Documente Academic

Documente Profesional

Documente Cultură

499

Încărcat de

Imane Khammouri0 evaluări0% au considerat acest document util (0 voturi)

164 vizualizări1 paginănorme 499

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentnorme 499

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

164 vizualizări1 pagină499

Încărcat de

Imane Khammourinorme 499

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

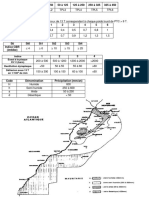

Guide to EN 499 – 1995

( EN ISO 2560 – A)

Symbol Tensile Strength Yield Strength Elongation

N/mm2 min.N/mm2 min.% Symbol Welding position

35 440-570 355 22 1 All positions

38 470-600 380 20 2 All positions, except vertical down

42 500-640 420 20 3 Flat butt weld, flat fillet weld, horizontal-

vertical fillet weld

46 530-680 460 20 4 Flat butt weld, flat fillet weld

50 560-720 500 18 5 Vertical down and positions according

to symbol 3

Symbol Metal recovery % Type of current

1 < 105 AC + DC

2 < 105 DC

3 > 105 d 125 AC + DC

4 > 105 d 125 DC

5 > 125 d 160 AC + DC

6 > 125 d 160 DC

7 > 160 AC + DC

8 > 160 DC

E 46 3 1 Ni B 5 4 H5

Covered electrode Hydrogen content

for manual metal-arc Symbol Coating type Symbol ml/100 g

welding deposited metal, max.

A Acid H5 5

B Basic H10 10

C Cellulosic H15 15

R Rutile

RR Rutile (thick coated)

RC Rutile-Cellulosic

RA Rutile-Acid

RB Rutile-Basic

Symbol Impact Energy Symbol Chemical composition *

Charpy-V

Temp.qC for 47Jmin. Mn Mo Ni

Z No requirements No symbol 2.0 - -

A + 20 Mo 1.4 0.3 – 0.6 -

0 0 MnMo > 1.4 – 2.0 0.3 – 0.6 -

2 - 20 1Ni 1.4 - 0.6 – 1.2

3 - 30 2Ni 1.4 - 1.8 – 2.6

4 - 40 3Ni 1.4 - > 2.6 – 3.8

5 - 50 Mn1Ni > 1.4 – 2.0 - 0.6 – 1.2

6 - 60 1NiMo 1.4 0.3 – 0.6 0.6 – 1.2

Z Any other agreed composition

* If not specified Mo<0.2, Ni<0.3, Cr<0.2, V<0.05, Nb<0.05, Cu<0.3.

Single values shown in the table mean maximum values.

S-ar putea să vă placă și

- 102-VB Safer N48Document1 pagină102-VB Safer N48Mathieu DouÎncă nu există evaluări

- Fiche TechniqueDocument1 paginăFiche TechniquejuÎncă nu există evaluări

- Al MG 3 Peraluman 300 Aluminium AW-5754 Fiche Technique RLSADocument2 paginiAl MG 3 Peraluman 300 Aluminium AW-5754 Fiche Technique RLSAMellierÎncă nu există evaluări

- Fiche Technique Safer G48 NDocument1 paginăFiche Technique Safer G48 NdttÎncă nu există evaluări

- MA ROD 270 - Id-Nr.363559-92Document12 paginiMA ROD 270 - Id-Nr.363559-92pomsarexnbÎncă nu există evaluări

- Fiche Produit Innershield Lincoln PDFDocument2 paginiFiche Produit Innershield Lincoln PDFAbdala Aziz HASSANÎncă nu există evaluări

- Exercice 01Document12 paginiExercice 01Ghizlane ID75% (4)

- BP SuiteDocument3 paginiBP SuiteSoufiane BettiouiÎncă nu există evaluări

- Exercice 01Document12 paginiExercice 01Ghizlane IDÎncă nu există evaluări

- Minera Standard 15 20kV PC - ZZ5732 PDFDocument2 paginiMinera Standard 15 20kV PC - ZZ5732 PDFYatma DiopÎncă nu există evaluări

- C% Si% MN% P% S% CR% Ni% Mo% Cu% Cr+Mo+Ni % DE - ADocument1 paginăC% Si% MN% P% S% CR% Ni% Mo% Cu% Cr+Mo+Ni % DE - Amaryem jemaiÎncă nu există evaluări

- Minera-standard-20kV - ZZ5733Document2 paginiMinera-standard-20kV - ZZ5733ALBERTÎncă nu există evaluări

- Böhler Fox Ev 50Document2 paginiBöhler Fox Ev 50Ferdak AmineÎncă nu există evaluări

- Norme: Encombrement Necessaire Pour Soudage Des EcrousDocument3 paginiNorme: Encombrement Necessaire Pour Soudage Des Ecroustazi marouaneÎncă nu există evaluări

- 11-Pressostat Pour Collecteur PDFDocument2 pagini11-Pressostat Pour Collecteur PDFAnis Ben FarhatÎncă nu există evaluări

- Norme Américaine AWS A 5Document4 paginiNorme Américaine AWS A 5ALP69100% (1)

- Flanges ASME B16 5 PDFDocument22 paginiFlanges ASME B16 5 PDFCitlali RiosÎncă nu există evaluări

- Schneider Electric - Harmony-XB4 - ZBE102Document5 paginiSchneider Electric - Harmony-XB4 - ZBE102Ayoub CobainÎncă nu există evaluări

- 11SMnPb37 FRDocument2 pagini11SMnPb37 FRNarimane BentyÎncă nu există evaluări

- 2 En10025 PDFDocument2 pagini2 En10025 PDFhdierkeÎncă nu există evaluări

- 1 ConvertiDocument7 pagini1 ConvertiMahdi DakÎncă nu există evaluări

- TA6VDocument1 paginăTA6Vlamiae el moustafiÎncă nu există evaluări

- Baguettes A Souder 2Document2 paginiBaguettes A Souder 2LUC BALOMOCK BIIGAÎncă nu există evaluări

- Fiche Stelux C FRDocument2 paginiFiche Stelux C FREdward BZHÎncă nu există evaluări

- Selectarc Panorama Francais - 150 PDFDocument20 paginiSelectarc Panorama Francais - 150 PDFThameur KamounÎncă nu există evaluări

- Électrodes Rutiles SoudageDocument1 paginăÉlectrodes Rutiles SoudageSimo SeprobÎncă nu există evaluări

- Alu 2017A-AU4GDocument2 paginiAlu 2017A-AU4GBESSIEREÎncă nu există evaluări

- Feinguss ListeDocument7 paginiFeinguss Listeمحمد الأمين شرفاويÎncă nu există evaluări

- Feinguss Legierungen FranzDocument4 paginiFeinguss Legierungen Franzabder2222Încă nu există evaluări

- Bureau Des M Thodes FRDocument10 paginiBureau Des M Thodes FRMhamad TaklaÎncă nu există evaluări

- Alliage 5083 Fiche TechniqueDocument2 paginiAlliage 5083 Fiche TechniquemakramÎncă nu există evaluări

- 4 Metaux Nobles 1Document13 pagini4 Metaux Nobles 1mohammed LautfiÎncă nu există evaluări

- C% Si% MN% P% S% DE ADocument1 paginăC% Si% MN% P% S% DE AYayaNosÎncă nu există evaluări

- Désignation Normalisée Des Aciers Et Des Fontes PDFDocument6 paginiDésignation Normalisée Des Aciers Et Des Fontes PDFRayen Ab100% (2)

- Annex 2 Pour ExamenDocument1 paginăAnnex 2 Pour ExamenBilal MgÎncă nu există evaluări

- H07VR PDFDocument2 paginiH07VR PDFIslam IslamÎncă nu există evaluări

- Catalogue Goujons À Souder Lisse Type NELSONDocument14 paginiCatalogue Goujons À Souder Lisse Type NELSONZakari LOUNISÎncă nu există evaluări

- P265GHDocument1 paginăP265GHImec InterÎncă nu există evaluări

- Cours Soudage PDFDocument118 paginiCours Soudage PDFTabka SouheilÎncă nu există evaluări

- SoudageDocument97 paginiSoudageWael Ben SalemÎncă nu există evaluări

- Harmony PDFDocument2 paginiHarmony PDFdilekhÎncă nu există evaluări

- Barres en Bronze Caracteristicas Mecanicas FR FRDocument3 paginiBarres en Bronze Caracteristicas Mecanicas FR FRkaroooma99Încă nu există evaluări

- 042-00-092 Titan-92lDocument1 pagină042-00-092 Titan-92lalexBÎncă nu există evaluări

- 042-00-093 Titan-93lDocument1 pagină042-00-093 Titan-93lalexBÎncă nu există evaluări

- Harmony XB4 ZBE101Document3 paginiHarmony XB4 ZBE101Marouane EzzouhairiÎncă nu există evaluări

- Glissement - FR - 2016 - Web PDFDocument196 paginiGlissement - FR - 2016 - Web PDFTuan NguyenÎncă nu există evaluări

- M1NB 7Document2 paginiM1NB 7ISGEÎncă nu există evaluări

- Exposé L Acier S235JRDocument10 paginiExposé L Acier S235JRSoulaiman AndahmouÎncă nu există evaluări

- 9 Japanese Standards PDFDocument2 pagini9 Japanese Standards PDFhdierkeÎncă nu există evaluări

- FT-4105B-BELVIS 4T TX ZN TB12 D4,8x20-BardageDocument3 paginiFT-4105B-BELVIS 4T TX ZN TB12 D4,8x20-BardageChrisÎncă nu există evaluări

- LNT26 FRDocument1 paginăLNT26 FRKhaled bouhlelÎncă nu există evaluări

- Complément 1-Désignations Et Choix Des Paramètres D'usinage Et D'outillageDocument4 paginiComplément 1-Désignations Et Choix Des Paramètres D'usinage Et D'outillageZyneb EttalebiÎncă nu există evaluări

- ZBE102 DATASHEET FR FR-FRDocument3 paginiZBE102 DATASHEET FR FR-FRBachir NasraouiÎncă nu există evaluări

- HE-HER-DE00-E-DT052 - Relais de Puissance MiniatureDocument6 paginiHE-HER-DE00-E-DT052 - Relais de Puissance Miniatureandrei belgiumÎncă nu există evaluări

- Designation Materiaux MetalliquesDocument12 paginiDesignation Materiaux Metalliquesblack stoneÎncă nu există evaluări

- Exercices Corrigé Codap24 Mars 6Document1 paginăExercices Corrigé Codap24 Mars 6Simo SeprobÎncă nu există evaluări

- Conditions de Coupe en DecolletageDocument1 paginăConditions de Coupe en DecolletageHamza RouihemÎncă nu există evaluări

- MP 7Document5 paginiMP 7sbamadouÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Introduction Aux Traitements Thermiques Des Métaux Et AlliagDocument19 paginiIntroduction Aux Traitements Thermiques Des Métaux Et AlliagImane KhammouriÎncă nu există evaluări

- Atmosphères de Traitement Thermique PDFDocument29 paginiAtmosphères de Traitement Thermique PDFKimo HakimÎncă nu există evaluări

- Traitements Thermiques Superficiels Des AciersDocument28 paginiTraitements Thermiques Superficiels Des AciersImane Khammouri100% (2)

- Traitements Thermiques Des Fontes-Guide de ChoixDocument9 paginiTraitements Thermiques Des Fontes-Guide de ChoixImane KhammouriÎncă nu există evaluări

- Choix Du Traitement Thermique Des Matériaux Ferreux Pour L'aDocument16 paginiChoix Du Traitement Thermique Des Matériaux Ferreux Pour L'aImane KhammouriÎncă nu există evaluări

- Ti - M4532 - Aciers Pour Traitements Thermiques - Mise en Oeuvre - G - MURRYDocument14 paginiTi - M4532 - Aciers Pour Traitements Thermiques - Mise en Oeuvre - G - MURRYJean Paul WeilerÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Atmosphères de Traitement Thermique PDFDocument29 paginiAtmosphères de Traitement Thermique PDFKimo HakimÎncă nu există evaluări

- Aciers Pour Traitements Thermiques-2 PDFDocument18 paginiAciers Pour Traitements Thermiques-2 PDFKimo HakimÎncă nu există evaluări

- Traitements Thermiques Des Fontes-Guide de ChoixDocument9 paginiTraitements Thermiques Des Fontes-Guide de ChoixImane KhammouriÎncă nu există evaluări

- Introduction Aux Traitements Thermiques Des Métaux Et AlliagDocument19 paginiIntroduction Aux Traitements Thermiques Des Métaux Et AlliagImane KhammouriÎncă nu există evaluări

- Choix Du Traitement Thermique Des Matériaux Ferreux Pour L'aDocument16 paginiChoix Du Traitement Thermique Des Matériaux Ferreux Pour L'aImane KhammouriÎncă nu există evaluări

- Ti - M4532 - Aciers Pour Traitements Thermiques - Mise en Oeuvre - G - MURRYDocument14 paginiTi - M4532 - Aciers Pour Traitements Thermiques - Mise en Oeuvre - G - MURRYJean Paul WeilerÎncă nu există evaluări

- Aciers Pour Traitements Thermiques-2 PDFDocument18 paginiAciers Pour Traitements Thermiques-2 PDFKimo HakimÎncă nu există evaluări

- Calcul Poutre AlvDocument279 paginiCalcul Poutre AlvYassir Nj100% (1)

- Aciers Pour Traitements Thermiques-2 PDFDocument18 paginiAciers Pour Traitements Thermiques-2 PDFKimo HakimÎncă nu există evaluări

- 10 Normes ElectriquesDocument3 pagini10 Normes Electriquesjavier_aby100% (2)

- Traitements Thermiques Superficiels Des AciersDocument28 paginiTraitements Thermiques Superficiels Des AciersImane Khammouri100% (2)

- Traitements Thermiques Superficiels Des AciersDocument28 paginiTraitements Thermiques Superficiels Des AciersImane Khammouri100% (2)

- Ti - M4532 - Aciers Pour Traitements Thermiques - Mise en Oeuvre - G - MURRYDocument14 paginiTi - M4532 - Aciers Pour Traitements Thermiques - Mise en Oeuvre - G - MURRYJean Paul WeilerÎncă nu există evaluări

- Désignation Aciers PDFDocument21 paginiDésignation Aciers PDFAnas MohtadiÎncă nu există evaluări

- Awsz49 Safetyinweldingandcutting 130528031946 Phpapp01Document31 paginiAwsz49 Safetyinweldingandcutting 130528031946 Phpapp01HassanSobohÎncă nu există evaluări

- 1-Cours - CND-2016-2017 - Pour Cite Internet PDFDocument125 pagini1-Cours - CND-2016-2017 - Pour Cite Internet PDFRABHI Mouldi100% (2)

- 3C - 12caillebotis - SP - BD (1) Controle Des CaillebotisDocument60 pagini3C - 12caillebotis - SP - BD (1) Controle Des CaillebotisImane Khammouri100% (1)

- 002-CTM Maintenance 2015 SommaireDocument16 pagini002-CTM Maintenance 2015 SommaireImane KhammouriÎncă nu există evaluări

- DTU-Fascicule 66-GC A Ossature en AcierDocument79 paginiDTU-Fascicule 66-GC A Ossature en Acierblaireauxx100% (1)

- DTU-Fascicule 66-GC A Ossature en AcierDocument79 paginiDTU-Fascicule 66-GC A Ossature en Acierblaireauxx100% (1)

- NF E86-200-5 NF EN 13445-5 V2 Du 2014-12-12 Récipient Sous Pression Non Soumi À La FlammeDocument84 paginiNF E86-200-5 NF EN 13445-5 V2 Du 2014-12-12 Récipient Sous Pression Non Soumi À La FlammeImane KhammouriÎncă nu există evaluări

- 03.07.1541-ISO 14555-2014-FR Soudage Des GoujonsDocument82 pagini03.07.1541-ISO 14555-2014-FR Soudage Des GoujonsImane KhammouriÎncă nu există evaluări

- Cours Catalyse Master RC Karim 22-23 Chapitre I-IIIDocument36 paginiCours Catalyse Master RC Karim 22-23 Chapitre I-IIISalah entertainmentÎncă nu există evaluări

- VerroDocument6 paginiVerroweldsaidiÎncă nu există evaluări

- Documentation MilléniumplusDocument12 paginiDocumentation MilléniumpluskandelaÎncă nu există evaluări

- Transfert de CotesDocument9 paginiTransfert de CotesGamatekÎncă nu există evaluări

- Processus de Fabrication1Document80 paginiProcessus de Fabrication1Alaa AbarÎncă nu există evaluări

- FiltreDocument2 paginiFiltreMartinezÎncă nu există evaluări

- Rapport PFA Etude, Conception Et Simulation ParDocument2 paginiRapport PFA Etude, Conception Et Simulation ParM.G.D OfficielÎncă nu există evaluări

- Epuration de L'eauDocument17 paginiEpuration de L'eaufatiha silaÎncă nu există evaluări

- Tableau Comparatif D'aluminiumDocument1 paginăTableau Comparatif D'aluminiumZackaria El IdrissiÎncă nu există evaluări

- Identifier La Place de L'imposition Dans La Chaîne GraphiqueDocument35 paginiIdentifier La Place de L'imposition Dans La Chaîne Graphiquerachida ajbayrÎncă nu există evaluări

- CN 3Document2 paginiCN 3Ahmed DjebbiÎncă nu există evaluări

- Correction Du DS-productique 2021-2022-2Document8 paginiCorrection Du DS-productique 2021-2022-2meissa chaouchÎncă nu există evaluări

- Projet Fin CycleDocument6 paginiProjet Fin CycleimenenouvelleÎncă nu există evaluări

- Soudage Electrode EnrobéeDocument4 paginiSoudage Electrode EnrobéeAbdessalam ReÎncă nu există evaluări

- Staubli - Mamelons + RéducteursDocument36 paginiStaubli - Mamelons + RéducteursGuillaume RITOUXÎncă nu există evaluări

- Décomposition SAP Ammoniac JPH VP0 LAST (Demo Version)Document165 paginiDécomposition SAP Ammoniac JPH VP0 LAST (Demo Version)Azzeddine EL-OhnÎncă nu există evaluări

- Flann EN 1Document2 paginiFlann EN 1Ali KarakeÎncă nu există evaluări

- FraisageDocument8 paginiFraisageSayf BouyeddaÎncă nu există evaluări

- Selection Table Stick Electrodes FRDocument1 paginăSelection Table Stick Electrodes FRLUC BALOMOCK BIIGAÎncă nu există evaluări

- Somac CEDocument8 paginiSomac CEJose Manuel ReyesÎncă nu există evaluări

- Roto MoulageDocument18 paginiRoto Moulagebamsibamsi5253Încă nu există evaluări

- Différents Acier Pour Le Traitement Thermique - Sarl DassonvilleDocument7 paginiDifférents Acier Pour Le Traitement Thermique - Sarl DassonvilleAyoub BOUFTINIÎncă nu există evaluări

- TP Soudeur TIG Et Électrode EnrobéeDocument2 paginiTP Soudeur TIG Et Électrode Enrobéehubertspriet02Încă nu există evaluări

- Séminaire Catalyseurs 2021Document110 paginiSéminaire Catalyseurs 2021Ikram MellahÎncă nu există evaluări

- Catalogue Defauts Acierie PDFDocument17 paginiCatalogue Defauts Acierie PDFYassine ZamzamiÎncă nu există evaluări

- Corrigé TD de FraisageDocument6 paginiCorrigé TD de Fraisageboulaabi hagerÎncă nu există evaluări

- Chaudiere TPC-LN Babcock WansonDocument2 paginiChaudiere TPC-LN Babcock WansonzakariaÎncă nu există evaluări

- Face Milling Cutter OE45 - en - WebDocument2 paginiFace Milling Cutter OE45 - en - WebTodorÎncă nu există evaluări

- Les Aciers Pour Émaillage Et L'acier Émaillé - ArcelorMittalDocument64 paginiLes Aciers Pour Émaillage Et L'acier Émaillé - ArcelorMittaltounsiÎncă nu există evaluări

- Bon de CommandeDocument2 paginiBon de CommandeYassine YassineÎncă nu există evaluări