Documente Academic

Documente Profesional

Documente Cultură

Arc Welding Rod Chart by

Încărcat de

tayyab ali0 evaluări0% au considerat acest document util (0 voturi)

395 vizualizări1 paginătable

Titlu original

table

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documenttable

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

395 vizualizări1 paginăArc Welding Rod Chart by

Încărcat de

tayyab alitable

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

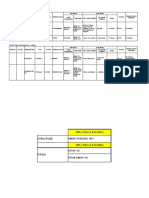

Arc Welding Rod Chart

by WcWelding.com

Type AWS Class Current Type Welding Position Weld Results

Mild Steel E6010 DCR F, V, OH, H Fast freeze, deep penetrating, flat

E6011 DCR, AC F, V, OH, H beads, all- purpose welding

E6012 DCS,AC F, V, OH, H Fill-freeze, low penetration, for poor

E6013 DCR,DCS,AC F, V, OH, H fit-up, good bead contour, minimum

E6014 DCS,AC F, V, OH, H spatter

E6020 DCR,DCS,AC F, H Fast-fill, high deposition, deep groove

E6024 DCR,DCS,AC F, H welds, single pass

E6027 DCR,DCS,AC F, H Iron powder, high deposition, deep

penetration

57014 DCR,DCS,AC F, V, OH, H Iron powder, low penetration, high

speed

E7024 DCR,DCS,AC F, H Iron powder, high deposition, single

and multiple pass

Low Hydrogen E6015 DCR F, V, OH, H Welding of high-sulphur and high-

E6016 DCR,AC F, V, OH, H carbon steels that tend to develop

E6018 DCR,AC F, V, OH, H porosity and crack under weld

E7016 DCR,AC F, V, OH, H deposit

E7018 DCR,AC F, V, OH, H

E7028 DCR,AC F, H

Stainless Steel E308-15,16 DC, AC F, V, OH, H Welding stainless steel 301, 302, 303

304, 308

E309-15,16 DC, AC F, V, OH, H Welding 309 alloy at elevated

temperature application and

dissimilar metals

E310-15,16 DC, AC F, V, OH, H Welding type 310 and 314 stainless

steel where high corrosion and

elevated temperatures are required

E316-15,16 DC, AC F, V, OH, H Welding type 316 stainless steel and

welds of highest quality. Contains less

carbon to minimize carbon transfer in

the weld. Type 316 reduces pitting

corrosion

E347-15,16 DC, AC F, V, OH, H For welding all grades of stainless

steels

Low Alloy E7011-A1 DCR, AC F, V, OH, H For welding carbon moly steels

E7020-A1 DCR, DCS, AC F

2

E8018-C3 DCR, AC F, V, OH, H For low alley, high-tensile strength

E10013-G DCS, AC F, V, OH, H For low alloy, high-tensile steels

DCR – Direct Current Reverse Polarity AC – Alternating Current

DCS – Direct Current Straight Polarity F – flat, V-vertical, OH – overhead, H-horizontal

S-ar putea să vă placă și

- ConsumableDocument8 paginiConsumablePeterWayÎncă nu există evaluări

- Stick Welding Rod ChartDocument1 paginăStick Welding Rod Chartshubhamgupta1384Încă nu există evaluări

- Designation & Selection of Welding ConsumablesDocument16 paginiDesignation & Selection of Welding ConsumablesAd Man GeTigÎncă nu există evaluări

- TLB Normenvergleich E 08092011 PDFDocument14 paginiTLB Normenvergleich E 08092011 PDFMuhammad Nur RizkiÎncă nu există evaluări

- TLB Normenvergleich E 08092011 PDFDocument14 paginiTLB Normenvergleich E 08092011 PDFlara_rajkumar667Încă nu există evaluări

- 3 - SELECTION OF WELDING ELECTRODES - StudentDocument15 pagini3 - SELECTION OF WELDING ELECTRODES - Studentrazlan ghazaliÎncă nu există evaluări

- Temp-Pro: Thermowell CatalogDocument26 paginiTemp-Pro: Thermowell CatalogSaeed VuÎncă nu există evaluări

- GearDocument1 paginăGearphong viÎncă nu există evaluări

- ATSB BrochureDocument4 paginiATSB BrochurePutroedidohÎncă nu există evaluări

- Piping Material CompositionDocument11 paginiPiping Material CompositionrezzdezzÎncă nu există evaluări

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 paginiCopper and Copper Alloys EN Standards For Copper AlloysAttef BedaweÎncă nu există evaluări

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 paginiCopper and Copper Alloys EN Standards For Copper AlloysLuis ReyesÎncă nu există evaluări

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 paginiCopper and Copper Alloys EN Standards For Copper AlloysNesanÎncă nu există evaluări

- Copper and Copper Alloys EN Standards For Copper AlloysDocument4 paginiCopper and Copper Alloys EN Standards For Copper AlloysAkshayBhatkandeÎncă nu există evaluări

- Electrode ClassificationDocument19 paginiElectrode ClassificationStarla HillÎncă nu există evaluări

- Welding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)Document52 paginiWelding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)cyÎncă nu există evaluări

- Cast Iron Flanged End Ball ValveDocument1 paginăCast Iron Flanged End Ball ValveTiến Nguyễn SongÎncă nu există evaluări

- Arc Welding Filler Metal Selection ChartDocument7 paginiArc Welding Filler Metal Selection Chartepriyono0% (1)

- Welding Fundamentals 3Document68 paginiWelding Fundamentals 3Saiprasad Thakar100% (1)

- EJ Handbook.A5Document261 paginiEJ Handbook.A5ElMacheteDelHuesoÎncă nu există evaluări

- C067Document49 paginiC067Gato Sesa0% (1)

- Taxonomy of MetalsDocument28 paginiTaxonomy of MetalsArlita RahmaÎncă nu există evaluări

- European Steel and Alloy Grades: X2Crnimon25-7-4 (1.4410)Document3 paginiEuropean Steel and Alloy Grades: X2Crnimon25-7-4 (1.4410)farshid KarpasandÎncă nu există evaluări

- 1 Valvula Globo Con Fuelle Didtek Acero Carbono PDFDocument1 pagină1 Valvula Globo Con Fuelle Didtek Acero Carbono PDFjoaquin torrano veraÎncă nu există evaluări

- X2CrNiMoN22-5-3 - 1 PDFDocument3 paginiX2CrNiMoN22-5-3 - 1 PDFAA86AAÎncă nu există evaluări

- C&K ET Series Sealed Subminiature Toggle Switches: Features/Benefits Typical ApplicationsDocument6 paginiC&K ET Series Sealed Subminiature Toggle Switches: Features/Benefits Typical ApplicationskędzierzawyÎncă nu există evaluări

- European Steel and Alloy GradesDocument2 paginiEuropean Steel and Alloy Gradesfarshid KarpasandÎncă nu există evaluări

- Gate ValvesDocument2 paginiGate ValvesArnold Ochochoque ArcosÎncă nu există evaluări

- HILCO Stick Electrodes at A GlanceDocument6 paginiHILCO Stick Electrodes at A Glanceziaee950Încă nu există evaluări

- SMAW InstructionDocument20 paginiSMAW InstructionSun Sun100% (1)

- Catalogue MetalweldDocument17 paginiCatalogue MetalweldRadivojevic SasaÎncă nu există evaluări

- Compatibility of Fasteners With Base MetalsDocument1 paginăCompatibility of Fasteners With Base MetalsmaniyarasanÎncă nu există evaluări

- LB-52 Lb-52u: Oh H Vu F Oh H VuDocument1 paginăLB-52 Lb-52u: Oh H Vu F Oh H VuMohd Farid OsmanÎncă nu există evaluări

- Technical Information: Material Properties (Nonferrous Metals)Document2 paginiTechnical Information: Material Properties (Nonferrous Metals)أبومحمدالزياتÎncă nu există evaluări

- Resistance Welding Coated Low Carbon SteelsDocument3 paginiResistance Welding Coated Low Carbon Steelsbressiani8416Încă nu există evaluări

- Ador - Welding RodDocument4 paginiAdor - Welding RodManoj DoshiÎncă nu există evaluări

- Fox - FFDocument1 paginăFox - FFGustavo NietoÎncă nu există evaluări

- C12200 PD Copper - Austral Wright Metals - AustraliaDocument3 paginiC12200 PD Copper - Austral Wright Metals - Australiamohsen_267Încă nu există evaluări

- Comparison Chart ElectrodeDocument2 paginiComparison Chart ElectrodeAsaad Mohamed67% (3)

- Material - (1 4462)Document2 paginiMaterial - (1 4462)Ashutosh PathakÎncă nu există evaluări

- EMS 003 Class B (HTHW) - Piping Materials Fabrication and Line ClassesDocument3 paginiEMS 003 Class B (HTHW) - Piping Materials Fabrication and Line ClassesclintÎncă nu există evaluări

- File 1557373151Document17 paginiFile 1557373151JOWAN PERKASAÎncă nu există evaluări

- Ficha Tecnica Anillos Oval RingDocument8 paginiFicha Tecnica Anillos Oval RingAndres AlfonsoÎncă nu există evaluări

- Shielded Metal Arc WeldingDocument78 paginiShielded Metal Arc Weldinghardish_trivedi700567% (3)

- Welding ProcessDocument9 paginiWelding ProcessrajuÎncă nu există evaluări

- BOQ For Pipe Fittings For Compressed Air PDFDocument1 paginăBOQ For Pipe Fittings For Compressed Air PDFsppatilÎncă nu există evaluări

- Catalog: Consumable Welding ProductsDocument76 paginiCatalog: Consumable Welding ProductsNicole S. TeodoroÎncă nu există evaluări

- Ceweld Catalogue 8-4-2016 enDocument48 paginiCeweld Catalogue 8-4-2016 enAzize AmrouneÎncă nu există evaluări

- 20090327134609-Meba Steel BrochureDocument4 pagini20090327134609-Meba Steel BrochurezhorvatovicÎncă nu există evaluări

- SCHNEIDER - 9-03 - DIN16270 - eDocument1 paginăSCHNEIDER - 9-03 - DIN16270 - eMohamed MusaÎncă nu există evaluări

- Trade Name AWS Class Polarity Description: Fleetweld 35Document4 paginiTrade Name AWS Class Polarity Description: Fleetweld 35Kathleen Joy BunedÎncă nu există evaluări

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20De la EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Încă nu există evaluări

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363De la EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Încă nu există evaluări

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDe la EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesDe la EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesEvaluare: 4.5 din 5 stele4.5/5 (7)

- Strength of Metals and Alloys: Proceedings of the 5th International Conference, Aachen, Federal Republic of Germany, August 27-31, 1979De la EverandStrength of Metals and Alloys: Proceedings of the 5th International Conference, Aachen, Federal Republic of Germany, August 27-31, 1979P. HaasenEvaluare: 5 din 5 stele5/5 (1)

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingDe la EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingÎncă nu există evaluări

- Expenses CalculatorDocument4 paginiExpenses Calculatortayyab aliÎncă nu există evaluări

- Api580 1Document5 paginiApi580 1RamyMoustafa100% (1)

- Business Expense BudgetDocument7 paginiBusiness Expense Budgettayyab aliÎncă nu există evaluări

- API 580 Exam 100 Q&ADocument23 paginiAPI 580 Exam 100 Q&Amajid100% (5)

- Risk Based Inspection Question Bank (B)Document5 paginiRisk Based Inspection Question Bank (B)tayyab aliÎncă nu există evaluări

- API 650 SummaryDocument176 paginiAPI 650 Summarytayyab ali100% (1)

- Api580 1Document5 paginiApi580 1RamyMoustafa100% (1)

- QUIZ - API 580-581 Risk Based Inspection PDFDocument13 paginiQUIZ - API 580-581 Risk Based Inspection PDFranjitpandey100% (4)

- Performance Requirements For Foot ProtectionDocument7 paginiPerformance Requirements For Foot Protectiontayyab aliÎncă nu există evaluări

- C 117 Â " 03 QZEXNW - PDFDocument4 paginiC 117 Â " 03 QZEXNW - PDFPercyMinchanÎncă nu există evaluări

- C 1383 - 98 - QzezodmDocument9 paginiC 1383 - 98 - QzezodmYasmin AminÎncă nu există evaluări

- ASTM-C-289-Potential Alcali-Silice Reactivity of Aggregates PDFDocument8 paginiASTM-C-289-Potential Alcali-Silice Reactivity of Aggregates PDFculicha23Încă nu există evaluări

- TWI Application Form - Rev 10Document3 paginiTWI Application Form - Rev 10tayyab aliÎncă nu există evaluări

- Foot Protection: Standard Test Methods ForDocument15 paginiFoot Protection: Standard Test Methods Fortayyab aliÎncă nu există evaluări

- CSWIP Question PaperDocument5 paginiCSWIP Question PaperAnonymous WMmxHiSKDÎncă nu există evaluări

- CSWIP Question PaperDocument5 paginiCSWIP Question PaperAnonymous WMmxHiSKDÎncă nu există evaluări

- 2 Welding InspectorDocument1 pagină2 Welding Inspectortayyab aliÎncă nu există evaluări

- 2 Welding InspectorDocument1 pagină2 Welding Inspectortayyab aliÎncă nu există evaluări

- Vision FormatDocument1 paginăVision Formattayyab aliÎncă nu există evaluări

- CSWIP Question PaperDocument5 paginiCSWIP Question PaperAnonymous WMmxHiSKDÎncă nu există evaluări

- 4 5839150597466490827Document16 pagini4 5839150597466490827tayyab aliÎncă nu există evaluări

- CSWIP Question PaperDocument5 paginiCSWIP Question PaperAnonymous WMmxHiSKDÎncă nu există evaluări

- Pak Rail TicketDocument1 paginăPak Rail Tickettayyab aliÎncă nu există evaluări

- 4 5839150597466490827Document16 pagini4 5839150597466490827tayyab aliÎncă nu există evaluări

- API 580 - Section 1 - 7 TermsDocument2 paginiAPI 580 - Section 1 - 7 TermsSERFORTEC CIA. LTDA.Încă nu există evaluări

- 116-C-0005 Naphtha Splitter 116-E-0027 Naphtha Splitter ReboilerDocument1 pagină116-C-0005 Naphtha Splitter 116-E-0027 Naphtha Splitter Reboilertayyab aliÎncă nu există evaluări

- API 580 QB (IT 30 Câu)Document8 paginiAPI 580 QB (IT 30 Câu)tayyab aliÎncă nu există evaluări

- API 580 QB (IT 30 Câu)Document8 paginiAPI 580 QB (IT 30 Câu)tayyab aliÎncă nu există evaluări

- API 580 - Section 1 - 7 TermsDocument2 paginiAPI 580 - Section 1 - 7 TermsSERFORTEC CIA. LTDA.Încă nu există evaluări

- API 580 (IT 15 Cau)Document5 paginiAPI 580 (IT 15 Cau)tayyab aliÎncă nu există evaluări

- Section 17 Weldability of SteelsDocument33 paginiSection 17 Weldability of Steelsmohammed dallyÎncă nu există evaluări

- ISO 3834 CertificateDocument1 paginăISO 3834 Certificatetarun3fauzdarÎncă nu există evaluări

- East SinghbhumDocument12 paginiEast SinghbhumadhunikmicaÎncă nu există evaluări

- Carbon Steel Fittings DimensionsDocument3 paginiCarbon Steel Fittings DimensionsgiorselÎncă nu există evaluări

- Max. Service Temp. Weld 500 550 550 600 600 600 600 700 700 750 900 Metal (°C)Document2 paginiMax. Service Temp. Weld 500 550 550 600 600 600 600 700 700 750 900 Metal (°C)Adriano Dorneles de OliveiraÎncă nu există evaluări

- Minutes of The 5th Meeting of The PMC Under The Chairmanship of Secretary HUADocument14 paginiMinutes of The 5th Meeting of The PMC Under The Chairmanship of Secretary HUARahul SrivastavaÎncă nu există evaluări

- Standard Specification For GB 700Document11 paginiStandard Specification For GB 700Huu Dong Ho100% (1)

- Structural SpecsDocument42 paginiStructural SpecsJosh Jaymes MasseÎncă nu există evaluări

- AISC Shapes Database Readme 14.1Document13 paginiAISC Shapes Database Readme 14.1HRCÎncă nu există evaluări

- WPQT ReceivingDocument3 paginiWPQT Receivingphilweld navotasÎncă nu există evaluări

- New Reference List of Our Supplies To Pallet PlantDocument4 paginiNew Reference List of Our Supplies To Pallet Plantdhawal gargÎncă nu există evaluări

- Color CodesDocument1 paginăColor CodesKatzlyn BayauaÎncă nu există evaluări

- Welding Procedure Specification (WPS) : Prequalified Qualified by Testing AWS D1.3 Sheet SteelDocument1 paginăWelding Procedure Specification (WPS) : Prequalified Qualified by Testing AWS D1.3 Sheet SteelaNKURÎncă nu există evaluări

- 05 Piping Classes List PDFDocument15 pagini05 Piping Classes List PDFShamsul Azhar MohdÎncă nu există evaluări

- Rr411802 Steel MakingDocument6 paginiRr411802 Steel MakingSRINIVASA RAO GANTAÎncă nu există evaluări

- CRSI Technical Note - Stainless Steel RebarDocument8 paginiCRSI Technical Note - Stainless Steel Rebaralum_91Încă nu există evaluări

- Defect IIWDocument3 paginiDefect IIWPPMÎncă nu există evaluări

- Temperature PN Barg Max Class Rating /: DEP Piping Class (Old)Document43 paginiTemperature PN Barg Max Class Rating /: DEP Piping Class (Old)Fatin Zulkifli100% (1)

- Macho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1Document2 paginiMacho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1emerson.mineiro100% (1)

- FreseDocument140 paginiFresea9r8f4g5d4s8r0% (1)

- Piping Wps (Asme Sec. Ix, Latest)Document4 paginiPiping Wps (Asme Sec. Ix, Latest)jaiyusryÎncă nu există evaluări

- S355 Low Carbon Manganese SteelDocument1 paginăS355 Low Carbon Manganese SteelCarlos LopezÎncă nu există evaluări

- Wires & Fluxes: W.E.F. 6 APRIL 2022Document16 paginiWires & Fluxes: W.E.F. 6 APRIL 2022Shivi ChaturvediÎncă nu există evaluări

- JSL Stainless Limited PDFDocument2 paginiJSL Stainless Limited PDFamartyaÎncă nu există evaluări

- Submerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelDocument17 paginiSubmerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelManish MÎncă nu există evaluări

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDocument1 paginăMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Încă nu există evaluări

- Steel Weight ChartDocument3 paginiSteel Weight ChartMark SupervilleÎncă nu există evaluări

- Section II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 5Document1 paginăSection II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 5洛霖Încă nu există evaluări

- Mid2 Objective PaperDocument2 paginiMid2 Objective PaperChilla DivyaÎncă nu există evaluări

- Resume Safwan Hanif Bin Shaiful HishamDocument1 paginăResume Safwan Hanif Bin Shaiful Hishamaccmic.accÎncă nu există evaluări