Documente Academic

Documente Profesional

Documente Cultură

Hazid Baclaran Depot

Încărcat de

SAMUEL POBREDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hazid Baclaran Depot

Încărcat de

SAMUEL POBREDrepturi de autor:

Formate disponibile

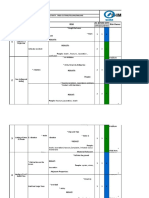

APA Group

VNIE 6-9 Project

Preliminary Construction HAZID Register

NOTES

VNIE 6-9 Project

Preliminary Construction HAZID Register

0 28/10/2015 Issued For Use GH DK RC SCALE DOCUMENT No. Rev

DRAWING No. DESCRIPTION REV DATE DESCRIPTION DRN CKD APP DATE

REFERENCE DRAWINGS REVISIONS

NTS VN69-RP-R-004 0

HAZID Attendees

Name Role Company

Derek Prentice Construction Manager APA

James McMahon Project Engineer APA

James Beckett Project Approvals Manager APA

Andrew Mills Project Land Coordinator APA

Darren Kay HSE Advisor APA

Gerard Harber HSE Advisor APA

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Planning Unclear - HSE Yes Possible Project Delay Minor (S) Possible Low APA is Principal Contractor Minor (S) Unlikely Negligible Yes Ensure CHATS are completed for all Darren Kay 30/10/2015 Open

expectations, lines of Possible legislative breach - CHAT completed for all Early Works Contractors Early Works Contractors, including but

authority & communication sanction APA HSE expectations communicated to contractors via not restricted to - Broadford Bead and

1 HSE requirements document and early Works HSE Blast, Riley Engineering, Qube,

Induction Newnham's, TCAC, Monarch, Cardno,

Lams, Infield Impact, ALS

Planning Lack of approved HSE Yes Possible Project Delay Major (H&S) Occasional High APA Construction HSE Management Plan Major (H&S) Rare Moderate Yes Work in Progress James McMahon 30/10/2015 Open

Management Increased potential for incident /

documentation injury - Possible serious injuries /

Prepare a HSE Coordination plan in James McMahon Open

potential fatality

circumstances where the APA

Possible legislative breach -

Construction HSE Management Plan is

sanction

not in force or not relevant

James Beckett Open

Main Construction Contractor CHSMP Hold - Main Construction Contractor to HOLD

provide project CHSMP when appointed

APA to advise contractors of environmental management Include any APA environmental James McMahon Open

requirements. For areas such as the NSW Pipe laydown expectations in the HSE Coordination

Area Plan and ensure that Early Works

Contractors address APA

James Beckett Open

Environmental requirements as part of

Environmental Procedures and or

SWMS

Main Construction Contractor CEMP Hold - Contractor to provide CEMP and HOLD

have it approved by APA (allow time for

review, and approval)

Approved APA Emergency Response Plans available for Prepare VNIE 6-9 ERP Bridging Plan James McMahon 6/11/2015 Open

all Brownfield Areas for use in all Brownfield areas and for

alignment when main Construction

Contractor is engaged

2 Contractor Emergency Response Plan / Procedures EW Contractors to submit ER Plan or James McMahon Prior Mobilisation Open

Procedure for review and approval by

APA.

Rescue Plans to be developed where

required prior to commencement of

activity - e.g. Confined Space Entry,

Working at Heights.

Prepare ER Contacts list for site and

vehicles

Conduct desktop emergency response James McMahon Prior Mobilisation Open

drill to test on-site and off-site response - Darren Kay

Exercises to be conducted on a risk

based approach - First scenario to be

conducted for NSW pipe laydown yard

Traffic Management Plan Prepare and submit Traffic James McMahon Prior Mobilisation Open

Management Plan Darren Kay

Benalla - Complete

Tallarook - Open

Bethungra - Open

SWMS to be provided by Contractor and sub Ensure that SWMS are provided with Darren Kay Prior Mobilisation Open

contractors. sufficient time to allow for review and

Contractor to review and approve sub-contractors approval prior to mobilisation, these can

SWMS or sub-contractors comply with Contractor be staged but must address upcoming

SWMS. scope.

APA to review and approve Contractor SWMS where Additional SWMS to be developed and

necessary. reviewed as required

Planning Lack of or inadequate Yes Possible ineffective or delayed Major (H&S) Occasional High Requirements included in Project Induction, HSE Major (H&S) Rare Moderate Yes Confirm if sufficient APA & or James McMahon Prior Mobilisation Open

Emergency / First Aid response causes escalation of Requirements Document and Project Emergency Contractor Occupational First Aiders are

Response consequences - Possible serious Response Bridging Plan to ensure available

injuries / potential fatality Sufficient numbers of personnel trained First Aiders

Potential Contractor Emergency Sufficient First Aid equipment / supplies held on site

Scenarios Identified: Emergency Contacts include external support numbers -

Vehicle incident - to or from site Hospitals etc

15/12/2015 Confidential Page 1 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Vehicle incident to or from site Hospitals etc.

Crush Injury - person struck by APA will provide equipment and James McMahon Prior Mobilisation Open

mobile plant supplies where the works is under

Fall injuries control of an APA PTW

3 Ensure the contractor has sufficient

Illness / Medical Emergency

Venomous animal Bite / Sting equipment and supplies where works

Heat Attack are NOT controlled by APA PTW

Cuts / Lacerations Confirm all contact numbers during drills James McMahon Prior Mobilisation Open

Strains Sprains and premobilisation checks Darren Kay

Burns

Broken bones

Planning Untrained personnel, Yes Increased potential for incident / Major (H&S) Occasional High Construction Industry Induction Card. Major (H&S) Rare Moderate Yes Confirm that all persons receive James McMahon Prior Mobilisation Open

inadequate knowledge, injury required inductions Darren Kay

skills and experience Potential fatality

Lack of induction training

Personnel do not hold

appropriate High Risk Work

Licences / Certificates / APA L1 L2 HSE Induction Ensure all persons complete APA L1 L2 James McMahon Prior Mobilisation Open

VOC as required. HSE Induction Darren Kay

APA Site Specific Induction Ensure all persons complete APA Site James McMahon Prior Mobilisation Open

Specific Induction Darren Kay

4 APA or Contractor Project Specific Induction Ensure all persons complete Contractor James McMahon Prior Mobilisation Open

project induction. Darren Kay

All personnel hold appropriate High Risk Construction Conduct a drill down audit on personnel Darren Kay During Mobilisation Open

Work Licences / certificates where required High Risk Work Licences and VOC

Contractor 1 - Open

Contractor 2 - Open

Contractor 3 - Open

Operators will be VoC'd VOC to be completed by Contractor James McMahon Ongoing Ongoing

VOC completed where required prior operator commencing.

* VOC to be provided by contractor or determined by Additional on-site VOC may be

APA based on site VOC or APA Transmission approval requested by APA.

of contractor

Planning PPE not available or worn Yes Increased risk of injury, possible Major (H&S) Occasional High Mandatory minimum PPE specified in Early Work Major (H&S) Rare Moderate Yes Discussion required around minimum All Ongoing Ongoing

impact head injury (potential for Induction: PPE Requirements for various SOW

person to be struck by mobile Hard Hat

plant not wearing HI Vis or struck Safety Glasses

by load; head body) Safety Footwear - ankle High lace up

5 Gloves to be carried on site at all times and used as for

all manual tasks

Long High Visibility shirt or vest 100% cotton

Long trousers 100% cotton

Other as required by SWMS or WI

Planning SIMOPS Yes SIMOPS cause site congestion Major (H&S) Occasional High Site demarcation as per Project Site Plan and PTW Major (H&S) Rare Moderate Yes Complete the VNIE 6 9 Permit to Work Janes McMahon Prior Mobilisation to Open

increased potential for incident / Management Plan Management Plan APA Brownfield

injury Liaison with APA Operations Areas

Construction Manager to liaise with Operations via pre-

start meeting and advise of Construction schedule which

may impact Operations

6

Conflict with Operations activities - Minor (S) Occasional Low Project schedule prepared and communicated to Minor (S) Unlikely Low TBC Nil N/A Ongoing

scheduled and unscheduled stakeholders

maintenance activities Construction Manager to liaise with Operations via pre-

Interruption to Construction start meeting and advise of Construction schedule which

Schedule - possible delays may impact Operations

Weekly look ahead provided

15/12/2015 Confidential Page 2 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

General HSE Fire Yes Fire, equipment damage - Medium (H&S) Occasional Moderate Fire prevention and control included in induction Medium (H&S) Unlikely Moderate Yes Conduct site fire hazard assessment for Darren Kay Hold

personal injury Fire response addressed in Emergency Response Plans main construction contract as part of

High standard of housekeeping maintained on site construction Hazid when contract is

Extinguisher on plant / equipment, offices, light vehicles awarded

Fuel and oil correctly stored and handled

All brownfield work controlled by PTW

8 Monitor days of high fire danger and total fire ban and

comply with requirements

Appropriate waste management procedures in place

Designated Smoking Areas / Rules implemented

General HSE Manual Handling Yes Personal injury - possible Medium (H&S) Occasional Moderate All personnel have received Manual Handling Awareness Medium (H&S) Unlikely Moderate Yes Nil N/A Ongoing

hospitalisation Training - induction

Mechanical lifting aids available and used

9 Manual Handling Controls included in SWMS as required

Pre-Starts / Toolbox

General HSE Heat - working in hot Yes Heat Induced Illness. Medium (H&S) Occasional Moderate All personnel have completed heat stress awareness Medium (H&S) Unlikely Moderate Yes Prepare and distribute Heat Stress Gerard Harber 13/11/2015 Open

conditions Personnel ill and requires training Awareness Toolbox

hospitalisation Heat Stress addressed at Pre-start - at the start of hot

weather and ongoing as required

Personnel and weather conditions monitored by

supervision

10

Sufficient water and ice available

Personnel have appropriate PPE wide brims for hard

hats, sunblock, long clothing,

Air conditioned facilities and plant

Trained First Aiders on site at all times

General HSE Slips Trip falls Yes Personal injury - possible Medium (H&S) Occasional Moderate High standards of housekeeping to be maintained in and Medium (H&S) Unlikely Moderate Yes Conduct Drill Down Audit or Site Darren Kay As per VNIE 69 Open

hospitalisation around the work area Inspection to confirm appropriate Audit Schedule

Only authorised persons to access site controls in SWMS and implemented on

Barricading / Bunting of trenches, holes, drop-off site

Plant Operating SWMS - includes facing machine and 3

points of contact when getting on off machines and no

11

jumping from machines

Float Loading Unloading SWMS - to include appropriate

controls

Truck loading Unloading SWMS - to include appropriate

controls

General HSE Inclement Weather - Yes Increased potential for incident / Medium (H&S) Occasional Moderate Site supervisor to monitor weather conditions and stop Medium (H&S) Rare Low Yes Nil N/A Ongoing

Personnel - Impact Injury - Slip Trip Fall injuries - work when conditions are likely to become unsafe

High Wind, Rain, Hail, Impact from windblown objects - High standards of housekeeping to be maintained on site

12 lightning, Person struck by falling tree

branches - Person struck by

lightning

General HSE Inclement Weather - Plant Yes Increased potential for collision Insignificant (F) Occasional Low Site supervisor to monitor weather conditions and stop Insignificant (F) Unlikely Negligible Yes Nil N/A Ongoing

& Equipment - Impact incident possible equipment work when conditions are likely to become unsafe

13 High Wind, Rain, Hail, damage Plant Operating SWMS

lightning,

General HSE Dust Yes Heavy dust clouds create poor Minor (H&S) Likely Moderate PPE - wearing AS safety glasses mandatory Minor (H&S) Possible Low Yes Ensure sufficient eyewash stations are James McMahon Prior Mobilisation Open

visibility and increased potential Eyewash station/s available available on site - portable for vehicles

14 for incident - Possible eye injury

General HSE Personnel impaired by Yes Increased risk of injury, possible Major (H&S) Occasional High APA & Contractor Drug & Alcohol Policy Major (H&S) Rare Moderate Yes Nil N/A Ongoing

alcohol / drugs fatality Test for cause and following incidents

Site supervisors to monitor the crew and take appropriate

action if a person is considered to be fatigued or impaired

15

by alcohol or drugs

15/12/2015 Confidential Page 3 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

General HSE Personnel fatigued or not fit Yes Increased risk of incident injury - Major (H&S) Occasional High Site supervisor to monitor crew Major (H&S) Rare Moderate Yes Review the APA VNIE 69 Fatigue James McMahon Prior Mobilisation Open

for duty possible fatality Max working hours 12 hrs Management Plan and implement

Truck drivers / contractors must comply with Heavy requirements as relevant to early works

Vehicle Fatigue Management Guidelines

16 Fatigue Risk Assessment to be completed prior to

commencement of main construction

Project Fatigue Management Plan

General HSE Uncontrolled Confined No Entrapment engulfment No confined Space Entry associate with Early Works Monitor early Works and ensure any James McMahon Ongoing Monitoring

Space Entry asphyxiation change to scope which includes

17 Personal injury - possible fatality potential entry to confined spaces is

addressed and risk assessed

General HSE Unauthorised Access / Yes Increased potential for incident / Significant (H&S) Possible High Traffic Management Plan, Fencing, Barricading, Signage, Significant (H&S) Rare Moderate Yes

Public Exposure to Project injury possible fatality Security on Machinery, Flashing Lights, public awareness

18 Areas / access planning / land owner consultation, include

public hazards in SWMS,

General HSE Unforeseen hazards Yes Increased potential for incident / Major (H&S) Occasional High Hazards or changed conditions trigger step back and Major (H&S) Rare Moderate Yes Communicate via management and Darren Kay Ongoing Ongoing

serious Injury possible fatality SWMS review if required. include in induction

All persons have the right & Responsibility to stop work

19 immediately in situations where there is any concerns

about changed conditions, unforeseen hazards and the

safety of the workplace.

Health & Poor hygiene practices / Yes Personnel illness / sickness Medium (H&S) Occasional Moderate Toilets and facilities provided and cleaned regularly at Medium (H&S) Unlikely Moderate Yes Confirm that portaloo etc. is available at James McMahon Prior Mobilisation Open

Hygiene unhygienic facilities Brownfield sites and portable facilities provided as Hot Tap location/s

required at Greenfield sites

Soap and paper towel available for hand washing soap

etc.

20 Designated smoking area established

Potable water provided

Appropriate waste management practices in place and

regular waste removal off-site

Driving to & Single or multiple vehicle Yes Vehicle Incident - Personal Injury / Major (H&S) Possible High All drivers licenced and Trained in 4WD Operation where Major (H&S) Occasional High Yes Complete traffic Risk Assessment/s for Darren Kay 13/11/2015 Open

from to site incident due to: fatality - Injury to livestock / required Risk Ranking public roads and complete and

(daily) Driver not competent, Poor wildlife APA Project Designated Drivers (Drivers licenced / remain high due implement VNIE 6 9 Travel

road conditions, Fatigue, Trained in 4WD Operation / Reviewed and Signed onto to the inability to Management Plan and Driving SWMS

Exceeding speed limit, Driving SWMS) control the

Complacency, Driver under Regular inspection and maintenance of vehicles - actions of other

the influence of alcohol or including Pre-Start Checks drivers on public

other drugs, Driving in Compliance with public driving rules roads

21 adverse weather Drivers Fit for Work

conditions, Driver distracted Travel and Journey Management Plan

(for example by mobile Traffic Risk Assessment and Management Plans

phone, loud radio, Compliance with APA Driving FRP

headphones/earphones Project Induction

used while driving), Actions APA Driver Induction (4WD Rollover Prevention / Lumley

of other driver, Sun Glare, Safe Drive)

Dust, Wildlife. Working in Severe Weather procedure - Road and

weather condition reports

Driving on ROW Single or multiple vehicle Yes Vehicle Incident - Personal Injury / Major (H&S) Possible High All drivers licenced and Trained in 4WD Operation where Major (H&S) Rare Moderate Yes Complete traffic Risk Assessment/s for Darren Kay 14/11/2015 Open

or ROW Access incident due to: fatality - Injury to livestock / required RoW and RoW Access Tracks and

Tracks Driver not competent, Poor wildlife APA Project Designated Drivers (Drivers licenced / complete and install signage and

road conditions, Fatigue, Trained in 4WD Operation / Reviewed and Signed onto complete actions arising as required

Exceeding speed limit, Driving SWMS)

Complacency, Driver under Regular inspection and maintenance of vehicles -

the influence of alcohol or including Pre-Start Checks

other drugs, Driving in Compliance with RoW project driving rules

adverse weather Project signage on access tracks and Row

conditions, Driver distracted Project communication protocols

22 (for example by mobile Drivers Fit for Work

phone, loud radio, Travel and Journey Management Plan

headphones/earphones Compliance with APA Driving FRP

used while driving), Actions Project Induction

of other driver, Sun Glare, APA Driver Induction (4WD Rollover Prevention / Lumley

Dust, Wildlife. Safe Drive)

Working in Severe Weather procedure - Road and

weather condition reports

No public access to RoW and limited access to RoW

Access Tracks

15/12/2015 Confidential Page 4 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Mobilisation - Absent or inadequate Plant Hold Possible equipment roll over off All personnel hold appropriate High risk Work Licences / TBC HOLD and assess as part of main Darren Kay Hold

Loading / / Equipment Loading float - unexpected / uncontrolled certificates - to be available on site construction Hazid

Unloading Plant Unloading SWMS movement of float - person struck VOC completed where required

and Equipment by plant / equipment / float Plant / Equipment Loading / Unloading SWMS ( Where possible site set up to include

possible serious impact crush Contractor or Sub-Contractor) hold point for deliveries

injury potential fatality Spotter engaged as required Site layout addresses this requirement

23

Exclusion zones to be established

Extendable floats available and used as required

All subcontractors comply with all control measures -

PPE, Fitness for Work, Equipment and Training and

Competency requirements etc.

Operation of Unidentified overhead Yes Possible electrocution - fatality Major (H&S) Possible High Work Method Statement refers to no go zones, and Major (H&S) Rare Moderate No Conduct an overhead services survey Darren Kay Prior mobilisation of Ongoing

mobile plant power lines, plant and spotters. Signage, catenary flags installed prior, power and identify and record the type and early works

equipment in equipment or loads are company pre notified, awareness from site induction, location of overhead services that contractors and

proximity to within the limits of approach change equipment to suit conditions, SWMS interface with project activity. ongoing

24 overhead power or make contact with Communicate this information to all

lines overhead power lines relevant personnel APA and Contract

and ensure that appropriate controls are

implemented

Receipt and Absent or ineffective Yes Fall from heights Medium (H&S) Occasional Moderate Persons not permitted to access backs of trucks / loads Medium (H&S) Unlikely Moderate Yes Confirm that EW Contractor Procedures Darren Kay Prior mobilisation of Ongoing

dispatch of unloading / loading Potential hospitalisation without appropriate risk assessment / controls and SWMS are appropriate early works

general goods procedures - Persons All work at height in accordance with Contractor WAH contractors and

to and from site accessing backs of trucks / Procedure and SWMS Discuss SLAPs for loading and ongoing

25 loads Loading Unloading conducted in accordance with unloading during main construction

Persons working at heights, Contractor Procedure / SWMS

Persons struck by unstable

loads

Incorrect Absent or incorrect Yes Fire, spill, soil contamination, skin Medium (E) Possible Moderate Procedure for handling bulk fuels, Licensed fuel tanker, Minor (E) Unlikely Low Yes Nil N/A Monitoring

transport, procedures irritation burns, explosion MSDSs on site, spill kits, drip tray, extinguishers provided

handling, Untrained personnel with all mobile plant and equipment including stationary

26 storage and Incorrect plant / equipment generators, Emergency Response Procedures, SWMS

delivery of bulk for refuelling

fuels / chemicals

Linepipe Absent or ineffective Yes Person struck or impacted by Major (H&S) Possible High Approved Contractor Line Pipe Handling and Transport Major (H&S) Rare Moderate Yes Review Lessons Learnt from previous Darren Kay 20/11/2015 Open

Handling and unloading / loading uncontrolled load dropped pipe - Procedures pipe drop incidents and ensure root

Transport procedures - Persons impact or crush injury - Potential Approved Load Restraint causes or contributing factors are

accessing backs of trucks / for disabling injury / Fatality Approved Lifting and Linepipe Stockpiling Procedures addressed

loads Exclusion zones established and maintained Conduct Process Observations and or

27

Persons working at heights, Trained and Competent personnel engaged Drill Down Audits to confirm that

Persons struck by unstable All Plant and Equipment Risk Assessed - Certified where controls are implemented and effective

loads, Persons under required - Inspected and Maintained

suspended load

Linepipe Pipe truck accident Yes Undetected damage to pipe, loss Medium (S) Possible Moderate Contractor quality control procedures, APA quality control Medium (S) Unlikely Moderate Yes Nil N/A

Handling and resulting in damage to pipe of integrity pipe used in procedures, Pipes would be checked and possibly

Transport causing integrity issues construction, resulting in stuck pig, quarantined following any incident with potential to

later in operation of pipe failure during hydrotest damage pipe, Pipe is checked prior to laying, Compliance

pipelines with API Code for Pipe Haulage included in the contract

28

and scope of works, Geometric tool through pipelines

prior to commissioning, Coating survey completed,

Emergency pipe available

Linepipe Pipe/Pipes fall from load Yes Damage to equipment - Injury to Major (H&S) Possible High Approved Linepipe loading and restraint procedure Major (H&S) Rare Moderate Yes Conduct Process Observations and or Darren Kay 20/11/2015 Open

Handling and during transport on public member of public possible fatality compliant with API Code for Pipe Haulage included in the Drill Down Audits to confirm that

Transport roads or travel on ROW, contract and scope of work controls are implemented and effective

29 ROW Access Tracks SWMS, Contractor Supervision ensures ( Checking, load

(especially in steep / difficult security, driver compliance with Heavy Vehicle FM

terrain) Guidelines, ground and weather conditions)

Survey - Uneven ground, use of Yes Personnel injured - slip trip fall - Minor (H&S) Occasional Low As per Contractor SWMS Minor (H&S) Possible Low Yes Conduct Process Observations and or Darren Kay 21/11/2015 Open

Pegging - hand tools, poor manual Impact / crush from hammer - Drill Down Audits to confirm that

Fencing - Soil handling techniques strain sprain possible medical controls are implemented and effective

30 testing treatment

15/12/2015 Confidential Page 5 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Survey - Interaction between mobile Yes Refer Item 49

Pegging - plant and equipment and

Fencing - Soil survey crew

31 Testing

Survey - Snakes and aggressive Yes Person suffers snake bite or is Major (H&S) Possible High Induction to all site/field personnel, first aid procedures, Major (H&S) Rare Moderate TBC Ensure that a HELM Risk Assessment James Beckett 21/11/2015 Open

Pegging - livestock (bulls stallions) attacked by aggressive landowner clearing on ROW, mandatory minimum clothing PPE is completed and that areas of concern

Fencing - Soil or livestock - Serious injury or requirements, first aid kits and compression bandages on are communicated to all relevant

32 Testing potential fatality location, trained first aiders, communication and access personnel

to medical aid, Emergency Response Plan

Survey - Posting / boring over Yes Damage to services and impact Major (H&S) Possible High Dial Before You Dig completed for all excavation work, Major (H&S) Rare Moderate Yes Nil N/A

Pegging - unidentified existing on existing gas pipelines - Existing services positively identified and marked on

Fencing - Soil services Coating Damage dent or alignment sheets or in work packs, Spotters engaged,

Testing deformation of pipe possible SWMS, APA Permit to Work Procedure where required

curtailment of supply and financial

impact

Contact with buried electrical

33 service - Electric shock /

Electrocution - possible fatality,

Contact with buried

communications cable -

Disruption to public

communication and financial

impact

Clear and Grade Noise and Dust Hold Personnel exposed to excessive PPE, Water trucks deployed for dust suppression, HOLD and assess as part of main N/A

noise and dust - hearing and SWMS construction Hazid

34 respiratory damage

Clear and Grade Interfacing dozer / grader Hold Vehicle Incident - Personal Injury / Traffic Management Plan, driver training, signage HOLD and assess as part of main N/A

with crossing traffic fatality construction Hazid

35

Clear and Grade Poor visibility conditions, Hold Potential for person to be struck All personnel to wear Hi-Vis Clothing, SWMS to include HOLD and assess as part of main N/A

person enters machine by dozer exclusion zone and communication protocols, personnel construction Hazid

blind spot, ground to have radios where required

36

personnel unsighted by

operator

Excavation and Unidentified buried Yes Damage to services and impact Major (H&S) Possible High Dial Before You Dig completed for all excavation work, Major (H&S) Rare Moderate Yes Nil N/A

Trenching services, plant and on existing gas pipelines - Existing services positively identified and marked on

equipment contact buried Coating Damage dent or alignment sheets or in work packs, Spotters engaged,

service deformation of pipe possible SWMS, APA Permit to Work Procedure where required,

curtailment of supply and financial Non-Destructive Excavation Techniques, Liaison with

impact landowners and line list

Contact with buried electrical

service - Electric shock /

37 Electrocution - possible fatality

Contact with buried

communications cable -

Disruption to public

communication and financial

impact

Damage to existing stock

crossing - landowner complaint

15/12/2015 Confidential Page 6 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Excavation and Open unprotected or Yes Trench collapse Mobile plant and Major (H&S) Possible High Placement of machinery out of the zone of influence, Major (H&S) Rare Moderate Yes Implement a schedule of periodic James McMahon As required Ongoing

Trenching unstable trench equipment roll or tip into trench - Machine SWMS, barricading installed around trenches inspections of any excavations left open

Light vehicle drives into open with lights for excavations near public roads, escape - especially after rain.

trench - Person engulfed by ramps

trench collapse Potential serious No persons need to enter excavations > 1.5m Conduct Process Observations and or

life threatening injuries - fatality All excavations subject to DBYD and APA PTW and Drill Down Audits to confirm that

Trapped fauna Excavation Permits controls are implemented and effective

Excavations greater than 1.5m - or where ground

38 conditions require- where personnel are required to enter

excavation, bench/batter/shored as required

Barricading installed around open trenches / excavations,

and left in safe condition overnight

Task specific SWMS developed

Toothless buckets on excavators working in vicinity of

underground utilities/services

Trained and Competent operators engaged and VOC

HDD / Thrust Unidentified buried Hold Damage to services and impact Dial Before You Dig completed for all excavation work, HOLD and assess as part of main N/A

Bores services, plant and on existing gas pipelines Existing services identified and marked on alignment construction Hazid

equipment contact buried Electrocution - possible fatality, sheets, Spotters engaged, APA Permit to Work

service Disruption to public Procedure, SWMS

39 communication,

Dent or deformation of pipe

possible ignited release of gas

HDD / Thrust Burst hydraulic hose Hold Environmental damage - spill to All equipment correctly rated and inspected prior to use, HOLD and assess as part of main N/A

40 Bores Loss of containment of ground - spill to water Approved Procedure and SWMS construction Hazid

drilling mud

HDD / Thrust Person enters open Hold Fall from heights, person caught No person to enter excavations greater than 1.5m HOLD and assess as part of main N/A

Bores unprotected or unstable in rotating parts - Engulfment / without correct benching, battering, shoring construction Hazid

trench Entrapment - Potential fatality Approved SWMS for HDD include exclusion zone and

Uncontrolled work at height controls for WAH and Work in Confined Space

41 Unguarded rotating parts Trained and competent personnel

Plant Hazard Assessment completed for all plant and all

guarding in place

Safe access / egress provided from excavation

Welding Contact with live electrical Yes Personal injury - possible PPE, Equipment check, tagging of electrical leads, HOLD and assess as part of main

components, burns, welding hospitalisation / fatality supporting leads, ELCB, welding screens in built up construction Hazid

42 flash from welding areas, Work Method Statement, SWMS

Welding Welding in residential / Yes Personal injury - possible Welding barriers, tents, warning signs: welding in HOLD and assess as part of main

industrial areas causing hospitalisation / LTI progress, SWMS, Prestart meeting, Work Method construction Hazid

43 flash and other injuries in Statement, competent operators,

public

Welding - Fitting Absent or failed procedures Yes Personal injury - possible All controls as per general Cranage HOLD and assess as part of main

external pipe Untrained personnel hospitalisation / LTI Mechanical lifting aids construction Hazid

clamp in bell Equipment / fittings SWMS

44 holes unserviceable or incorrectly Competent personnel

rated

Tie-in Welds Unstable excavation Yes HOLD HOLD and assess as part of main

Lack of adequate access / construction Hazid

45

egress

Potential gaseous

Hot Tap Incorrect hot tapping Yes Loss of containment ignited Major (H&S) Possible High Risk Assessment - Hot Tapping HAZID to be conducted Major (H&S) Rare Moderate Yes Nil N/A

procedure / or procedures release of high pressure gas - and all actions closed via readiness review

not followed H&S Person/s impacted by Approved Hot Tapping Procedure and ITP

Equipment fittings release of high pressure gas or Qualified Welding Procedures and Personnel

unserviceable or incorrectly unrestrained objects under Liaison with APA PCC, AEMO, CFA, MFB

rated pressure - Nitrogen introduced APA Permit to Work

46 Untrained or incompetent into persons breathing zone - Competent contractors engaged

personnel engaged Serious disabling injury possible Refer to controls for lifting over live assets

Hot Tapping equipment fatality Nitrogen Awareness to be addressed in Induction

dropped on live line Nitrogen vents to be bleed away from areas where a

persons breathing zone can be impacted

15/12/2015 Confidential Page 7 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Access to Poorly defined worksite Yes Possible excessive load on buried Minor (F) Occasional Low Access to site as per APA PTW Minor (S) Unlikely Low Yes Steel road plates to be installed where James McMahon As required Ongoing

brownfield sites Unauthorised site access service - possible damage dent or Traffic Management Plan required

deformation of pipework - supply All buried services have been positively identified

interruption Load carrying capacity of buried services calculated and

Possible contact with above all axel loads know for mobile plant

ground facilities -supply Entire work area is Brownfield and demarcated with

47 interruption barricading to above ground pipework as required

Access restriction for project Authorised plant only enters designated areas

activities

Introduction of ignition source into

Hazardous Area - possible fire /

explosion

Plant & Defective / poorly Yes Mechanical failure - equipment Insignificant (E) Occasional Low All equipment to be fit for purpose, maintained in Insignificant (E) Unlikely Negligible Yes Plant to be inspected prior to N/A

Equipment maintained plant and damage, environmental damage - accordance with OEM requirements, subject to Plant commencement on site

Preparation equipment spill / leaks Hazard Assessment prior to arrival on site and subject to Contractor to provide Plant Risk

ongoing daily Pre-start checks. Assessments and service record,

registration details (if required) upon

Spill kits to be available on site. mobilisation

48

Mechanical failure - equipment Medium (H&S) Occasional Moderate All equipment to be fit for purpose, maintained in Medium (H&S) Unlikely Moderate Yes Include information on machine blind James McMahon Prior Open

damage, possible injury to accordance with OEM requirements, subject to Plant spots as part of Induction or Pre-start commencement

personnel Hazard Assessment prior to arrival on site and subject to

ongoing daily Pre-start checks.

Operation of Mobile Plant and equipment Yes Persons / vehicles in work zone, Major (H&S) Possible High All Brownfield activities conducted under APA PTW Major (H&S) Rare Moderate Yes Conduct Process Observations and or James McMahon As required Open

Plant & operating in close proximity potential impact from operating Personnel to wear Hi Vis Clothing Drill Down Audits to confirm that

Equipment to personnel plant, moving loads, falling Trained and competent operator/s engaged controls are implemented and effective

objects Essential personnel only on-site

Collision with pedestrians or site Spotter used as required

vehicles Hazards associated with Plant & Equipment movements

addressed at Induction and pre-start

Effective Communications established on site (hardware

and procedures) handheld radios for pedestrians

No mobile phones in brownfield areas - as per PTW

Mobile Plant approach / passing protocols established -

exclusion zones established and implemented where

required

Separation of light vehicles and pedestrians from mobile

plant via Traffic Management Plan where required

Site layout plan prepared and approved where required

49

Traffic Management Plan addresses: access points -

hold points - Light vehicle, Heavy vehicle and pedestrian

separation - Office, Crib and amenities layout, light

vehicle parking, laydown area, refuelling area, traffic

control for interaction with local public roads potentially

affected by project activities. (as per previous action)

All light vehicles, mobile plant and equipment operated

on site shall be fitted with reversing alarms and flashing

lights and on when on-site

Awareness provided via Induction and Pre-starts

Rotating beacon / reversing beepers fitted

Earthworks Personnel in close proximity Yes Slip Trip Fall to depth Medium (H&S) Occasional Moderate No persons need to enter excavations > 1.5m Medium (H&S) Unlikely Moderate TBC

Trenching / to operating plant - Person struck by mobile plant All excavations subject to DBYD and APA PTW and

Excavations authorised / unauthorised Personal injury - possible LTI Excavation Permits

Failure to locate Excavations greater than 1.5m - or where ground

underground services conditions require- where personnel are required to enter

Open excavations excavation, bench/batter/shored as required

Trench collapse Barricading installed around open trenches / excavations,

50 Snakes trapped in trench and left in safe condition overnight

Task specific SWMS developed

Toothless buckets on excavators working in vicinity of

underground utilities/services

Trained and Competent operators engaged and VOC

15/12/2015 Confidential Page 8 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Compaction in Vibration in close proximity HOLD Monitor early Works and ensure any James McMahon Ongoing Monitoring

brownfield areas to pipeline exceed design change to scope which includes

PP velocity - coating potential entry to confined spaces is

damage addressed and risk assessed

51

Vibration affects

compressor/s - Unit trip on

vibration

Import Export Introduction of Yes Personal injury - possible Medium (H&S) Occasional Moderate All imported material to be certified as clean and weed Medium (H&S) Unlikely Low Yes Nil N/A

soil contaminated soil hospitalisation and seed free

Incorrect disposal of All material taken off-site to be disposed of at an agreed

52

excavated material disposal facility

Underground Manual Handling Yes Personal injury - Slip/Trip/Fall - Barricading and signage installed along open HOLD and assess as part of main

installation of Open excavations Strain / Sprain excavations or surrounding trenching area construction Hazid

conduit and Uneven surfaces Chemical exposure Mandatory PPE requirements.

cabling / Trench spoil Correct manual handling technique, mechanical aid, and

53 earthing Uncontrolled use of team lifts etc.

systems etc. solvents / glues Task specific SWMS

All Chemicals handled and applied in accordance with

MSDS

Formwork & Uneven surfaces Yes Personal injury, sprains, cuts, Medium (H&S) Occasional Moderate Trained and experienced crew engaged Medium (H&S) Unlikely Moderate Yes Nil N/A

Concreting Exposed Reo bar etc. struck by moving plant Mandatory PPE requirements and as per SWMS MSDS

Manual Handling Slips Trips Falls rubber steel capped boots/gloves during pour etc.

Incorrect use of or defective Concrete burns Communication with other trades and barricading where

hand / power tools required

Personnel in close proximity High standard of housekeeping maintained

to Agi Truck movements Correct manual handling technique, mechanical aid, and

Chemical exposure to team lifts etc.

54 concrete and products Task specific SWMS

Other trades Spotter engaged as required (no person to stand behind

reversing vehicle)

Hold down bolts, exposed reo to be capped and

monitored

Agi truck fitted with reversing alarm / flashing beacon and

spotter

No Agi washout on site

Electrical Works completed by un Yes Personal injury - possible electric Major (H&S) Occasional High All work on the installation, repair, alteration or removal of Major (H&S) Rare Moderate Yes Validate electrical licence and certificate Darren Kay As required Monitoring

Installation and qualified person or not in shock / electrocution - potential an electrical circuit, associated fittings, equipment, of compliance, where required, for all

use of electrical compliance with relevant fatality accessories and infrastructure shall only be completed by electrical work

power tools standard persons holding an Electrical Licence or permit of the

relevant class and in accordance with AS/NZS

3000:2007 Electrical installations, and AS/NZS

3012:2010 Electrical installations - Construction and

demolition sites and other relevant standards. Similarly

all work requiring isolation of electrical supply must be

55 completed in accordance with the APA Isolation LOTO

procedure.

All electrical equipment and hand tools purchased, hired

or introduced to the project must comply with the

requirements of the relevant Australian Standard and be

tested and tagged in accordance with AS/NZS

3760:2010 In-service safety inspection and testing of

electrical equipment.

General Untrained / unqualified Uncontrolled load - Dropped or Significant (H&S) Occasional High Only qualified Crane drivers to drive cranes and qualified Significant (H&S) Unlikely Moderate Yes Nil N/A

Cranage and persons engaged operator / falling objects - person struck by riggers to select and apply rigging and direct crane driver

rigging rigger / dogman load All plant to be inspected on daily basis and records kept

Prestart inspection not Damage to the machine, damage in site office

carried out to other plant equipment. Maintenance to be carried out in accordance with

Defective poorly maintained manufactures guidelines

or incorrectly rated plant / Task specific SWMS and lift plans as required

56 equipment Rigging register established and maintained

Poorly maintained or Exclusion zones established as required

underrated rigging gear Tag lines used as req'd

Uncontrolled loads Compliance with APA Fatal Risk Protocols and APA

Lifting Protocol

15/12/2015 Confidential Page 9 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Lifting over live Untrained / unqualified Yes Uncontrolled load - contact with

assets persons engaged crane live assets

operator / rigger / dogman Dropped or falling objects -

Prestart inspection not contact with live assets

carried out

Incorrect crane set up Contact with station pipework - Significant (F) Possible High Only qualified crane drivers to operate crane and Significant (F) Rare Moderate Yes Nil N/A

Defective poorly maintained dent, gouge or deformation of advanced riggers to select and apply rigging and direct

or incorrectly rated plant / pipework no loss of containment crane driver

equipment Financial impact on operations - Crane to be correctly certified and inspected on daily

Poorly maintained or Significant, Project Delay 1 week - basis and records kept in site office

underrated rigging gear 1 month Minor Crane maintenance to be carried out in accordance with

Uncontrolled loads manufactures guidelines

Unprotected assets - above All rigging equipment to have current certification, and

ground pipeline, small bore Contact with station pipework - Major (H&S) Possible High inspected prior to use Major (H&S) Rare Moderate Yes Nil N/A

pipework, instruments and dent, gouge or deformation of Rigging register established and maintained

instrument lines, electrical pipework - loss of containment Task specific SWMS which includes SWMS review for

cabling, structures etc... unignited release of high pressure management of change and requirement to protect live

gas - H&S Person/s impacted by assets

release of high pressure gas or Exclusion zones established as required

unrestrained objects under All lifting over / near live assets under APA permits

pressure - Serious disabling injury Compliance with APA Fatal Risk Protocols and APA

possible fatality - Major Lifting Protocol

Contact with station pipework - Catastrophic Possible High Catastrophic (H&S) Rare High Yes Nil N/A

dent, gouge or deformation of (H&S)

pipework - loss of containment

ignited release of high pressure

gas - H&S Person/s impacted by

ignited release of high pressure

gas - Serious disabling injury

Fatality - Possible Multiple

Fatalities - Catastrophic

57

Contact with small bore pipework, Major (H&S) Occasional High Major (H&S) Rare Moderate Yes Nil N/A

small valves, instruments /

instrument lines - dent, gouge

deformation with failure of

pipework or fitting - loss of

containment unignited release of

high pressure gas - H&S Person/s

impacted by release of high

pressure gas or unrestrained

objects under pressure - Serious

disabling injury possible fatality -

Major

Contact with small bore pipework, Catastrophic Possible High Catastrophic (H&S) Rare High Yes Nil N/A

small valves, instruments / (H&S)

instrument lines - dent, gouge

deformation with failure of

pipework or fitting - loss of

containment ignited release of

high pressure gas - H&S Person/s

impacted by ignited release of

high pressure gas - Serious

disabling injury Fatality - Possible

Multiple Fatalities - Catastrophic

Contact with live electrical HOLD and assess as part of main

components in brownfield - construction Hazid

damage to electrical component -

H&S person in contact with

electrical supply - electric shock

possible electrocution - fatality -

Major

15/12/2015 Confidential Page 10 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

Installation of Inexperienced / unqualified Yes Person struck or impacted by Trained and competent personnel engaged HOLD and assess as part of main

structural persons engaged uncontrolled load - impact or Only qualified crane drivers to operate cranes and construction Hazid

steel/skids Incorrect procedures used crush injury - Potential for qualified riggers to select and apply rigging and direct

or procedures not followed disabling injury crane driver

Defective, Incorrect or un- Operational pipework / All plant to be inspected on daily basis and records kept

calibrated tools used instruments struck by uncontrolled in site office

uncontrolled loads load - dent or deformation of Maintenance to be carried out in accordance with

pipework, small bore tubing or manufactures guidelines

instrument damaged - potential Rigging register established and maintained

loss of containment - persons SWL not exceeded

58 struck by high pressure gas - Spotters engaged as required

possible fire / explosion All work in brownfield area controlled by APA Permit to

Work

hazards discussed at pre-start

Task specific SWMS and lift plans as required

Exclusion zones established as required

Tag lines shall be used

Compliance with APA Fatal Risk Protocols

Pipework isolated and depressurised where possible

Instruments and tubing identified with Hi Vis Tape where

required

Steelwork Untrained unqualified TBC Personal Injury Medium (H&S) Occasional Moderate All work conducted under APA PTW Medium (H&S) Unlikely Moderate Yes Nil N/A

Fabrication - Hot persons engaged Slip trip fall Trained and competent persons engaged

work - Cutting - Defective or Incorrect tools Foreign objects in eye All tools and equipment subject to pre-start inspection

Grinding - used Cut lacerations from contact with All electrical equipment tagged and tested as per

Welding - Fixing Falling / Flying objects grinder or buff (Electrical Work & Equipment)

Exposed electrical parts Stabbing, laceration from High standard of housekeeping maintained

Poor housekeeping protruding objects Fire extinguishers available at work site

Protruding objects - Burns, contact with hot surfaces Correct tools used for the job no 9 inch grinders on

uncapped reo bar - hold Contact with live electrical worksite and use of HH grinder > 5" subject to risk

down bolts components assessment (discuss use of Demo Saw)

Task specific PPE as per SWMS

Do not work off ladders; use work platforms, EWP etc.

while working at height, only trained and competent

persons to do so.

59 Correct manual handling technique, mechanical aid, and

team lifts etc.

Gas bottles secured and correctly stored

Exclusion zones established as required Yes Nil N/A

Safety glasses and full face shield to be worn (Double

eye protection), Gloves, safety boots, long sleeve shirt

and long leg trousers

Correct PPE used for oxy cutting / arc welding and

welding screens deployed as required

Flashback arresters installed at regulator and handpiece

All reo-bar and hold down bolts to be capped - and

monitored

Contractor Procedure / SWMS

Installation of Inexperienced / unqualified Yes Operational pipework / Major (H&S) Possible High Trained and competent personnel engaged Major (H&S) Rare Moderate Yes Nil N/A

pipework / bolt / persons engaged instruments struck by uncontrolled Only qualified crane drivers to operate cranes and

torque Incorrect procedures used load - dent or deformation of qualified riggers to select and apply rigging and direct

or procedures not followed pipework, small bore tubing or crane driver

Defective, Incorrect or not instrument damaged - potential All plant to be inspected on daily basis and records kept

calibrated tools used loss of containment - persons in site office

Poor housekeeping leads / struck by high pressure gas - Maintenance to be carried out in accordance with

hoses possible fire / explosion manufactures guidelines

Manual handling Person struck or impacted by SWL not exceeded

spills and injection injuries uncontrolled load - impact or Task specific SWMS and lift plans as required

60 Compressed air crush injury - Potential for Rigging register established and maintained

Stored energy disabling injury Exclusion zones established as required

crush injuries Incorrect torque value applied - Tag lines shall be used

dropping objects potential for escape of high Compliance with APA Fatal Risk Protocols

asset damage pressure gas during testing / Approved Bolting / Unbolting / Torqueing / Flange

purging - Possible project delay Closure procedure available and applied

Potential for damage to flange,

gaskets, instruments - Possible

project delay

15/12/2015 Confidential Page 11 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

ZERO Harm

Acceptable &

Job Step Activity / Job Credible (Y / Consequence Description Consequence Likelihood Risk Ranking Comment / Additional Controls /

Potential Hazards Consequence Likelihood Risk Ranking Existing Controls ALARP? Action by Due Date Status

ID Step N) (Without controls) (Residual) (Residual) (Residual) Actions

(Yes / No)

VNIE 6 - 9 Pre Construction HAZID

On-Site Service Untrained personnel, Yes Unintended operation of plant - Major (H&S) Occasional High Trained and competent persons engaged to conduct Medium (H&S) Unlikely Moderate Yes Nil N/A

& Repairs - inadequate knowledge, Person struck by or caught by service and repair in accordance with OEM procedures

Plant / skills and experience. moving plant - Personal injury - and Approved Procedures.

Equipment Absent or inadequate Potential fatality Appropriate Isolation LOTO procedures applied as

61 service / repair procedures required

Failure to isolate energy

sources

On-Site Service Untrained personnel, Yes Environmental damage - spill / Insignificant (E) Occasional Low Trained and competent persons engaged to conduct Insignificant (E) Unlikely Negligible Yes Nil N/A

& Repairs - inadequate knowledge, leaks service and repair in accordance with OEM procedures.

Plant / skills and experience. Refuelling Procedure + Bunded fuel tank + Fire

Equipment Absent or inadequate extinguisher

service / repair procedures. Oil storage on site

62

Contaminated soil disposed of by licensed contractor

Portable spill kits available on site.

15/12/2015 Confidential Page 12 of 12

VN69-RP-R-004 VNIE 6-9 Preliminary Construction HAZID Register.xls

APA Matrix Ref : APA Risk Management Policy June 2013 V2

Insignificant Minor Medium Signifcant Major Catastrophic

External medical treatment but excluding Injury or illness requiring hospitalisation

CONSEQUENCES

First aid treatment only with the ability to Fatality OR life threatening injuries OR

Health & Safety hospitalisation with the ability to return to and resulting in the inability to return to Permanent partial disability Multiple fatalities

return to work immediately permanent total disability

work the next day work the next day (LTI)

Prolonged (more than 12 months but

An uncontrolled off‐site release of event

Short‐term (less than 12 months) less than 2 years) reversible impairment An uncontrolled off‐site release or event Uncontained, long‐term serious

resulting in reversible prolonged (more

Limited impairment to minimal area of temporary impairment to the biological or to the biological or physical environment in wide area resulting in reversible environmental degradation OR

Environment than 2 years but less than 5 years)

low significance. physical environment of a very localised of a localised area (<1ha) which is easily long‐term environmental impairment of permanent impairment to ecosystem

impairment to the environment but which

area (,0.1ha). rectified and which does not affect ecosystem function. function or habitat.

does not affect ecosystem function.

ecosystem function.

Will occur during the course

Frequent of the Project

LOW MODERATE HIGH EXTREME EXTREME EXTREME

Will probably occur during

Likey the course of the Project

LOW MODERATE HIGH HIGH EXTREME EXTREME

Has been known to occur in

Occasional LOW LOW MODERATE HIGH HIGH EXTREME

FREQUENCY

comparable Projects

May occur during the course

Possible of the Project

NEGLIGIBLE LOW MODERATE HIGH HIGH HIGH

Not expected to occur but

has the potential to occur

Unlikely during the course of the

NEGLIGIBLE LOW MODERATE MODERATE HIGH HIGH

Project

Conceivable, but only in

Rare exceptional circumstances

NEGLIGIBLE NEGLIGIBLE LOW MODERATE MODERATE HIGH

RISK LEVEL RISK MANAGEMENT ACTIONS

EXTREME Immediate action required and risk monitored at Board level

HIGH Executive Management attention needed and risk monitored

MODERATE Management responsibility must be specified

LOW Manage by routine procedures

NEGLIGIBLE Review periodically to ensure risk has not increased

15/12/2015 Confidential Page 1 of 1

AS2885 MATRIX

Catastrophic Major Severe Minor Negligible

Typical Severity Class

Few fatalities, or several people with Injury or illness requiring Injuries requiring first aid

People (AS2885-2007) Multiple fatalities result Minimal impact on health & safety

life-threatening injuries hospital treatment treatment

Short term interruption or

Prolonged interruption or long term Short term interruption or

Commercial / Supply (AS2885-2007) Long term interruption of supply restriction of supply but shortfall No impact; no restriction of supply

restriction of supply prolonged restriction of supply

met from other sources

CONSEQUENCES

Effects widespread; viability of Effect very localised (<0.1 ha) No effect, or minor on-site effects

Major off-site impact or long term Localised (<1 ha) & short term

Environment (AS2885-2007) ecosystems or species affected; and very short term (weeks), rectified immediately with

severe effects or rectification difficult (<2 yr) effects, easily rectified

permanent major changes minimal rectification negligible residual effect

Continuous national and / or Regional / sate coverage,

Managed locally, some publicity Issue resolved in day to day

international coverage, major National press coverage, regulatory regulator wants formal

Reputation or Regulatory in local press, general management. Small local publicity.

regulatory restrictions imposed investigation explanation & remedial action

regulatory query No regulatory involvement

possible loss of licence plans

Business Continuity The survival and / or continued Business disruption such that the Delivery times causing financial Delays in delivery cause Temporary delay in service

profitability of the company is in business will return to a level loss and / or breach of contract, problems to either internal or delivery with little effect, business

doubt somewhere less than previous, growth delayed for over six external customers, growth would return to normal

growth indefinitely shelved months, business return after options put off for months, immediately

several days business as usual achieved

after several hours

Maximum risk less than $5 Maximum risk less than

Assets or Profitability Risk may exceed $50 million Maximum risk less than $50 million Maximum risk less than $5,000

million $500,000

Occasional Frequent

Expected to occur once per

Extreme Extreme High Intermediate Low

year or more

May occur occasionally in the

life of the pipeline, once every Extreme High Intermediate Low Low

10 years

FREQUENCY

Unlikely

Unlikely to occur within the life

of the pipeline, but possible, High High Intermediate Low Negligible

once every 100 years

Remote

Not anticipated for this pipeline

at this location, once every High Intermediate Low Negligible Negligible

1000 years

Hypothetical

Incident theoretically possible,

but has never occurred on a

Low Negligible Negligible Negligible

similar pipeline, less than

once every 10000 years

RISK LEVEL RISK MANAGEMENT ACTIONS

EXTREME The risks are considered intolerable and have to be reduced to INTERMEDIATE or lower and, for an in service pipeline, have to be reduced immediately.

HIGH The risks are considered intolerable and have to be reduced to INTERMEDIATE or lower.

INTERMEDIATE The risks are higher than desired and actions are required to reduce the risk to LOW, NEGLIGIBLE or at least ALARP.

LOW The risks are considered manageable through the application of risk management measures detailed in the safety and operating plan to ensure appropriate measures are in place to keep the risk at an

NEGLIGIBLE No further action is required for this level of risk beyond regular reviews.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- LRT1 Admin BLDG Daily BA SheetDocument2 paginiLRT1 Admin BLDG Daily BA SheetSAMUEL POBREÎncă nu există evaluări

- JHA Lifting-Moving Heavy Objects - ROMODocument5 paginiJHA Lifting-Moving Heavy Objects - ROMOSAMUEL POBREÎncă nu există evaluări

- Demolition: Hazards & Control MeasuresDocument9 paginiDemolition: Hazards & Control MeasuresSAMUEL POBREÎncă nu există evaluări

- Hazard Identification and Risk Assessment Control - Tree Cutting & Earth BallingDocument11 paginiHazard Identification and Risk Assessment Control - Tree Cutting & Earth BallingSAMUEL POBREÎncă nu există evaluări

- Hazard Identification and Risk Assessment Control - Tree Cutting & Earth BallingDocument9 paginiHazard Identification and Risk Assessment Control - Tree Cutting & Earth BallingSAMUEL POBREÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 7es Lesson PlanDocument3 pagini7es Lesson PlanEZAR-casticÎncă nu există evaluări

- First Aid A NecessityDocument41 paginiFirst Aid A NecessityAlfred Melvin SolivaÎncă nu există evaluări

- First Aid PDFDocument22 paginiFirst Aid PDFaripally NagarjunaÎncă nu există evaluări

- Method Statement: First Fix JoineryDocument8 paginiMethod Statement: First Fix JoineryShaijan JosephÎncă nu există evaluări

- PMS MSDS-95-octane-petrol-premiumDocument15 paginiPMS MSDS-95-octane-petrol-premiumJumco OPS WarriÎncă nu există evaluări

- First Aid and CPR (Presentation)Document76 paginiFirst Aid and CPR (Presentation)Christian Mark De JesusÎncă nu există evaluări

- Health 3RD QuarterDocument4 paginiHealth 3RD QuarterMary Joyce Gabutero- CatudioÎncă nu există evaluări

- Mapeh 9 Second QuarterDocument7 paginiMapeh 9 Second QuarterMary CrisÎncă nu există evaluări

- Devcon Fasmetal 10 (HVAC) Hardener 19770Document20 paginiDevcon Fasmetal 10 (HVAC) Hardener 19770Mohamed HamedÎncă nu există evaluări

- Precaution ARY Measures: Before, During and After An EarthquakeDocument18 paginiPrecaution ARY Measures: Before, During and After An EarthquakeRussell IslaÎncă nu există evaluări

- Teaching PlanDocument5 paginiTeaching PlanPrincess Huey GreyÎncă nu există evaluări

- HPE G7 ST Book Final PDFDocument146 paginiHPE G7 ST Book Final PDFKassahun91% (34)

- Physical Education SbaDocument46 paginiPhysical Education SbaDaniel Dowding80% (5)

- Sözleşme İSEÇ Örnek Plan - PerakendeDocument10 paginiSözleşme İSEÇ Örnek Plan - PerakendeSerkan CebeciogluÎncă nu există evaluări

- Check List First AidDocument6 paginiCheck List First AidNatasha VanyaÎncă nu există evaluări

- Anonymous Survival Guide For Citizens in A RevolutionDocument15 paginiAnonymous Survival Guide For Citizens in A RevolutionLala Paroubek100% (4)

- Method Statement - Concrete Slab Installation - SSBSDocument23 paginiMethod Statement - Concrete Slab Installation - SSBSrnp2007123Încă nu există evaluări

- Health Week 1-3 - 3rd QuarterDocument8 paginiHealth Week 1-3 - 3rd QuarterNoemelyn VecinaÎncă nu există evaluări

- TSB-ERM 01-01 Emergency Response Plan r5 - With AttachmentsDocument29 paginiTSB-ERM 01-01 Emergency Response Plan r5 - With AttachmentsMarwotoÎncă nu există evaluări

- Chapter 1 First Aid in The WorkplaceDocument32 paginiChapter 1 First Aid in The WorkplaceAnna MethyldaÎncă nu există evaluări

- MaxigardDocument17 paginiMaxigardrizqi dwikiÎncă nu există evaluări

- Recitation in Labor Law ReviewDocument13 paginiRecitation in Labor Law ReviewFruitie SyÎncă nu există evaluări

- Medicare Catalogue MailDocument28 paginiMedicare Catalogue MailmabrijoeÎncă nu există evaluări

- Jas ProformqaDocument5 paginiJas Proformqaapi-289750485Încă nu există evaluări

- Module 2 - The Basics of First AidDocument6 paginiModule 2 - The Basics of First AidRonald Michael QuijanoÎncă nu există evaluări

- First Aid EssentialsDocument5 paginiFirst Aid EssentialsQueen ValleÎncă nu există evaluări

- Mep Hse PlanDocument25 paginiMep Hse PlanMahammadÎncă nu există evaluări

- KDC HSE-IIPPManual v.2015Document156 paginiKDC HSE-IIPPManual v.2015VikasÎncă nu există evaluări

- Hand Tools & Electrical Equipment Technology)Document5 paginiHand Tools & Electrical Equipment Technology)Tim CockingÎncă nu există evaluări

- AHA Trainings and Seminar in The PhilippinesDocument1 paginăAHA Trainings and Seminar in The PhilippinesNURSES' PADÎncă nu există evaluări