Documente Academic

Documente Profesional

Documente Cultură

Qw-483 Suggested Format For Welding Procedure Qualification Records (PQR)

Încărcat de

aliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Qw-483 Suggested Format For Welding Procedure Qualification Records (PQR)

Încărcat de

aliDrepturi de autor:

Formate disponibile

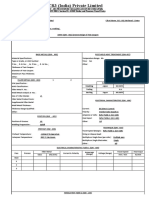

QW-483 SUGGESTED FORMAT FOR WELDING PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASME Boiler & Pressure Vessel Code)

Record Actual Conditions Used to Weld test Coupon.

Company Name ACME Welding

Procedure Qualification Record No. ACME-SMAW-PQR-004 (supplemental) Date 2/20/11

WPS No. ACME-SMAW-WPS-004

Welding Process(es) SMAW

Type (Manual, Automatic, Semi-Auto.) Manual

JOINTS (QW-402)

70 degree groove angle

0.375 inch thick plate

0.125 inch root opening

0.125 inch root face

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.)

BASE METALS (QW-403)

POSTWELD HEAT TREATMENT (QW-407)

Material Spec. SA-285

Type or C Temperature None performed

Grade Time None performed

P-No. 1 Group 1 to P-No. 1 Group 1 Other

Thickness of Test Coupon 0.375 inch

Diameter of Test Coupon NA

Other Plate

GAS (QW-408)

Percent Composition

Gas(es) (Mixture) Flow Rate

Shielding

Trailing

FILLER METALS (QW-404) Backing

SFA Specification 5.1 ELECTRICAL CHARACTERISTICS (QW-409)

AWS Classification E6011 Current DC

Filler Metal F-No. 3 Polarity Reverse (electrode positive)

Weld Metal Analysis A-No. 1 Amps Volts

Size of Filler Metal 3/16 inch Tungsten Electrode Size

Max. Pass Thickness 3/16 inch Other

Weld Metal Thickness 0.375 inch

Other

TECHNIQUE (QW-410)

POSITIONS (QW-405) Travel Speed Manual

Position of Groove 1G String or Weave Bead Root-stringer Fill-weave

Weld Progression (Uphill, Downhill) None Oscillation NA

Other Multipass or Single Pass (per side) Multipass

Single or Multiple Electrodes Single

Use of Thermal Processes NA

PREHEAT (QW-406) Other

Preheat Temp. 65 º F

Heat Input: 18,750 J/in.

Interpass Temp. 250 º F

Max. Current: 150 amps, Max. Voltage: 25 volts

Other

Min. Travel Speed: 5 ipm

QW-483 (Back)

PQR No. ACME-SMAW-PQR-004

Tensile Test (QW-150)

Specimen Ultimate Ultimate Type of

No. Width Thickness Area Total Load, lb. Unit Stress, psi Failure &

Location

Guided-Bend Tests (QW-160)

Type and Figure No. Result

Toughness Tests (QW-170)

Specimen Notch Specimen Test Impact Values

No. Location Size Temp. ft-lb % Shear Mils Drop Weight Break (Y/N)

W-1 Weld Metal Standard - 20 º F 55

W-2 Weld Metal Standard - 20 º F 60

W-3 Weld Metal Standard - 20 º F 70

HAZ-1 HAZ Standard - 20 º F 30

HAZ-2 HAZ Standard - 20 º F 28

HAZ-3 HAZ Standard - 20 º F 25

Comments:____This is supplemental PQR only, to meet the requirements of construction code CC-Test Code, 2010 Edition

Fillet-Weld Test (QW-180)

Result – Satisfactory: Yes No Penetration into Parent Metal: Yes No

Macro - Results

Other Tests

Type of Test

Deposit Analysis

Other

Welder's Name Frank Welder Clock No. 9999 Stamp No.

Tests Conducted By: Fly By Night Testing Lab Test No. FBN-791

We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with the requirements of

Section IX of the ASME Code.

Manufacturer ACME Welding

Date Tested 2/25/11 By Fred Garfarkle

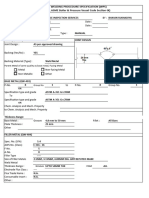

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name ACME Welding By: Fred Garfarkle

WPS No. ACME-SMAW-WPS-004 Date 2/25/11 Supporting PQR No.(s) ACME-SMAW-PQR-003

Revision No. Original Date 2/25/11 ACME-SMAW-PQR-004

Welding Process(es) SMAW Type(s) Manual

(Automatic, Manual, Machine, or Semi-Auto.)

JOINTS (QW-402) Details

Joint Design Vee, Single bevel, or U-groove

Backing With or without

Backing Material (Type) Any P-No. 1 material, when used

(Refer to both backing and retainers)

X Metal Nonfusing Metal Root Opening: 3/16 inch, maximum

Retainers: Not permitted

Nonmetallic Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

(At the option of the Mfr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness

procedures, for multiple process procedures, etc.)

*BASE METALS (QW-403)

P-No. 1 Group No. 1 to P-No. 1 Group No. 1

OR

Specification type and grade All

to Specification type and grade All

OR

Chem. Analysis and Mech. Prop.

to Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal: Groove 3/8 inch to 3/4 inch Fillet All

Other All pipe diameters

*FILLER METALS (QW-404)

Spec. No. (SFA) 5.1 or 5.5

AWS No. (Class) E6011 only

F-No. 3

A-No. 1

Size of Filler Metals 3/32 inch, 1/8 inch, or 5/32 inch

Weld Metal

Thickness Range:

Groove 3/4 inch, maximum

Fillet No limit

Electrode-Flux (Class) None

Flux Trade Name NA

Consumable Insert NA

Other Maximum pass thickness 1/8 inch

* Each base metal-filler metal combination should be recorded individually

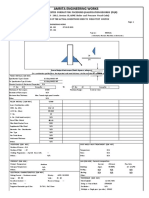

QW-482 (Back)

WPS No. ACME-SMAW-WPS-004 Rev. Original

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove All Temperature Range Not permitted

Welding Progression: Up No Down Yes Time Range Not permitted

Position(s) of Fillet All

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temp. Min. 0ºF Gases (Mixture) Flow Rate

Interpass Temp. Max. 350 º F

Preheat Maintenance NA Shielding

(Continuous or special heating, where applicable, should be recorded) Trailing

Backing

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC Polarity Reverse (EP)

Amps (Range) 150 max. Volts (Range) 25 max. Heat Input limited to 18,750 J/in, maximum

(Amps and volts range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a tabular

form similar to that shown below.)

Tungsten Electrode Size and Type

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW

(Spray arc, short circuiting arc, etc.)

Electrode Wire feed speed range

TECHNIQUE (QW-410)

String or Weave Bead Either, as needed

Orifice or Gas Cup Size NA

Initial and Interpass Cleaning (Brushing, Grinding, etc.) Remove all rust, paint, slag, and debris by grinding or wire brushing

Method of Back Gouging NA

Oscillation NA

Contact Tube to Work Distance NA

Multiple or Single Pass (per side) Multipass only

Multiple or Single Electrodes Single electrode

Travel Speed (Range) Manual

Peening Not permitted

Other Thermal processes NA for this P-Number Group Number qualification

Filler Metal Current

Other

(e.g., Remarks, Com-

Travel ments, Hot Wire

Weld Type Amp Volt Speed Addition, Technique,

Layer (s) Process Class Dia. Polar. Range Range Range Torch Angle, etc.)

Root SMAW E6011 As needed EP 150 max. 25 max. 5 ipm,

min.

Fill SMAW E6011 As needed EP 150 max. 25 max. 5 ipm,

min.

Cover SMAW E6011 As needed EP 150 max. 25 max. 5 ipm,

min.

S-ar putea să vă placă și

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Fillet Inspection SheetDocument2 paginiFillet Inspection SheetShankey JAlanÎncă nu există evaluări

- Transducer Handbook: User's Directory of Electrical TransducersDe la EverandTransducer Handbook: User's Directory of Electrical TransducersÎncă nu există evaluări

- SAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Document2 paginiSAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Lovedeep SinghÎncă nu există evaluări

- Qw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Document3 paginiQw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Zam Zam NoorÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFEmma DÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFEmma DÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFDwi Agus YuliyantoÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFEmma DÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFedinson castrilloÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFazizÎncă nu există evaluări

- PQR - 007 샘플Document2 paginiPQR - 007 샘플주용환Încă nu există evaluări

- PQR - 007 샘플Document2 paginiPQR - 007 샘플주용환Încă nu există evaluări

- Procedure Qualification RecordDocument2 paginiProcedure Qualification RecordDan ClarkeÎncă nu există evaluări

- Suggested Format PQRDocument2 paginiSuggested Format PQRAngel RebolloÎncă nu există evaluări

- Form PQR 2 AsmeDocument6 paginiForm PQR 2 AsmeZam Zam NoorÎncă nu există evaluări

- Aditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)Document1 paginăAditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)Anand MakasanaÎncă nu există evaluări

- QW 483Document2 paginiQW 483delta lab sangliÎncă nu există evaluări

- SC PTSS PQRDocument3 paginiSC PTSS PQRprayogaÎncă nu există evaluări

- Form PQR 1 AsmeDocument6 paginiForm PQR 1 AsmeZam Zam NoorÎncă nu există evaluări

- PQRDocument2 paginiPQRafqzfieÎncă nu există evaluări

- 37507022-WPS-PQR-SS-316 LDocument5 pagini37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Acfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Document6 paginiAcfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Daniel CamposÎncă nu există evaluări

- Procedure Qualification Record (PQR)Document3 paginiProcedure Qualification Record (PQR)surjithkocherilÎncă nu există evaluări

- Welding Procedure Specification FormatDocument3 paginiWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocument3 paginiToaz - Info Welding Procedure Specification Format PRKarim ZahranÎncă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriÎncă nu există evaluări

- Graycor WPS 19 SampleDocument5 paginiGraycor WPS 19 SampleRaul SebastiamÎncă nu există evaluări

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 paginiWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainÎncă nu există evaluări

- Qw-482 Welding Procedure Specification (WPS)Document3 paginiQw-482 Welding Procedure Specification (WPS)Sagar GourÎncă nu există evaluări

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 paginiWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberÎncă nu există evaluări

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 paginiJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148Încă nu există evaluări

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 paginiQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghÎncă nu există evaluări

- WPS1Document10 paginiWPS1bhavin178Încă nu există evaluări

- WPS-PQR Gr. WCBDocument9 paginiWPS-PQR Gr. WCBansarmulla711Încă nu există evaluări

- WPS-PQR Gr. CF8MDocument9 paginiWPS-PQR Gr. CF8Mansarmulla711Încă nu există evaluări

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 paginiWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Sample Editable WPSDocument2 paginiSample Editable WPSsbmmlaÎncă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedÎncă nu există evaluări

- WPS-ASME SEC IX-for PSODocument3 paginiWPS-ASME SEC IX-for PSOSultan ZebÎncă nu există evaluări

- WPS-CS-113 Rev.1Document2 paginiWPS-CS-113 Rev.1Muhammad BilalÎncă nu există evaluări

- PQWDocument3 paginiPQWcorey jacobsÎncă nu există evaluări

- Welding Procedure SpecificationDocument27 paginiWelding Procedure SpecificationGopakumar K100% (2)

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 paginiAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyÎncă nu există evaluări

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiÎncă nu există evaluări

- WPS and PQRDocument4 paginiWPS and PQRdandiar1Încă nu există evaluări

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadÎncă nu există evaluări

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 paginiQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiÎncă nu există evaluări

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 paginiQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaÎncă nu există evaluări

- WPS GTAW-SMAW h2Document1 paginăWPS GTAW-SMAW h2Jesus Gabrielw Blanco GhostbustersIzÎncă nu există evaluări

- Tips Wps FormatDocument5 paginiTips Wps FormatWaqas WaqasÎncă nu există evaluări

- Wps PQR Welder Qualification Certification ConsultancyDocument2 paginiWps PQR Welder Qualification Certification ConsultancyEmam SayedÎncă nu există evaluări

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 paginiBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyÎncă nu există evaluări

- Form Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponDocument2 paginiForm Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponMijanur Rahman100% (1)

- Smaw PQR FinalDocument3 paginiSmaw PQR Finalsheikmoin100% (1)

- Suria Engineering: Procedure Qualification Record (PQR)Document2 paginiSuria Engineering: Procedure Qualification Record (PQR)suria qaqcÎncă nu există evaluări

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 paginiWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiÎncă nu există evaluări

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pagini(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Mechanical Engineering M.Abdul GhoziDocument4 paginiMechanical Engineering M.Abdul GhoziRizaldy PhoenksÎncă nu există evaluări

- WPS Astm - A 53Document2 paginiWPS Astm - A 53S. K. M. ShujonÎncă nu există evaluări

- Constructing Ashby MapDocument9 paginiConstructing Ashby MapIr FankovicÎncă nu există evaluări

- 06 The Chlor-Alkali Industry PDFDocument26 pagini06 The Chlor-Alkali Industry PDFpetrolorito100% (2)

- EVS 1101 QuestionsDocument7 paginiEVS 1101 QuestionsJameson CongoÎncă nu există evaluări

- WEP Energy Question BankDocument2 paginiWEP Energy Question BankAJ SkybornÎncă nu există evaluări

- 1046a User's Guide 01046-90004Document180 pagini1046a User's Guide 01046-90004omarou18Încă nu există evaluări

- ASTM Casting MaterialsDocument1 paginăASTM Casting Materialschy_81Încă nu există evaluări

- Tempering MartensiteDocument21 paginiTempering Martensitejardel de matosÎncă nu există evaluări

- Cytotoxic Screening of Tropical Plants Using Brine Shrimp Lethality TestDocument20 paginiCytotoxic Screening of Tropical Plants Using Brine Shrimp Lethality TestPrograma BRICÎncă nu există evaluări

- Activity Sheets For Chem With NamesDocument6 paginiActivity Sheets For Chem With Namesapi-283862617100% (1)

- VNMU Named After MI Пирогова - Electronic MagazineDocument3 paginiVNMU Named After MI Пирогова - Electronic MagazineWilliam Opoku AsamoahÎncă nu există evaluări

- Drinking Water AssesmentDocument9 paginiDrinking Water AssesmentMeenu AgarwalÎncă nu există evaluări

- Supervision Manual As Guidance For Supervisory StaffDocument20 paginiSupervision Manual As Guidance For Supervisory StaffAxelÎncă nu există evaluări

- NVT Simulation of Argon Using Lennard-Jones PotentialDocument2 paginiNVT Simulation of Argon Using Lennard-Jones Potentialt_sairamÎncă nu există evaluări

- C17H PDFDocument40 paginiC17H PDFramau619Încă nu există evaluări

- AIIMS 2019 Chemistry Sample Question PaperDocument10 paginiAIIMS 2019 Chemistry Sample Question PapermisostudyÎncă nu există evaluări

- Soap and DtergenetsDocument13 paginiSoap and DtergenetsAkanksha PanigrahyÎncă nu există evaluări

- The Permanence and Care of Color PhotographsDocument24 paginiThe Permanence and Care of Color PhotographschioqueÎncă nu există evaluări

- HC Verma Gauss Law SolutionsDocument31 paginiHC Verma Gauss Law SolutionsSakshamÎncă nu există evaluări

- Hi9813 6 - Hi9813 5Document4 paginiHi9813 6 - Hi9813 5Vani IIÎncă nu există evaluări

- Eh40 2005Document74 paginiEh40 2005Adel SukerÎncă nu există evaluări

- Corrosometer ER Probe Selection GuideDocument4 paginiCorrosometer ER Probe Selection GuideHenny CasanovaÎncă nu există evaluări

- Chapter 1 - Essential Ideas 64: Exercise 1.78Document1 paginăChapter 1 - Essential Ideas 64: Exercise 1.78Dennoh OlengoÎncă nu există evaluări

- Packer Failure PDFDocument23 paginiPacker Failure PDFAnonymous rey6aU3ZÎncă nu există evaluări

- Differential EquationDocument9 paginiDifferential EquationmCmAlÎncă nu există evaluări

- Going Great Lengths To Identify WavelengthsDocument9 paginiGoing Great Lengths To Identify Wavelengthsapi-250299627Încă nu există evaluări

- 2016 Powerblanket CatalogDocument40 pagini2016 Powerblanket CatalogNathaniel EvansÎncă nu există evaluări

- SSG Manual: Dow Performance SiliconesDocument59 paginiSSG Manual: Dow Performance SiliconesAditya KÎncă nu există evaluări

- Class 6 NSO Sample Paper (2017-18)Document2 paginiClass 6 NSO Sample Paper (2017-18)ZaraÎncă nu există evaluări

- Pi Acryleze Ent Coat StabDocument2 paginiPi Acryleze Ent Coat StabFlorin PătrulescuÎncă nu există evaluări