Documente Academic

Documente Profesional

Documente Cultură

Canatuan Mine

Încărcat de

Liza BalteraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Canatuan Mine

Încărcat de

Liza BalteraDrepturi de autor:

Formate disponibile

Canatuan mine

Location

- located in the province of Zamboanga del Norte, Philippines.

Mining History

- Gold panning activity in the Canatuan Creek area was first recorded in the mid

1980s.

- In 1990 prospectors discovered an extensive field of gold-bearing boulders and

the first test pit was sunk that year.

- By 1994, the area was being worked by nearly 1,500 small scale miners.

- In 1994 TVI Pacific reached an option agreement with the initial prospectors and

continued extensive exploration.

- In 1995 a pre-feasibility study was carried out, and in 1996 a two feasibility

studies were completed.

- In 2003 a new feasibility assessment was carried out, which recommended

further infill drilling to better define the deposit, and this drilling was carried out in

2004. Two more feasibility studies were carried out in 2004 and 2006.

- In April 2008 operations to mine and recover gold and silver from the oxide layer

were concluded, and the related ore processing facilities were being converted

to process the sulphide deposit.

- The sulphide deposit mining and processing achieved commercial operations on

March 1, 2009.

- In January 2010 TVI announced a joint venture with the Philippine-based

company DACON.

Ore Type

- gold, silver, copper and zinc.

Separation Process

- Canatuan sulphide open pit operation is designed such that the water from the

pit (acid mine drainage) flows to the lowest elevation and is impounded at the

tailings dam. This is unlike the typical open pit operations where a burrow will be

dug out from the mountain and mechanical dewatering systems are applied.

Annual Production

- Gossan phase gold and silver operation (now closed) from 2004 to 2008 TVIRD

operated an open pit mine, milling and processing operation producing gold and

silver doré from the Gossan ore deposit. Over that period the operation

produced in the order of 100,000 oz of gold (Au) and 1,700 oz of silver (Ag).

- Sulphide phase copper and zinc production capacity is 1,850 tonnes per day of

ore, with a request to increase this to 2,500 tonnes per day. Total material moved

has averaged 3,800 tonnes per day and will peak at 6,700 tonnes per day in

2012 . The operating fleet of the mine includes 54 haul trucks, 9 excavators, six

bulldozers, and four loaders.

Company Existing Social Environment and Rehabilitation Project

- The principal control activities related to the current operation are those of water

management (runoff and process water), and water monitoring tailings

management (permanent containment of the non-mineral material that is

physically separated from the ore in the process plant).

- TVIRD's annual activities include progressive rehabilitation with the primary focus

on slope stabilization and erosion control, revegetation and reforestation

activities including soil conditioning and sediment control.

Bibliography

- Irimia R, Gottschling M (2016) Taxonomic revision of Rochefortia Sw. (Ehretiaceae,

Boraginales). Biodiversity Data Journal 4: e7720. https://doi.org/10.3897/BDJ.4.e7720

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- THE MEDIUM SHAPES THE MESSAGEDocument56 paginiTHE MEDIUM SHAPES THE MESSAGELudovica MatildeÎncă nu există evaluări

- The Importance and Functions of ArtDocument3 paginiThe Importance and Functions of ArtMae BalteraÎncă nu există evaluări

- Food Labelling Regulation ExplainedDocument3 paginiFood Labelling Regulation ExplainedMae BalteraÎncă nu există evaluări

- Habawel V Court of Tax AppealsDocument1 paginăHabawel V Court of Tax AppealsPerry RubioÎncă nu există evaluări

- 21st Century Third World GeographyDocument3 pagini21st Century Third World GeographyMae Baltera0% (1)

- Test I. Multiple Choice. Encircle The Letter That Corresponds Your AnswerDocument6 paginiTest I. Multiple Choice. Encircle The Letter That Corresponds Your AnswerLiza BalteraÎncă nu există evaluări

- Semi Detailed Lesson Plan in Common Kitchen ToolsDocument3 paginiSemi Detailed Lesson Plan in Common Kitchen ToolsLiza Baltera78% (23)

- Special Power of AttorneyDocument1 paginăSpecial Power of AttorneyLiza BalteraÎncă nu există evaluări

- The SAMR Model: A Framework for Technology IntegrationDocument1 paginăThe SAMR Model: A Framework for Technology IntegrationMae BalteraÎncă nu există evaluări

- What Is Assessment of LearningDocument1 paginăWhat Is Assessment of LearningMae BalteraÎncă nu există evaluări

- School uniform exemption request letterDocument1 paginăSchool uniform exemption request letterLiza BalteraÎncă nu există evaluări

- Copernicus' Heliocentric TheoryDocument4 paginiCopernicus' Heliocentric TheoryLiza BalteraÎncă nu există evaluări

- English Filipino: MathematicsDocument3 paginiEnglish Filipino: MathematicsLiza BalteraÎncă nu există evaluări

- Student Learning OutcomesDocument1 paginăStudent Learning OutcomesMae BalteraÎncă nu există evaluări

- The Milky Way Galaxy and The Solar SystemDocument4 paginiThe Milky Way Galaxy and The Solar SystemMae Baltera50% (2)

- Unit With Deed of SaleDocument1 paginăUnit With Deed of SaleLiza BalteraÎncă nu există evaluări

- Test PaperDocument1 paginăTest PaperLiza BalteraÎncă nu există evaluări

- Group 3 10 Mahogany Research FINALDocument17 paginiGroup 3 10 Mahogany Research FINALMae BalteraÎncă nu există evaluări

- Interpersonal Communication ModelDocument2 paginiInterpersonal Communication ModelMae BalteraÎncă nu există evaluări

- Basic Napkin FoldingDocument2 paginiBasic Napkin FoldingLiza BalteraÎncă nu există evaluări

- Asian LiteratureDocument2 paginiAsian LiteratureMae BalteraÎncă nu există evaluări

- The Influence of the Japanese Garden on the Traits of Cavinti ResidentsDocument2 paginiThe Influence of the Japanese Garden on the Traits of Cavinti ResidentsLiza BalteraÎncă nu există evaluări

- Caterer Personnel Catering Is The Industry Responsible For Providing Beverages, Food, and OtherDocument6 paginiCaterer Personnel Catering Is The Industry Responsible For Providing Beverages, Food, and OtherMae BalteraÎncă nu există evaluări

- Organizing and Managing Food ServiceDocument2 paginiOrganizing and Managing Food ServiceMae BalteraÎncă nu există evaluări

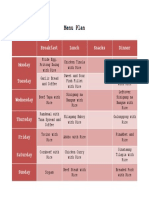

- Menu Plan: Breakfast Lunch Snacks Dinner Monday TuesdayDocument1 paginăMenu Plan: Breakfast Lunch Snacks Dinner Monday TuesdayLiza BalteraÎncă nu există evaluări

- Sell Used Car DeedDocument1 paginăSell Used Car Deedzatarra_12Încă nu există evaluări

- 78basic Napkins Folding: de Leon, Nina Mickela E. Btvted - FSM 2B Mrs. MalilayDocument1 pagină78basic Napkins Folding: de Leon, Nina Mickela E. Btvted - FSM 2B Mrs. MalilayLiza BalteraÎncă nu există evaluări

- Mica B. Yabut BSTM 1 Mr. Elijah AbadDocument4 paginiMica B. Yabut BSTM 1 Mr. Elijah AbadLiza BalteraÎncă nu există evaluări

- ACTION PLAN 20 Days 2019Document28 paginiACTION PLAN 20 Days 2019Liza BalteraÎncă nu există evaluări

- Amaezing Kitchen drinks and food menuDocument2 paginiAmaezing Kitchen drinks and food menuLiza BalteraÎncă nu există evaluări

- CHAPTER 6 Review QuestionsDocument4 paginiCHAPTER 6 Review QuestionsPelaez VincentÎncă nu există evaluări

- Assessment 1 Test QuestionnaireDocument2 paginiAssessment 1 Test QuestionnaireLiza BalteraÎncă nu există evaluări

- Danielle Smith: To Whom It May ConcernDocument2 paginiDanielle Smith: To Whom It May ConcernDanielle SmithÎncă nu există evaluări

- WebquestDocument3 paginiWebquestapi-501133650Încă nu există evaluări

- Aggregate Demand and Supply: A ReviewDocument36 paginiAggregate Demand and Supply: A ReviewYovan DharmawanÎncă nu există evaluări

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDocument10 paginiBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaÎncă nu există evaluări

- Yamaha Stagepas 300Document54 paginiYamaha Stagepas 300Ammar MataradzijaÎncă nu există evaluări

- Comparing environmental impacts of clay and asbestos roof tilesDocument17 paginiComparing environmental impacts of clay and asbestos roof tilesGraham LongÎncă nu există evaluări

- G.R. No. 122039 May 31, 2000 VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco Salva, RespondentsDocument56 paginiG.R. No. 122039 May 31, 2000 VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco Salva, RespondentsJayson AbabaÎncă nu există evaluări

- Computer Application in Business NOTES PDFDocument78 paginiComputer Application in Business NOTES PDFGhulam Sarwar SoomroÎncă nu există evaluări

- MongoDB vs RDBMS - A ComparisonDocument20 paginiMongoDB vs RDBMS - A ComparisonShashank GuptaÎncă nu există evaluări

- Computer Science Practical File WorkDocument34 paginiComputer Science Practical File WorkArshdeep SinghÎncă nu există evaluări

- Rochester MN Unified Development Code (Draft)Document442 paginiRochester MN Unified Development Code (Draft)randyÎncă nu există evaluări

- 2012 NAPTIN DocumentDocument48 pagini2012 NAPTIN DocumentbenaikodonÎncă nu există evaluări

- Dse Placement Report PDFDocument78 paginiDse Placement Report PDFAbhijithKríshñàÎncă nu există evaluări

- CIGB B164 Erosion InterneDocument163 paginiCIGB B164 Erosion InterneJonathan ColeÎncă nu există evaluări

- Transmission Line ProtectionDocument111 paginiTransmission Line ProtectioneccabadÎncă nu există evaluări

- Appendix 9A: Standard Specifications For Electrical DesignDocument5 paginiAppendix 9A: Standard Specifications For Electrical Designzaheer ahamedÎncă nu există evaluări

- Counsel For Plaintiff, Mark Shin: United States District Court Northern District of CaliforniaDocument21 paginiCounsel For Plaintiff, Mark Shin: United States District Court Northern District of CaliforniafleckaleckaÎncă nu există evaluări

- Solved Problems: EEE 241 Computer ProgrammingDocument11 paginiSolved Problems: EEE 241 Computer ProgrammingŞemsettin karakuşÎncă nu există evaluări

- Reason Document 0n Rev.3Document58 paginiReason Document 0n Rev.3d bhÎncă nu există evaluări

- E4PA OmronDocument8 paginiE4PA OmronCong NguyenÎncă nu există evaluări

- Readiness of Barangay Masalukot During TyphoonsDocument34 paginiReadiness of Barangay Masalukot During TyphoonsJerome AbrigoÎncă nu există evaluări

- Banaue Rice Terraces - The Eighth WonderDocument2 paginiBanaue Rice Terraces - The Eighth Wonderokloy sanchezÎncă nu există evaluări

- RIE 2013 Dumping and AD DutiesDocument21 paginiRIE 2013 Dumping and AD Dutiessm jahedÎncă nu există evaluări

- Analysis of Financial Ratios of Manufacturing CompaniesDocument61 paginiAnalysis of Financial Ratios of Manufacturing CompaniesNine ZetÎncă nu există evaluări

- BS en 12951-2004Document26 paginiBS en 12951-2004Mokhammad Fahmi IzdiharrudinÎncă nu există evaluări

- DPD 2Document1 paginăDPD 2api-338470076Încă nu există evaluări

- TVS Sport User Manual BS6Document69 paginiTVS Sport User Manual BS6tonemetoneÎncă nu există evaluări

- HOS Dials in The Driver App - Samsara SupportDocument3 paginiHOS Dials in The Driver App - Samsara SupportMaryÎncă nu există evaluări