State of The Environment 2017Document53 paginiThe State of The Environment 2017Pacha_2010Încă nu există evaluări

- Q&A2Document3 paginiQ&A2Marv MarvÎncă nu există evaluări

- Macronutrients ProteinsDocument2 paginiMacronutrients ProteinsEllice O. MonizÎncă nu există evaluări

- Reflective Essay: Writing in The Genetics DiscourseDocument5 paginiReflective Essay: Writing in The Genetics DiscourseAnonymous AY6XDZHBxPÎncă nu există evaluări

- Summary Water Treatment PlantDocument4 paginiSummary Water Treatment PlantDalil Nur FarahaniÎncă nu există evaluări

- Mapeh 10 2nd PrelimsDocument4 paginiMapeh 10 2nd PrelimsBlaize PascualÎncă nu există evaluări

- Bio SaftyDocument7 paginiBio Saftyapi-283956320Încă nu există evaluări

- Confirmation 1068409Document3 paginiConfirmation 1068409ankiosaÎncă nu există evaluări

- ORA.007 Pharmaceutical Microbiology ManualDocument92 paginiORA.007 Pharmaceutical Microbiology ManualNindyÎncă nu există evaluări

- Test 4Document4 paginiTest 4Hiếu Nguyễn HữuÎncă nu există evaluări

- Assisted SuicideDocument30 paginiAssisted SuicideAlex Mini AndraÎncă nu există evaluări

- Mdbsis09 CA A III 2017Document4 paginiMdbsis09 CA A III 2017Guneyden GuneydenÎncă nu există evaluări

- Colegio de San Gabriel Arcangel, Inc.: READING REPORT in - Complementary and Alternative MedicineDocument2 paginiColegio de San Gabriel Arcangel, Inc.: READING REPORT in - Complementary and Alternative MedicineJonille EchevarriaÎncă nu există evaluări

- High Yield Surgery Compatible VersionDocument77 paginiHigh Yield Surgery Compatible Version17kimpÎncă nu există evaluări

- Trends, issues, and magnitude of psychiatric nursingDocument4 paginiTrends, issues, and magnitude of psychiatric nursingsona0% (1)

- CyberneticsDocument3 paginiCyberneticsTanya ChawdaÎncă nu există evaluări

- 31.ergonomic Approach of Modification of Seat - EncDocument11 pagini31.ergonomic Approach of Modification of Seat - EncSHASHANK ROHITÎncă nu există evaluări

- Ar-Afff 3 MSDS LCFDocument5 paginiAr-Afff 3 MSDS LCFMark YeÎncă nu există evaluări

- SASO 1431 (GS 1355) SorbitolDocument5 paginiSASO 1431 (GS 1355) SorbitolakÎncă nu există evaluări

- What Are The Advantages and Disadvantages of Using Coal To Generate ElectricityDocument6 paginiWhat Are The Advantages and Disadvantages of Using Coal To Generate ElectricityArchie CuyacotÎncă nu există evaluări

- Marijuana Fact SheetDocument1 paginăMarijuana Fact Sheetapi-355176759Încă nu există evaluări

- Wound HealingDocument44 paginiWound HealingSorin Niky MocanuÎncă nu există evaluări

- Administering Blood Transfusion GuideDocument1 paginăAdministering Blood Transfusion GuideKyla ManarangÎncă nu există evaluări

- Clinical Profile of Hoarseness of Voice: A Hospital-Based Cross-Sectional StudyDocument5 paginiClinical Profile of Hoarseness of Voice: A Hospital-Based Cross-Sectional Studynurul atika havizÎncă nu există evaluări

- Serial number verification formDocument1 paginăSerial number verification formArjelyÎncă nu există evaluări

- IlpDocument13 paginiIlpapi-253729868Încă nu există evaluări