Documente Academic

Documente Profesional

Documente Cultură

Test Procedure (HTC)

Încărcat de

raja qammar0 evaluări0% au considerat acest document util (0 voturi)

71 vizualizări1 paginăTest Procedure (HTC

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentTest Procedure (HTC

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

71 vizualizări1 paginăTest Procedure (HTC)

Încărcat de

raja qammarTest Procedure (HTC

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

29-Aug-2019 (Submitted to : M/s Petrofac / PSC JV ( KNPC , CFP MAB-1)

TEST PROCEDURE FOR CHECKING SUITABILITY OF USING THERMON HTC (T3) BEYOND THE

RECOMMENDED SHELF LIFE ( 1YR FROM THE DATE OF MANUFACTURING ) UPTO A MAXIMUM

OF 6 MONTHS FROM THE EXPIRY DATE

Step.1 :

Segregate the expired HTC pails which are within 18 months from the date of manufacturing batch wise and

select a HTC pail from a particular batch of pails

Step.2:

Open the HTC pail and check physical condition. If found ok proceed to step.3 or if found solidified and not

suitable for troweling carry on the salvaging process as per the procedure demonstrated at site by THERMON

on 28th May 2019 ( copy of the document attached) and then proceed to step.3

Step.3 : TROWEL TEST

The texture is checked by taking a hand trowel, loading with product, inverting and holding for ten (10)

seconds. If the material does not fall off suddenly then the compound is ok, otherwise it has to be mixed

properly, and the trowel test re-conducted. If the compound fails again reject the pail and the entire batch

stands rejected.

Step.4 : CURE TEST

A sample of product (about 100 gms) from each batch is placed in an Aluminum tray and exposed to 200°F

(94°C) for 4 hours. Product shall have cured to rock hard consistency after the heat ageing and after having

cooled down to ambient temperature. Should a cure not occur, two more samples are prepared and similarly

cured, both additional samples shall cure to a rock hard consistency or all the pails from that batch stands

rejected.

Step.5 : CHEMICAL STABILITY TEST

HTC product from each batch is placed in an airtight plastic bag /container for 48 hours minimum at room

temperature. Product should not cure during this period of time. If the product cures, the batch stands

rejected.

Step.6: BOND SHEAR TEST

The product from the sample pail shall be trowelled on a 2” x 2” piece of 18 gauge steel plate and

sandwiched within an identical piece on top such that a ¼” thick layer of cured HTC results. The sample shall

be cured in the oven at 200°F (94°C) for 4 hours. Subsequently it shall be placed in the production pull tester

and shall withstand the force of pull (150 lb/in2) without losing bond. Should a failure occur two more

samples shall be prepared and similarly cured and tested. If any of the samples fail the batch stands rejected

REPEAT THE SAME PROCEDURE

FOR EACH BATCH OF EXPIRED

PAILS SELECTED FOR TESTING (

WITHIN 6MONTHS OF EXPIRY)

S-ar putea să vă placă și

- Astm C974Document2 paginiAstm C974deivisbtsÎncă nu există evaluări

- Sampling Materials For ShotcreteDocument2 paginiSampling Materials For ShotcreteEvert RiveraÎncă nu există evaluări

- Astm D3512 PDFDocument2 paginiAstm D3512 PDFEDGAR IMANÎncă nu există evaluări

- F495 PDFDocument2 paginiF495 PDFsabaris ksÎncă nu există evaluări

- Sampling Materials For ShotcreteDocument2 paginiSampling Materials For Shotcretesmanoj354Încă nu există evaluări

- TB 117 2013Document13 paginiTB 117 2013Max WanÎncă nu există evaluări

- MTM0126 - 96 Hour Humidity Test, Paint Materials On PlasticsDocument2 paginiMTM0126 - 96 Hour Humidity Test, Paint Materials On Plasticsalper ozturkÎncă nu există evaluări

- C1304-08 (2013) Standard Test Method For Assessing The Odor Emission of Thermal Insulation MaterialsDocument2 paginiC1304-08 (2013) Standard Test Method For Assessing The Odor Emission of Thermal Insulation MaterialsAlabbas FadhelÎncă nu există evaluări

- Determining Effect of Packaging On Food and Beverage Products During StorageDocument3 paginiDetermining Effect of Packaging On Food and Beverage Products During StoragepravkovoilaÎncă nu există evaluări

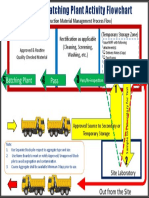

- Proposed Source To Batching Plant Flowchart - Edited - 06.04.2022 PDFDocument1 paginăProposed Source To Batching Plant Flowchart - Edited - 06.04.2022 PDFudayÎncă nu există evaluări

- Astm e 460 - 04Document3 paginiAstm e 460 - 04Francisco Guerra100% (1)

- Astm C 97-2018Document4 paginiAstm C 97-2018Mohammed AliÎncă nu există evaluări

- MAS Kit Instruction ManualDocument6 paginiMAS Kit Instruction Manualfionafong0402Încă nu există evaluări

- Sampling and Preparation of Wet Blue and Wet White For Physical and Chemical TestsDocument3 paginiSampling and Preparation of Wet Blue and Wet White For Physical and Chemical Testsmohammed karasnehÎncă nu există evaluări

- T - 491 Water Immersion Number of PaperboardDocument4 paginiT - 491 Water Immersion Number of Paperboardomar hernandezÎncă nu există evaluări

- Abrasion Resistance - MartindaleDocument3 paginiAbrasion Resistance - Martindalemeghana rajÎncă nu există evaluări

- Candelaria Experiment1 SoilMechLabDocument12 paginiCandelaria Experiment1 SoilMechLabHarley O. CandelariaÎncă nu există evaluări

- Width of Leather: Standard Test Method ForDocument2 paginiWidth of Leather: Standard Test Method ForTarakJanaÎncă nu există evaluări

- Abrasion Resistance by The Martindale MethodDocument12 paginiAbrasion Resistance by The Martindale MethodVignesh NagappanÎncă nu există evaluări

- ASTM E873 (Densidad Aparente)Document2 paginiASTM E873 (Densidad Aparente)Alejo DelgadoÎncă nu există evaluări

- Selection of Suitable Test ProcedureDocument27 paginiSelection of Suitable Test Procedurebrarjasleenk1210Încă nu există evaluări

- IS516 - Part1 - Sec1 - 2021 ReffDocument20 paginiIS516 - Part1 - Sec1 - 2021 ReffKarnalPreethÎncă nu există evaluări

- E 920 Â " 97 - RTKYMC05NWDocument2 paginiE 920 Â " 97 - RTKYMC05NWhans ccÎncă nu există evaluări

- PART Agsdf SFD GSDF G FSDG DSFGDocument6 paginiPART Agsdf SFD GSDF G FSDG DSFGHarshitSmiokitChauhanÎncă nu există evaluări

- D 4333 - 99 RDQZMZMDocument2 paginiD 4333 - 99 RDQZMZMfrostestÎncă nu există evaluări

- 22669-Article Text-113210-1-10-20180101Document4 pagini22669-Article Text-113210-1-10-20180101apachaicrÎncă nu există evaluări

- F1140 PDFDocument5 paginiF1140 PDFรอคนบนฟ้า ส่งใครมาให้ สักคน100% (1)

- ASTM E873 - Bulk Density of Densified Particulate Biomass FuelsDocument2 paginiASTM E873 - Bulk Density of Densified Particulate Biomass FuelsSYAHIRAH BINTI ROSLIÎncă nu există evaluări

- D7160 16Document7 paginiD7160 16ertfgbdfbÎncă nu există evaluări

- 2.9.40. Uniformity of Dosage Units 20940eDocument4 pagini2.9.40. Uniformity of Dosage Units 20940ecupidvishu123Încă nu există evaluări

- D 2471 - 99Document3 paginiD 2471 - 99Christian HinostrozaÎncă nu există evaluări

- PhthalatesopDocument8 paginiPhthalatesopferhinoÎncă nu există evaluări

- Method of Testing The Smell of Interior Parts: Nissan Engineering StandardDocument17 paginiMethod of Testing The Smell of Interior Parts: Nissan Engineering StandardjenwitbunjongsatÎncă nu există evaluări

- D 1758 96 Rde3ntgtukve PDFDocument9 paginiD 1758 96 Rde3ntgtukve PDFdidbeauÎncă nu există evaluări

- Qa QC BenthosDocument16 paginiQa QC BenthosGilbert NdibeÎncă nu există evaluări

- Astm d5261Document2 paginiAstm d5261lee_cur_van4883100% (3)

- SPE-119242-MS Myths About ProppantDocument15 paginiSPE-119242-MS Myths About ProppantAtul SinghÎncă nu există evaluări

- Student Laboratory ManualDocument34 paginiStudent Laboratory ManualCE PassajÎncă nu există evaluări

- Astm D5444-15Document3 paginiAstm D5444-15UNUSED MUSIC MIRANDAÎncă nu există evaluări

- Celda Flash Site Skim Air Test Procedure With PhotosDocument9 paginiCelda Flash Site Skim Air Test Procedure With Photosealfaro6580Încă nu există evaluări

- HbA1c User Manual-20220413001Document2 paginiHbA1c User Manual-20220413001Pedro RodriguezÎncă nu există evaluări

- Extraction of Medical Plastics: Standard Practice ForDocument4 paginiExtraction of Medical Plastics: Standard Practice FormmorozoÎncă nu există evaluări

- Leather ASTM D3790-79-2001Document2 paginiLeather ASTM D3790-79-2001Gulfam HussainÎncă nu există evaluări

- Measuring Mass Per Unit Area of Geotextiles: Standard Test Method ForDocument2 paginiMeasuring Mass Per Unit Area of Geotextiles: Standard Test Method ForAyman ZakariaÎncă nu există evaluări

- Soil Tests: Participant Workbook Laboratory ManualDocument167 paginiSoil Tests: Participant Workbook Laboratory Manualkylo_Ren100% (1)

- Specimen Log SheetDocument1 paginăSpecimen Log SheetMUHAMMAD WILDAN ILYAS BIN MOHAMED GHAZALI / ENGÎncă nu există evaluări

- Melt Flow Test Procedure: POLYOX Water-Soluble ResinsDocument1 paginăMelt Flow Test Procedure: POLYOX Water-Soluble ResinsNia SyafiqqÎncă nu există evaluări

- Metodo AOCS Am 5 04 PDFDocument3 paginiMetodo AOCS Am 5 04 PDFRosa VelásquezÎncă nu există evaluări

- D 2944 - 71 R98 Rdi5ndq - PDFDocument2 paginiD 2944 - 71 R98 Rdi5ndq - PDFLupita CarelyÎncă nu există evaluări

- MQA103T LECTURE-4 ICH Guidelines On Quality (Part 1)Document35 paginiMQA103T LECTURE-4 ICH Guidelines On Quality (Part 1)Shyam Sunder PancholiÎncă nu există evaluări

- Hold Time Study ProtocolDocument9 paginiHold Time Study ProtocolMubarak Patel100% (1)

- Commercially Packaged Laboratory Apparatus: Standard Specification ForDocument2 paginiCommercially Packaged Laboratory Apparatus: Standard Specification ForAhmed AlzubaidiÎncă nu există evaluări

- Flow charts of pharmaceutical quality control tests for different dosage formsDe la EverandFlow charts of pharmaceutical quality control tests for different dosage formsÎncă nu există evaluări

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersDe la EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersÎncă nu există evaluări

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1De la EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Evaluare: 4.5 din 5 stele4.5/5 (2)

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsDe la EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsÎncă nu există evaluări

- DMS 6310Document6 paginiDMS 6310mumarbsc7244Încă nu există evaluări

- 4-4-3-A ing-DEF - VPDFDocument8 pagini4-4-3-A ing-DEF - VPDFARAZ KÎncă nu există evaluări

- EN1348Document17 paginiEN1348GiriPrasath67% (3)

- Test Covered PDFDocument1 paginăTest Covered PDFraja qammarÎncă nu există evaluări

- Iso 4624 PDFDocument15 paginiIso 4624 PDFRajan Steeve50% (2)

- SECTION 09 96 00 High Performance Coatings GeneralDocument8 paginiSECTION 09 96 00 High Performance Coatings Generalraja qammarÎncă nu există evaluări

- Pile Load TestDocument2 paginiPile Load Testraja qammarÎncă nu există evaluări

- Calibration Certificate For UTMDocument2 paginiCalibration Certificate For UTMraja qammar100% (1)

- Project Information: Test Report For Bulk Density Agregate - ASTM C29/C29M-09Document2 paginiProject Information: Test Report For Bulk Density Agregate - ASTM C29/C29M-09raja qammarÎncă nu există evaluări

- Concrete Trial Mix: Jabbar Al Ahmad Causeway Project MPW Hyundai E &CDocument2 paginiConcrete Trial Mix: Jabbar Al Ahmad Causeway Project MPW Hyundai E &Craja qammarÎncă nu există evaluări

- SECTION 03 41 00 Structural Precast Concrete Part 1 - GeneralDocument16 paginiSECTION 03 41 00 Structural Precast Concrete Part 1 - Generalraja qammarÎncă nu există evaluări

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument4 paginiCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammarÎncă nu există evaluări

- 2530Document4 pagini2530pollux23100% (1)

- Materials 12 01325 PDFDocument21 paginiMaterials 12 01325 PDFRodolfoMarínÎncă nu există evaluări

- SECTION 09 96 00 High Performance Coatings GeneralDocument8 paginiSECTION 09 96 00 High Performance Coatings Generalraja qammarÎncă nu există evaluări

- Astm D 6926 Marshall Specimen Prepration PDFDocument6 paginiAstm D 6926 Marshall Specimen Prepration PDFrajeshji_000Încă nu există evaluări

- Hydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics LaboratoryDocument9 paginiHydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics Laboratoryraja qammarÎncă nu există evaluări

- Calibration Procedures Virginia PDFDocument81 paginiCalibration Procedures Virginia PDFraja qammarÎncă nu există evaluări

- Jelsa EnglDocument1 paginăJelsa Englraja qammarÎncă nu există evaluări

- L3b Hydrometer AnalysisDocument5 paginiL3b Hydrometer Analysisjesus_vitangcolÎncă nu există evaluări

- Jelsa Engl PDFDocument1 paginăJelsa Engl PDFraja qammarÎncă nu există evaluări

- Direct Shear CalculationDocument8 paginiDirect Shear Calculationraja qammarÎncă nu există evaluări

- Test Covered PDFDocument1 paginăTest Covered PDFraja qammarÎncă nu există evaluări

- Direct Shear Test On Sand: Void Ratio CalculationDocument3 paginiDirect Shear Test On Sand: Void Ratio CalculationWijaya KusumaÎncă nu există evaluări

- T S R T.S.R.: (Dd-Mmm-Year)Document2 paginiT S R T.S.R.: (Dd-Mmm-Year)raja qammarÎncă nu există evaluări

- Concure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust ProoferDocument4 paginiConcure 1315 (White) : Eco-Friendly, Acrylic Based, White Curing Compound, Sealer and Dust Prooferraja qammarÎncă nu există evaluări

- Calibration Procedures Virginia PDFDocument81 paginiCalibration Procedures Virginia PDFraja qammarÎncă nu există evaluări

- Measurement of Rate of Absorption of Hardened ConcreteDocument3 paginiMeasurement of Rate of Absorption of Hardened Concreteraja qammarÎncă nu există evaluări

- Ubc 2008 Spring Dykeman DonnaDocument304 paginiUbc 2008 Spring Dykeman Donnaraja qammarÎncă nu există evaluări

- TDS-BS 3262 Thermoplastics PDFDocument2 paginiTDS-BS 3262 Thermoplastics PDFraja qammarÎncă nu există evaluări

- PRS Lab Manual 2020 2 SP FinalDocument25 paginiPRS Lab Manual 2020 2 SP Finalstephan dsilvaÎncă nu există evaluări

- Experimental Investigation On Concrete-Filled Corrugated Steel Tubular Column Under Constant Axial Load and Cyclic Load PDFDocument23 paginiExperimental Investigation On Concrete-Filled Corrugated Steel Tubular Column Under Constant Axial Load and Cyclic Load PDFTamir EnkhÎncă nu există evaluări

- Specifications For Highway Drainage - OxfordshireDocument11 paginiSpecifications For Highway Drainage - OxfordshirexkishanÎncă nu există evaluări

- MANUAL MEDICIÓN RODADO Custom Track Service HandbookDocument776 paginiMANUAL MEDICIÓN RODADO Custom Track Service HandbookAlejandro CortesÎncă nu există evaluări

- enDocument40 paginienRegistr Registr91% (11)

- Four Stroke Diesel EngineDocument17 paginiFour Stroke Diesel Engineamirsyawal87Încă nu există evaluări

- 690+ ParkerDocument148 pagini690+ Parkerjohxav10Încă nu există evaluări

- 12d20105a Experimental Stress AnalysisDocument1 pagină12d20105a Experimental Stress AnalysissubbuÎncă nu există evaluări

- PI Metal Detector Hammerhead PDFDocument15 paginiPI Metal Detector Hammerhead PDFAlvaro Garcia100% (1)

- Dampers For Power Plant PDFDocument31 paginiDampers For Power Plant PDFNikhil Mukesh Varshney100% (3)

- Seminar On Steam EngineDocument26 paginiSeminar On Steam EngineEr Akhilesh Singh100% (1)

- Cost Classifications For Preparing External Financial StatementsDocument4 paginiCost Classifications For Preparing External Financial StatementsEduÎncă nu există evaluări

- Dge 169Document6 paginiDge 169Krittika ChandranÎncă nu există evaluări

- Types of Wall PanelingDocument7 paginiTypes of Wall Panelingsm_jdsÎncă nu există evaluări

- Shaper Planer and SlotterDocument21 paginiShaper Planer and SlotterBharathiraja MoorthyÎncă nu există evaluări

- Development of Filament Winding Machine For Producing Round Shapes With Different Fiber ReinforcementsDocument7 paginiDevelopment of Filament Winding Machine For Producing Round Shapes With Different Fiber ReinforcementsŞafak ÖzdenÎncă nu există evaluări

- Water Distribution System Specifications: St. Charles County Public Water Supply District NO. 2Document45 paginiWater Distribution System Specifications: St. Charles County Public Water Supply District NO. 2muhammad iqbalÎncă nu există evaluări

- Comparitive Study of Shear WallDocument51 paginiComparitive Study of Shear WallEspn Sachin100% (1)

- ATA 24 - ElectricalDocument68 paginiATA 24 - ElectricalJose JimenezÎncă nu există evaluări

- Lab 1 Silicon Diode S21314Document5 paginiLab 1 Silicon Diode S21314Muhd RzwanÎncă nu există evaluări

- Research ReviewDocument8 paginiResearch ReviewJOSEPH OLUWABUKOLAÎncă nu există evaluări

- Cooling Tower ReportDocument11 paginiCooling Tower Reportbae zazÎncă nu există evaluări

- Caterpillar Motor GradersDocument32 paginiCaterpillar Motor GradersAshraf m aliÎncă nu există evaluări

- Pipe WeldingDocument13 paginiPipe WeldingFord Katim100% (4)

- FYP Allocation AY 2012-2013 Sem 1Document7 paginiFYP Allocation AY 2012-2013 Sem 1Yandi LayadiÎncă nu există evaluări

- 5.1 Combustion of OilDocument6 pagini5.1 Combustion of Oilkcp1986Încă nu există evaluări

- Terminal Blocks: J - AccessoriesDocument24 paginiTerminal Blocks: J - Accessoriespaula09Încă nu există evaluări

- D2784Document7 paginiD2784rimi7alÎncă nu există evaluări

- Buckling H BeamDocument2 paginiBuckling H BeamНемања КараклајићÎncă nu există evaluări

- Characteristics of NanomaterialsDocument9 paginiCharacteristics of Nanomaterialssandhiya padmanabanÎncă nu există evaluări