Documente Academic

Documente Profesional

Documente Cultură

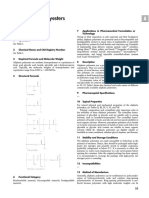

Figure 1. Structure of PLGA

Încărcat de

Jessie Chu0 evaluări0% au considerat acest document util (0 voturi)

20 vizualizări5 paginiPoly(lactide-co-glycolide) (PLGA) is a synthetic biodegradable copolymer of lactic acid and glycolic acid that can be used as a particulate emulsifier. PLGA nanoparticles can attach to oil-water interfaces and form a physical barrier that stabilizes emulsions and prevents droplet coarsening. The surface properties of PLGA particles, such as hydrophobicity, can be adjusted by varying the polymer composition and synthesis process. When used as an emulsifier, PLGA particles preferentially form oil-in-water emulsions with uniform droplet sizes. The particles provide kinetic stability through electrostatic and steric interactions at the interface without being toxic.

Descriere originală:

plga

Titlu original

PLGA Jessie

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPoly(lactide-co-glycolide) (PLGA) is a synthetic biodegradable copolymer of lactic acid and glycolic acid that can be used as a particulate emulsifier. PLGA nanoparticles can attach to oil-water interfaces and form a physical barrier that stabilizes emulsions and prevents droplet coarsening. The surface properties of PLGA particles, such as hydrophobicity, can be adjusted by varying the polymer composition and synthesis process. When used as an emulsifier, PLGA particles preferentially form oil-in-water emulsions with uniform droplet sizes. The particles provide kinetic stability through electrostatic and steric interactions at the interface without being toxic.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

20 vizualizări5 paginiFigure 1. Structure of PLGA

Încărcat de

Jessie ChuPoly(lactide-co-glycolide) (PLGA) is a synthetic biodegradable copolymer of lactic acid and glycolic acid that can be used as a particulate emulsifier. PLGA nanoparticles can attach to oil-water interfaces and form a physical barrier that stabilizes emulsions and prevents droplet coarsening. The surface properties of PLGA particles, such as hydrophobicity, can be adjusted by varying the polymer composition and synthesis process. When used as an emulsifier, PLGA particles preferentially form oil-in-water emulsions with uniform droplet sizes. The particles provide kinetic stability through electrostatic and steric interactions at the interface without being toxic.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

CHU YUAN SHAN 260110152009

PLGA (EMULSIFIER)

Introduction

Poly(lactide-co-glycolide) (PLGA) is a synthetic copolymer of lactic acid

(a-hydroxy propanoic acid) and glycolic acid (hydroxy acetic acid). Lactic acid

contains an asymmetric carbon atom, and therefore has two optical isomers: L(+)

lactic acid and D(-) lactic acid. Lactic acid is present in nature as either an

intermediate or an end product in carbohydrate metabolism. It is widely distributed

in all living creatures (man, animals, plants, and microorganisms). Glycolic acid

occurs in nature to a limited extent. Poly(lactide-co-glycolide) degrades in vivo to

innocuous products. Its final degradation products are lactate (salt form of lactic

acid) and glycolate (salt form of glycolic acid).

Poly(lactide-co-glycolide) can be synthesized by direct polycondensation of

lactic acid and glycolic acid. However, the most efficient route to obtain high-

molecular weight (MW) copolymers is the ring opening polymerization of lactide

and glycolide. Lactide and glycolide are the cyclic diesters of lactic acid and

glycolic acid, respectively, and they are prepared by thermal degradation of lactic

and glycolic acid oligomers, respectively.

Figure 1. Structure of PLGA

Particles synthesised from biocompatible synthetic polymers are an

attractive alternative emulsifier. Compared with particles traditionally used, latex

particles have the advantage of being relatively monodisperse, giving greater

control over the drop size. Synthetic routes that produce polymeric particles with a

wide range of functional surface groups have been established. This flexibility

offers improved control of particle wetting. Altering the properties of particle-

stabilised emulsions typically involves changing the proportions of the liquid

phases, using different particles or adding surfactants. In contrast, changing the

wettability of latex particles with surfaces coated by ionizable carboxylic acid

groups, for example, simply involves changing the pH or ionic strength.

One of the most frequently studied and widely used polymers of

pharmaceutical interest is poly(lactic acid) (PLA) and its copolymers with glycolic

acid (PLGA). Due to the different crystallinity and hydrophobicity of lactic and

glycolic acid, ‘custom-made’ particles may be synthesised for the specific needs of

different applications. The properties of PLGA particles, including their surface

hydrophobicity, can be adjusted by varying the copolymer composition [29] and

the ratio of the components [30] or by chemically modifying the polymer surface

[31]. Another advantage is that non-toxic lactic and glycolic acids are produced

when these copolymers decompose due to enzymatic or hydrolytic reactions. Here,

we describe the first evaluation of nanoparticles of PLGA as particulate emulsifiers.

The surface properties of the particles were characterised by measuring the

charging behaviour of the particles and the oil–water wetting behaviour of PLGA

films. The mechanisms by which PLGA nanoparticles impart stability to emulsions

were investigated by determining the influence of the particle concentration on drop

stability and size.

Polymer name Poly(lactide-co-glycolide) (PLGA)

Synonyms Polyglactin;DL- PLGA

Chemical name 1,4-Dioxane-2,5-dione, 3,6-dimethyl-, polymer with 1,4-

dioxane-2,5-dione

Structure

Molecular 2000 to >100 000

weight

Characteristics Aliphatic polyesters are a group of synthesized

homopolymers or copolymers. They are nontoxic and

can easily be fabricated into a variety of novel devices,

such as rods, screws, nails, and cylinders. The

polymers are commercially available in varying

molecular weights as both homopolymers and

copolymers. Molecular weights of polyesters range

from 2000 Da to greater than 100 000 Da.

Comonomer ratios of lactic acid and glycolic acid (or

lactide and glycolide) for poly(DL-lactide-co-

glycolide) range from 85 : 15 to 50 : 50.

Polymer composition and crystallinity play important

roles in the solubility of these aliphatic polyesters. The

crystalline homo- polymers of glycolide or glycolic

acid are soluble only in strong solvents, such as

hexafluoroisopropanol.

The crystalline homopolymers of lactide or lactic acid

also do not have good solubility in most organic

solvents. However, amorphous polymers of DL-

lactide or DL-lactic acid and copolymers of lactide or

lactic acid with a low glycolide or glycolic acid

content are soluble in many organic solvents

Aliphatic polyesters are slightly soluble or insoluble

in water, methanol, ethylene glycol, heptane, and

hexane.

Benefit can impart kinetic stability to emulsions by attaching

to the oil–water interface and forming a physical

barrier to drop coarsening

Their biodegradation products are nontoxic,

noncarcinogenic, and nonteratogenic.

No incompatibility

Preparation and characterisation of PLGA-stabilised emulsions

Emulsions were prepared by mixing oil and aqueous PLGA dispersions

together using a rotor–stator mixer (Ingenieurbüro CAT X1030D, M. Zipperer

GmbH) with a 10 mm diameter shaft operated at 1300 rpm. The type of emulsion

formed was tested by observing whether a drop of emulsion dispersed when added

to a small volume of pure water or oil. Emulsion sizes were measured by laser

diffraction (Malvern Mastersizer). Emulsions were diluted with MilliQ water to the

ratio of 1/100 and measured in the spec- ified cells at 20 ± 0.5 °C. The volume-

weighted average drop size (D(4, 3)) and the uniformity of the distributions (U)

were used in the analysis of emulsion size distributions. U is the extent of deviation

from the median in the distribution. The degree of creaming and phase separation

was recorded by visual inspection of samples stored in glass vials at ambient

temperatures. The emulsion structure was visualised using Cryo-Scanning Electron

Microscopy (cryo-SEM) to image fractured surfaces of frozen emulsions using a

Philips XL30 Field Emission Scanning Electron Microscope fitted with a CT1500

HR Low Temperature Cryo system.

Mechanism of PLGA as a emulsifier

It has been demonstrated that PLGA nanoparticles are effective Pickering

emulsifiers. In the special case of oils that dissolve PLGA, emulsions are instead

stabilised by polymer molecules. The PLGA particles were synthesised by

interfacial deposition using PVA as a stabilising surfactant. Measurements of the

particle charging behaviour indicated that there are both electrostatic and steric

contributions to dispersion stability. The presence of the relatively hydrophilic PVA

molecules on the particle surfaces means that they preferentially stabilise oil-in-

water emulsions formed from a wide range of oils (polar and non-polar). Uniform

drop size distributions are readily formed by mechanical mixing, providing that the

mixing time is controlled. Emulsion structure and stability is determined by the

amount of particles present.

It is well documented that dispersions of nanometre-sized PLGA particles

can be prepared by interfacial deposition. PLGA precipitates at the interface and

particles form rapidly. In most cases, a surfactant is required to stabilise the

polymeric particles as they condense in the aqueous phase. We chose to use the

neutral water-soluble polymer PVA to impart kinetic stability to the nanoparticle

dispersions. Incorporation of PVA molecules into the PLGA nanoparticle surfaces

reduces the particle hydrophobicity sufficiently for the particles to preferentially

stabilise oil-in-water emulsions.

PLGA nanoparticles can impart kinetic stability to emulsions by attaching

to the oil–water interface and forming a physical barrier to drop coarsening. The

(natural) surface hydrophobicity of the PLGA particles is also an important factor

in the colloidal interactions that affect drop stability. Particles can only attach to

drop surfaces providing that they approach closely enough for the thin liquid film

to rupture and for the three phase contact line formed to establish a stable wetting

perimeter. Electrostatic repulsive interactions between the particles and droplets in

water, however, generate an energy barrier to close approach. The PLGA particles

are weakly negatively charged. Droplets of non-polar oils, such as dodecane, are

weakly negatively charged due to adsorption of hydroxide ions. Hydrolysis will

generate an additional source of negative surface charges on droplets of polar oils,

such as isopropyl myristate. The hydrophobic attractions between PLGA particles

and the oil droplets dominate, however, and heterocoagulation occurs. Thus, in all

the cases studied here, the particles stabilise oil- in-water emulsions.

References

Rowe, C. Raymond. 2009. Handbook of Pharmaceutical Excipients 6th Edition.

USA: RPS Publishing.

Whitby, C. 2012. Poly(lactic-co-glycolic acid) as a particulate emulsifier. Journal

of Colloid and Interface Science. 375 (2012) 142–147.

S-ar putea să vă placă și

- Teaching Note 2 - PLGADocument4 paginiTeaching Note 2 - PLGAArdiellaputriÎncă nu există evaluări

- A Litterature Review of PLADocument22 paginiA Litterature Review of PLAJames WangÎncă nu există evaluări

- Polylactic Acid (PLA) Research, Development and IndustrializationDocument12 paginiPolylactic Acid (PLA) Research, Development and IndustrializationΘεανώ ΚαρώνηÎncă nu există evaluări

- CelluloseDocument7 paginiCelluloseSMIT CHRISTIANÎncă nu există evaluări

- Biodegradable Polymers: 2.1.1. Physico-Chemical PropertiesDocument19 paginiBiodegradable Polymers: 2.1.1. Physico-Chemical PropertiesJuliaNofadiniÎncă nu există evaluări

- Polylactic Acid Polyols in Urethane Coatings - 2019-11-01 - PCI MagazineDocument17 paginiPolylactic Acid Polyols in Urethane Coatings - 2019-11-01 - PCI MagazineTomGaliciaÎncă nu există evaluări

- Gelling Agent: Ips Academy College of Pharmacy IndoreDocument42 paginiGelling Agent: Ips Academy College of Pharmacy Indoreayushi shuklaÎncă nu există evaluări

- Water Soluble Polymers 2006Document10 paginiWater Soluble Polymers 2006A1234 AJEFÎncă nu există evaluări

- Gelatin IntroDocument10 paginiGelatin IntroMihai SebastianÎncă nu există evaluări

- Characterization and Analysis of PLA and Its PrecursorDocument10 paginiCharacterization and Analysis of PLA and Its PrecursornierzaÎncă nu există evaluări

- Pva and Polyalkylene GlycolDocument7 paginiPva and Polyalkylene Glycolhaqmaula81Încă nu există evaluări

- 07 Lecture SP21 (Bio Polymer) CHM 748Document14 pagini07 Lecture SP21 (Bio Polymer) CHM 748sobia tabassumÎncă nu există evaluări

- 3-Pharmaceutical PolymersDocument49 pagini3-Pharmaceutical Polymersahmed hotyÎncă nu există evaluări

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDocument13 paginiColloids and Surfaces A: Physicochemical and Engineering AspectsMarceta BrankicaÎncă nu există evaluări

- Synthesis of Alkyl Polyglycoside Surfactants From Tert-Butyl Glycosides and Fatty AcidsDocument6 paginiSynthesis of Alkyl Polyglycoside Surfactants From Tert-Butyl Glycosides and Fatty AcidsSimón RamírezÎncă nu există evaluări

- Biodegradable MaterialsDocument39 paginiBiodegradable MaterialsPurnahuti PandaÎncă nu există evaluări

- Polymers: Enzyme-Catalyzed Modifications of Polysaccharides and Poly (Ethylene Glycol)Document20 paginiPolymers: Enzyme-Catalyzed Modifications of Polysaccharides and Poly (Ethylene Glycol)Cuong CaoÎncă nu există evaluări

- Polyalkylene Polyethylene Glycols #3Document23 paginiPolyalkylene Polyethylene Glycols #3rotterson9616100% (2)

- Flocculation PDFDocument5 paginiFlocculation PDFSunilÎncă nu există evaluări

- Starch Based Polymer PDFDocument10 paginiStarch Based Polymer PDFSachikanta PradhanÎncă nu există evaluări

- Degradation of PolyDL-lactide-co-glycolide 5050 Im PDFDocument12 paginiDegradation of PolyDL-lactide-co-glycolide 5050 Im PDFVishwarup GoswamiÎncă nu există evaluări

- Bae 2000Document11 paginiBae 2000Ahmed Abd El-FattahÎncă nu există evaluări

- Xanthan Gum EorDocument5 paginiXanthan Gum EorTanmay SharmaÎncă nu există evaluări

- Polymers ChemistryDocument26 paginiPolymers ChemistryMessaoud AmrouneÎncă nu există evaluări

- Solubilizing Excipients in Oral and Injectable FormulationsDocument30 paginiSolubilizing Excipients in Oral and Injectable FormulationsHiếu BùiÎncă nu există evaluări

- Chemical Ingredients and Their Roles in SDS - PAGE: Human HomeostasisDocument9 paginiChemical Ingredients and Their Roles in SDS - PAGE: Human HomeostasisAyan SamaddarÎncă nu există evaluări

- 2017 03 01 Structure Impact of Two Galactomannan Fractions On Their Viscosity Properties in Dilute Solution, Unperturbed State and Gel StateDocument32 pagini2017 03 01 Structure Impact of Two Galactomannan Fractions On Their Viscosity Properties in Dilute Solution, Unperturbed State and Gel StateJair EspinozaÎncă nu există evaluări

- PlaDocument15 paginiPlaGanga DharanÎncă nu există evaluări

- Acrylic ResinDocument14 paginiAcrylic ResinKrishna YeoleÎncă nu există evaluări

- Aqueous Emulsions FromDocument5 paginiAqueous Emulsions Fromlongk52aÎncă nu există evaluări

- Unit-4 Part B BiopolymersDocument16 paginiUnit-4 Part B Biopolymersdieselsingh2409Încă nu există evaluări

- Biodegradable Polymers: Madhuri PhuteDocument26 paginiBiodegradable Polymers: Madhuri PhuteDrAmit VermaÎncă nu există evaluări

- Practical 06 Object: PropertiesDocument3 paginiPractical 06 Object: PropertiesAqsa BanoÎncă nu există evaluări

- Applications of Xanthan GumDocument5 paginiApplications of Xanthan Gumcindy aprilliaÎncă nu există evaluări

- Polymer FluidsDocument4 paginiPolymer FluidsEduardo ArvizuÎncă nu există evaluări

- HPE Aliphatic PolyestersDocument5 paginiHPE Aliphatic Polyestersaliya faizaÎncă nu există evaluări

- Carbo PolDocument8 paginiCarbo PolRia MardianaÎncă nu există evaluări

- Food Hydrocolloid Edible Films and CoatingsDocument34 paginiFood Hydrocolloid Edible Films and CoatingsLiani FarahanaÎncă nu există evaluări

- Chemistry De-GradationDocument6 paginiChemistry De-GradationRao AtiqÎncă nu există evaluări

- Determination MW of Polymer - Intrinsic ViscosityDocument11 paginiDetermination MW of Polymer - Intrinsic ViscosityGuery SaenzÎncă nu există evaluări

- 8 Special Polyesters: 8.1 PolycarbonatesDocument8 pagini8 Special Polyesters: 8.1 Polycarbonateskavya shahÎncă nu există evaluări

- Industrial Preparation of Demulsifiers: Theory and ApplicationsDocument14 paginiIndustrial Preparation of Demulsifiers: Theory and Applicationswahab aliÎncă nu există evaluări

- Blend Starch PLADocument11 paginiBlend Starch PLAalcy reneÎncă nu există evaluări

- Acrylamide PolymerizationDocument16 paginiAcrylamide PolymerizationUmakanth Reddy Vudumula100% (1)

- Lab Manual 3 CPB 30103 Biochemical Engineering Experiment 3Document5 paginiLab Manual 3 CPB 30103 Biochemical Engineering Experiment 3tusen krishÎncă nu există evaluări

- Surfactants - Emulsifiers Surfactants EmulsifiersDocument62 paginiSurfactants - Emulsifiers Surfactants EmulsifiersUmut Erkılıç100% (1)

- Pre FormulationDocument53 paginiPre FormulationSaiesh PhaldesaiÎncă nu există evaluări

- Colloidal Emulsions in Inks and AdhesivesDocument4 paginiColloidal Emulsions in Inks and AdhesivesAnujÎncă nu există evaluări

- Enhanced Oil Recovery Techniques: VFSTR Iv Year B.Tech Petroleum Engineering I-SemisterDocument58 paginiEnhanced Oil Recovery Techniques: VFSTR Iv Year B.Tech Petroleum Engineering I-Semisterjaahnavi choudaryÎncă nu există evaluări

- OF CVPsDocument18 paginiOF CVPsClassic AddaÎncă nu există evaluări

- Graphene PublishedDocument32 paginiGraphene PublishedTayyab AliÎncă nu există evaluări

- 06-Mechanisms of Crude Oil DemulsificationDocument10 pagini06-Mechanisms of Crude Oil DemulsificationajostosÎncă nu există evaluări

- Polymer CharacterizationDocument8 paginiPolymer CharacterizationGerald LimÎncă nu există evaluări

- What Are HydrogelsDocument4 paginiWhat Are HydrogelsHossein NajafzadehÎncă nu există evaluări

- Formulation and Stability of A Soap Microemulsion and The Apparent PKA Herein 2013 Journal of Colloid and Interface ScienceDocument8 paginiFormulation and Stability of A Soap Microemulsion and The Apparent PKA Herein 2013 Journal of Colloid and Interface ScienceAndrea CalderaÎncă nu există evaluări

- Surface Chemistry of Surfactants and PolymersDe la EverandSurface Chemistry of Surfactants and PolymersEvaluare: 5 din 5 stele5/5 (1)

- The Greatest Classics of Russian Literature in One VolumeDe la EverandThe Greatest Classics of Russian Literature in One VolumeÎncă nu există evaluări

- Biochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingDe la EverandBiochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingEvaluare: 4 din 5 stele4/5 (1)

- Nano ParticleDocument25 paginiNano ParticleJessie ChuÎncă nu există evaluări

- Gallic Acid Determination Spectroscopy UvDocument6 paginiGallic Acid Determination Spectroscopy UvJessie ChuÎncă nu există evaluări

- Article Wjpps 1417426767Document9 paginiArticle Wjpps 1417426767Jessie ChuÎncă nu există evaluări

- Purpose of BABE: Chu Yuan ShanDocument9 paginiPurpose of BABE: Chu Yuan ShanJessie ChuÎncă nu există evaluări

- 2012Sm2Test 07 02Document6 pagini2012Sm2Test 07 02Jessie ChuÎncă nu există evaluări

- Revision Chapter 1 Till 5Document16 paginiRevision Chapter 1 Till 5Jessie ChuÎncă nu există evaluări

- Analysis Vitamin b2Document7 paginiAnalysis Vitamin b2Jessie ChuÎncă nu există evaluări

- 1450 81090702169R PDFDocument16 pagini1450 81090702169R PDFdevoydouglasÎncă nu există evaluări

- Modern Physics: Luis A. AnchordoquiDocument27 paginiModern Physics: Luis A. Anchordoquih shekarlabÎncă nu există evaluări

- Dr. Shina Gautam Associate Professor, Chemical Engineering, Shroff S. R. Rotary Institute of Chemical TechnologyDocument45 paginiDr. Shina Gautam Associate Professor, Chemical Engineering, Shroff S. R. Rotary Institute of Chemical TechnologyJITENDRA CARPENTERÎncă nu există evaluări

- Tutorial Heterocyclic CompoundsDocument3 paginiTutorial Heterocyclic CompoundssiddarthpharmaÎncă nu există evaluări

- Solubility CurveDocument2 paginiSolubility CurveDanni SulaimanÎncă nu există evaluări

- 11051Document3 pagini11051Yashmeen KaurÎncă nu există evaluări

- Book of Abstracts RAA2011Document241 paginiBook of Abstracts RAA2011Vornicu NicoletaÎncă nu există evaluări

- Tifr Dec2011 Question PaperDocument15 paginiTifr Dec2011 Question Papertvsagar830% (1)

- FSDFSDFSDFSDFSDFSDFSDFSDFSDFSDFSDFSDFDocument3 paginiFSDFSDFSDFSDFSDFSDFSDFSDFSDFSDFSDFSDFNavjotSinghÎncă nu există evaluări

- Griffith ElmagDocument6 paginiGriffith ElmagnadiaÎncă nu există evaluări

- Mechanical Q&A 1Document62 paginiMechanical Q&A 1makeencvÎncă nu există evaluări

- Soal HysysDocument99 paginiSoal HysysHengky PrasetyoÎncă nu există evaluări

- Nicole-Wave Phenomena MarkschemeDocument2 paginiNicole-Wave Phenomena Markschemezhuo xuÎncă nu există evaluări

- Science3 q1 Mod2 Changesinmaterials v2Document32 paginiScience3 q1 Mod2 Changesinmaterials v2ALJEM TUBIGONÎncă nu există evaluări

- As and A Level Chemistry Core Practical 4 Hydrolysis Student Teacher Technician WorksheetsDocument5 paginiAs and A Level Chemistry Core Practical 4 Hydrolysis Student Teacher Technician WorksheetsonehllznÎncă nu există evaluări

- Is 12711 1989Document22 paginiIs 12711 1989Trupti PawarÎncă nu există evaluări

- Chem Prelim Exam2018Document5 paginiChem Prelim Exam2018James PeregrinoÎncă nu există evaluări

- Models - Mph.conical Quantum DotDocument10 paginiModels - Mph.conical Quantum Dotlahoual70Încă nu există evaluări

- Experiment 13 Post LabDocument40 paginiExperiment 13 Post LabEmill Jayson CaypunoÎncă nu există evaluări

- Fins SolutionsDocument5 paginiFins Solutionsdab111Încă nu există evaluări

- Soxhlet Extraction: By-Shewarega HabtamuDocument12 paginiSoxhlet Extraction: By-Shewarega HabtamuAbdisa GemechuÎncă nu există evaluări

- 21 Surface CondensersDocument12 pagini21 Surface CondensersMohsin EhsanÎncă nu există evaluări

- HT Lecture 13 ConvectionSolvedProblemsDocument17 paginiHT Lecture 13 ConvectionSolvedProblemsclaudette colladoÎncă nu există evaluări

- Chemistry Practical File (WSD E-Book)Document36 paginiChemistry Practical File (WSD E-Book)dhruvsinghal679% (14)

- Termo PRDocument99 paginiTermo PRSapnaÎncă nu există evaluări

- Preparation of Cyclohexene From CyclohexanolDocument7 paginiPreparation of Cyclohexene From CyclohexanolDumile Nombasa100% (5)

- Compilation of 20 Journals Regarding Phase Change MaterialsDocument14 paginiCompilation of 20 Journals Regarding Phase Change MaterialsKTINE08Încă nu există evaluări

- 11 Chemistry Impq States of Matter KvsDocument7 pagini11 Chemistry Impq States of Matter KvsAnant MadhavÎncă nu există evaluări

- δ-Bi2O3 thin films prepared by reactive sputtering - Fabrication and characterizationDocument6 paginiδ-Bi2O3 thin films prepared by reactive sputtering - Fabrication and characterizationrafael pimentelÎncă nu există evaluări