Documente Academic

Documente Profesional

Documente Cultură

Dev - Length PDF

Încărcat de

thongchai_007Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dev - Length PDF

Încărcat de

thongchai_007Drepturi de autor:

Formate disponibile

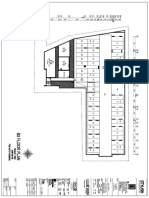

Development Length of deformed bars (ACI 318-02)

1. Tension bars : ld = αβγλψ ldb ≥ 300 mm.

fy 1 ⎛ c + K tr ⎞

where ldb = 0.28db ; 1.5 ≤ ⎜ ⎟ ≤ 2.5

f c' ⎛ c + K tr ⎞ ⎝ db ⎠

⎜ ⎟

⎝ db ⎠

( c + Ktr ) fy

with = 1.5 ==Î ldb = 0.18db

db f c'

α = rft. location factor

= 1.3 top rft. (has fresh conc. > 300 mm. depth below it)

= 1.0 other rft.

β = coating factor =Î 1.0 for uncoated , 1.2 for epoxy coated, etc.

γ = rft. size factor =Î 0.8 for db ≤ 20 mm. , 1.0 otherwise

λ = lightweight agg. factor =Î 1.0 for normal wt., 1.3 for lightwt.

ψ = excess rft. factor = Asreq. / Asprov.

c = spacing or cover dimension

= min ( dist.from center of bar to the nearest conc.surface, ½ c to c

of bars being developed )

Ktr = transverse rft.index = Atr f yt /(105sn)

Atr = total As of transverse rft.within spacing s ( eg. Ast in column )

fyt = fy of transverse steel

s = max. spacing of transverse steel, c to c

n = no. of bars being developed

2. Compression bars: ld = ψη ldb ≥ 200 mm.

where ldb = 0.075 db f y / f c' ≥ 0.0043 db fy

η = factor account for spiral or tied columns

= 0.75 when - spiral: dstir ≥ 6 mm. & pitch ≤ 100 mm.

- tied: dstir ≥ 12 mm. & spacing ≤ 100 mm.

3. Bundled bars : ( both tension and compression bars )

- 1 & 2 bars use ld of individual bar

- 3 bars use 1.2 ld

- 4 bars use 1.33 ld

4. Hooks in tension : ldh = βλψδφ lhb ≥ min ( 8db , 150 mm. )

where lhb = 0.08d b f y / f c'

δ = 0.8 ( with enclosed hook along ldh with spacing ≤ 3 db,main )

φ = 0.7 ( with side cover ≥ 60 mm. & tail cover ≥ 50 mm.)

** for round bars: assume av. μ RB ≈ μ DB / 2 =Î ld , RB = 1.20ld , DB 40 ****

Development Length, Hook and Splices. (ACI 318-02)

f y = 4000 ksc basic dev.length: l db =kd b f y / (f c ' )^0.5 : (0.11 <= k <= 0.18)

fc' = 280 ksc basic hook : l hb =0.08d b f y / (f c ' )^0.5

use k = 0.18 basic comp bar: l db = 0.075 d b f y /(f c ' ) ^0.5 >= 0.0043d b f y

Max.Development Length (cm) Max.Lap Splices ( class B ) cm

size (mm)

tens. bar top tens bar hook comp.bar tens. bar top tens bar comp.bar col comp bar

9 37 48 21 24 48 63 36 36

10 34 45 19 20 45 58 30 30

12 41 54 23 22 54 70 34 30

16 55 72 31 29 72 93 45 37

20 69 89 38 36 89 116 56 46

25 108 140 48 45 140 182 70 58

28 120 157 54 50 157 204 78 65

32 138 179 61 57 179 233 90 74

SR:l d_min 36 36 10d b ,18 24 36 36 36 36

SD:l d_min 30 30 8d b ,15 20 30 30 30 30

Note: Reduce l d of tens_bar, top bar, hook and comp_bar by factor A s,req / A s,prov , but >= l d_ min

Bundled bars_ ten&comp ; 2 bars use l d, 3 bars use 1.2 l d , 4 bars use 1.33 l d .

For class A splice, A s,prov /A s,req >=2 and spliced area <=50%, reduce the class B splice by factor 1.3

For RB: assume bond strength is 0.5 that of DB, i.e., use fy = 4800ksc.

S-ar putea să vă placă și

- Development Length and Splices LengthDocument6 paginiDevelopment Length and Splices LengthAnton_Young_1962Încă nu există evaluări

- Proiect Normativ P 118 1 Iunie 2016Document15 paginiProiect Normativ P 118 1 Iunie 2016Mihai AndreiasÎncă nu există evaluări

- Lap-Length As Per 1992Document6 paginiLap-Length As Per 1992RahulÎncă nu există evaluări

- Design Calculation of Elastomeric Bearing 70 MT (400 x 200 x 39) mmDocument1 paginăDesign Calculation of Elastomeric Bearing 70 MT (400 x 200 x 39) mmNamrataÎncă nu există evaluări

- Shear Connection EC3Document15 paginiShear Connection EC3lucianduÎncă nu există evaluări

- Verify ASTM A992 W12 × 30Document29 paginiVerify ASTM A992 W12 × 30qgfytzvqabzqrxyilmÎncă nu există evaluări

- Verify ASTM A992 W12 × 30Document28 paginiVerify ASTM A992 W12 × 30ankhbayar batkhuuÎncă nu există evaluări

- M.sc. Concrete FormulaeDocument17 paginiM.sc. Concrete FormulaeSana UllahÎncă nu există evaluări

- Machine Design - INHOUSE 3Document28 paginiMachine Design - INHOUSE 3Pia May Torres PablicoÎncă nu există evaluări

- Development LengthsDocument1 paginăDevelopment LengthsMatthew Dilan ArroyoÎncă nu există evaluări

- Design of I C Engine Connecting RodDocument6 paginiDesign of I C Engine Connecting RodBinoy K BÎncă nu există evaluări

- Raft Xls - ProjectDocument10 paginiRaft Xls - ProjectDilon TkhomaÎncă nu există evaluări

- SDCDSCDocument9 paginiSDCDSCAnish NeupaneÎncă nu există evaluări

- SPRING STRESS CALCULATORDocument3 paginiSPRING STRESS CALCULATORDE GUZMAN, MELVIN CARLO A.Încă nu există evaluări

- 76 9 Design of CranesDocument11 pagini76 9 Design of Cranesrip111176Încă nu există evaluări

- Optimized Specifications for Utilities EquipmentDocument71 paginiOptimized Specifications for Utilities EquipmentHerianto SilalahiÎncă nu există evaluări

- Calculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Document18 paginiCalculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Liviu Ion100% (1)

- Design Aid 15.4.4 Required Development Lengths, In., For Reinforcing Bars (Grade 60)Document1 paginăDesign Aid 15.4.4 Required Development Lengths, In., For Reinforcing Bars (Grade 60)troyscribdÎncă nu există evaluări

- Chapter 9 Development Length and SplicingDocument48 paginiChapter 9 Development Length and SplicingiiMa sticÎncă nu există evaluări

- General Data Pk3L P34 Pk4L P35 Pk5LDocument22 paginiGeneral Data Pk3L P34 Pk4L P35 Pk5LAnonymous 24MCFJXÎncă nu există evaluări

- BAFFLE PLATE AND STIFFENER DESIGN CALCULATION FOR HYDRO CARBON/WASTE WATER DRAIN DRUMDocument6 paginiBAFFLE PLATE AND STIFFENER DESIGN CALCULATION FOR HYDRO CARBON/WASTE WATER DRAIN DRUMshaishavÎncă nu există evaluări

- Development and Splices of Reinforcement According Aci318M-08, Chapter 12Document2 paginiDevelopment and Splices of Reinforcement According Aci318M-08, Chapter 12Matiur Rahman BasumÎncă nu există evaluări

- 2-Way SlabDocument7 pagini2-Way SlabBunny HopperÎncă nu există evaluări

- Design BridgeDocument7 paginiDesign BridgeJohn Lloyd Palaganas TulaganÎncă nu există evaluări

- Bridge DesignDocument6 paginiBridge DesignJohn Lloyd Palaganas TulaganÎncă nu există evaluări

- Ibong Tiririt (MDSP 1) Machine Design and Shop Practice ProblemsDocument173 paginiIbong Tiririt (MDSP 1) Machine Design and Shop Practice ProblemsRoss AlteaÎncă nu există evaluări

- Beam Design 1Document22 paginiBeam Design 1shamen amarasekaraÎncă nu există evaluări

- Unnamed Gornja GredaDocument7 paginiUnnamed Gornja GredasehmediaÎncă nu există evaluări

- Reinforced Concrete Beam DesignDocument25 paginiReinforced Concrete Beam DesignantenehÎncă nu există evaluări

- Date Initiale: Calcule:: ATENTIE !!! - Pentru Radier Procentul Minim de Armare 0.15%Document4 paginiDate Initiale: Calcule:: ATENTIE !!! - Pentru Radier Procentul Minim de Armare 0.15%Petrescu BogdanÎncă nu există evaluări

- OPTIMIZAREA UNEI GRINZI DUBLU TDocument6 paginiOPTIMIZAREA UNEI GRINZI DUBLU TAanei Ionut LaurentiuÎncă nu există evaluări

- Practical Lesson 4Document11 paginiPractical Lesson 4marjory.dezÎncă nu există evaluări

- ACI 318M - 08 Development and Splices of Reinforcement - EditingDocument2 paginiACI 318M - 08 Development and Splices of Reinforcement - EditingHassan Ali SadiqÎncă nu există evaluări

- Is800-2007 Appendix PDFDocument85 paginiIs800-2007 Appendix PDFDebasish MondalÎncă nu există evaluări

- Chapter-5 ExampleDocument8 paginiChapter-5 ExampleomarÎncă nu există evaluări

- Apparent AssignmetDocument115 paginiApparent AssignmetMahlet EshetuÎncă nu există evaluări

- Inner Members DesignDocument4 paginiInner Members DesignARSEÎncă nu există evaluări

- 06 Practical Application Bolted Cylindrical VesselDocument12 pagini06 Practical Application Bolted Cylindrical Vesselenrico.michelatoÎncă nu există evaluări

- OSD Calculation 09238Document10 paginiOSD Calculation 09238Anonymous O404LiV4CÎncă nu există evaluări

- Panel Type Case No. : Analysis & Design of SlabDocument3 paginiPanel Type Case No. : Analysis & Design of SlabMiky TemaÎncă nu există evaluări

- RCD Design Dibelopmin LingDocument10 paginiRCD Design Dibelopmin LingDAN MARK OPONDAÎncă nu există evaluări

- NEW - Structural Design & Analysis (Pt. 1)Document23 paginiNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezÎncă nu există evaluări

- PEDDS4Document11 paginiPEDDS4Dhruv PandavÎncă nu există evaluări

- SteelDocument8 paginiSteelAhmed M WasselÎncă nu există evaluări

- Bab Vii Perhitungan Balok B1 7.1 Properties Balok B1: ρ ρaksenDocument3 paginiBab Vii Perhitungan Balok B1 7.1 Properties Balok B1: ρ ρaksenAnanta Eka YudistiraÎncă nu există evaluări

- EAS Andika Wahyu Kusuma 5008201133Document16 paginiEAS Andika Wahyu Kusuma 5008201133Chou ChouÎncă nu există evaluări

- ..... Development Length and Lap Splices: GivenDocument5 pagini..... Development Length and Lap Splices: GivenMrAlittle FingerÎncă nu există evaluări

- Corbel Design Spreadsheet: (2/3 Avf + An)Document3 paginiCorbel Design Spreadsheet: (2/3 Avf + An)edisonmalahito100% (1)

- DESIGN CRACKING WIDTH 2G1 BEAMDocument13 paginiDESIGN CRACKING WIDTH 2G1 BEAMJade Paul D. BesanaÎncă nu există evaluări

- Final FormulasDocument11 paginiFinal FormulasRafael TreviñoÎncă nu există evaluări

- Powerscrew SampleDocument3 paginiPowerscrew Sampleemilianojr gameÎncă nu există evaluări

- Properties of Bolts: - Bolt Grades 4.6, 5.6 and 8.8Document2 paginiProperties of Bolts: - Bolt Grades 4.6, 5.6 and 8.8mustfa khedrÎncă nu există evaluări

- حل بروبلمات مقاومه فصل ٧Document15 paginiحل بروبلمات مقاومه فصل ٧حسن صالح حسن المياحيÎncă nu există evaluări

- Lug - On - FlangeDocument17 paginiLug - On - Flangeshaishav100% (1)

- Sample Calculation For Flat SlabDocument9 paginiSample Calculation For Flat SlabDax TingÎncă nu există evaluări

- Section : Fy Mpa Fu Mpa ƳDocument27 paginiSection : Fy Mpa Fu Mpa ƳMadhav PurohitÎncă nu există evaluări

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDe la EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsÎncă nu există evaluări

- CAL - PCWN (Plum Chaeng Watthana)Document59 paginiCAL - PCWN (Plum Chaeng Watthana)thongchai_007Încă nu există evaluări

- 6×25 (26) Fi WSDocument1 pagină6×25 (26) Fi WSthongchai_007Încă nu există evaluări

- Wind Load (EIT)Document3 paginiWind Load (EIT)thongchai_007Încă nu există evaluări

- Load Comb ASCE 98Document1 paginăLoad Comb ASCE 98thongchai_007Încă nu există evaluări

- Shear WallDocument12 paginiShear Wallthongchai_007Încă nu există evaluări

- SCAN Explain & Reply CommentsDocument7 paginiSCAN Explain & Reply Commentsthongchai_007Încă nu există evaluări

- Development Length of Deformed Bars (ACI 318-02) : L L F L D C K F D C K D F L D FDocument2 paginiDevelopment Length of Deformed Bars (ACI 318-02) : L L F L D C K F D C K D F L D Fthongchai_007Încă nu există evaluări

- Area 200 Struct-ModelDocument1 paginăArea 200 Struct-Modelthongchai_007Încă nu există evaluări

- Combinations of Loads (ACI 95) : Load CasesDocument1 paginăCombinations of Loads (ACI 95) : Load Casesthongchai_007Încă nu există evaluări

- IAW PREM Sale GalleryDocument43 paginiIAW PREM Sale Gallerythongchai_007Încă nu există evaluări

- Mat FootingDocument8 paginiMat Footingthongchai_007Încă nu există evaluări

- Project Details SheetDocument7 paginiProject Details Sheetthongchai_007Încă nu există evaluări

- Finite element analysis of plates using matrix equationsDocument20 paginiFinite element analysis of plates using matrix equationsthongchai_007Încă nu există evaluări

- The Reserve Thonglor - CAD For Inform1Document1 paginăThe Reserve Thonglor - CAD For Inform1thongchai_007Încă nu există evaluări

- EAPH ADD Column and Beam (FL Above 38 To 39)Document2 paginiEAPH ADD Column and Beam (FL Above 38 To 39)thongchai_007Încă nu există evaluări

- 3872-Article Text-7098-1-10-20180104 PDFDocument5 pagini3872-Article Text-7098-1-10-20180104 PDFthongchai_007Încă nu există evaluări

- Project Details SheetDocument7 paginiProject Details Sheetthongchai_007Încă nu există evaluări

- DD2 P1ab-S-8-01 Stair Details 1 PDFDocument1 paginăDD2 P1ab-S-8-01 Stair Details 1 PDFthongchai_007Încă nu există evaluări

- PREM For TenderDocument382 paginiPREM For Tenderthongchai_007100% (1)

- WallDocument9 paginiWallthongchai_007Încă nu există evaluări

- Reserve ThonglorDocument1 paginăReserve Thonglorthongchai_007Încă nu există evaluări

- So Samui MOMDocument6 paginiSo Samui MOMthongchai_007Încă nu există evaluări

- 8 TH FloorDocument11 pagini8 TH Floorthongchai_007Încă nu există evaluări

- Plum Chokchai 4: แบบ For Construction แบบ LanscapeDocument30 paginiPlum Chokchai 4: แบบ For Construction แบบ Lanscapethongchai_007Încă nu există evaluări

- Load Case Load Combin Ation: Sls7 Sls8 Sls9 SLS10Document1 paginăLoad Case Load Combin Ation: Sls7 Sls8 Sls9 SLS10thongchai_007Încă nu există evaluări

- ACI Moment Coefficient Design AID PDFDocument13 paginiACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Permanent Design CertificateDocument2 paginiPermanent Design Certificatethongchai_007Încă nu există evaluări

- Worksheet: This Worksheet With Header Is 70 Rows Deep Per Page Engineering With The SpreadsheetDocument4 paginiWorksheet: This Worksheet With Header Is 70 Rows Deep Per Page Engineering With The Spreadsheetthongchai_007Încă nu există evaluări

- Dhaka Mass Rapid Transit Development Project List of Drawings Jica Loan No. BD - P69Document19 paginiDhaka Mass Rapid Transit Development Project List of Drawings Jica Loan No. BD - P69thongchai_007Încă nu există evaluări

- Lviv in Your Pocket - October December 2009Document23 paginiLviv in Your Pocket - October December 2009Anti FreezeÎncă nu există evaluări

- Ala CalculationDocument4 paginiAla CalculationAgus SupriadiÎncă nu există evaluări

- Chapter 4 BTE3243Document76 paginiChapter 4 BTE3243Muhammad Shafiq Bin Abdul KarimÎncă nu există evaluări

- Possessive Pronouns and Adjectives ExplainedDocument5 paginiPossessive Pronouns and Adjectives ExplainedwilfredoÎncă nu există evaluări

- Introduction To Well ServiceDocument16 paginiIntroduction To Well ServiceDini Nur IslamiÎncă nu există evaluări

- Critical Success FactorsDocument12 paginiCritical Success Factorsmoon1377Încă nu există evaluări

- DuPont Shift Schedule ExplainedDocument3 paginiDuPont Shift Schedule ExplainedHanzÎncă nu există evaluări

- TerraPower Case PDFDocument7 paginiTerraPower Case PDFKaustav DeyÎncă nu există evaluări

- B1 exam preparation tipsDocument4 paginiB1 exam preparation tipsAnanth Divakaruni67% (6)

- Thesis Document1Document51 paginiThesis Document1ericson acebedoÎncă nu există evaluări

- A Project About Wild Animals Protection Week and Kalakad Mundanthurai Tiger ReserveDocument50 paginiA Project About Wild Animals Protection Week and Kalakad Mundanthurai Tiger ReserveSweetÎncă nu există evaluări

- Hubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliDocument12 paginiHubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliRirisÎncă nu există evaluări

- Classified2020 1 16770965Document2 paginiClassified2020 1 16770965Mohamed MaharÎncă nu există evaluări

- DFA and DOLE Not Liable for Repatriation Costs of Undocumented OFWDocument80 paginiDFA and DOLE Not Liable for Repatriation Costs of Undocumented OFWdhanty20Încă nu există evaluări

- Socio-Economic and Government Impact On Business: Lesson 4.4Document18 paginiSocio-Economic and Government Impact On Business: Lesson 4.4racelÎncă nu există evaluări

- Chp2 Taxonomy SW MaintaineanceDocument7 paginiChp2 Taxonomy SW MaintaineanceTooba AkhterÎncă nu există evaluări

- A Sample Demonstration Lesson PlanDocument9 paginiA Sample Demonstration Lesson PlanMarie Patrize Punzalan100% (1)

- It Complaint Management SystemDocument26 paginiIt Complaint Management SystemKapil GargÎncă nu există evaluări

- Design Procedure For Steel Column Bases With Stiff PDFDocument8 paginiDesign Procedure For Steel Column Bases With Stiff PDFAchilles TroyÎncă nu există evaluări

- Our Solar System Lesson PlanDocument20 paginiOur Solar System Lesson PlanDean EqualÎncă nu există evaluări

- DPBH Technical Bulletin 08-23-16 - Transfer of Medical RecordsDocument5 paginiDPBH Technical Bulletin 08-23-16 - Transfer of Medical RecordsBlayne OsbornÎncă nu există evaluări

- M-3311 DNP ProtocolDocument32 paginiM-3311 DNP ProtocolmaheshÎncă nu există evaluări

- HNI Corporation 2020 Annual Report Highlights Growth StrategyDocument84 paginiHNI Corporation 2020 Annual Report Highlights Growth StrategyRainy DaysÎncă nu există evaluări

- Kanban Card Creator v1.1Document30 paginiKanban Card Creator v1.1bukdownload04Încă nu există evaluări

- Vsan 70 Monitoring Troubleshooting GuideDocument51 paginiVsan 70 Monitoring Troubleshooting GuideRosembert AvilaÎncă nu există evaluări

- MODULE 7-11 Notes PrefiDocument7 paginiMODULE 7-11 Notes PrefiPASCUAL, ALJON R.Încă nu există evaluări

- Clean Air Council Announces Diesel Pollution Retrofit With Local Port OperatorsDocument4 paginiClean Air Council Announces Diesel Pollution Retrofit With Local Port OperatorscleanaircouncilÎncă nu există evaluări

- Well Logging Interpretation Methodology For Carbonate Formation Fracture System Properties DeterminationDocument11 paginiWell Logging Interpretation Methodology For Carbonate Formation Fracture System Properties Determinationel hadiÎncă nu există evaluări

- Thermal Engineering Lesson Plan for Mechanical Engineering StudentsDocument3 paginiThermal Engineering Lesson Plan for Mechanical Engineering StudentsblessyÎncă nu există evaluări

- India's Elite Anti-Naxalite Force CoBRADocument6 paginiIndia's Elite Anti-Naxalite Force CoBRAhumayunsagguÎncă nu există evaluări