Documente Academic

Documente Profesional

Documente Cultură

Austempered Ductile Iron Castings: Standard Specification For

Încărcat de

Raja HoneTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Austempered Ductile Iron Castings: Standard Specification For

Încărcat de

Raja HoneDrepturi de autor:

Formate disponibile

Designation: A897/A897M − 06 (Reapproved 2011)

Standard Specification for

Austempered Ductile Iron Castings1

This standard is issued under the fixed designation A897/A897M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A370 Test Methods and Definitions for Mechanical Testing

1.1 This specification covers ductile iron castings that are of Steel Products

subsequently heat treated by an austempering process as A732/A732M Specification for Castings, Investment, Car-

defined in 10.1. bon and Low Alloy Steel for General Application, and

Cobalt Alloy for High Strength at Elevated Temperatures

1.2 The application of the austempering heat treatment A834 Specification for Common Requirements for Iron

extends the range of properties achievable in ductile iron Castings for General Industrial Use

castings. E8 Test Methods for Tension Testing of Metallic Materials

1.3 No precise quantitative relationship can be stated be- E10 Test Method for Brinell Hardness of Metallic Materials

tween the properties of the iron in various locations of the same E23 Test Methods for Notched Bar Impact Testing of Me-

casting or between the properties of castings and those of a test tallic Materials

specimen cast from the same iron (see Appendix X1). How- 2.2 Military Standard:

ever, austempering heat treatment will tend to diminish any MIL-STD-129 Military Marking for Shipment and Storage3

differences in mechanical properties.

1.4 The production of castings, machining (if required), and 3. Ordering Information

the austempering heat treatments may be performed by differ-

3.1 Orders for material to this specification shall include the

ent manufacturers, as covered in Section 15. The purchaser

following information:

should establish by contract agreement, at the time of ordering,

the responsibility of the various parties for meeting the 3.1.1 ASTM designation, with year of issue,

specification requirements. 3.1.2 Grade of austempered ductile iron required (see Table

1 and Sections 6 and 7),

1.5 The values stated in either SI units or inch-pound units

3.1.3 Chemical composition requirements, if any (see Sec-

are to be regarded separately as standard. The values stated in

tion 4),

each system may not be exact equivalents; therefore, each

3.1.4 Heat treated microstructure restrictions (see Section

system shall be used independently of the other. Combining

10),

values from the two systems may result in non-conformance

with the standard. 3.1.5 Test coupon criteria (see Section 12),

1.5.1 Exception—Within the text, the SI units are shown in 3.1.6 Lot size and tests per lot (see 12.6 and Section 15),

brackets. 3.1.7 Special requirements, if desired, including hardness,

radiographic soundness, magnetic particle inspection, pressure

2. Referenced Documents tightness, dimensions, or surface finish (see Section 9),

2.1 ASTM Standards:2 3.1.8 Certification, if required (see Section 16),

A247 Test Method for Evaluating the Microstructure of 3.1.9 Special preparation for delivery, if required (see Sec-

Graphite in Iron Castings tion 17).

4. Chemical Composition

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron 4.1 Although this specification has no specific chemical

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and requirements, such requirements may be agreed upon between

Ductile Iron Castings.

Current edition approved Nov. 1, 2011. Published April 2012. Originally the manufacturer, heat treater, and the purchaser.

approved in 1990. Last previous edition approved in 2006 as A897/A897M - 06.

DOI: 10.1520/A0897_A0897M-06R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A897/A897M − 06 (2011)

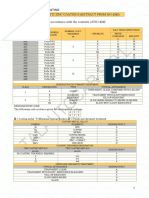

TABLE 1 Mechanical Property Requirements of Grades

Inch-pound units Grade Grade Grade Grade Grade Grade

110/70/11 130/90/09 150/110/07 175/125/04 200/155/02 230/185/01

Tensile strength, min, ksi 110 130 150 175 200 230

Yield strength, min, ksi 70 90 110 125 155 185

Elongation in 2 in., min, % 11 9 7 4 2 1

Impact energy, ft-lbA 80 75 60 45 25 15

Typical hardness, HBW, kg/mm2B 241–302 269–341 302–375 341–444 388–477 402–512

A

Unnotched charpy bars tested at 72 ± 7°F. The values in the table are a minimum for the average of the highest three test values of the four tested samples.

B

Hardness is not mandatory and is shown for information only.

SI units Grade Grade Grade Grade Grade Grade

750/500/11 900/650/09 1050/750/07 1200/850/04 1400/1100/02 1600/1300/01

Tensile strength, min, MPa 750 900 1050 1200 1400 1600

Yield strength, min, MPa 500 650 750 850 1100 1300

Elongation in 50 mm, min, % 11 9 7 4 2 1

Impact energy, JA 110 100 80 60 35 20

Typical hardness, HBW, kg/mm2B 241–302 269–341 302–375 341–444 388–477 402–512

A

Unnotched charpy bars tested at 22 ± 4°C. The values in the table are a minimum for the average of the highest three test values of the four tested samples.

B

Hardness is not mandatory and is shown for information only.

5. Microstructure 7. Impact Requirements

5.1 The graphite component of the microstructure shall 7.1 The iron represented by the test specimens shall con-

consist of a minimum 80 % spheroidal graphite conforming to form to the impact properties presented in Table 1.

Types I and II per Test Method A247. 7.2 Impact energy requirements apply only after test mate-

5.2 The matrix microstructure shall substantially consist of rial has been austempered. The impact test specimens must be

ausferrite (acicular ferrite and high carbon, stable austenite). finish ground to required dimensions after heat treatment.

Proeutectoid ferrite will also be present in Grade 110/70/11

[750/500/11]. 8. Hardness

5.3 The cooling rate within some sections may not be 8.1 The area or areas on the castings where hardness is to be

sufficient to avoid the formation of pearlite or other high checked shall be established by agreement between the manu-

temperature transformation products. In some cases, the maxi- facturer and purchaser, or the manufacturer and the end user.

mum acceptable quantities of these microconstituents and the 8.2 Brinell hardness shall be determined according to Test

location(s) within the casting may be established by agreement Method E10 after sufficient material has been removed from

between the manufacturer, heat treater, and the purchaser. the casting surface to insure representative hardness readings.

5.4 Martensite may be present in minor amounts in the The 10 mm ball and 3000 kg load shall be used unless

microstructures of Grades 200/155/02 [1400/1100/02] and otherwise specified and agreed upon.

230/185/01 [1600/1300/01]. Acceptable quantities of marten-

site may be established by agreement between the manufac- 9. Special Requirements

turer, heat treater, and the purchaser. 9.1 When specified in the contract or purchase order,

5.5 The microstructure shall be substantially free of unde- castings shall meet special requirements as to hardness, chemi-

sirable microconstituents, the details of which shall be agreed cal composition, microstructure, pressure tightness, radio-

upon by the manufacturer, heat treater, and the purchaser. graphic soundness, magnetic particle inspection, dimensions,

and surface finish. Refer to Specification A834 for a list of

5.6 The manufacturer, heat treater, and the purchaser may common requirements for iron castings not specifically refer-

agree upon special chemical compositions or processing re- enced elsewhere in this specification.

quirements to limit the microconstituents described in 5.3, 5.4,

and 5.5. 9.2 When specified in the contract or purchase order,

castings shall meet special requirements prior to the austem-

6. Mechanical Properties pering heat treatment operation.

6.1 Tensile property requirements include tensile strength, 10. Heat Treatment

yield strength, and elongation and apply only after austemper-

ing heat treatment. 10.1 Castings produced in accordance with this specifica-

tion shall be heat treated by an austempering process consisting

6.2 The iron represented by the test specimens shall con- of heating the castings to a fully austenitic, homogeneous

form to the requirements as presented in Table 1. condition or an austenite/ferrite condition for Grade 110/70/11

6.3 The yield strength shall be determined by the 0.2 % [750/500/11], cooling (at a rate usually sufficient to avoid the

offset method (see Test Methods E8). formation of pearlite) to a temperature above the martensite

Copyright by ASTM Int'l (all rights reserved); 2

A897/A897M − 06 (2011)

start temperature, and isothermally transforming the matrix

structure for a time sufficient to produce the desired properties.

This process shall produce a microstructure that is substantially

ausferrite or ausferrite/proeutectoid ferrite for Grade 110/70/11

[750/500/11].

10.2 Upon agreement between the manufacturer and the

purchaser, tension test specimens described in Section 13 may

be machined prior to the austempering heat treatment. In this

case, heat treatment shall be performed in an inert or carbon

controlled environment so as to prevent carburization, decar-

burization, or scaling. Handling and fixturing must be such as

to prevent test bar distortion (see X1.4). “Y” Block Size

For Castings of For Castings of For Castings of

10.3 Re-austempering of castings or any deviation from the Thickness Less Thickness 1⁄2 Thickness of 11⁄2

Dimensions

established heat treating process is only permissable with the Than 1⁄2 in. to 11⁄2 in. [13 to 38 in. [38 mm]

approval of the casting purchaser. [13 mm] mm] and Over

in. [mm] in. [mm] in. [mm]

11. Workmanship, Finish, and Appearance A ⁄ [13]

12 1 [25] 3 [75]

B 15⁄8 [40] 21⁄8 [55] 5 [125]

11.1 The surfaces of castings shall be clean and free of C 2 [50] 3 [75] 4 [100]

adhering molding material, heat treatment oils or salts, cracks, D 4 [100] 6 [150] 8 [200]

E 7 [175] 7 [175] 7 [175]

hot tears, or other injurious defects such as slag and surface approx approx approx

porosity. Dimensions shall conform to drawings or patterns F 9⁄16 [14] 1 1⁄16 [27] 3 1⁄16 [78]

supplied by the purchaser. G 7 1⁄8 [180] 7 1⁄8 [180] 7 1⁄8 [180]

approx approx approx

11.2 Castings shall not have chilled corners or center chill in

areas to be machined. FIG. 2 Y-Blocks for Test Coupons

11.3 Welding repair is not acceptable on austempered cast-

ings. core sand having a minimum wall thickness of 11⁄2 in. [38-mm]

for the 1⁄2 -in. [13-mm] and 1-in. [25-mm] sizes and 3 in.

12. Test Coupons

[76-mm] for the 3-in. [76-mm] size. The coupons shall be left

12.1 Separately cast test coupons from which the tension in the mold until they have cooled to a black color (900°F

test and Charpy test specimens are machined shall be cast to [480°C] or less). The size and type of coupon cast to represent

the size and shape shown in Fig. 1 or Fig. 2. A modified keel the casting shall be at the option of the purchaser. In case no

block cast from the mold shown in Fig. 3 may be substituted option is expressed, the manufacturer shall make the choice.

for the 1-in. [25-mm] Y-block or the 1-in. [25-mm] keel block.

12.2 When investment castings are made in accordance with

The test coupons shall be cast in open molds made of suitable

this specification, the manufacturer may use cast-to-size test

specimens that are either incorporated in the mold with the

castings or separately cast using the same type of mold and the

same thermal conditions that are used to produce the castings.

The test specimens shall be made to the dimensions shown in

Fig. 1 of Specification A732/A732M or Fig. 5 of Test Methods

and Definitions A370. The exact procedure to be used for

producing test specimens shall be agreed upon by the manu-

facturer and the purchaser.

12.3 When castings made in accordance with this specifi-

cation are produced by nodularization directly in the mold, the

manufacturer may use either separately cast test coupons or test

specimens cut from castings. If test bars are to be cut from

castings, test bar location shall be agreed upon by the purchaser

and the manufacturer and indicated on the casting drawing.

When separately cast test coupons are used, selection shall be

as outlined in 12.1 and shown in Figs. 1-6. Appendix X2

provides guidelines for selection of coupons with mold cooling

rates representative of various casting sections.

12.4 Test coupons shall be poured from the same ladle or

heat as the castings they represent and, unless otherwise agreed

upon by the manufacturer and the purchaser, shall be subject to

FIG. 1 Keel Block for Test Coupons the same post inoculation and alloying practice.

Copyright by ASTM Int'l (all rights reserved); 3

A897/A897M − 06 (2011)

FIG. 3 Mold for Modified Keel Block

12.5 Test coupons shall be heat treated with the castings Positions A (preferred) or B in Fig. 4. The test bars may be

they represent. machined before or after heat treatment in accordance with

12.6 The number of test coupons and the number of tests 10.2.

required per order or lot size shall be established at the time of 14. Impact Test Specimens

ordering. This agreement should include a definition of lot size.

14.1 The unnotched Charpy impact strength shall be deter-

Lot size can be defined to include the entire order, a specified

mined according to Test Methods E23 with the following

portion of that order, a specified manufacturing production

variations: Specimens are to be prepared unnotched to dimen-

period, or a specified quantity of parts shipped to the purchaser.

sions in Fig. 9 of Test Methods E23. Blanks from which test

12.7 If any test specimen shows obvious defects, another specimens are machined shall be cut only from Positions A or

may be cut from the same test block or from another test block B in Fig. 4. Test temperature shall be 72 6 7°F [22 6 4°C].

representing the same metal. Positions other than “A” or “B” in Four specimens shall be tested, with the lowest impact energy

Fig. 4 shall not be used. In those cases where removal of test value discarded and the remaining three values averaged. The

bars from actual castings has been agreed upon (see 12.2 and average impact energy shall meet the requirement of Table 1.

12.3), a second test bar may be obtained from an alternate

location of equivalent section or from a second casting 15. Responsibility for Quality and Inspection

processed in the same lot. 15.1 At the time of an order, the purchaser should establish

an agreement for quality and inspection requirements with the

13. Tension Test Specimens manufacturers. The form of this agreement depends upon

13.1 The standard round tension test specimen with a 2-in. which of the conditions in 15.2 or 15.3 are determined to exist.

[50-mm] gage length shown in Fig. 5 shall be used, except 15.2 If all manufacturing operations are performed by a

when the 1⁄2-in. [13-mm] Y-block coupon is used. In this case, single manufacturer, that manufacturer is responsible for per-

either of the test specimens shown in Fig. 6 shall be satisfac- formance of all quality and inspection requirements covered

tory. Tension test specimens shall be machined only from herein.

Copyright by ASTM Int'l (all rights reserved); 4

A897/A897M − 06 (2011)

FIG. 4 Sectioning Procedure for Y-Blocks

FIG. 5 Standard Round Tension Test Specimen with 2-in. [50-mm] Gage Length

15.3 If, at the time of ordering, the purchaser determines 15.4 To avoid future disputes, the purchaser can require that

that more than one manufacturer will contribute to the casting, all companies in the manufacturing chain be identified.

machining, and heat treatment operations, in any sequential Changes shall not be made without approval of the purchaser.

fashion, an agreement should be negotiated that defines and The manufacturer(s) may require the purchaser to provide

assigns individual responsibility for each specific quality and written agreement for any changes mutually agreed upon.

inspection requirement. This does not prevent an agreement

wherein any one manufacturer in the chain of sequential 15.5 Unless specified to the contrary by the purchaser, any

operations can agree to assume full responsibility for all quality of the manufacturers in the chain may use his or her own or any

and inspection requirements. other facilities for performance of the inspection requirements.

Copyright by ASTM Int'l (all rights reserved); 5

A897/A897M − 06 (2011)

Responsibility for meeting the specified properties remains

with the parties defined in 15.2 or 15.3. This shall not prevent

the purchaser from also performing any or all of the quality and

inspection requirements.

16. Certification

16.1 Where required by contract, the manufacturer’s certi-

fication shall be furnished to the purchaser stating that the

material was manufactured, sampled, tested, and inspected in

accordance with the material specification and was found to

meet the requirements. The certification shall include the

results of all tests performed.

17. Preparation for Delivery

17.1 Unless otherwise specified in the contract or purchase

order, cleaning, drying, preservation, and packaging of castings

shall be in accordance with the manufacturer’s commercial

practice. Packaging and marking shall be adequate to ensure

safe delivery by the carrier.

17.2 Government Procurement—When specified in the con-

tract or purchase order, marking for shipment shall be in

accordance with the requirements of MIL-STD-129.

18. Keywords

18.1 Ausferrite; Austempering; Ductile Cast Iron; Harden-

FIG. 6 Examples of Small-Size Specimens Proportional to Stan- ability; Heat Treatment; Proeutectoid Ferrite

dard 1⁄2-in. [13-mm] Round Specimen

APPENDIXES

(Nonmandatory Information)

X1. MECHANICAL PROPERTIES OF CASTINGS

X1.1 In order to achieve the required mechanical properties eters have been shown to yield excellent results.

in castings, or test coupons, the iron must have a chemical X1.2.1 The castings should be free of non-metallic inclu-

composition that provides sufficient hardenability to fully sions, carbides, shrink and dross. Proper purchasing, storage

respond in the austempering heat treatment cycle. The response and use of charge materials will minimize the occurrence of

to heat treatment is affected by the effective section size, carbides and gas defects. Proper molding control will minimize

graphite nodule count, and chemical composition. It also surface defects and other sub-surface discontinuities. The

depends on the capabilities of the specific heat treater’s castings should be properly gated and poured using consistent

equipment. The heavier the effective section size and the more and effective treatment and inoculation techniques to yield

massive the casting, the slower will be the cooling or quench- shrink free castings. Any of the aforementioned non-

ing rate in the austempering cycle. This quenching rate must conforming conditions will reduce the toughness of an ADI

exceed some critical value to attain the correct microstructure component, even if adequate for conventional ductile iron. The

(ausferrite or ausferrite and proeutectoid ferrite). following should be met as a minimum: Nodule Count 100/

mm2 and Nodularity 80%.

X1.2 Published literature and commercial heat treaters as

X1.2.2 The carbon equivalent (CE) can be approximated

well as many foundries can provide information on required by the relationship: CE = %C + 1/3 (%Si). It should be

alloy additions needed for specific parts, casting section sizes, controlled as follows in Table X1.1.

or masses. Austempered Ductile Iron can be successfully

produced from ductile iron castings with a wide range of X1.3 Alloying elements such as Molybdenum, Copper,

chemical compositions and configurations. There is no opti- Nickel and additional Manganese above the base metal level

mum recipe; however those produced to the following param- should be added only when additional hardenability is required

Copyright by ASTM Int'l (all rights reserved); 6

A897/A897M − 06 (2011)

TABLE X1.1 Suggested Carbon Equivalent Ranges for Various

Section Sizes

Section Size CE Range

0 to 1⁄2 in. (0 to 13 mm) 4.4 to 4.6

1⁄2 to 2 in. (13 to 51 mm) 4.3 to 4.6

Over 2 in. (51 mm) 4.3 to 4.5

for heavy sections. Increased hardenability is only required to X1.3.2 The preceding guidelines are intended to be useful

avoid the formation of pearlite during quenching. The amount parameters for production. Good ADI can, and is, being

of alloying required (if any) will be a function of the alloy produced from ductile iron not meeting these criteria, however,

content in the base metal, the part configuration and the these criteria represent sound, commercial practices known to

austempering process used. The proper alloy composition produce good results. They do not constitute a guarantee of

should be determined jointly by the foundry and the heat final properties.

treating source. Addition of alloying elements when not re-

quired does not enchance the properties of ADI and merely X1.4 Machining of tension test specimens after austemper-

adds to the cost of the iron. Composition guidelines are ing may be difficult, particularly for the higher strength grades.

recommended in Table X1.2 and Table X1.3. For this reason, some manufacturers prefer to machine the test

X1.3.1 Other nodulizing elements like beryllium, calcium, bars to size or near net size (with some final grinding

strontium, barium, yttrium, lanthanum and cerium should be allowances) before the austempering operation. (Warning—

present only to the extent that they are used to replace Mg in Achieving the required mechanical properties and austempered

treatment. The amount of residual Mg plus the amounts of microstructure in the smaller cross sections of a premachined

these elements should not exceed 0.06%. Carbide forming test bar does not ensure the correct response in the heavier

elements (like Cr, Ti , V) tend to be additive in effect with Mn sections of actual parts, as explained in X1.1. When prema-

and/or Mo; thus, one should take note of this in alloy design to chined test bars are to be used, it is recommended that adequate

avoid the formation of carbides in the casting. austempering be verified. This can be done by sectioning a

TABLE X1.2 Suggested Targets and Control Ranges for Intentionally Added Elements

Element Recommended Range

Carbon 3.60 % ± 0.20 %

Carbon should be controlled within the recommended range except when deviations are required to produce

a defect-free casting. If too high levels of carbon are present, carbon flotation can occur and reduce the

apparent strength levels of ADI.

Silicon 2.50 % ± 0.20 %

Silicon is one of the most important elements in ADI because it promotes graphite formation, decreases the

solubility of carbon in austenite, increases the eutectoid temperature and inhibits the formation of bainitic

carbide. Excessively high levels of Si can suppress ausferrite in localized areas by stabilizing ferrite.

Magnesium (% S x 0.76) + 0.025 % ± 0.005 %

Magnesium is added to create the conditions for graphite nodules to form. Excessively high levels will

promote carbide formation while low levels promote nonspheroidal graphite.

Manganese 0.35% ± 0.05 %

Manganese additions above that of the base metal composition are not recommended because Mn

segregates to the last to freeze regions of the casting and will retard the formation of ausferrite if the nodule

count is not sufficiently high to break up the Mn segregated region. In section sizes up to 1⁄2 in. or 13 mm, Mn

targets as high as 0.60 % have been used due to high nodule counts. In section sizes over 1⁄2 in. (13 mm) or

in the presence of Mo other carbide formers, the Mn target should be reduced to 0.35 % or less to minimize

the formation of cell boundary carbides which may negatively affect component machinability or ductility, or

both.

Copper 0.80 % maximum, only as needed ± 0.05 %

Copper may be added to ADI to increase hardenability in additions up to 0.80 %. Above this level, Cu creates

a diffusion barrier around the graphite nodules, thus inhibiting carbon mobility during austenitizing.

Nickel 2.0 % maximum, only as needed ± 0.10 %

Nickel may be used to increase the hardenability of ductile iron in additions up to 2.0 %. Because of the costs

associated with the use of Ni, larger additions may be cost prohibitive.

Molybdenum 0.30 % maximum (only as needed) ± 0.03 %

Molybdenum is the most potent hardenability agent in ADI and may be necessary in heavy section castings to

prevent the formation of pearlite. Both tensile strength and ductility decrease as the Mo content increases

beyond that required for hardenability. This deterioration in properties is likely caused by the segregation of

Mo to cell boundaries and the formation of carbides. The level of Mo should be restricted to not more than

0.30 % in heavy section castings.

Copyright by ASTM Int'l (all rights reserved); 7

A897/A897M − 06 (2011)

TABLE X1.3 Suggested Targets and Control Ranges for Trace or Tramp Elements

Trace or Tramp Elements Suggested Target (or maximum) Typical Control Range

Sn Tin 0.02% maximum ± 0.003 %

Sb Antimony 0.002% maximum ± 0.0003 %

P Phosphorus 0.04% maximum

S Sulfur 0.02% maximum

O Oxygen 50 ppm maximum

Cr Chromium 0.10% maximum

Ti Titanium 0.040 % maximum

V Vanadium 0.10% maximum

Al Aluminium 0.050% maximum

As Arsenic 0.020% maximum

Bi Bismuth 0.002% maximum

B Boron 0.0004% maximum

Cd Cadmium 0.005% maximum

Pb Lead 0.002% maximum

Se Selenium 0.030% maximum

Te Tellurium 0.003% maximum

casting, examining the microstructure in that section, and then equate austempering response is identified, increased alloying

comparing the results with that of a premachined test bar that as discussed in X1.3 may be required.)

has been austempered in the same furnace load. When inad-

X2. Y-BLOCK SELECTION

X2.1 Table X2.1 provides guidelines for the selection of TABLE X2.1 Equivalent Geometric Shapes Corresponding to

Y-blocks that have cooling rates that are representative of Y-BlocksA

Y-Block Infinite Plate Round Cube

equivalent shapes having the dimensions shown. Size, in. [mm] Thickness, in. Diameter, Edge, in.

[mm] in. [mm] [mm]

0.5 [13] 0.5 [13] 1.2 [30] 1.8 [46]

1.0 [25] 0.9 [22] 1.8 [46] 2.8 [72]

3.0 [76] 1.6 [40] 3.1 [80] 4.8 [120]

A

For castings with cross sections that would require a Y-block greater than 3 in.

[76mm], alloy requirements must be based upon experimental trials with test

castings or previous experience with similar parts. Test coupons should be

selected upon agreement between the producer and the purchaser.

Copyright by ASTM Int'l (all rights reserved); 8

A897/A897M − 06 (2011)

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 9

S-ar putea să vă placă și

- MOM - Control PlanDocument17 paginiMOM - Control PlanraghulramasamyÎncă nu există evaluări

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 paginiFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshÎncă nu există evaluări

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 paginiCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaÎncă nu există evaluări

- Heat Treatment - Self Assessment - CQ 9Document12 paginiHeat Treatment - Self Assessment - CQ 9sunil mathewÎncă nu există evaluări

- ASTM A563 - Portland BoltDocument5 paginiASTM A563 - Portland BoltamrÎncă nu există evaluări

- Engineering Standards: Material Specification Metals GM6435MDocument6 paginiEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovÎncă nu există evaluări

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetDocument6 paginiCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITÎncă nu există evaluări

- Industrial Fasteners, Nuts & BoltsDocument79 paginiIndustrial Fasteners, Nuts & BoltsMudduKrishna shettyÎncă nu există evaluări

- Delforno Takeaway MenuDocument2 paginiDelforno Takeaway MenuSirkd ShumbaÎncă nu există evaluări

- Data Sheet HV-HR ItDocument3 paginiData Sheet HV-HR ItKemo TufoÎncă nu există evaluări

- Is Iso 16160 2005Document11 paginiIs Iso 16160 2005Amber HudsonÎncă nu există evaluări

- Astm b117 Testing v1Document3 paginiAstm b117 Testing v1maddumaÎncă nu există evaluări

- Sae Ams 4500h Copper, Sheet, Strip, and PlateDocument6 paginiSae Ams 4500h Copper, Sheet, Strip, and Platechris nelsonÎncă nu există evaluări

- IATF 16949 2016 Gap ToolDocument232 paginiIATF 16949 2016 Gap Toolvaibhavmalhotra14Încă nu există evaluări

- Etq 114Document12 paginiEtq 114Patricio100% (1)

- AISI1045Document2 paginiAISI1045Sandip JawalkarÎncă nu există evaluări

- Wilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Document3 paginiWilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Ray Mark De TorresÎncă nu există evaluări

- TSB1503G 9 P 1Document18 paginiTSB1503G 9 P 1kk_pammu_915176926Încă nu există evaluări

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDocument17 paginiLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjÎncă nu există evaluări

- ISO 4020 ExtractDocument2 paginiISO 4020 ExtractBartek HajaÎncă nu există evaluări

- D0031 (2012-N) NES: Marking of Polymeric PartsDocument16 paginiD0031 (2012-N) NES: Marking of Polymeric PartsDiego CamargoÎncă nu există evaluări

- ASTM B833 Standard Specification For Metal Injection Molding (MIM), Ferrous Structural Parts1Document4 paginiASTM B833 Standard Specification For Metal Injection Molding (MIM), Ferrous Structural Parts1David VegaÎncă nu există evaluări

- Zinc Plating: Randhir Kumar Singh Asst Professor OpjitDocument16 paginiZinc Plating: Randhir Kumar Singh Asst Professor OpjitRahul PandeyÎncă nu există evaluări

- Oxygen-Free Copper in Wrought Forms For Electron DevicesDocument6 paginiOxygen-Free Copper in Wrought Forms For Electron DevicesErick Vargas100% (1)

- Astm A 623 - 08 Tin Mill Products-General RequirementsDocument38 paginiAstm A 623 - 08 Tin Mill Products-General Requirementsjose_ruben_64Încă nu există evaluări

- Sae J82-2013Document6 paginiSae J82-2013Marcos RosenbergÎncă nu există evaluări

- Supplier Quality Management A Complete Guide - 2021 EditionDe la EverandSupplier Quality Management A Complete Guide - 2021 EditionÎncă nu există evaluări

- GS1 DataMatrix Guideline0115Document62 paginiGS1 DataMatrix Guideline0115Riadh JellaliÎncă nu există evaluări

- Spira FOD Prevention Program 2 11 2021Document14 paginiSpira FOD Prevention Program 2 11 2021Tin NguyenÎncă nu există evaluări

- Corrosion Testing and MeasurementsDocument9 paginiCorrosion Testing and MeasurementsVaish NaviÎncă nu există evaluări

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Document5 paginiTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺Încă nu există evaluări

- Cab Basic Details: National Accreditation Board For Testing and Calibration LaboratoriesDocument6 paginiCab Basic Details: National Accreditation Board For Testing and Calibration LaboratorieskrlalitÎncă nu există evaluări

- Jed 021M1Document2 paginiJed 021M1Reginaldo Santos100% (1)

- Vermont Gage CatalogDocument120 paginiVermont Gage CatalogRobert RothÎncă nu există evaluări

- Iso 6508 3 2015 en PDFDocument8 paginiIso 6508 3 2015 en PDFMohan.v100% (1)

- Astm A313 2003Document7 paginiAstm A313 2003ArefkhanÎncă nu există evaluări

- Sae J51-2015Document11 paginiSae J51-2015NastyÎncă nu există evaluări

- OBS - 510 - Rev 01 - Eng MilliporeDocument4 paginiOBS - 510 - Rev 01 - Eng MilliporeSakthy ArunaÎncă nu există evaluări

- Tycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Document1 paginăTycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Alexis BarolinÎncă nu există evaluări

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 paginiControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingÎncă nu există evaluări

- Technical Specfication - en 1563 - SGDocument4 paginiTechnical Specfication - en 1563 - SGstores svaplÎncă nu există evaluări

- Anexa 3 BI261Document69 paginiAnexa 3 BI261ahmadove1Încă nu există evaluări

- M6x1.0x23 Long HHS Control PlanDocument2 paginiM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsÎncă nu există evaluări

- Nyloc Nut Is 7002 PDFDocument11 paginiNyloc Nut Is 7002 PDFsanjibkrjana0% (1)

- ISO Managementsysteme Seminare & Audits AIAG CQI Standards Automotive SupportDocument31 paginiISO Managementsysteme Seminare & Audits AIAG CQI Standards Automotive SupportMohamed Haris100% (1)

- Hexalubulour BoltDocument20 paginiHexalubulour BoltMitesh MakvanaÎncă nu există evaluări

- Astm B111Document9 paginiAstm B111mmlingÎncă nu există evaluări

- Surface Discontinuities of Nuts, Inch and Metric Series: Standard Specification ForDocument5 paginiSurface Discontinuities of Nuts, Inch and Metric Series: Standard Specification ForDeen ewÎncă nu există evaluări

- Unified Thread StandardDocument4 paginiUnified Thread StandardFredÎncă nu există evaluări

- Example of Why-Why Analysis:: Problem: Oil Leaks From Cylinder Rod Each Time It OperatesDocument1 paginăExample of Why-Why Analysis:: Problem: Oil Leaks From Cylinder Rod Each Time It OperatesVenkatesanÎncă nu există evaluări

- GQADocument26 paginiGQARaduz HaduzÎncă nu există evaluări

- Worldwide Engineering Standards: Low Carbon Sheet SteelDocument13 paginiWorldwide Engineering Standards: Low Carbon Sheet SteelaldairlopesÎncă nu există evaluări

- Debit Policy - SupplierDocument1 paginăDebit Policy - SupplierSAKTHIVEL AÎncă nu există evaluări

- Ford 970Document4 paginiFord 970amanÎncă nu există evaluări

- Plating Control Plan-31 MARCH 09Document10 paginiPlating Control Plan-31 MARCH 09Rohtash fastner100% (1)

- Friction Stir Welding of Dissimilar Alloys and MaterialsDe la EverandFriction Stir Welding of Dissimilar Alloys and MaterialsEvaluare: 3 din 5 stele3/5 (1)

- Astm A897 - A897m-22Document11 paginiAstm A897 - A897m-22anant11235Încă nu există evaluări

- Austempered Ductile Iron Castings: Standard Specification ForDocument8 paginiAustempered Ductile Iron Castings: Standard Specification ForMahendra AhirwarÎncă nu există evaluări

- Ductile Iron Castings: Standard Specification ForDocument6 paginiDuctile Iron Castings: Standard Specification ForLuis F. LoachamínÎncă nu există evaluări

- AC7114-4 Rev M Final EDITORIAL 2DECDocument60 paginiAC7114-4 Rev M Final EDITORIAL 2DECRaja HoneÎncă nu există evaluări

- AC7114-1 Rev M Final Editorial 5 DECDocument60 paginiAC7114-1 Rev M Final Editorial 5 DECRaja HoneÎncă nu există evaluări

- ISO To ASDocument16 paginiISO To ASRaja HoneÎncă nu există evaluări

- Apartment Lease Contract: October 5, 2020Document54 paginiApartment Lease Contract: October 5, 2020Raja HoneÎncă nu există evaluări

- AC7114 REV N - 1 EDITORIAL FinalDocument35 paginiAC7114 REV N - 1 EDITORIAL FinalRaja HoneÎncă nu există evaluări

- Eddyfi Ectane2: Getting Started WithDocument68 paginiEddyfi Ectane2: Getting Started WithRaja HoneÎncă nu există evaluări

- NANDTB Identification Number: NANDTB N.D.T. LEVEL 3 Application Form Transition To EN4179Document11 paginiNANDTB Identification Number: NANDTB N.D.T. LEVEL 3 Application Form Transition To EN4179Raja HoneÎncă nu există evaluări

- AC7114 Rev M NADCAP AUDIT CRITERIADocument37 paginiAC7114 Rev M NADCAP AUDIT CRITERIARaja Hone100% (2)

- AC7114-2 Rev LDocument41 paginiAC7114-2 Rev LRaja Hone100% (2)

- Digital Ferrite Meter TMF110: Product DescriptionDocument2 paginiDigital Ferrite Meter TMF110: Product DescriptionRaja HoneÎncă nu există evaluări

- Evers and Sons Inc.: Welding Procedure Specification (WpsDocument3 paginiEvers and Sons Inc.: Welding Procedure Specification (WpsRaja HoneÎncă nu există evaluări

- Feritscope FMP30: Operators ManualDocument240 paginiFeritscope FMP30: Operators ManualRaja HoneÎncă nu există evaluări

- ASTM Comparison PDFDocument1 paginăASTM Comparison PDFRaja HoneÎncă nu există evaluări

- Procedures For Assessing The FitnessDocument12 paginiProcedures For Assessing The FitnessRaja HoneÎncă nu există evaluări

- Brittle Fracture and Reporting OverviewDocument38 paginiBrittle Fracture and Reporting OverviewRaja HoneÎncă nu există evaluări

- Study 2016 Article ManagingColdTemperatureAndBritDocument12 paginiStudy 2016 Article ManagingColdTemperatureAndBritRaja HoneÎncă nu există evaluări

- K & B Industries: Welding Procedure Specification (WpsDocument4 paginiK & B Industries: Welding Procedure Specification (WpsRaja HoneÎncă nu există evaluări

- WPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWDocument1 paginăWPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWRaja HoneÎncă nu există evaluări

- Doterra Enrollment Kits 2016 NewDocument3 paginiDoterra Enrollment Kits 2016 Newapi-261515449Încă nu există evaluări

- RENCANA KERJA Serious Inspeksi#3 Maret-April 2019Document2 paginiRENCANA KERJA Serious Inspeksi#3 Maret-April 2019Nur Ali SaidÎncă nu există evaluări

- LOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCDocument1 paginăLOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCMÎncă nu există evaluări

- Blade Torrent 110 FPV BNF Basic Sales TrainingDocument4 paginiBlade Torrent 110 FPV BNF Basic Sales TrainingMarcio PisiÎncă nu există evaluări

- Form Three Physics Handbook-1Document94 paginiForm Three Physics Handbook-1Kisaka G100% (1)

- HRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesDocument6 paginiHRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesAkosi EtutsÎncă nu există evaluări

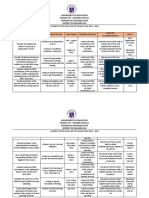

- Action Plan Lis 2021-2022Document3 paginiAction Plan Lis 2021-2022Vervie BingalogÎncă nu există evaluări

- Newsletter 289Document10 paginiNewsletter 289Henry CitizenÎncă nu există evaluări

- Historical Development of AccountingDocument25 paginiHistorical Development of AccountingstrifehartÎncă nu există evaluări

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocument3 paginiMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezÎncă nu există evaluări

- Exp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.Document7 paginiExp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.AbhishEk SinghÎncă nu există evaluări

- Discover Mecosta 2011Document40 paginiDiscover Mecosta 2011Pioneer GroupÎncă nu există evaluări

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Document2 paginiGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiÎncă nu există evaluări

- Saet Work AnsDocument5 paginiSaet Work AnsSeanLejeeBajan89% (27)

- G.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARDocument2 paginiG.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARTheodore DolarÎncă nu există evaluări

- Cabling and Connection System PDFDocument16 paginiCabling and Connection System PDFLyndryl ProvidoÎncă nu există evaluări

- On CatiaDocument42 paginiOn Catiahimanshuvermac3053100% (1)

- Maths PDFDocument3 paginiMaths PDFChristina HemsworthÎncă nu există evaluări

- Underwater Wellhead Casing Patch: Instruction Manual 6480Document8 paginiUnderwater Wellhead Casing Patch: Instruction Manual 6480Ragui StephanosÎncă nu există evaluări

- United Nations Economic and Social CouncilDocument3 paginiUnited Nations Economic and Social CouncilLuke SmithÎncă nu există evaluări

- Lab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabDocument7 paginiLab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabHayat AnsariÎncă nu există evaluări

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 paginiAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariÎncă nu există evaluări

- 5 Star Hotels in Portugal Leads 1Document9 pagini5 Star Hotels in Portugal Leads 1Zahed IqbalÎncă nu există evaluări

- Chapter 5Document3 paginiChapter 5Showki WaniÎncă nu există evaluări

- Introduce Letter - CV IDS (Company Profile)Document13 paginiIntroduce Letter - CV IDS (Company Profile)katnissÎncă nu există evaluări

- Labstan 1Document2 paginiLabstan 1Samuel WalshÎncă nu există evaluări

- Hager Pricelist May 2014Document64 paginiHager Pricelist May 2014rajinipre-1Încă nu există evaluări

- Enerparc - India - Company Profile - September 23Document15 paginiEnerparc - India - Company Profile - September 23AlokÎncă nu există evaluări

- Fernando Salgado-Hernandez, A206 263 000 (BIA June 7, 2016)Document7 paginiFernando Salgado-Hernandez, A206 263 000 (BIA June 7, 2016)Immigrant & Refugee Appellate Center, LLCÎncă nu există evaluări

- Micron Interview Questions Summary # Question 1 Parsing The HTML WebpagesDocument2 paginiMicron Interview Questions Summary # Question 1 Parsing The HTML WebpagesKartik SharmaÎncă nu există evaluări