Documente Academic

Documente Profesional

Documente Cultură

A3 Report Vios Double Layer Sobek

Încărcat de

M Saputra Paytren PurwakartaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A3 Report Vios Double Layer Sobek

Încărcat de

M Saputra Paytren PurwakartaDrepturi de autor:

Formate disponibile

Purwakarta, 25/10/ 2019

PT. TOYOTA BOSHOKU

INDONESIA KARPET VIOS DOUBLE LAYER SOBEK

QUALITY ASSURANCE DEPARTMENT

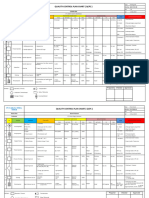

I. BACKGROUND II. CLARIFY THE PROBLEM V. ANALYZE THE ROOT CAUSE

Karpet Vios DL Sobek

1. SASARAN Ideal Situation :

>> Tidak ada masalah yang terjadi pada Customer TARGET :

2. KONDISI IDEAL No NG Part Delivered

>> Tidak ada Masalah --> Tidak ada karpet sobek Problem : MATERIAL MAN METHOD MACHINE ENVIRONMENT

Current Situtation : Terdapat karpet sobek

3. ACTUAL

ACTUAL :

>> 18 Oktober 2019

NG Part Delivered Tidak ada perubahan Tidak ada perubahan Tidak ada pengecekan Saat proses produksi Tidak ada perubahan

bagian base di final sensor cutter eror,

NG ditemukan di TB INA (oktober'19) cutter memotong

mtr inspect

sendiri karpet

6 5

pcs

4 sensor cutter rusak

2

0 0 0 0 0 0

0

18 19 20 21 22 23 24

Tanggal

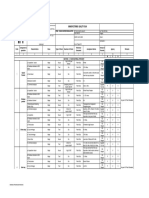

III. BREAK DOWN THE PROBLEM

VI. DEVELOP COUNTER MEASURE

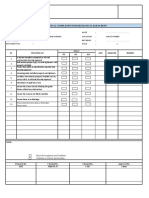

Flow of Production and Final Inspection

Problem

Occurence

Material Receiving FINISH

QC MIXING CARDING

Carpet Process PUNCHING

Delivered

Storage QC

PT.TB INA

Problem

Realease

Sensor Cutter VII. EVALUATE & MONITORING COUNTER MEASURE

rusak

Tidak ada karpet robek yang terkirim ke customer NG

30

panjang (m)

20

10

0 0 0 0 0 0 0 0

0

Cutter 25 26 27 28 29 30 0 0

Tanggal

IV. TARGET VIII. STANDARDIZE VIII. NEXT ACTION

1. Pengecekan base karpet

PT. MULTIWARNA KARPETINDO AGUNG mengirim produk ke customer sesuai standard Follow up hasil improvement

S-ar putea să vă placă și

- CPS Meeting-IeDocument2 paginiCPS Meeting-IeMohammad KamruzzamanÎncă nu există evaluări

- The Visual LISP EditorDocument192 paginiThe Visual LISP Editorloopback127xyzÎncă nu există evaluări

- Inspection Report FormDocument1 paginăInspection Report Forminterconnect_scottÎncă nu există evaluări

- 6 Sigma SD Shaft Dia. VariationDocument32 pagini6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- Spare Parts ListDocument22 paginiSpare Parts Listsilvio bandeira100% (2)

- Dokumen - Tips - QCPC Bracket BumperDocument3 paginiDokumen - Tips - QCPC Bracket BumpervolkÎncă nu există evaluări

- Security Intelligence Fundamentals: Student NotebookDocument245 paginiSecurity Intelligence Fundamentals: Student NotebookMohsine AzouliÎncă nu există evaluări

- Livro B P Lathi Sinais e Sistemas Lineares 2 Ed PDFDocument864 paginiLivro B P Lathi Sinais e Sistemas Lineares 2 Ed PDFw2ttec developerÎncă nu există evaluări

- Daily Report 11 May 2022Document4 paginiDaily Report 11 May 2022Abdoel KhalimÎncă nu există evaluări

- RTL Modeling With Systemverilog For Simulation A DownloadDocument4 paginiRTL Modeling With Systemverilog For Simulation A DownloadVijay0% (1)

- BillDocument6 paginiBillRoniel CedeñoÎncă nu există evaluări

- Contoh Perhitungan Sheet PileDocument8 paginiContoh Perhitungan Sheet PileAnonymous iU0Vh4pÎncă nu există evaluări

- Batch Manufacturing RecordDocument7 paginiBatch Manufacturing RecordAnu JoshiÎncă nu există evaluări

- QCPC Pmi FanDocument14 paginiQCPC Pmi FanMaelEdwardAritonangÎncă nu există evaluări

- TPL 340062 Ujn STP CVL SBR Design Document r0Document326 paginiTPL 340062 Ujn STP CVL SBR Design Document r0epe civilÎncă nu există evaluări

- 4.1) Water Spider Optimization by Eliminating Duplicate ActivitiesDocument9 pagini4.1) Water Spider Optimization by Eliminating Duplicate ActivitiessanyamÎncă nu există evaluări

- CI CD For Modern Applications by Darko Mesaros 1579812522Document70 paginiCI CD For Modern Applications by Darko Mesaros 1579812522ShubhamSetiaÎncă nu există evaluări

- LOW AREA In-Kind ScheduleDocument25 paginiLOW AREA In-Kind Schedulejohn tabierosÎncă nu există evaluări

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocument7 paginiBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruÎncă nu există evaluări

- 202301-Quality Management-75053Document30 pagini202301-Quality Management-75053SRJ Do ItÎncă nu există evaluări

- Daily Report 17 May 2022Document5 paginiDaily Report 17 May 2022Abdoel KhalimÎncă nu există evaluări

- Daily Report 12 May 2022Document4 paginiDaily Report 12 May 2022Abdoel KhalimÎncă nu există evaluări

- A3 Report RustyDocument7 paginiA3 Report RustyMarketing BonecomÎncă nu există evaluări

- NCC-IMS-FM-07-02 - Fire Extinguisher Checklist Is7.0Document1 paginăNCC-IMS-FM-07-02 - Fire Extinguisher Checklist Is7.0baseimÎncă nu există evaluări

- HC IFI: Hindustan Chemicals G.T.Road, Opp. RR Auto PetrolDocument4 paginiHC IFI: Hindustan Chemicals G.T.Road, Opp. RR Auto PetrolKarna Satish KumarÎncă nu există evaluări

- Washer - 1Document1 paginăWasher - 1sunshinequalityu4Încă nu există evaluări

- PANEL DB FormDocument1 paginăPANEL DB Formdoly damanikÎncă nu există evaluări

- 64350-K60 - B600 Cover, R Under Side - DoneDocument17 pagini64350-K60 - B600 Cover, R Under Side - DoneMiguel HernandezÎncă nu există evaluări

- Logssheet Proses PsaDocument33 paginiLogssheet Proses PsaAgustino SianiparÎncă nu există evaluări

- Bill 2 - Civil WorksDocument112 paginiBill 2 - Civil WorksKavi RangasamyÎncă nu există evaluări

- Name of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil NaduDocument4 paginiName of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil Nadua paul jayakumarÎncă nu există evaluări

- Gatid Muti-Purpose BLDGDocument27 paginiGatid Muti-Purpose BLDGQuality AssuranceÎncă nu există evaluări

- Schedulle Pelaksanaan: No Item Pekerjaan Bobot % Prestasi Fisik KeteranganDocument1 paginăSchedulle Pelaksanaan: No Item Pekerjaan Bobot % Prestasi Fisik KeteranganAlfian ASÎncă nu există evaluări

- WR01Document4 paginiWR01Engineering WorkshopÎncă nu există evaluări

- Icl Condensate TrapDocument5 paginiIcl Condensate TrapAlberto CamposÎncă nu există evaluări

- Sr. No. Item Description Unit Quantity Purpose Arrange From Remarks Plan Mobilize Available Required Approved Dispatch Received PendingDocument1 paginăSr. No. Item Description Unit Quantity Purpose Arrange From Remarks Plan Mobilize Available Required Approved Dispatch Received PendingjawadÎncă nu există evaluări

- Requerimiento Concreto Semanal - Almacen Testigos N°6 - 22.11.2019Document11 paginiRequerimiento Concreto Semanal - Almacen Testigos N°6 - 22.11.2019Miguelangel ChávezÎncă nu există evaluări

- SFTCSHT (Sindo)Document1 paginăSFTCSHT (Sindo)Tony CeÎncă nu există evaluări

- Stock Audit Report FinalDocument22 paginiStock Audit Report FinalHemant AherÎncă nu există evaluări

- Sample Report For Amazon FBA Jeans - RedactedDocument37 paginiSample Report For Amazon FBA Jeans - RedactedChulaka PitigalaÎncă nu există evaluări

- Lampiran Punch Mechanical WorksDocument1 paginăLampiran Punch Mechanical WorksHeri SulaimanÎncă nu există evaluări

- 02a. Fat Trap PVC GeneralDocument1 pagină02a. Fat Trap PVC Generaljefri hasgianÎncă nu există evaluări

- Recovery Schedule Plan 2 PDFDocument1 paginăRecovery Schedule Plan 2 PDFRicardo NapitupuluÎncă nu există evaluări

- Cover 5W1H SheetDocument1 paginăCover 5W1H Sheetpurchase.electricals2Încă nu există evaluări

- Operation Management Assignment: SEPTEMBER 24, 2018Document8 paginiOperation Management Assignment: SEPTEMBER 24, 2018KarinaÎncă nu există evaluări

- WR01Document4 paginiWR01Engineering WorkshopÎncă nu există evaluări

- DC 958Document2 paginiDC 958mkarthiÎncă nu există evaluări

- Mechanical Check List Pumps.R5Document2 paginiMechanical Check List Pumps.R5Armando BiringkanaeÎncă nu există evaluări

- Requerimiento Concreto SemanalDocument11 paginiRequerimiento Concreto SemanalMiguelangel ChávezÎncă nu există evaluări

- Bored Pile BBS (8m) - Jan 30, 2019Document2 paginiBored Pile BBS (8m) - Jan 30, 2019Jimmy PimentelÎncă nu există evaluări

- SACEP - RTCC - Delivery #0971347-02Document16 paginiSACEP - RTCC - Delivery #0971347-02Ryan condeÎncă nu există evaluări

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 paginăCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaÎncă nu există evaluări

- RD 245Kv GR POWERDocument10 paginiRD 245Kv GR POWERGanesh VeluÎncă nu există evaluări

- Manufacturing Progress 04112023Document17 paginiManufacturing Progress 04112023Indra AdriantoÎncă nu există evaluări

- Renovation Works FrameDocument1 paginăRenovation Works FrameAdrian DyÎncă nu există evaluări

- Apd JB-0028-T-S CipadaDocument5 paginiApd JB-0028-T-S Cipadalutfi gunardiÎncă nu există evaluări

- QM C 7.1 Ab 0001 LDocument3 paginiQM C 7.1 Ab 0001 LalokrajamanÎncă nu există evaluări

- Cartoner Cdi 73Document22 paginiCartoner Cdi 73Ritche Lim BragaisÎncă nu există evaluări

- Form10 Shipment Report - Nov 2020Document1 paginăForm10 Shipment Report - Nov 2020darithÎncă nu există evaluări

- SACEP - RTCC - Delivery #0971541-10Document16 paginiSACEP - RTCC - Delivery #0971541-10Ryan condeÎncă nu există evaluări

- 2305-0-18456-Po 14523644Document2 pagini2305-0-18456-Po 14523644Alfonso LopezÎncă nu există evaluări

- Stock Level Change RequestDocument2 paginiStock Level Change RequestPatrick HillmanÎncă nu există evaluări

- LQC STDDocument2 paginiLQC STDAstronÎncă nu există evaluări

- Omega: ConsultantDocument7 paginiOmega: ConsultantSumit JainÎncă nu există evaluări

- 01.RAB BUARAN RENOVASI FASADE ANWIDZING 102020 (Ok)Document1 pagină01.RAB BUARAN RENOVASI FASADE ANWIDZING 102020 (Ok)asep otingÎncă nu există evaluări

- Inspection of Installation Grounding Cable: Cscec-Tata JoDocument2 paginiInspection of Installation Grounding Cable: Cscec-Tata Jodoly damanikÎncă nu există evaluări

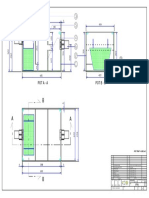

- Flow Process: Mass-Production Pre-LaunchDocument1 paginăFlow Process: Mass-Production Pre-LaunchM Saputra Paytren PurwakartaÎncă nu există evaluări

- MWSB 338BDocument1 paginăMWSB 338BM Saputra Paytren PurwakartaÎncă nu există evaluări

- FX Nuke: System ManualDocument21 paginiFX Nuke: System ManualM Saputra Paytren PurwakartaÎncă nu există evaluări

- Flow Process: Pre-LaunchDocument1 paginăFlow Process: Pre-LaunchM Saputra Paytren PurwakartaÎncă nu există evaluări

- Shepherd Harmonic Pattern: NotesDocument1 paginăShepherd Harmonic Pattern: NotesDeepak V.Încă nu există evaluări

- Pair Strength Analyzer PDFDocument8 paginiPair Strength Analyzer PDFموهد ريضزإنÎncă nu există evaluări

- NPP 250 Sign PDFDocument2 paginiNPP 250 Sign PDFM Saputra Paytren PurwakartaÎncă nu există evaluări

- Specification:-Ljrl,/t + (NPP250) : MIR Sinar SuminoeDocument2 paginiSpecification:-Ljrl,/t + (NPP250) : MIR Sinar SuminoeM Saputra Paytren PurwakartaÎncă nu există evaluări

- DOTS User Manual v4210Document58 paginiDOTS User Manual v4210Bull433Încă nu există evaluări

- Gender Differences in Online Gaming: A Literature Review: August 2014Document12 paginiGender Differences in Online Gaming: A Literature Review: August 2014Jessa Mae CacÎncă nu există evaluări

- Juniper SSG5Document66 paginiJuniper SSG5Carlos Flores UrtechoÎncă nu există evaluări

- Econ3150 v12 Note01 PDFDocument6 paginiEcon3150 v12 Note01 PDFRitaSilabanÎncă nu există evaluări

- Ftse 100Document0 paginiFtse 100james22121Încă nu există evaluări

- CENG400-Midterm-Fall 2014Document9 paginiCENG400-Midterm-Fall 2014Mohamad IssaÎncă nu există evaluări

- DSE4210 DSE4220 Operators Manual PDFDocument42 paginiDSE4210 DSE4220 Operators Manual PDFLeo BurnsÎncă nu există evaluări

- Setup and User Guide: Mediaaccess Tg788Vn V2Document159 paginiSetup and User Guide: Mediaaccess Tg788Vn V2Fernando GonzálezÎncă nu există evaluări

- Form PDocument2 paginiForm Ptanmoy0% (1)

- Open Loop Vs Closed LoopDocument3 paginiOpen Loop Vs Closed LoopDonny Priyo Wicaksono100% (1)

- LED ButtonDocument14 paginiLED Buttonlabirint10Încă nu există evaluări

- Mapua University: School of EECEDocument8 paginiMapua University: School of EECEBenj MendozaÎncă nu există evaluări

- Mcommerce AssignDocument9 paginiMcommerce AssignRose Rhodah Marsh100% (1)

- FDNL S1600 WDocument3 paginiFDNL S1600 WJederVieiraÎncă nu există evaluări

- Use Case DiagramDocument29 paginiUse Case Diagramshohanur rahmanÎncă nu există evaluări

- Midterm CisDocument8 paginiMidterm CisJeacy Mae GallegoÎncă nu există evaluări

- SDS2 7.1-Assorted Tools PDFDocument94 paginiSDS2 7.1-Assorted Tools PDFwayne6088Încă nu există evaluări

- Cashier Docu SCC2015Document44 paginiCashier Docu SCC2015th3g3ntl3m4nÎncă nu există evaluări

- EN 61800-100 UserManual 1905Document176 paginiEN 61800-100 UserManual 1905Tikal TikaldromedariusÎncă nu există evaluări

- td12 UpdateDocument2 paginitd12 UpdateSergio Muñoz MuñozÎncă nu există evaluări

- Nguyen Dinh Truong Giang: Work Experience EducationDocument1 paginăNguyen Dinh Truong Giang: Work Experience EducationTôi LàÎncă nu există evaluări

- Et80, Et1010, Et1080Document4 paginiEt80, Et1010, Et1080KUNOÎncă nu există evaluări

- pt2000 TopgunusermanualDocument140 paginipt2000 TopgunusermanualCucuilinÎncă nu există evaluări

- Anova BiometryDocument33 paginiAnova Biometryadityanarang147Încă nu există evaluări