Documente Academic

Documente Profesional

Documente Cultură

Plating Process Audit Checksheet 9332E-X

Încărcat de

abhionlysterDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plating Process Audit Checksheet 9332E-X

Încărcat de

abhionlysterDrepturi de autor:

Formate disponibile

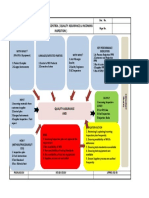

Quality Management System Evaluation -Plating Process

Vendor

Vendor Name : Audit Date :

code:

Contact

Phone :

Address :

E-mail :

Plant Head : Quality Head:

Mobile No: Mobile No:

Email Id: Email Id:

Survey / Auditor's Team :

Sr. No. Name Sign

2

Business Details:-

Copy of QMS Certification

Customer List

Organizational Structure - Including Quality Dept.

Lists to be enclosed :

Test & Measuring Equipments

List of type of surface protections conducted

Consent letter from PCB - Pollution Control Board

Score

Sr. Mark Actions Needed

Sr. No. Parameter Check Point Award Remarks / References

No. s (Yes /No)

ed

1 0 No system

Does the organization have QMS

1 2 4 ISO 9001/IATF 16949

system?

3 5 ISO 9001/IATF 16949 & ISO 14001

Has State Pollution Control Board 1 0 NO

(SPCB) given consent to operate

2

to plant facility for surface

finishing? 2 5 Yes

1 0 No control

Whether incoming parts /

chemicals inspection done in 2 3 RQC Incoming Inspection Standard available

3 RQC? Is there any reaction plan

available if parts got rejected in RQC done as per Incoming Inspection Standard &

3 4

RQC? records maintained.

4 5 Reaction plan for the non conformities available.

1 0 No control

Weather incoming parts / 2 3 Identification available

chemicals are stored with proper

4

identification at their location,

FIFO maintained? 3 4 Identification & Location available

4 5 FIFO for incoming parts / chemicals effectively done

No Control Plan/Work Instructions/SOP/Process

1 0

sheet

Whether Control Plan, SOP, WI, 2 3 Available partially

5 Process sheet are available at

each station? 3 4 Available for all but not displayed at all stations.

4 5 Available for all & displayed at all stations

1 0 No Standards/MIS-P / Matrix available

Are there plating Standards/ MIS-

P / Matrix part wise containing

Standards/MIS-P / Matrix available other than shop

6 plating requirements i.e. plating 2 3

floor

type, thickness, SST life, DHE etc.

available with supplier?

3 5 Standards/MIS-P / Matrix are available at shop floor

1 0 No

Whether customer approved

Control Plan for barrel & tank Available but not signed by chemical expert, platter &

7 2 3

plating is available with reaction customer.

plan to operators.

Available & signed by chemical expert, platter &

3 5

customer.

1 0 No

Is pretreatment of parts

8 2 3 Not as per SOP or control plan

conducted?

3 5 Conducted as per SOP or control plan

1 0 No

Whether there is oil content

9 monitoring available at soak 2 3 Oil content monitoring done partially.

cleaning /degreasing tank.

3 5 Oil content monitoring full compliance.

1 0 NO

Is pH of cleaning

10 2 3 Done randomly or partially

media/degreasing checked?

3 5 Done with the fixed duration & records maintained

1 0 No Control

What is the time control Time control mechanism using log sheet & records

11 2 3

mechanism used? maintained

3 5 Time control with timer and buzzer

Score

Sr. Mark Actions Needed

Sr. No. Parameter Check Point Award Remarks / References

No. s (Yes /No)

ed

1 0 No

Is cleaning/washing media

12 2 3 Discarded randomly

frequently discarded?

Discarded with the defined frequency & records

3 5

maintained

1 0 No

Whether DM water is using in

DM water conductivity checked but record not

13 tanks & its conductivity 2 3

maintained.

maintained properly?

3 5 DM water conductivity checked & record maintained.

1 0 Not as per manufacturing recommendation

What are Current and Voltages

14

used?

2 5 As per manufacturing recommendation

1 0 No Agitation

What agitation mechanism is

15 2 3 Manual agitation

used?

3 5 Mechanical agitation

1 0 Not available

What recirculation mechanism is

16

used?

2 5 Pumping mechanism

1 0 Not controlled

How is temperature of the bath Using thermocouple with analog or digital system &

17 2 3

controlled and maintained/ records maintained

3 5 Buzzer system

1 0 No

Is chemistry of bath checked and

Randomly checked or checked but no records

18 maintained at pre-treatment 2 3

maintained

process?

Checked with defined frequency and records

3 5

maintained

1 0 No Agitation

19 Passivation: Agitation mechanism 2 3 Manual agitation

3 5 Mechanical agitation

1 0 No Control

How is time & pH in Passivation Time control mechanism using log sheet & records

20 2 3

controlled? maintained

Time control with timer and buzzer & pH controlled by

3 5

on line pH meter & record maintained.

1 0 No done

Whether top coat/ lacquer /sealant

21 2 3 Done on some parts (partial compliance)

is doing for all Minda parts?

3 5 Done on all parts.

1 0 No

Is chemistry of bath checked and Randomly checked or Checked but no records

22 2 3

maintained at plating barrel /tank? maintained

Checked with defined frequency and records

3 5

maintained

1 0 No

Whether there is parts list

Part list available for De-hydrogen embrittlement time

23 available for De-hydrogen 2 3

& temp.

embrittlement with time & temp.?

De-hydrogen embrittlement done within 4hrs of acid

3 5

pickling & records maintained.

Whether TTR(temp. travel rate) is

done for oven, temperature

1 0 Not performed

uniformity surveys performed

yearly? Ovens should be tested

24 both empty and dense load. Parts 2 3 Partial compliance

must come upto temperature

within one hour of entering oven Performed with the mentioned specifications &

3 5

and meet temperature tolerance records maintained

specified by customer.

1 0 Not system

Whether there is calibration

frequency defined for all test &

25 2 3 Partial compliance

measuring equipments & records

maintained?

Performed on all test & measuring equipments &

3 5

records maintained

1 0 No control

Whether Hexavalent & Trivalent

process are doing at separate

26 2 3 Done at separate location within the plant premises.

locations & if not, proper action

taken to avoid mixing?

3 5 No hexavalent plating done in plant premises.

1 0 No

Does quality department review,

27 address and document customer 2 3 Action plan evident, but no Effectiveness monitoring

and internal concerns?

Reviewed with action plan, Customer feedback,

3 5

Effectiveness monitoring & records maintained

1 0 No plan

Is there any preventative

28 maintenance program? For 2 3 Partial PM plan

Barrels, racks, baskets, rectifiers

3 5 PM plan and compliance evident

1 0 No identification throughout process

Is product clearly identified and

29 staged throughout the plating

process? (To avoid part mixing)

Score

Sr. Mark Actions Needed

Sr. No. Parameter Check Point Award Remarks / References

No. s (Yes /No)

ed

Is product clearly identified and

29 staged throughout the plating 2 3 Identification/tagging at partial stages

process? (To avoid part mixing)

Identification/tagging at all stages with proper control

3 5

& guideline to the operators

1 0 Not defined

Is rejection area clearly defined

30 and are non confirming parts 2 3 Defined and followed

being properly disposed?

Defined and followed, Red bin with Lock & key

3 5

arrangement, scrap note records.

1 0 No. S.S.T. plan available.

2 3 Available but implementation partial.

Whether S.S.T. plan is available &

31

implemented.

3 4 Available & implemented for all parts.

Available & implemented for all parts & action taken

4 5

for non-conformities.

1 0 No

Are PPEs used throughout the

32 2 3 Partially used

shop floor?

3 5 Used everywhere as per requirements.

1 0 No

Whether there is a chemical

storage area? Is free from

33 2 3 Partially maintained.

dust/moisture content or other

environmental impact?

3 5 Full compliance

1 0 No

Whether they register the entry of

chemicals? Whether they have

34 maintained minimum & maximum 2 3 Partially entry made.

stock of chemicals with reorder

qty.?

3 5 Full compliance

1 0 No Process audits conducted

35 Is process audit conducted? 2 3 Audit plan with check sheets available

Compliance with defined frequency verified, with NC

3 5

closure.

1 0 No Inspection

2 3 Final inspection done but no records maintained

36 Is Final Inspection & PDQA done?

Final Inspection done with records but no PDQA

3 4

report provided.

Final Inspection done with records. PDQA report

4 5

provided for all lots.

1 0 No rework procedure defined

Whether they handled rework

37 process properly & maintain its 2 3 Partially compliance as per defined procedure

record?

3 5 Full compliance with procedure

1 0 No control

Whether they take proper

38 measures to maintain DFT as 2 3 Partially compliance

required in drawing?

Full compliance with records (sample from each

3 5

barrel & rack thickness checked before drag out).

1 0 No

Is annual maintenance of the

39 2 3 Followed partially

facility carried out?

3 5 Followed and evident

1 0 No

Are packaging standards

40 2 3 Followed partially

followed?

Followed and verified, packing std. available for all

3 5

Minda parts.

TOTAL SCORE 200 TOTAL SCORE ACHIEVED

PERCENTAGE SCORE ACHIEVED :-

Auditees :

Sr. No. NAME TITLE Sign

1

2

3

4

Auditor (Leader) Comments :

Grade Category Criteria Brief description

A Good >75% points Good -keep it up

B Need Improvement 50% to 75% points Supplier will submit action plan to improve within one month & re-audit will be planned.

C Not Qualified Below 50 % (Consolidation) Need to take call with purchase to make supplier consolidation plan.

Note:- 1) Action to be taken where score is ZERO or as per auditor recommendation for individual check point, supplier also take internal actions where scope of improvement.

2) Supplier to submit action plan on non-conformities within 3 working days & closure with evidences within 15 working days from audit date.

9332E-X, 10.06.2019

S-ar putea să vă placă și

- Risk Assessment HandbookDocument35 paginiRisk Assessment HandbookmeliaminorÎncă nu există evaluări

- APQP ProcedureDocument9 paginiAPQP ProcedurePk Nimiwal100% (4)

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pagini(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYAÎncă nu există evaluări

- MSIL Audit Cheklist 16Document22 paginiMSIL Audit Cheklist 16Pravin Balasaheb GunjalÎncă nu există evaluări

- 123Document30 pagini123Pinkoo QualityÎncă nu există evaluări

- List of PPAP Documents: SR No. Document Title Documents Formats / Templates RemarksDocument30 paginiList of PPAP Documents: SR No. Document Title Documents Formats / Templates RemarksrajarajanÎncă nu există evaluări

- Red Flag Report PDFDocument33 paginiRed Flag Report PDFAnurag JagnaniÎncă nu există evaluări

- F QA 03 In-Process Inspection ReportDocument2 paginiF QA 03 In-Process Inspection ReportVikas Kashyap100% (1)

- Control Plan & FmeaDocument9 paginiControl Plan & FmeaManu SharmaÎncă nu există evaluări

- Laxmi Industries: Sampling PlanDocument1 paginăLaxmi Industries: Sampling PlanMadhavan Ram100% (1)

- 4M Change MatrixDocument1 pagină4M Change MatrixAnkit SainiÎncă nu există evaluări

- Root Cause Techniques PresentationDocument17 paginiRoot Cause Techniques Presentationqc_531040655Încă nu există evaluări

- Tier-2 Audit ChecksheetDocument17 paginiTier-2 Audit ChecksheetSilambarasan KÎncă nu există evaluări

- Supplier Audit Check Sheet.Document1 paginăSupplier Audit Check Sheet.ALI ASGHARÎncă nu există evaluări

- Presentation On Project Quality ManagementDocument45 paginiPresentation On Project Quality ManagementVVNAGESWAR100% (1)

- IATF16949 Transition Audit Document Review Draft V5 Final Points EnglishDocument6 paginiIATF16949 Transition Audit Document Review Draft V5 Final Points EnglishSudhagarÎncă nu există evaluări

- Name of Auditee Nature of Audit Audit Period Audit Start Date End Date Audit StaffDocument3 paginiName of Auditee Nature of Audit Audit Period Audit Start Date End Date Audit StaffAmitmil MbbsÎncă nu există evaluări

- APQP ChecklistDocument18 paginiAPQP ChecklistmichaelbarkovicÎncă nu există evaluări

- MSES Manual PDFDocument206 paginiMSES Manual PDFDirect DD90% (10)

- Manufacturing Process AuditDocument1 paginăManufacturing Process AuditSachin Kumbhar100% (1)

- 4M Change Tracking SheetDocument1 pagină4M Change Tracking SheetKanaiya Jha100% (5)

- P13-Process For APQPDocument6 paginiP13-Process For APQPBangali Singh100% (1)

- Ok Part NG: (Vendor Non-Conformance Report)Document2 paginiOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MÎncă nu există evaluări

- OHSAS180012007 Health Safety Management System ManualDocument36 paginiOHSAS180012007 Health Safety Management System ManualCandra Wae Lah100% (3)

- One Point LessonDocument8 paginiOne Point LessonVenkatesanÎncă nu există evaluări

- Manufacturing Process Audit Report: Customer Part No. Part Name Line/Area/ PorcessDocument1 paginăManufacturing Process Audit Report: Customer Part No. Part Name Line/Area/ PorcessNaresh kumarÎncă nu există evaluări

- 06.supplier QMS Development Audit ChecklistDocument5 pagini06.supplier QMS Development Audit ChecklistvishvendanÎncă nu există evaluări

- IATF Objective Data Analysis - Quality - ExampleDocument1 paginăIATF Objective Data Analysis - Quality - ExampleSachin RamdurgÎncă nu există evaluări

- NPD Check SheetDocument6 paginiNPD Check Sheets.charlieÎncă nu există evaluări

- 4 M Change ProcedureDocument2 pagini4 M Change ProcedureManasi shindeÎncă nu există evaluări

- Process Driven Comprehensive Auditing A New Way To Conduct ISO 90012008 Internal Audits, Second Edition PDFDocument152 paginiProcess Driven Comprehensive Auditing A New Way To Conduct ISO 90012008 Internal Audits, Second Edition PDFHosam MahmoudÎncă nu există evaluări

- Iatf ActivitiesDocument6 paginiIatf ActivitiesWizard tube and Engineered componentÎncă nu există evaluări

- Route Card: Material SummaryDocument7 paginiRoute Card: Material SummaryBalram Ji100% (1)

- Evidences To Be Maintained As Per APQP For PMDocument3 paginiEvidences To Be Maintained As Per APQP For PMSachin RamdurgÎncă nu există evaluări

- T2 VSA With RequirementDocument8 paginiT2 VSA With RequirementSandeep K Malhotra100% (3)

- Required Doc For IATFDocument3 paginiRequired Doc For IATFAbhayÎncă nu există evaluări

- System Audit RequirementDocument37 paginiSystem Audit Requirementavinashbatra171% (7)

- Red Bin Analysis FormatDocument1 paginăRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- Sr. No. Requirements: Ppap Check ListDocument3 paginiSr. No. Requirements: Ppap Check Listkamlesh kuchekarÎncă nu există evaluări

- Product Audit FormatDocument2 paginiProduct Audit FormatSUBODHH50% (2)

- MBO CQI 11 2020 2nd EditionDocument81 paginiMBO CQI 11 2020 2nd EditionHoang TanÎncă nu există evaluări

- Apqp Status LogDocument1 paginăApqp Status Logsathyabalaraman67% (3)

- Turtle Diagram Type and Extent Control For QA DepartmentDocument1 paginăTurtle Diagram Type and Extent Control For QA Departmentsuresh kumar50% (2)

- 1 2 3 - 4M Change Part TagDocument4 pagini1 2 3 - 4M Change Part TagIt's me DJÎncă nu există evaluări

- CQI-27 Casting Process Tables Stakeholder Review Final PDFDocument213 paginiCQI-27 Casting Process Tables Stakeholder Review Final PDFSelvaraj Simiyon90% (10)

- Rework & Repair ProcedureDocument1 paginăRework & Repair ProcedureManu Sharma100% (4)

- Internal Audit Check Sheet QualityDocument6 paginiInternal Audit Check Sheet QualityRamdas PaithankarÎncă nu există evaluări

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 paginiClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneÎncă nu există evaluări

- Questions Process Audit: P2. Project ManagementDocument11 paginiQuestions Process Audit: P2. Project ManagementR JÎncă nu există evaluări

- Iatf-Qm-08 - Operation 8.5.1.1Document22 paginiIatf-Qm-08 - Operation 8.5.1.1SATISH HALGEKARÎncă nu există evaluări

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoDocument10 paginiFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapÎncă nu există evaluări

- IATF 16949 DocumenDocument1 paginăIATF 16949 Documenpunitg_2Încă nu există evaluări

- IATF Quality Manual-GEC U-2 PDFDocument53 paginiIATF Quality Manual-GEC U-2 PDFNarendra100% (1)

- QAF12 Process Audit Rev 09Document4 paginiQAF12 Process Audit Rev 09ukavathekarÎncă nu există evaluări

- Red Bin Analysis ProcedureDocument4 paginiRed Bin Analysis ProcedureVenkatesan92% (12)

- Integrated Management System Manual: September 2016Document37 paginiIntegrated Management System Manual: September 2016Raul PerezÎncă nu există evaluări

- 2010 Vol X No 1 IJGFMDocument131 pagini2010 Vol X No 1 IJGFMInternational Consortium on Governmental Financial ManagementÎncă nu există evaluări

- .013-00-Checking AidsDocument3 pagini.013-00-Checking Aidsdaniel_sasikumarÎncă nu există evaluări

- 4M Change Monitoring Sheet: If There Is Any Change During The Shift Mark It With RedDocument1 pagină4M Change Monitoring Sheet: If There Is Any Change During The Shift Mark It With RedDINESHCHOUDHARY88Încă nu există evaluări

- IATF Implementation Plan and Co-Ordinator RolesDocument3 paginiIATF Implementation Plan and Co-Ordinator RolesKumaravel50% (2)

- Supplier Quality Survey Form2Document4 paginiSupplier Quality Survey Form2Sutha Tamil NambeÎncă nu există evaluări

- Product Audit Check SheetDocument3 paginiProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- Forging Audit ChecklistDocument15 paginiForging Audit ChecklistAnkurÎncă nu există evaluări

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Document5 paginiShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- IATF 16949 2016 Mandatory ProcedureDocument1 paginăIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- Department: Lab Auditor: AuditeeDocument2 paginiDepartment: Lab Auditor: AuditeeAnkit SainiÎncă nu există evaluări

- MACE Formats 1Document46 paginiMACE Formats 1Ashish VaidÎncă nu există evaluări

- CAPA Hole Burr (TSSR)Document3 paginiCAPA Hole Burr (TSSR)Mohit Singh0% (1)

- Layout Inspection Report XH5DR June 20 2012Document17 paginiLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- ISO 9001 Certificate and Impact On Food Quality: Benha Veterinary Medical JournalDocument6 paginiISO 9001 Certificate and Impact On Food Quality: Benha Veterinary Medical JournalevelynÎncă nu există evaluări

- LRQA NERS Requirements Document V8.1 Final For Issue November 2021Document68 paginiLRQA NERS Requirements Document V8.1 Final For Issue November 2021David MarkidesÎncă nu există evaluări

- CIVIL SERVICE COMMISSION-Chief Human Resource SpecialistDocument3 paginiCIVIL SERVICE COMMISSION-Chief Human Resource SpecialistVoltaire BernalÎncă nu există evaluări

- FINAL CA Audit INTEGRATED CASE STUDY BASED MCQs PDFDocument25 paginiFINAL CA Audit INTEGRATED CASE STUDY BASED MCQs PDFJinal SanghviÎncă nu există evaluări

- MSC - AccountingDocument3 paginiMSC - AccountingDownloadingÎncă nu există evaluări

- Chapter 17Document4 paginiChapter 17hanna sanchezÎncă nu există evaluări

- Rights and Privileges of ShareholdersDocument40 paginiRights and Privileges of Shareholdersswatantra.s887245Încă nu există evaluări

- Hacken - AuditReport ProgramDocument10 paginiHacken - AuditReport ProgramMemong KittyÎncă nu există evaluări

- Auditor Liability: Fair and Reasonable' Punishment?Document6 paginiAuditor Liability: Fair and Reasonable' Punishment?kawsursharifÎncă nu există evaluări

- Vanguard Lifestrategy Funds Icvc: Annual Report and Financial StatementsDocument129 paginiVanguard Lifestrategy Funds Icvc: Annual Report and Financial Statementsice1112Încă nu există evaluări

- WBGRMRoadmap 005 Part 3 RMOverview FINALPDFDocument15 paginiWBGRMRoadmap 005 Part 3 RMOverview FINALPDFERMIYAS TARIKUÎncă nu există evaluări

- Auditor Independence and Audit Quality PDFDocument22 paginiAuditor Independence and Audit Quality PDFadamÎncă nu există evaluări

- Practice Examination in Auditing TheoryDocument28 paginiPractice Examination in Auditing TheoryGabriel PonceÎncă nu există evaluări

- NBCA Competency Assessment SystemDocument169 paginiNBCA Competency Assessment SystemIurii SocolÎncă nu există evaluări

- MI-F-4.3.2-app06-001 - Internal Audit ReviewDocument1 paginăMI-F-4.3.2-app06-001 - Internal Audit ReviewHernanda ImawanÎncă nu există evaluări

- 9207 - Faculty Publications Report 2017 02Document104 pagini9207 - Faculty Publications Report 2017 02Atta GebrilÎncă nu există evaluări

- Requirements For FSSC 22000 Version 4.1 Upgrade AuditsDocument3 paginiRequirements For FSSC 22000 Version 4.1 Upgrade AuditsLuis Mario Lopez CanoÎncă nu există evaluări

- Chapter 5Document56 paginiChapter 5lyj1017100% (1)

- Acct 620 Chapter 10Document42 paginiAcct 620 Chapter 10teddyh2oÎncă nu există evaluări

- Sample Job PostingDocument2 paginiSample Job PostingGamer ArenaÎncă nu există evaluări

- PSA 501: Audit Evidence - Specific Consideration For Selected Items InventoryDocument3 paginiPSA 501: Audit Evidence - Specific Consideration For Selected Items InventoryhanselÎncă nu există evaluări