Documente Academic

Documente Profesional

Documente Cultură

MOCT Optical Current Transducer System: 69 KV To 765 KV Systems, 50/60 HZ

Încărcat de

JAY PARIKHTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MOCT Optical Current Transducer System: 69 KV To 765 KV Systems, 50/60 HZ

Încărcat de

JAY PARIKHDrepturi de autor:

Formate disponibile

May 2000 Descriptive Bulletin

Supercedes 38-450 38-450

dated September 1, 1996

MOCT Optical Current Transducer System

69 kV to 765 kV Systems, 50/60 Hz

Application

The Magneto-Optic Current Transducer (MOCT) is a

passive optical current transducer which uses light to

accurately measure current on high-voltage systems.

The MOCT system is suitable for outdoor application

and has an accurate metering current range from less

than 5 amps to 2000 amps using the same sensor.

Higher current rated designs are available upon

request. Metering accuracy exceeds class 0.2 per

IEC 185 standards.

The MOCT system provides a 1.0 amp current output

for metering. A low-voltage analog output can also be

supplied to interface the MOCT system to certain

protective relays. Contact the factory for application

assistance.

Standard Bill of Material

Three phases of MOCT sensors mounted on

polymer insulator columns with preterminated fiber

optic cable in the insulator. Optical Sensor

Optical

Path

Electronic MOCT signal processing module suitable Within

for installation in the substation control house. Sensor

Alalyzer

Fiber optic cables for transmission of the light

signals between the optical sensors and the MOCT Photo Diode

Opening

electronic module. for Current

Carrying

Optical

Conductor

Fiber

LEC

Polarizer

MOCT Optical Sensor Assembly

ABB Power Transmission

CONTROL HOUSE

ELECTRONIC MODULES

ILIACO

SIGNAL

PROCESSING

ELECTRONIC ELECTRONIC

METER OPTICS RELAY

ELECTRONICS

MOCT System Configuration

Benefits of the MOCT Optical Current Transducer System

The MOCT system can satisfy current sensing needs for revenue metering or protective relaying in a wide variety of

applications. Following is a list of key benefits:

High Accuracy for metering over a wide range of primary currents.

No requirement for oil or gas insulation system

Improved safety with no mechanism for failure or open secondary

Significantly smaller size and lighter weight than oil- or SF6-insulated equipment

Total isolation from surges for microprocessor-based meters and relays

No magnetic core ferroresonace or saturation limits

More than ten years of field proven experience

All dimensions are in inches unless specified otherwise

26.4

9.9 11.9

1.75

4.8

9.5 1.125

H1 H2

FOR 362 KV ONLY

4.00

.531 1.125

Ø 15.0 1.75

4.00

.375 THK

HIGH-VOLTAGE

TERMINAL DETAIL

DIM. A Ø 6.5

5.3

GROUND PAD 1/2-13 TAP (2)

7.4

JUNCTION BOX

FRONT VIEW 1.75

GROUND PAD

16.4

12.0

X-3

SPARE

X-1

15.9 11.8

X-2

X-4

VIEW OF FIBER

CONNECTIONS IN

1.25 X 0.88

SLOT (REQ.-4)

JUNCTION BOX

FRONT

MOUNTING DIMENSIONS

Mi ni mum C reep

Maxi mum D i mensi on A Wei ght

B IL D i stance

S ystem

kV

Voltage kV i nches mm i nches mm lbs. kg

72.5 350 48.9 1242 70 1778 110 50

121 550 62.6 1590 113 2870 117 53

145 650 70.2 1783 137 3479 120 54

169 750 79.3 2014 165 4191 123 56

242 900 97.5 2477 222 5638 133 60

245 1050 109.6 2784 260 6604 139 63

362 1300 132.0 3355 272 6900 348 158

525 1800 191.2 4856 433 11000 410 186

800 2050 C ontact Factory

Product Bulletin

38-450

ABB Power T&D Company Inc.

High-Voltage Switchgear

125 Theobold Ave.

Greensburg, PA 15601 USA

Ph. (724) 838-5205 Fax (724) 838-5299 Printed in USA

www.abb.com May 2000

S-ar putea să vă placă și

- MANUAL - CONTROL - FOR - HEATER - Sensor - Circuit - Circuit Diagram - SeekIC PDFDocument2 paginiMANUAL - CONTROL - FOR - HEATER - Sensor - Circuit - Circuit Diagram - SeekIC PDFOvanio MolinaÎncă nu există evaluări

- Isscc 2021 Tutorial: Silicon Photonics: From Basics To AsicsDocument88 paginiIsscc 2021 Tutorial: Silicon Photonics: From Basics To AsicsdxzhangÎncă nu există evaluări

- SMAC Actuators User ManualDocument52 paginiSMAC Actuators User ManualElectromateÎncă nu există evaluări

- 6545 - 6845 - MHZ - VFO - Oscillator - Circuit - Signal - Processing - Circuit DiagramDocument2 pagini6545 - 6845 - MHZ - VFO - Oscillator - Circuit - Signal - Processing - Circuit Diagrammax_orwellÎncă nu există evaluări

- Moduł Igbt Mig30j103h Toshiba DatasheetDocument16 paginiModuł Igbt Mig30j103h Toshiba DatasheetAnti-cosmoÎncă nu există evaluări

- JVL The MAC Motor AC-Servo Motors With Integrated Driver MAC400 To MAC3000Document16 paginiJVL The MAC Motor AC-Servo Motors With Integrated Driver MAC400 To MAC3000Electromate100% (1)

- Electrolytic Cleaning Line Motor Control Drive InstallationDocument7 paginiElectrolytic Cleaning Line Motor Control Drive InstallationPrakash KumarÎncă nu există evaluări

- Is Now Part ofDocument10 paginiIs Now Part ofParsons LuchoÎncă nu există evaluări

- Two-Wire End-of-Line Programmable Hall-Effect Switch/Latch: Description Features and BenefitsDocument21 paginiTwo-Wire End-of-Line Programmable Hall-Effect Switch/Latch: Description Features and Benefitsmario230991Încă nu există evaluări

- Optocouplers isolate modem data access arrangementsDocument7 paginiOptocouplers isolate modem data access arrangementsAsistencia Técnica JLFÎncă nu există evaluări

- Circuit Note: IEPE-Compatible Interface For Wideband MEMS Accelerometer SensorsDocument6 paginiCircuit Note: IEPE-Compatible Interface For Wideband MEMS Accelerometer SensorsLuis CaballeroÎncă nu există evaluări

- Sensors 15 19466Document22 paginiSensors 15 19466HaÎncă nu există evaluări

- Application Note 1321: High Speed CMOS Optocoupler Applications in Industrial Field Bus NetworksDocument8 paginiApplication Note 1321: High Speed CMOS Optocoupler Applications in Industrial Field Bus Networkssteviej85Încă nu există evaluări

- A High Performance Delta-Sigma Modulator For Neurosensing - Sensors-15-19466Document22 paginiA High Performance Delta-Sigma Modulator For Neurosensing - Sensors-15-19466Generation GenerationÎncă nu există evaluări

- Seminar ReportDocument8 paginiSeminar ReportMusthafa Thandottil100% (4)

- Arteche - CT - Sdo Oct - enDocument12 paginiArteche - CT - Sdo Oct - enTESLA IngenieriaÎncă nu există evaluări

- MS 360-380Wp 9BB 166 PERC 120cells Mono Solar Panel SpecificationDocument2 paginiMS 360-380Wp 9BB 166 PERC 120cells Mono Solar Panel SpecificationZsolt SzabóÎncă nu există evaluări

- Introduction To ElectronicsDocument22 paginiIntroduction To ElectronicsJhoanna DacatimbangÎncă nu există evaluări

- Open ROADM MSA Specification Ver 3 01Document91 paginiOpen ROADM MSA Specification Ver 3 01mcclaink06Încă nu există evaluări

- High Gain Darlington Output Optocouplers: Technical DataDocument8 paginiHigh Gain Darlington Output Optocouplers: Technical Datakt2018Încă nu există evaluări

- Automatic Night Light ControlDocument25 paginiAutomatic Night Light Controlkirubel Desta100% (1)

- Nuts & Volts 25-10 - Oct 2004Document108 paginiNuts & Volts 25-10 - Oct 2004blahblahname100% (2)

- CM Eng Smart Connectors ZeliskoDocument20 paginiCM Eng Smart Connectors ZeliskoLong Đạt NguyễnÎncă nu există evaluări

- Welotec Whitepaper Substation Automation enDocument9 paginiWelotec Whitepaper Substation Automation enClaudioÎncă nu există evaluări

- Abb Pricelist 2016 16.03.2016 PDFDocument216 paginiAbb Pricelist 2016 16.03.2016 PDFhiralalnhpcÎncă nu există evaluări

- Two-Wire Hall-Effect Switch APS11500: Description Features and BenefitsDocument22 paginiTwo-Wire Hall-Effect Switch APS11500: Description Features and Benefitsmario230991Încă nu există evaluări

- PF 42 Lincoln PDFDocument34 paginiPF 42 Lincoln PDFnikolovskidareÎncă nu există evaluări

- Cofem Catalogue Addressable Conventional 2019Document72 paginiCofem Catalogue Addressable Conventional 2019SlavkoÎncă nu există evaluări

- Phase Control An-3006Document6 paginiPhase Control An-3006Tantri Rahmawati100% (1)

- MP EcoGO.+MRL,+Gearless+Architecture,+ALL In+cabinet+Document6 paginiMP EcoGO.+MRL,+Gearless+Architecture,+ALL In+cabinet+Stefan DÎncă nu există evaluări

- MITSUBISHI HYBRID IC DRIVES IGBT MODULESDocument2 paginiMITSUBISHI HYBRID IC DRIVES IGBT MODULESGian MontillaÎncă nu există evaluări

- Av02 0891en - Ds - Acpl m60l - 2017 03 03 1827568Document15 paginiAv02 0891en - Ds - Acpl m60l - 2017 03 03 1827568mikeguo76Încă nu există evaluări

- SMS-Tork Electric Actuator, Electrical Flange Ball Valve, Butterfly ValveDocument16 paginiSMS-Tork Electric Actuator, Electrical Flange Ball Valve, Butterfly Valveharry wiliamÎncă nu există evaluări

- CN0510Document6 paginiCN0510Jordi DuranVallsÎncă nu există evaluări

- Sak 5664500000 enDocument335 paginiSak 5664500000 enTaz UddinÎncă nu există evaluări

- Solar Simulation Standards and QuickSun Measurement SystemDocument34 paginiSolar Simulation Standards and QuickSun Measurement SystemMohamad YazdaniÎncă nu există evaluări

- RCTrms 0318Document2 paginiRCTrms 0318supinstrumkkÎncă nu există evaluări

- A Nexans Company: Catalogue 2009Document31 paginiA Nexans Company: Catalogue 2009Mosa Elnaid ElnaidÎncă nu există evaluări

- Datasheet PDFDocument3 paginiDatasheet PDFIonut37Încă nu există evaluări

- Numerical RelaysDocument38 paginiNumerical Relaysashutosh2009Încă nu există evaluări

- A82-00-0109 Datasheets USDocument3 paginiA82-00-0109 Datasheets UScarrei JohnÎncă nu există evaluări

- Littlefuse Fast Action FuseDocument2 paginiLittlefuse Fast Action FuseCarlosDíazPeñaÎncă nu există evaluări

- SSt-Eclipse Model E4xx/5xx DSP-Based Digital Servo DrivesDocument3 paginiSSt-Eclipse Model E4xx/5xx DSP-Based Digital Servo DrivesRchrdStrkÎncă nu există evaluări

- Si8751/52 Data Sheet: Isolated FET Driver With Pin Control or Diode Emulator InputsDocument27 paginiSi8751/52 Data Sheet: Isolated FET Driver With Pin Control or Diode Emulator InputsAnti-cosmoÎncă nu există evaluări

- Not For New Design: ACS750xCA-050Document9 paginiNot For New Design: ACS750xCA-050ali_saitÎncă nu există evaluări

- Seminar Report On Numerical RelayDocument20 paginiSeminar Report On Numerical RelayAnurag Determined100% (1)

- DC Power For Test Rig and Lab: Laboratory Power Supplies Electronic LoadsDocument16 paginiDC Power For Test Rig and Lab: Laboratory Power Supplies Electronic Loadsjose0enar0munozÎncă nu există evaluări

- Mp2565dn LF ZDocument20 paginiMp2565dn LF ZnvkjhejfjÎncă nu există evaluări

- Advanced Motion Controls BE25A20ACDocument9 paginiAdvanced Motion Controls BE25A20ACServo2GoÎncă nu există evaluări

- Introduction To Charge Mode Accelerometers: Two System ConceptsDocument3 paginiIntroduction To Charge Mode Accelerometers: Two System ConceptsNg Wei LihÎncă nu există evaluări

- Arteche CT Sdo Oct enDocument12 paginiArteche CT Sdo Oct enfirstone10Încă nu există evaluări

- Power Wave Advanced Module & Advanced Module Aluminum: Operator'S ManualDocument34 paginiPower Wave Advanced Module & Advanced Module Aluminum: Operator'S ManualnikolovskidareÎncă nu există evaluări

- Hall-Effect, Direction-Detection Sensors: FeaturesDocument10 paginiHall-Effect, Direction-Detection Sensors: FeaturesDiego GraçanoÎncă nu există evaluări

- 8900 DsDocument14 pagini8900 DsSergei OssifÎncă nu există evaluări

- Multifunction Telecom Switch: DescriptionDocument8 paginiMultifunction Telecom Switch: DescriptionPhong DoÎncă nu există evaluări

- An Industrial Training Report (Ec 781) Solar Charge Controller Simoco Telecommunication LTDDocument18 paginiAn Industrial Training Report (Ec 781) Solar Charge Controller Simoco Telecommunication LTDAmar TuladharÎncă nu există evaluări

- Introduction of Toll Tax MachineDocument90 paginiIntroduction of Toll Tax Machineanand011Încă nu există evaluări

- Liquid Resistance StarterDocument4 paginiLiquid Resistance StarterHpnote100% (1)

- Analog Modules, Inc.: Model 762Document5 paginiAnalog Modules, Inc.: Model 762Haiqa AbbasÎncă nu există evaluări

- SC CalculationsDocument112 paginiSC CalculationsJAY PARIKHÎncă nu există evaluări

- GRE Word ThesaurusDocument137 paginiGRE Word ThesaurusPhanidhar GubbalaÎncă nu există evaluări

- Company Logo: Cable Size CalculationDocument7 paginiCompany Logo: Cable Size Calculationahmadgce04Încă nu există evaluări

- Hindalco Routine Test Report Page No. 4 & 5Document2 paginiHindalco Routine Test Report Page No. 4 & 5JAY PARIKHÎncă nu există evaluări

- Irr - Pa & Id Fan - Boiler 1Document14 paginiIrr - Pa & Id Fan - Boiler 1Jay Rameshbhai ParikhÎncă nu există evaluări

- CEA Battery ManagementDocument112 paginiCEA Battery ManagementJAY PARIKHÎncă nu există evaluări

- GRE Word ThesaurusDocument137 paginiGRE Word ThesaurusPhanidhar GubbalaÎncă nu există evaluări

- CT Testing at ERDA & HALOLDocument3 paginiCT Testing at ERDA & HALOLJAY PARIKHÎncă nu există evaluări

- Best PracticesDocument28 paginiBest PracticesJAY PARIKHÎncă nu există evaluări

- CableInstallation PDFDocument8 paginiCableInstallation PDFJAY PARIKHÎncă nu există evaluări

- Keeping SafeDocument3 paginiKeeping SafeJay Rameshbhai ParikhÎncă nu există evaluări

- 3AH1 Operating InstrDocument29 pagini3AH1 Operating InstrJAY PARIKHÎncă nu există evaluări

- CableDocument2 paginiCableJAY PARIKHÎncă nu există evaluări

- CT Testing at ERDA & HALOLDocument3 paginiCT Testing at ERDA & HALOLJAY PARIKHÎncă nu există evaluări

- 3AH3 Circuit Breaker DetailsDocument28 pagini3AH3 Circuit Breaker Details2003vinayÎncă nu există evaluări

- 3AH Catalog PDFDocument75 pagini3AH Catalog PDFalsilva2014100% (1)

- Boiler DraftDocument22 paginiBoiler DraftJAY PARIKHÎncă nu există evaluări

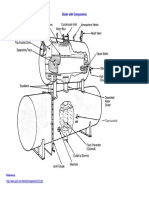

- Air CompressorsDocument10 paginiAir CompressorsJAY PARIKHÎncă nu există evaluări

- Voltage Regulator DECS-100 ManuelDocument81 paginiVoltage Regulator DECS-100 Manuelctsak100% (1)

- SynchroniserDocument21 paginiSynchroniserJAY PARIKHÎncă nu există evaluări

- Boiler TechnologiesDocument5 paginiBoiler TechnologiesSubhabrata SahaÎncă nu există evaluări

- SynchroniserDocument21 paginiSynchroniserJAY PARIKHÎncă nu există evaluări

- WoodwardDocument4 paginiWoodwardKUNALJAYÎncă nu există evaluări

- 011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inDocument1 pagină011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inJAY PARIKHÎncă nu există evaluări

- MX3EG1A Automatic Synchronizer Technical ManualDocument38 paginiMX3EG1A Automatic Synchronizer Technical Manualsgshekar30Încă nu există evaluări

- 0507BoilerwithComponents PDFDocument1 pagină0507BoilerwithComponents PDFJAY PARIKHÎncă nu există evaluări

- Boiler Water TreatmentDocument7 paginiBoiler Water TreatmentJAY PARIKH100% (1)

- Statement Showing Cost & Profitability of Power Generated - Cogeneration PlantDocument19 paginiStatement Showing Cost & Profitability of Power Generated - Cogeneration PlantJAY PARIKHÎncă nu există evaluări

- Procedure For Calculation of Efficiency-1Document7 paginiProcedure For Calculation of Efficiency-1JAY PARIKHÎncă nu există evaluări

- Improve Primary Air Heater EfficiencyDocument4 paginiImprove Primary Air Heater EfficiencyJAY PARIKHÎncă nu există evaluări

- Power Electronics Project Title PDFDocument4 paginiPower Electronics Project Title PDFpowerÎncă nu există evaluări

- Hegel Catalogue 2010Document11 paginiHegel Catalogue 2010LukaszÎncă nu există evaluări

- Samsung ln23 26 32 40 r81bx Chassis GBP 23 26 32 40 MlaDocument132 paginiSamsung ln23 26 32 40 r81bx Chassis GBP 23 26 32 40 MlaDaniel Norberto DemariaÎncă nu există evaluări

- ICT Premium Products Passwords SY 2019-2020Document8 paginiICT Premium Products Passwords SY 2019-2020Dharen Job CornelioÎncă nu există evaluări

- Huawei LTE TDD CA Solution OverviewDocument29 paginiHuawei LTE TDD CA Solution OverviewChido Morgan100% (2)

- Control de Temperatura Omron Modelo E5c2Document6 paginiControl de Temperatura Omron Modelo E5c2Jose MarcanoÎncă nu există evaluări

- 5054 s16 QP 22 PDFDocument16 pagini5054 s16 QP 22 PDFAhmediqraÎncă nu există evaluări

- Radio and Telivison: Live BroadcastDocument12 paginiRadio and Telivison: Live Broadcastdeadpoet27Încă nu există evaluări

- Floorplaning Guidelines for Macro and Memory PlacementDocument23 paginiFloorplaning Guidelines for Macro and Memory PlacementBindu MakamÎncă nu există evaluări

- HBXX 6516DS VTMDocument2 paginiHBXX 6516DS VTMajobudiÎncă nu există evaluări

- Accuforce 12v 40ah Data SheetDocument2 paginiAccuforce 12v 40ah Data SheetAntoine GrsÎncă nu există evaluări

- Otn Fec Po Opt TM AeDocument1 paginăOtn Fec Po Opt TM Aenobita3Încă nu există evaluări

- Electromagnetic Regenerative Shock Absorber DesignDocument23 paginiElectromagnetic Regenerative Shock Absorber Designsanjeevbijarnia0160% (5)

- 01 - GST UL System Overview - 2017v2.1Document42 pagini01 - GST UL System Overview - 2017v2.1RaviÎncă nu există evaluări

- Day 3 Slot 3 Mid Sm23 SummerDocument32 paginiDay 3 Slot 3 Mid Sm23 SummerNayeem SarkarÎncă nu există evaluări

- Battery ReplacementDocument3 paginiBattery ReplacementHakim HamzaouiÎncă nu există evaluări

- System On Chip PresentationDocument70 paginiSystem On Chip Presentationshree_rs81Încă nu există evaluări

- Topcon RL-H5A - EDocument2 paginiTopcon RL-H5A - EAudityaÎncă nu există evaluări

- Smart Helmet Using GSM and GPSDocument6 paginiSmart Helmet Using GSM and GPSAnonymous kw8Yrp0R5rÎncă nu există evaluări

- TLE4275 q1Document28 paginiTLE4275 q1GG Módulos AutomotivosÎncă nu există evaluări

- A2c31376 C3 Atic35Document1 paginăA2c31376 C3 Atic35jhon ortiz100% (1)

- 6793352842190-770-2.2 - Catalog - 2019 - Facts - en - R1.00Document29 pagini6793352842190-770-2.2 - Catalog - 2019 - Facts - en - R1.00Ahmed FathyÎncă nu există evaluări

- Manual PVPMDocument62 paginiManual PVPMMenthor555Încă nu există evaluări

- O2 Sensor Simulator CircuitDocument4 paginiO2 Sensor Simulator CircuitTeddy Khant100% (1)

- Irjet V3i7136Document5 paginiIrjet V3i7136Rajesh SharmaÎncă nu există evaluări

- H30D E G F User S ManualDocument41 paginiH30D E G F User S Manualaradon11Încă nu există evaluări

- Tvs LP 45 LiteDocument2 paginiTvs LP 45 LiteDevendra Dev0% (1)

- Design of A Low-Dropout Regulator With On-Chip Frequency CompensationDocument3 paginiDesign of A Low-Dropout Regulator With On-Chip Frequency Compensationnaveen1030Încă nu există evaluări

- KLIPSCH Computer Speaker Service ManualDocument21 paginiKLIPSCH Computer Speaker Service ManualEric CreechÎncă nu există evaluări

- Panasonic TX-L24C3BDocument80 paginiPanasonic TX-L24C3BLeonardo PradoÎncă nu există evaluări