Documente Academic

Documente Profesional

Documente Cultură

Phenol From Cumene

Încărcat de

aliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Phenol From Cumene

Încărcat de

aliDrepturi de autor:

Formate disponibile

Phenol from Cumene

22.2 Phenol production from Cumene

22.2.1 Reactions

Peroxidation: Cumene + Air → Cumene Hydroperoxide.

Hydrolysis: Cumene Hydroperoxide + H2SO4 → Phenol + Acetone.

22.2.2 For Peroxidation

• Aqueous emulsion is prepared using emulsification agents.

• Operating conditions: Normal T & P.

• Emusification agent: NaOH (Alkali).

22.2.3 For Hydrolysis

• 10 – 25 % H2SO4 (Aqueous) is used.

• Operating conditions: 55 – 65°C and atmospheric pressure conditions.

Process Description:

• Fresh cumene is mixed with hydrogenated unreacted cumene, cumene + alpha methyl styrene

(recycle streams).

• The pre-purification step involves converting unsaturates such as alpha methyl styrene and others

to saturates. This is done by using nickel catalyst at 100°C and feeding hydrogen to the pre-purification

reactor. The product from this unit then mixes with the fresh cumene.

• The fresh cumene and processed cumene and alpha methyl styrene are fed to the oxidation reactor.

The oxidation reactor refers to a gas liquid reaction between air (Oxygen) and the cumene.

• An emulsion of cumene is prepared in the oxidation reactor by adding alkali to it.

• pH is maintained in the range of 8.5 – 10.5 to suit good emulsification conditions.

• After reaction, vent gases are condensed and recycled back and the product is sent to a cleavage

unit.

• The cleavage unit consists of a stirrer and is fed with fresh and recycled H2SO4 aqueous solution to

enable the hydrolysis of cumene hydroperoxide.

• The product streams from the cleavage unit enter a settler (phase separator) which upon gravity

settling yields two streams namely the acid rich aqueous stream and the phenol rich organic stream.

• The aqueous stream consists of the sulphuric acid and is sent back to the cleavage unit as a recycle

stream.

• The organic stream consists of cumene (unreacted), phenol (product), acetone (side product), alpha

methyl styrene (side product) and acetophenone (side product).

• The organic stream from the gravity settler unit then enters a scrubber fed with water. In this

operation, water extracts the remaining acids in the organic stream and produces crude phenol

stream. Water leaving the unit consists of acidified wash water.

• The crude phenol then enters a distillation unit that separates acetone from the other components.

• The bottom product from this distillation column enters a vacuum distillation column that produces

cumene as a top product.

• The bottom product from the distillation column enters another vacuum distillation unit to produce

alpha methyl styrene.

• The bottom product of this distillation column enters the final vacuum distillation unit to produce

phenol as top product and acetophenone as the bottom product.

S-ar putea să vă placă și

- Phenol Production from Cumene & TolueneDocument9 paginiPhenol Production from Cumene & TolueneAnonymous RJkpep7D0rÎncă nu există evaluări

- Although This Process Is No Longer in Common UseDocument15 paginiAlthough This Process Is No Longer in Common Usedia_aldy100% (1)

- Phenol PlantDocument33 paginiPhenol PlantrakeshÎncă nu există evaluări

- Phenol ProductionDocument9 paginiPhenol ProductionPlant Design100% (1)

- Cumene to Phenol ProcessDocument2 paginiCumene to Phenol ProcessaliÎncă nu există evaluări

- Cumene peroxidation process guideDocument2 paginiCumene peroxidation process guideEdrian A. Mañalong100% (1)

- CUMENEDocument24 paginiCUMENEhiteshÎncă nu există evaluări

- Cumene To PhenolDocument73 paginiCumene To Phenolvpsrpuch67% (3)

- Ethyl BenzeneDocument11 paginiEthyl BenzeneIan Jasper SabordoÎncă nu există evaluări

- Production of PhenolDocument65 paginiProduction of Phenolchaitanyavura67% (3)

- PRODUCTION OF ACETONE FROM ISOPROPYL ALCOHOLDocument12 paginiPRODUCTION OF ACETONE FROM ISOPROPYL ALCOHOLRabia SabirÎncă nu există evaluări

- Acrylic Acid ProductionDocument2 paginiAcrylic Acid ProductionZeynep HoşgörÎncă nu există evaluări

- Acrylic 2520acid 2520 Material 2520 BalanceDocument6 paginiAcrylic 2520acid 2520 Material 2520 Balanceapi-3714811Încă nu există evaluări

- Design of EthylbenzeneDocument5 paginiDesign of Ethylbenzenesahar vahdatifarÎncă nu există evaluări

- Project 4 Acrylic AcidDocument16 paginiProject 4 Acrylic AcidN193746100% (3)

- Propylene and Ethylene Production from MethanolDocument149 paginiPropylene and Ethylene Production from MethanolGlacier RamkissoonÎncă nu există evaluări

- G06 Aryclic ProductionDocument300 paginiG06 Aryclic ProductionJacky100% (1)

- Cumene To Phenol 2Document73 paginiCumene To Phenol 2vpsrpuch0% (1)

- Kuwait University Chemical Engineering Plant Design Hysys ReportDocument20 paginiKuwait University Chemical Engineering Plant Design Hysys ReportCrazy HelloÎncă nu există evaluări

- Production of PhenolDocument11 paginiProduction of PhenolJohn Raymart RaferÎncă nu există evaluări

- Ethylene Oxide Kinetics and MechanismDocument10 paginiEthylene Oxide Kinetics and MechanismjohnÎncă nu există evaluări

- Chemical Kinetics On Thermal Decompositions of CumeneDocument8 paginiChemical Kinetics On Thermal Decompositions of CumeneMario Alonso Velasquez FlorezÎncă nu există evaluări

- Wasteless Economic Method of Production of Phenol and AcetoneDocument14 paginiWasteless Economic Method of Production of Phenol and AcetoneSiswand BIn Mohd AliÎncă nu există evaluări

- Benzene Production Using Hydrodealkylation RouteDocument3 paginiBenzene Production Using Hydrodealkylation RouteCluisantony Jayco DizeÎncă nu există evaluări

- Production of PhenolDocument22 paginiProduction of PhenolShubhranshu Kathuria71% (7)

- Introduction to Acrylic Acid: Properties, Production, and UsesDocument262 paginiIntroduction to Acrylic Acid: Properties, Production, and Useslucas100% (6)

- Maleic Anhydride Production from ButaneDocument5 paginiMaleic Anhydride Production from ButaneMagdyÎncă nu există evaluări

- Ethyl Benzene ProductionDocument6 paginiEthyl Benzene ProductionsoheilsedÎncă nu există evaluări

- Production of Ethylene OxideDocument22 paginiProduction of Ethylene OxideShahabuddin Khan Niazi100% (1)

- Lecture 5 Acetic AcidDocument6 paginiLecture 5 Acetic AcidYan LaksanaÎncă nu există evaluări

- Production of Acrylic Acid from Propylene Plant DesignDocument280 paginiProduction of Acrylic Acid from Propylene Plant Designmuaad salah89% (9)

- Ethylene Oxide Production Process PDFDocument2 paginiEthylene Oxide Production Process PDFTim100% (2)

- Official Acrylic Acid 0712docxDocument42 paginiOfficial Acrylic Acid 0712docxTÚ Cao Ngọc ThiệnÎncă nu există evaluări

- Production of PhenolDocument67 paginiProduction of PhenolAhmed Ali100% (4)

- Production of Phenol and Bisphenol A ReportDocument47 paginiProduction of Phenol and Bisphenol A ReportvpsrpuchÎncă nu există evaluări

- Hda Process Flow Diagram PDFDocument2 paginiHda Process Flow Diagram PDFadnan mukhtar50% (2)

- Material Balances Design Problem - Acrylic Acid Production: Process StreamsDocument39 paginiMaterial Balances Design Problem - Acrylic Acid Production: Process StreamsmoheedÎncă nu există evaluări

- 5 6251216941030047774Document41 pagini5 6251216941030047774Salihah AbdullahÎncă nu există evaluări

- Acrylic Acid Final ReportDocument13 paginiAcrylic Acid Final ReportlynnÎncă nu există evaluări

- Ethylene 2520oxide Energy 2520 BalanceDocument9 paginiEthylene 2520oxide Energy 2520 BalanceDick El RinoceronteÎncă nu există evaluări

- Acrylic Acid - MohitDocument42 paginiAcrylic Acid - MohitvickuÎncă nu există evaluări

- Raschig-Phenol Process EditedDocument5 paginiRaschig-Phenol Process EditedEJa ChiCks50% (2)

- Chapter I - Introduction To CumeneDocument4 paginiChapter I - Introduction To CumeneQilah Kamarudin100% (1)

- ETHYLBENZENEDocument19 paginiETHYLBENZENEolaÎncă nu există evaluări

- Cumene ManufactringDocument74 paginiCumene ManufactringTan JieSheng100% (1)

- Conceptual Design of Water Separation Process in Glycerol-Based Acrylic Acid ProductionDocument9 paginiConceptual Design of Water Separation Process in Glycerol-Based Acrylic Acid Productiongg ogg100% (1)

- For Hysys UsersDocument5 paginiFor Hysys UsersZohaib RanaÎncă nu există evaluări

- Side ReactionsDocument22 paginiSide ReactionsAna Mariel VenturaÎncă nu există evaluări

- PRODUCTIONOFMALEICANHYDRIDEFROMOXIDATIONOFn BUTANE PDFDocument456 paginiPRODUCTIONOFMALEICANHYDRIDEFROMOXIDATIONOFn BUTANE PDFRitik Chaudhary100% (2)

- Hydrodealkylation SimulationDocument8 paginiHydrodealkylation SimulationSchaieraÎncă nu există evaluări

- Reactions: Phenol Production From CumeneDocument2 paginiReactions: Phenol Production From CumeneAhmed Hassan RashedÎncă nu există evaluări

- CT-308 Phenol Production-2023Document22 paginiCT-308 Phenol Production-2023Divyansh NagarÎncă nu există evaluări

- Petrochemical 2Document60 paginiPetrochemical 2AnilKumarÎncă nu există evaluări

- Production of CumeneDocument5 paginiProduction of CumeneMohit YaduwanshiÎncă nu există evaluări

- Unit 3Document29 paginiUnit 3ASHISH K.K.Încă nu există evaluări

- Chapter 9 - Manufacture of C3 CompoundDocument15 paginiChapter 9 - Manufacture of C3 CompoundMicrosoft GamingÎncă nu există evaluări

- Flow Diagram of Isopropyl AlcoholDocument2 paginiFlow Diagram of Isopropyl Alcoholshamsullah100% (1)

- Lecture 18: Isopropanol and Acetone From Propylene: Module 3: PetrochemicalsDocument2 paginiLecture 18: Isopropanol and Acetone From Propylene: Module 3: Petrochemicalsshamsullah hamdardÎncă nu există evaluări

- Pce2 Unit-II AromaticsDocument87 paginiPce2 Unit-II AromaticsMeghana SÎncă nu există evaluări

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresDe la EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresEvaluare: 5 din 5 stele5/5 (1)

- Assignment No 2Document1 paginăAssignment No 2aliÎncă nu există evaluări

- Circular Notification 242020Document1 paginăCircular Notification 242020aliÎncă nu există evaluări

- Assignment No 2Document1 paginăAssignment No 2aliÎncă nu există evaluări

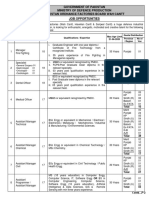

- Government of Pakistan Ministry of Defence Production Pakistan Ordnance Factories Board Wah Cantt Job OpportunitiesDocument5 paginiGovernment of Pakistan Ministry of Defence Production Pakistan Ordnance Factories Board Wah Cantt Job OpportunitiesMuhammad Luqman ArifÎncă nu există evaluări

- Personal info & resume of Hamza NisarDocument2 paginiPersonal info & resume of Hamza NisaraliÎncă nu există evaluări

- HKDSE Chemistry MC Chapter 11Document10 paginiHKDSE Chemistry MC Chapter 11ScribdÎncă nu există evaluări

- SDS Asam SulfatDocument8 paginiSDS Asam SulfatQuality AssuranceÎncă nu există evaluări

- Motorcycle: Type 1: Wet Cell BatteriesDocument12 paginiMotorcycle: Type 1: Wet Cell BatteriesMonish BudhaniÎncă nu există evaluări

- Full Download Consumer Behaviour 6th Edition Schiffman Solutions ManualDocument36 paginiFull Download Consumer Behaviour 6th Edition Schiffman Solutions Manualntunroulia100% (36)

- NP Coaxial Pulsed Corona DischargeDocument5 paginiNP Coaxial Pulsed Corona DischargeKin Wai CheahÎncă nu există evaluări

- Macgyver How-To HandbookDocument194 paginiMacgyver How-To HandbookmoisesramosÎncă nu există evaluări

- H2O2 vs. KIkinetics PracticalDocument3 paginiH2O2 vs. KIkinetics PracticalMehul KhimaniÎncă nu există evaluări

- Chapter-2 Acids, Bases & Salts NotesDocument10 paginiChapter-2 Acids, Bases & Salts NotesMohammed RamzanÎncă nu există evaluări

- Nozag Spindels Systemkatalog 2015 eDocument160 paginiNozag Spindels Systemkatalog 2015 eRuben PauwelsÎncă nu există evaluări

- Dew Point Od Acid GasDocument4 paginiDew Point Od Acid GassrshahÎncă nu există evaluări

- Methods For Chemical Analysis of Steels: Indian StandardDocument5 paginiMethods For Chemical Analysis of Steels: Indian StandardAryansh Rocky RanaÎncă nu există evaluări

- Current Developments in Esterification Reaction: A Review On Process and ParametersDocument23 paginiCurrent Developments in Esterification Reaction: A Review On Process and ParametersStanley YohanesÎncă nu există evaluări

- SNR Bearing Units - ThermoplasticDocument35 paginiSNR Bearing Units - ThermoplasticVolodymyrÎncă nu există evaluări

- BL NurBio Activity 7 - Proteins Precipitation (REVISED 6.25.20)Document8 paginiBL NurBio Activity 7 - Proteins Precipitation (REVISED 6.25.20)Niño PadacaÎncă nu există evaluări

- Ujian Kimia Bab 1 Tingkatan 5Document11 paginiUjian Kimia Bab 1 Tingkatan 5Rosemarzuna SallehÎncă nu există evaluări

- History of The Chemical Industry 1750 To 1930 - An OutlineDocument12 paginiHistory of The Chemical Industry 1750 To 1930 - An OutlineNia NurainiÎncă nu există evaluări

- GROUP 1 - CHE 026L LAS 9 - Chemical ReactionsDocument7 paginiGROUP 1 - CHE 026L LAS 9 - Chemical ReactionsShiena MosquedaÎncă nu există evaluări

- Astm D 2036-98 CianuroDocument20 paginiAstm D 2036-98 CianuroGianinaRoncalChávezÎncă nu există evaluări

- CH 3 Chemical Reaction Worksheet 1Document19 paginiCH 3 Chemical Reaction Worksheet 1Alia ShabbirÎncă nu există evaluări

- Ion Exchange Resins ExplainedDocument33 paginiIon Exchange Resins Explainednermeen ahmedÎncă nu există evaluări

- Chemical Analysis of Cuprous Oxide and Copper Pigments: Standard Test Methods ForDocument5 paginiChemical Analysis of Cuprous Oxide and Copper Pigments: Standard Test Methods ForLito EstimosÎncă nu există evaluări

- Qualitative Tests for Elements in Organic Compounds (QTEOCDocument10 paginiQualitative Tests for Elements in Organic Compounds (QTEOCRovic MelladoÎncă nu există evaluări

- 3 Step KlasonDocument7 pagini3 Step KlasonAshianti StennyÎncă nu există evaluări

- 3,4,5 Chapter Chemistry XyzDocument136 pagini3,4,5 Chapter Chemistry XyzizhanfilzaÎncă nu există evaluări

- FluxDocument9 paginiFluxking59Încă nu există evaluări

- MSDS SummaryDocument7 paginiMSDS SummaryHeru HarnadiÎncă nu există evaluări

- Acid N Salt RevisionDocument6 paginiAcid N Salt RevisionTennarasu PannirselvamÎncă nu există evaluări

- Pharmaceutical Fronts, 04 (02), E71-E77 (2022) - IsavuconazoliumDocument7 paginiPharmaceutical Fronts, 04 (02), E71-E77 (2022) - IsavuconazoliumSam SonÎncă nu există evaluări

- 4500-B Boron (Editorial Revisions, 2011)Document3 pagini4500-B Boron (Editorial Revisions, 2011)TaniaCarpioÎncă nu există evaluări

- Acids, Bases and SaltsDocument21 paginiAcids, Bases and Saltsdarth92vaderÎncă nu există evaluări