Documente Academic

Documente Profesional

Documente Cultură

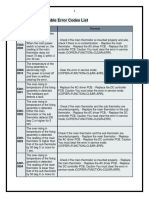

Canon IRC1020 Trouble Error Codes

Încărcat de

nafeesDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Canon IRC1020 Trouble Error Codes

Încărcat de

nafeesDrepturi de autor:

Formate disponibile

1

Canon iRC1020 Trouble Error Codes

2

Error in start-up of fixing

- Check of the connector

assembly Disconnection of main

of the low-voltage power

When 1 sec passed after thermistor,

E000- supply PCB -

energization of the heater, the disconnection of fixing

0000 Replacement of fixing

detected temperature of the heater, error in DC

sleeve unit - Replacement

main thermistor is not 5 deg C controller PCB.

of DC controller PCB

or more (0 deg C at power on).

Error in overheating of fixing

assembly - Check of the connector

The status where the detected of the low-voltage power

Error in main thermistor,

E001- temperature of the main supply PCB -

error in DC controller

0000 thermistor is 225 deg C Replacement of fixing

PCB.

(approx. 0.84V equivalent) or sleeve unit - Replacement

more is detected for 0.5 of DC controller PCB

continuous sec or more.

Error in overheating of fixing

assembly - Check of the connector

The status where the detected of the low-voltage power

Error in sub thermistor,

E001- temperature of the sub supply PCB -

error in DC controller

0001 thermistor is 245 deg C Replacement of fixing

PCB.

(approx. 2.12V equivalent) or sleeve unit - Replacement

more is detected for 0.5 of DC controller PCB

continuous sec or more.

Error in abnormally low

temperature of fixing assembly Error in low-voltage

- Replacement of low-

The status where the detected power supply PCB,

voltage power supply PCB

E003- temperature of the main disconnection of main

- Replacement of fixing

0000 thermistor is 100 deg C thermistor, error in DC

sleeve unit - Replacement

(approx. 2.60V equivalent) or controller PCBor 20

of DC controller PCB

less is detected for 0.5 msec.

continuous sec or more.

Error in abnormally low

temperature of fixing assembly

- Check of the connector

The status where the detected

of the low-voltage power

temperature of the sub Error in sub thermistor,

E003- supply PCB -

thermistor is less than 100 deg error in DC controller

0001 Replacement of fixing

C (approx. 0.38V equivalent) is PCB.

sleeve unit - Replacement

detected 0.5 continuous sec or

of DC controller PCB

more after energization of the

heater.

Error in fixing power supply

drive circuit

E004- Error in fixing control - Replacement of low-

Cannot detect the zero cross

0000 circuit block. voltage power supply PCB

signal for the specified period

or more.

E012- Error in activation of motor Error in ETB motor, error - Replacement of ETB

0000 When 3.5 sec passed after in DC controller PCB. motor - Replacement of

3

activation of ETB motor, the DC controller PCB

cycle of ETB motor speed

detection signal does not

become its specified value.

Error in activation of motor

After ETB motor speed

- Replacement of ETB

E012- detection signal became the Error in ETB motor, error

motor - Replacement of

0001 specified value of the cycle, it in DC controller PCB

DC controller PCB

exceeds the specified cycle for

2 continuous sec or more.

Error in activation of motor Y

When 2.5 sec passed after

Error in drum motor, - Replacement of drum

E012- activation of the yellow drum

error in DC controller motor - Replacement of

0002 motor, the cycle of drum motor

PCB. DC controller PCB

speed detection signal does

not become its specified value.

Error in activation of motor Y

After the yellow drum motor

Error in drum motor, - Replacement of drum

E012- speed detection signal became

error in DC controller motor - Replacement of

0003 the specified value of the cycle,

PCB. DC controller PCB

it exceeds the specified cycle

for 2 continuous sec or more.

Code Description Causes Remedy

Error in activation of motor

M

When 2.5 sec passed after

Cause Error in drum - Replacement of drum motor -

E012- activation of the magenta

motor, error in DC Replacement of DC controller

0004 drum motor, the cycle of

controller PCB. PCB

drum motor speed

detection signal does not

become its specified value.

Error in activation of motor

M

After the magenta drum

motor speed detection - Replacement of drum motor -

E012- Error in drum motor, error

signal became the specified Replacement of DC controller

0005 in DC controller PCB.

value of the cycle, it PCB

exceeds the specified cycle

for 2 continuous sec or

more.

Error in activation of motor - Replacement of drum motor -

E012- Error in drum motor, error

C Replacement of DC controller

0006 in DC controller PCB.

Description When 2.5 sec PCB

4

passed after activation of

the cyan drum motor, the

cycle of the drum motor

speed detection signal does

not become its specified

value.

Error in activation of motor

C

After the cyan drum motor

- Replacement of drum motor -

E012- speed detection signal Error in drum motor, error

Replacement of DC controller

0007 became the specified value in DC controller PCB.

PCB

of the cycle, it exceeds the

specified cycle for 2

continuous sec or more.

Error in activation of motor

Bk

When 2.5 sec passed after

- Replacement of drum motor -

E012- activation of the black drum Error in drum motor, error

Replacement of DC controller

0008 motor, the cycle of the drum in DC controller PCB.

PCB

motor speed detection

signal does not become its

specified value.

Error in activation of motor

Bk

After the black drum motor

- Replacement of drum motor -

E012- speed detection signal Error in drum motor, error

Replacement of DC controller

0009 became the specified value in DC controller PCB.

PCB

of the cycle, it exceeds the

specified cycle for 2

continuous sec or more.

Error in activation of fixing

motor

When 2.5 sec passed after

- Replacement of fixing motor -

E014- activation of fixing motor, Error in fixing motor, error

Replacement of DC controller

0000 the cycle of the fixing motor in DC controller PCB.

PCB

speed detection signal does

not become its specified

value.or more.

Error in activation of fixing

motor

After the fixing motor speed

- Replacement of fixing motor -

E014- detection signal became Error in fixing motor, error

Replacement of DC controller

0001 the specified value of the in DC controller PCB.

PCB

cycle, it exceeds the

specified cycle for 2

continuous sec or more.ore.

E015- Failure in developing Developing Check the developing

5

0000 disengagement disengagement disengagement mechanism.

Developing cylinder mechanism fault, Replace developing

disengagement mechanism developing disengagement disengagement solenoid.

does not function correctly. solenoid fault, developing Replace developing

disengagement sensor disengagement sensor.

fault, DC controller PCB Replace DC controller PCB.

fault.

- Replacement of ETB unit -

Error in high-voltage joint

Error in density sensor Dirt on density sensor, (Check high-voltage joint for

E020- Cannot receive enough error in density sensor, each color, and each joint to

0000 light when detecting image error in DC controller PCB, high-voltage PCB) -

density. error in toner cartridge Replacement of DC controller

- Replacement of toner

cartridge

Code Description Causes Remedy

Toner level sensor

Memory controller PCB

failure - Replace toner cartridge - Replace

E024- assembly fault, DC

Failure output from memory controller PCB - Replace

0000 controller PCB assembly

the toner level DC controller PCB

fault, toner cartridge fault.

sensor (Yellow).

Toner level sensor

Cause Memory controller

failure - Replace toner cartridge - Replace

E024- PCB assembly fault, DC

Failure output from memory controller PCB - Replace

0001 controller PCB assembly

the toner level DC controller PCB

fault, toner cartridge fault.

sensor (Magenta).

Toner level sensor

Memory controller PCB

failure - Replace toner cartridge - Replace

E024- assembly fault, DC

Failure output from memory controller PCB - Replace

0002 controller PCB assembly

the toner level DC controller PCB

fault, toner cartridge fault.

sensor (Cyan).

Toner level sensor

Memory controller PCB

failure - Replace toner cartridge - Replace

E024- assembly fault, DC

Failure output from memory controller PCB - Replace

0003 controller PCB assembly

the toner level DC controller PCB

fault, toner cartridge fault.

sensor (Black).

Error in

environment

Environment sensor fault,

E066- sensorbly - Replace environment sensor -

DC controller PCB assembly

0000 Failure in Replace DC controller PCB

fault.

environment

sensor.

E078- Error in primary Terminal assembly fault, - Replace ETB estrangement

0000 transfer transfer roller estrangement solenoid - Replace ETB unit -

6

estrangement unit solenoid fault, EBT unit fault, Terminal assembly fault (check on

Primary transfer high-voltage power PCB every contact between the terminals

estrangement unit assembly fault. of each color and the high voltage

does not function PCB assembly)

properly.

Error in scanner

motor, laser unit,

Laser scanner unit fault, DC

E100- BD - Replace laser scanner unit -

controller PCB assembly

0000 Yellow scanner Replace DC controller PCB

fault.

assembly

malfunction.

Error in scanner

motor, laser unit,

Laser scanner unit fault, DC

E100- BD - Replace laser scanner unit -

controller PCB assembly

0001 Magenta scanner Replace DC controller PCB

fault.

assembly

malfunction.

Error in scanner

motor, laser unit,

Laser scanner unit fault, DC

E100- BD - Replace laser scanner unit -

controller PCB assembly

0002 Cyan scanner Replace DC controller PCB

fault.

assembly

malfunction.

Error in scanner

motor, laser unit,

Laser scanner unit fault, DC

E100- BD - Replace laser scanner unit -

controller PCB assembly

0003 Black scanner Replace DC controller PCB

fault.

assembly

malfunction.

Code Description Causes Remedy

Error in scanner motor,

E100- laser unit, BD laser scanner unit fault, DC - Replace laser scanner unit -

0004 Failure output of a controller PCB fault. Replace DC controller PCB

magenta BD signal

Error in scanner motor,

E100- laser unit, BD laser scanner unit fault, DC - Replace laser scanner unit -

0005 Failure output of a controller PCB fault. Replace DC controller PCB

magenta BD signal

Error in CPR sensor Dirty color displacement Replace ETB unit - Terminal

Cannot detect color detection sensor, color assembly fault (check on every

E194- displacement detection displacement detection contact between the terminals

0000 pattern, detected results sensor fault, DC controller of each color and the high

fall outside the PCB assembly fault, toner voltage PCB assembly) -

acceptable range. cartridge fault. Replace DC controller PCB -

7

Replace toner cartridge

Error in DCON ROM

Updating the ROM on

E196-

the DC controller PCB - Replace DC controller PCB

0001

assembly has been

failed.

E197- Internal communication - Replace DC controller PCB -

0000 error Replace video controller PCB

DC controller memory

E198- malfunction DC controller PCB - Replace DC controller PCB

0000 DC controller memory assembly fault. assembly

malfunction.

The CCD unit moves - Replace reader HP sensor. -

E202- Reader HP sensor fault

backward, but does not Replace reader motor sensor. -

0001 Reader HP outward fault.

move to the home position. Replace reader unit.

Reader HP sensor fault The CCD unit moves - Replace reader HP sensor. -

E202-

Reader HP homeward forward, but does not move Replace reader motor sensor. -

0002

fault to the home position. Replace reader unit.

Error in light intensity of

E225- the lamp.

Replace reader unit.

0000 Decrease of light

intensity of the lamp.

EEPROM access error

E248- EEPROM data cannot be

Error at EEPROM Replace reader unit.

0001 read at power-on.

power-on

Code Description Causes Remedy

EEPROM access

E248- error EEPROM writing cannot be

Replace reader unit.

0002 Error in EEPROM performed.

writing

EEPROM access

EEPROM reading cannot be

E248- error

performed after writing is Replace reader unit.

0003 Error in EEPROM

performed.

reading after writing

EEPROM access

E248- error EEPROM register writing cannot

Replace reader unit.

0004 Error in EEPROM be performed.

register writing

Main controller PCB

- Check the connection of

E351- fault

Main controller PCB fault. main controller PCB. -

0000 Internal error of the

Replace main controller PCB.

main controller PCB

8

- Disconnection from the card

reader has been detected since

Communication - Check the connectors of the

communication started after

error of options card reader and image

confirmation of normal connection

E719- Erroneous processor PCB. - Replace the

to the card reader (after power-on).

0000 communication with card reader for normal

- A serial communication error has

card reader (serial connection. - Replace the

occurred. (The serial

communication) image processor PCB.

communication error cannot be

recovered.)

- Disconnection from the coin - Check the connection

vendor has been detected since between the image processor

Communication

communication started after PCB and serial PCB. - Check

error of options

confirmation of normal connection the connectors of the serial

E719- Erroneous

to the coin vendor (after power-on). PCB and coin vendor for

0002 communication with

- A serial communication error has normal connection. - Replace

coin vendor (serial

occurred. (The serial the serial PCB. - Check the

communication)

communication error cannot be coin vendor. - Replace the

recovered.) image processor PCB.

Language file/boot

ROM/USB memory

E744- The language file version does not Download a language file of

error

0001 match Bootable. the correct version.

Language file

version error

Language file/boot

ROM/USB memory

E744- The language file is longer than the Download a language file of

error

0002 permitted size. the correct version.

Language file size

error

Language file/boot

ROM/USB memory

E744- The language file version does not Download a language file of

error

0003 match Bootable. the correct version.

Language file

version error

Language file/boot

ROM/USB memory

E744- Download a language file of

error Reading of language file is invalid.

0004 the correct version.

Language file read

error

Code Description Causes Remedy

Error in power supply fan

- Replace the power

E804- The fan lock detection signal is Power supply fault, DC

supply fan - Replace the

0000 input for about 10 sec or longer controller PCB fault.

DC controller PCB

continuously.

E805- Error in duplexing fan/CPU fan Duplexing fan fault, - Replace the duplexing

9

0005 The duplexing fan lock detection DC controller PCB fan - Replace the DC

signal is input for about 10 sec or fault. controller PCB

longer continuously.

Error in pressure release

- Replace the fixing drive

mechanism Fixing drive assembly

E840- assembly - Replace the

Although passing 2.5 sec from the fault, fixing pressure

0000 fixing pressure release

start of HP control, HP (pressure release cam fault.

cam

condition) cannot be controlled.

S-ar putea să vă placă și

- How Fat Cells WorkDocument5 paginiHow Fat Cells WorknafeesÎncă nu există evaluări

- How Helicopters WorkDocument11 paginiHow Helicopters WorknafeesÎncă nu există evaluări

- How The Digestive System WorksDocument9 paginiHow The Digestive System WorksnafeesÎncă nu există evaluări

- CanonDocument747 paginiCanonnafeesÎncă nu există evaluări

- Canon IR4570 Trouble Error CodesDocument22 paginiCanon IR4570 Trouble Error Codesnafees100% (3)

- Ricoh Aficio MPC4000 Trouble Error CodesDocument25 paginiRicoh Aficio MPC4000 Trouble Error CodesnafeesÎncă nu există evaluări

- How The Sun WorksDocument27 paginiHow The Sun WorksnafeesÎncă nu există evaluări

- Konica-Minolta Bizhub 250 Trouble Error CodesDocument11 paginiKonica-Minolta Bizhub 250 Trouble Error Codesnafees100% (1)

- How Circuit Breakers Work 9Document4 paginiHow Circuit Breakers Work 9nafeesÎncă nu există evaluări

- Konica-Minolta Bizhub 423 Error CodesDocument26 paginiKonica-Minolta Bizhub 423 Error Codesnafees0% (1)

- Ricoh Aficio MPC6501 Trouble Error CodesDocument55 paginiRicoh Aficio MPC6501 Trouble Error Codesnafees100% (1)

- Charging FaultsDocument1 paginăCharging FaultsnafeesÎncă nu există evaluări

- How Food WorksDocument19 paginiHow Food WorksnafeesÎncă nu există evaluări

- How To Install Android 4Document39 paginiHow To Install Android 4nafeesÎncă nu există evaluări

- Ricoh Aficio MPC2030 Trouble Error CodesDocument19 paginiRicoh Aficio MPC2030 Trouble Error CodesnafeesÎncă nu există evaluări

- Ricoh Aficio MPC3000 Trouble Error CodesDocument23 paginiRicoh Aficio MPC3000 Trouble Error CodesnafeesÎncă nu există evaluări

- Ricoh Aficio MPC2500 Trouble Error CodesDocument23 paginiRicoh Aficio MPC2500 Trouble Error CodesnafeesÎncă nu există evaluări

- Ricoh Alicia MPC3503SP Trouble Error CodesDocument46 paginiRicoh Alicia MPC3503SP Trouble Error CodesnafeesÎncă nu există evaluări

- Ricoh Aficio MP7000 Trouble Error CodesDocument35 paginiRicoh Aficio MP7000 Trouble Error CodesnafeesÎncă nu există evaluări

- Ricoh Aficio MPC3002 Trouble Error CodesDocument27 paginiRicoh Aficio MPC3002 Trouble Error CodesnafeesÎncă nu există evaluări

- Canon IR Advance C5030 Trouble Error CodesDocument73 paginiCanon IR Advance C5030 Trouble Error Codesnafees100% (8)

- Ricoh Aficio MP6500SP Trouble Error CodesDocument48 paginiRicoh Aficio MP6500SP Trouble Error CodesnafeesÎncă nu există evaluări

- Canon IR Advance C2020 Trouble Error CodesDocument62 paginiCanon IR Advance C2020 Trouble Error Codesnafees50% (2)

- Ricoh Aficio MP4500 Trouble Error CodesDocument19 paginiRicoh Aficio MP4500 Trouble Error Codesnafees100% (1)

- Ricoh Aficio MP4002 Trouble Error CodesDocument26 paginiRicoh Aficio MP4002 Trouble Error Codesnafees100% (1)

- Canon IR Advance C2025 Trouble Error Codes - 1Document73 paginiCanon IR Advance C2025 Trouble Error Codes - 1nafeesÎncă nu există evaluări

- Ricoh Aficio MPC2000 Trouble Error CodesDocument20 paginiRicoh Aficio MPC2000 Trouble Error Codesnafees100% (1)

- Canon IR105 Trouble Error CodesDocument32 paginiCanon IR105 Trouble Error Codesnafees0% (2)

- Canon IR Advance 6265 Error CodesDocument56 paginiCanon IR Advance 6265 Error CodesnafeesÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CJR Fisika Umum IDocument17 paginiCJR Fisika Umum IveronikaÎncă nu există evaluări

- Pocket Book AGDocument67 paginiPocket Book AGsudiraharjaÎncă nu există evaluări

- Website Catalog MOTORS v2 PDFDocument8 paginiWebsite Catalog MOTORS v2 PDFИгорь КернякевичÎncă nu există evaluări

- Athens 803 and The EkphoraDocument18 paginiAthens 803 and The EkphoradovescryÎncă nu există evaluări

- History of Costa RicaDocument2 paginiHistory of Costa Ricakrishnan MishraÎncă nu există evaluări

- Squares and Square Roots Chapter Class ViiiDocument24 paginiSquares and Square Roots Chapter Class ViiiManas Hooda100% (1)

- MalachiteDocument2 paginiMalachiteAkhil KumarÎncă nu există evaluări

- Danh M C AHTN 2017 - HS Code 2017 PDFDocument564 paginiDanh M C AHTN 2017 - HS Code 2017 PDFBao Ngoc Nguyen100% (1)

- Tas 5731Document60 paginiTas 5731charly36Încă nu există evaluări

- Quiz - Ionic EquilibriumDocument2 paginiQuiz - Ionic EquilibriumSiddÎncă nu există evaluări

- Samuelson and Nordhaus ch22 PDFDocument30 paginiSamuelson and Nordhaus ch22 PDFVictor ManatadÎncă nu există evaluări

- 9 Quw 9 CjuDocument188 pagini9 Quw 9 CjuJavier MorenoÎncă nu există evaluări

- Embedded Systems:: Hacking of Electronic EquipmentsDocument76 paginiEmbedded Systems:: Hacking of Electronic EquipmentsKailashi Chandra SekharÎncă nu există evaluări

- N Methylpyrrolidone: Chemical Synonym General InformationDocument5 paginiN Methylpyrrolidone: Chemical Synonym General InformationMohamed AdelÎncă nu există evaluări

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageDocument6 paginiThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoÎncă nu există evaluări

- Eurolite Led TMH 7 PDFDocument2 paginiEurolite Led TMH 7 PDFSarahÎncă nu există evaluări

- Ingles y Español Unidad 7Document9 paginiIngles y Español Unidad 7Pier Jhoani Ñañez LlanosÎncă nu există evaluări

- Aipl2009 V120000001Document7 paginiAipl2009 V120000001Olof HedinÎncă nu există evaluări

- 159 SnackDocument97 pagini159 SnackGuy PlaterÎncă nu există evaluări

- VENUS e CatalogueDocument38 paginiVENUS e CatalogueGanesh BabuÎncă nu există evaluări

- Black Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonDocument44 paginiBlack Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonmarcÎncă nu există evaluări

- Time Series - Practical ExercisesDocument9 paginiTime Series - Practical ExercisesJobayer Islam TunanÎncă nu există evaluări

- Geology and Mineralization of The Maggie Creek DistrictDocument28 paginiGeology and Mineralization of The Maggie Creek DistrictRockstone Research Ltd.Încă nu există evaluări

- SDS Super PenetrantDocument5 paginiSDS Super Penetrantaan alfianÎncă nu există evaluări

- The Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateDocument22 paginiThe Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateOkawa TakeshiÎncă nu există evaluări

- 1 Soundcraft Notepad User GuideDocument40 pagini1 Soundcraft Notepad User GuideNives KurjakÎncă nu există evaluări

- Grocery GatewayDocument2 paginiGrocery GatewayKumari Mohan0% (2)

- E11133 MB Pin Definition v2 Print Vendor Only PDFDocument18 paginiE11133 MB Pin Definition v2 Print Vendor Only PDFLuciano MalancaÎncă nu există evaluări

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsDocument21 paginiEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoÎncă nu există evaluări

- Reservoir Rock PropertiesDocument148 paginiReservoir Rock Propertiesiscribdusername100% (7)