Documente Academic

Documente Profesional

Documente Cultură

WPS Format For Asme Ix - Wps - Gtaw Fcaw Gmaw

Încărcat de

The Welding Inspections Community0 evaluări0% au considerat acest document util (0 voturi)

292 vizualizări1 paginăWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Titlu original

WPS format for Asme Ix - Wps - Gtaw Fcaw Gmaw

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

292 vizualizări1 paginăWPS Format For Asme Ix - Wps - Gtaw Fcaw Gmaw

Încărcat de

The Welding Inspections CommunityWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

The Welding Inspections Community

https://www.weldinginspections.net

contact@weldinginspections.net

Vung Tau City, SR. Viet Nam

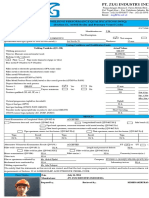

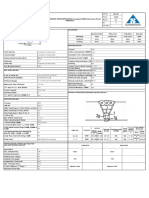

WELDING PROCEDURE SPECIFICATION

(ASME SECTION IX – 2019 EDITION)

DESCRIPTION JOINT SKETCH

.1 WPS no.:

.2 Date of issue:

.3 Applicable code:

.4 Welding process:

.5 Supporting PQR no.:

JOINTS (QW-402) GTAW FCAW

.1 Groove design:

.4 Backing:

.5 Backing:

.10 Root spacing:

.11 Retainers:

BASE METALS (QW-403) POSITIONS (QW-405) GTAW FCAW

.5 Group no.: .1 Position:

.6 T limits: .3 Vertical welding:

.8 T qualified:

.9 Max. pass thick. <= 13 mm: PREHEAT (QW-406)

.10 T limit (S. cir. Arc)

.11 P-no. qualified: .1 Min. preheat temperature:

FILLER METALS (QW-404) .2 Preheat maint.:

.3 Size [mm] .3 Max. inter-pass temperature:

.4 F-No. PWHT (QW-407)

.5 A-No. .1 PWHT temperature:

.6 Diameter [mm] .2 T & T range:

.7 Diameter > 6mm

.12 Spec. no. or Class. SFA/A

.14 Filler ELECTRICAL CHARACTERISTICS (QW-409)

.22 Consumable insert .1 Heat input:

.23 Filler metal product form .2 Transfer mode:

.24 Supplemental filler .3 Pulsing current:

.27 Alloy elements .4 Current & polarity:

.30 Max. deposit metal thick. .8 I & E range:

.32 t limit (S. cir. Arc) .12 Tungsten electrode:

.33 Classification

.50 Flux

TECHNIQUE (QW-410)

GAS (QW-408) .1 String / weave:

.1 Trailing or composition: .3 Orifice, nozzle or gas cup size:

.2 Single, mixture, or % .5 Method cleaning:

.3 Flow rate .6 Method back gouge:

.5 Backing flow: .7 Oscillation:

.9 Backing or composition: .8 Tube work distance [mm]

.10 Shielding or trailing: .9 Multi to single pass/side:

.10 Single to multi electrodes:

.11 Closed to out chamber:

REMARKS .15 Electrode spacing:

.25 Manual or automatic:

(*) .26 Peening:

.64 Use of thermal processes:

WELDING PARAMETERS

Filler metal Current & Ampere Travel speed Heat Input

Layer Process Voltage range Others

Class. Dia. polarity Range [mm/minute] [kJ/mm]

Root GTAW

Hot GTAW

Fill FCAW

Cap FCAW

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

Page | 1

S-ar putea să vă placă și

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Gta+sma PQRDocument3 paginiGta+sma PQRRahul MoottolikandyÎncă nu există evaluări

- Wps 15614 TemplateDocument2 paginiWps 15614 Template0502raviÎncă nu există evaluări

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pagini2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanÎncă nu există evaluări

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 paginiNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVÎncă nu există evaluări

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 paginiP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonÎncă nu există evaluări

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocument12 paginiDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaÎncă nu există evaluări

- MTC Er70s 2Document1 paginăMTC Er70s 2Mirza BaigÎncă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingMohammed MusaÎncă nu există evaluări

- Hardness Test Report: Test Details Machine DetailsDocument1 paginăHardness Test Report: Test Details Machine DetailsESHWAR CHARYÎncă nu există evaluări

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pagini177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- WELDING PROCEDURE SPECIFICATION SHEET 2 OF 2Document2 paginiWELDING PROCEDURE SPECIFICATION SHEET 2 OF 2surya1960Încă nu există evaluări

- PQR FormDocument2 paginiPQR Formpokok assamÎncă nu există evaluări

- Welder and Welding Operator Performance Qualification RecordDocument1 paginăWelder and Welding Operator Performance Qualification RecordAsif HameedÎncă nu există evaluări

- Cert Piping W54.5Document2 paginiCert Piping W54.5SANU0% (1)

- New Microsoft Excel WorksheetDocument6 paginiNew Microsoft Excel Worksheetravi00098Încă nu există evaluări

- 3580Document1 pagină3580milamiroslavaÎncă nu există evaluări

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pagini1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- WPQR SBM 029Document3 paginiWPQR SBM 029HoJienHauÎncă nu există evaluări

- ASME 9 Multi Process Welding Procedures QW200Document2 paginiASME 9 Multi Process Welding Procedures QW200Teodor EzaruÎncă nu există evaluări

- Baosteel hot rolled steel plate quality certificateDocument3 paginiBaosteel hot rolled steel plate quality certificateDang TranÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- Destructive Test Report for Welding SamplesDocument14 paginiDestructive Test Report for Welding SamplesMark AnthonyÎncă nu există evaluări

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 paginiTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanÎncă nu există evaluări

- WPS List For Piping: (Asme Section Ix)Document2 paginiWPS List For Piping: (Asme Section Ix)Ali MoosaviÎncă nu există evaluări

- PMI Testing Ensures Material Specification ComplianceDocument24 paginiPMI Testing Ensures Material Specification ComplianceSANKARAN.KÎncă nu există evaluări

- WPS Welding Procedure SpecificationDocument1 paginăWPS Welding Procedure SpecificationburakÎncă nu există evaluări

- Spec Sheet - Handler 187Document4 paginiSpec Sheet - Handler 187Hobart Welding ProductsÎncă nu există evaluări

- Welding Procedure Qualification Record: Shipyard LogoDocument4 paginiWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 paginiVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTAÎncă nu există evaluări

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 paginiPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluÎncă nu există evaluări

- Welding Procedure Specification SampleDocument2 paginiWelding Procedure Specification Samplesamer_saif8456100% (1)

- Method Statement For In-Situ Metallography Test: DCSM Project 2019Document5 paginiMethod Statement For In-Situ Metallography Test: DCSM Project 2019Thinh NguyenÎncă nu există evaluări

- WPS Ernicu 7 R1 3 6 PDFDocument4 paginiWPS Ernicu 7 R1 3 6 PDFandresÎncă nu există evaluări

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 paginiQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonÎncă nu există evaluări

- Public-: Rev. D E English 03 / 2014Document33 paginiPublic-: Rev. D E English 03 / 2014xaviereduardoÎncă nu există evaluări

- BPVC Ix QW-482Document2 paginiBPVC Ix QW-482ganesh82Încă nu există evaluări

- Quality and Environment Manual Revision 28Document23 paginiQuality and Environment Manual Revision 28Gabriel GaraventaÎncă nu există evaluări

- Tigweldarc Alloys: Certification of TestsDocument1 paginăTigweldarc Alloys: Certification of TestsArunÎncă nu există evaluări

- Indt QCP RT HJ 05NDocument14 paginiIndt QCP RT HJ 05NAsad Bin Ala QatariÎncă nu există evaluări

- Hardness Tester Novotest T Ud2Document4 paginiHardness Tester Novotest T Ud2Rushikesh JoshiÎncă nu există evaluări

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 paginiSample Wps Carbon Steel GTAW SMAW PDFirwanÎncă nu există evaluări

- Supercito (E 42 5 B 32 h5)Document1 paginăSupercito (E 42 5 B 32 h5)brunizzaÎncă nu există evaluări

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 paginiWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniÎncă nu există evaluări

- Welder Certificate Akilesh YadavDocument1 paginăWelder Certificate Akilesh Yadavtripatipankaj023Încă nu există evaluări

- JIS G3452 PipeDocument0 paginiJIS G3452 PipefaridyeniÎncă nu există evaluări

- ArcelorMittal DOMSpecsDocument12 paginiArcelorMittal DOMSpecsAnurag DixitÎncă nu există evaluări

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 paginăTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdÎncă nu există evaluări

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- Wps-01 C.S. GtawDocument2 paginiWps-01 C.S. GtawMohamed Tarek HamamÎncă nu există evaluări

- 2011-IWE IIW Sep OKDocument1 pagină2011-IWE IIW Sep OKanon_837486352Încă nu există evaluări

- En 13920-2015Document8 paginiEn 13920-2015mihaiÎncă nu există evaluări

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 paginiUtoc Preliminary Wps Shell Project 270807 PDFErick HoganÎncă nu există evaluări

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 paginăAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityÎncă nu există evaluări

- Asmeix Wps Fcawgmaw 191019041529 PDFDocument1 paginăAsmeix Wps Fcawgmaw 191019041529 PDFvinod100% (1)

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 paginăWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - SmawDocument1 paginăWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityÎncă nu există evaluări

- ASME IX Sample WPS GTAW SMAWDocument1 paginăASME IX Sample WPS GTAW SMAWDeepak ShrivastavÎncă nu există evaluări

- WPS Format For ISO 15614-1 WPSDocument1 paginăWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For ISO 15614-1 PWPSDocument1 paginăWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For AWS D1.1 - WPS - SAWDocument1 paginăWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For AWS D1.1 - WelderDocument1 paginăWPS Format For AWS D1.1 - WelderThe Welding Inspections Community100% (1)

- WPS Format For ISO 9606-1 WelderDocument2 paginiWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- WPS Format For AWS D1.1 - PQR - SMAWDocument3 paginiWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- WPS Format For ISO 15614-1 PQRDocument3 paginiWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 paginăWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 paginăWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For ASME IX - WQTDocument1 paginăWPS Format For ASME IX - WQTThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For ASME IX - WPS - SAWDocument1 paginăWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - SmawDocument1 paginăWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - GtawDocument1 paginăWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 paginăWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For ASME IX - PQR-AllDocument3 paginiWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Topic 3Document28 paginiTopic 3Ashraf YusofÎncă nu există evaluări

- Veiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inDocument8 paginiVeiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inYakov Mario QuinterosÎncă nu există evaluări

- Risk and Risk ManagementDocument8 paginiRisk and Risk ManagementMARY JUSTINE PAQUIBOTÎncă nu există evaluări

- Foundation ProblemsDocument71 paginiFoundation Problemsيقين يقين0% (1)

- Theories of SelfDocument5 paginiTheories of SelfTd Devi AmmacayangÎncă nu există evaluări

- DMS 48 NormesDocument11 paginiDMS 48 NormesSonia WittmannÎncă nu există evaluări

- w5 Philo Module 5Document24 paginiw5 Philo Module 5prestonvela15Încă nu există evaluări

- Atpl Formula MergedDocument74 paginiAtpl Formula Mergeddsw78jm2mxÎncă nu există evaluări

- Strategic Investment Plan ForDocument78 paginiStrategic Investment Plan Forapi-3833112Încă nu există evaluări

- T38N/T48N: Suffix Code Instruction ManualDocument1 paginăT38N/T48N: Suffix Code Instruction ManualaliÎncă nu există evaluări

- Basf Masteremaco Application GuideDocument15 paginiBasf Masteremaco Application GuideSolomon AhimbisibweÎncă nu există evaluări

- Eccsa Five Year (2014 15 - 2018 19) Strategic PlanDocument95 paginiEccsa Five Year (2014 15 - 2018 19) Strategic Planyayehyirad100% (1)

- Samsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingDocument47 paginiSamsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingOuadghiri Badre Ddine50% (2)

- Hardware Devices Used in Virtual Reality TechnologiesDocument6 paginiHardware Devices Used in Virtual Reality TechnologiesTheMoon LightÎncă nu există evaluări

- Halo Outdoor slmt1000 - slmt1000wDocument1 paginăHalo Outdoor slmt1000 - slmt1000wFrank MoyaÎncă nu există evaluări

- Development Drop - Number - Peformance - For - EstimateDocument11 paginiDevelopment Drop - Number - Peformance - For - Estimateanon_459056029Încă nu există evaluări

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACDocument13 paginiAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiÎncă nu există evaluări

- Guidlines Norms For Grant of Permission For Construction of Acce001Document6 paginiGuidlines Norms For Grant of Permission For Construction of Acce001Abhi Corleone BallackÎncă nu există evaluări

- The Scientific MethodDocument4 paginiThe Scientific MethodRob LovÎncă nu există evaluări

- EN6VC IIIa 6.2 - 2023 2024Document2 paginiEN6VC IIIa 6.2 - 2023 2024Ma. Feliza SaliganÎncă nu există evaluări

- NCP 1014Document24 paginiNCP 1014rodricaldasÎncă nu există evaluări

- BOQ Sample of Electrical DesignDocument2 paginiBOQ Sample of Electrical DesignAshik Rahman RifatÎncă nu există evaluări

- Mental AspectDocument29 paginiMental AspectBenjii CarlosÎncă nu există evaluări

- Interview Questions and Answer or Learning Pega - 39Document11 paginiInterview Questions and Answer or Learning Pega - 39Sharad Mishra100% (1)

- Dayal Bagh: Spircon 2013: Book of AbstractsDocument202 paginiDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- Jupiter - The Giant Planet That Destroys CometsDocument2 paginiJupiter - The Giant Planet That Destroys Cometsmaiche amarÎncă nu există evaluări

- Drainage PDFDocument1 paginăDrainage PDFSwapnil JainÎncă nu există evaluări

- 1 Clock Domain CrossingDocument35 pagini1 Clock Domain CrossingRamakrishnaRao SoogooriÎncă nu există evaluări

- Chem 361 Separation Methods IntroDocument8 paginiChem 361 Separation Methods IntroTwum SomoahÎncă nu există evaluări