Documente Academic

Documente Profesional

Documente Cultură

Sample Wps Multi Process

Încărcat de

Mohammed Elmodathir AliDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sample Wps Multi Process

Încărcat de

Mohammed Elmodathir AliDrepturi de autor:

Formate disponibile

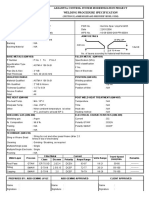

Willie Wonka’s Widget Welding Works

Welding Procedure Specification

WPS: SMA/FCA-1F3F6 Rev.: A Date: 15-Oct-08

Supporting PQR: Susan 6 Rev.: Original Date: 12-Oct-08

Process: SMAW MA X SA - ME - AU -

Welder: Miller D400

Process: FCAW MA - SA X ME - AU -

Welder: Lincoln PowerWave 300

Base Metal

Specification: ASTM A53 ASTM A572

Alloy/Grade: B Grade 55

P No.: 1 1

Product Pipe Plate

Welded To

Form:

Thickness: 1/16 thru 1¼ inch 1/16 thru 1¼ inch

Diameter: 1 inch or larger NA

Group No.: 1 2

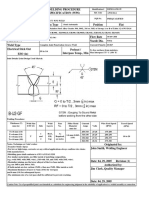

Joint Details

Joint Type: T and Corner

Single Fillet Weld;

Groove Type: Fillets and TF1.0

CF1.0

LF1.0

T2

Suitable for Corner Joints,

T- Joints, and Lap Joints. BB1C.0

CB1C.0

Bevel Grooves 60° to 120°

TF1.0

TB1C.0

45° min.

CJP Single Bevel Groove

w/ Backing, Suitable for

Butt Joints, Corner Joints,

Groove 50° min. CF1.0

& T-Joints

Angle:

LF1.0

T1 required when specified by

WS = T min the welding symbol.

Root Face: 1/32 to 1/8 inch Unless otherwise specified,

the minimum fillet size is equal to

the thickness of the thinner member.

Root Radius: NA 3/16 to 5/16 in.

Backing to fit

tight to members.

Max. gap - 1/16 in.

Root 0 to 1/16 inch Skew

Opening: < 60°

Skewed Joint;

Suitable for Skewed T-Joints

Backing: Optional

Assumed

Z Loss

Dihedral Angle

O

60 1/16 in.

50 O 3/32 in.

Back Gouge: Req. if not back WS

T1 40 O 3/16 in.

gouged Z Loss

BG Method CAC-A / Grind

Filler Metal

Process: SMAW FCAW

Weld Layer: Root and 2nd layer All remaining (fill and cover)

Specification: SFA 5.1 -- SFA 5.20 --

Classification: E6010 -- E71T-1 --

Diameter: 1/8 inch -- 0.045 inch --

F Number 3 6

A No.: 1 -- 1 --

Max. Layer 1/4 inch -- 3/8 inch --

Thickness:

Max. Deposit ½ inch ¾ inch

thickness

Consumable None -- NA --

Insert;

Classification: NA -- NA --

Flux: NA -- NA --

S-ar putea să vă placă și

- WPSDocument6 paginiWPSYASH BARDHAN SinghÎncă nu există evaluări

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 paginiIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS-2 InchDocument2 paginiWPS-2 InchKarthikeyan MpÎncă nu există evaluări

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 paginiCSM-QR-02-2, Medical Gas BPS TablesaadmaadmÎncă nu există evaluări

- WPQ-1083 3G PDFDocument2 paginiWPQ-1083 3G PDFduendex360100% (1)

- Electrodes EnglishDocument139 paginiElectrodes Englishcostelino72Încă nu există evaluări

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 paginăPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraÎncă nu există evaluări

- PQR Sample PrintoutDocument2 paginiPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- WPS 316 L PDFDocument4 paginiWPS 316 L PDFIrinaÎncă nu există evaluări

- For Fillet Weld Joint Project:Production ManifoldDocument1 paginăFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Format WPQDocument2 paginiFormat WPQAkash Singh TomarÎncă nu există evaluări

- WPS Format For ASME IX - PQR-AllDocument3 paginiWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Sample Forms AWS, ASME and APIDocument14 paginiSample Forms AWS, ASME and APIaamirtec301Încă nu există evaluări

- WPS BhelDocument2 paginiWPS BhelpradhankruhsnaÎncă nu există evaluări

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 paginăWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- PQRDocument3 paginiPQRnazirulhakimÎncă nu există evaluări

- Wps Butt AWSDocument4 paginiWps Butt AWSMohd Ashraf75% (4)

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 paginăD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Încă nu există evaluări

- Manual Joints (QW - 402) : Page 1 of 12Document12 paginiManual Joints (QW - 402) : Page 1 of 12miteshpatel191Încă nu există evaluări

- Ami-003 WPSDocument2 paginiAmi-003 WPSBenjamin BrownÎncă nu există evaluări

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 paginăQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasÎncă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingMohammed MusaÎncă nu există evaluări

- Welding Proposed Pwps For Our Jubail WorkDocument2 paginiWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 paginiWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamed100% (1)

- Gmaw Complete Aws d1.6Document1 paginăGmaw Complete Aws d1.6Silvia CardenasÎncă nu există evaluări

- WPS D1.6 Annex m1 PDFDocument1 paginăWPS D1.6 Annex m1 PDFbollascribdÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityÎncă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedÎncă nu există evaluări

- Welding Defects Poster 600x900 Lores enDocument1 paginăWelding Defects Poster 600x900 Lores enMostafa ZedÎncă nu există evaluări

- Piping WpsDocument37 paginiPiping WpsZulfokar FahdawiÎncă nu există evaluări

- Clad PQRDocument5 paginiClad PQRRinshadÎncă nu există evaluări

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 paginiWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanÎncă nu există evaluări

- 202 1sp 0 Saw Cs CsDocument8 pagini202 1sp 0 Saw Cs CskrishimaÎncă nu există evaluări

- WPS FormatDocument2 paginiWPS FormatAmit SarkarÎncă nu există evaluări

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 paginiBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarÎncă nu există evaluări

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 pagină07.4 111 FW ML PF WPS 20mm ENGViktorÎncă nu există evaluări

- PT Kuwera Karya Me: PanduDocument2 paginiPT Kuwera Karya Me: PanduGalang Pratama PutraÎncă nu există evaluări

- Welding Procedure Specification Sample - New EditionDocument2 paginiWelding Procedure Specification Sample - New EditiondanteÎncă nu există evaluări

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 pagină193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- WQT Form (ASME) 04-23Document1 paginăWQT Form (ASME) 04-23hanz bermejoÎncă nu există evaluări

- Reports - QAQC - R0Document10 paginiReports - QAQC - R0talupurumÎncă nu există evaluări

- 004 Gtaw P5aDocument16 pagini004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- D17.1 D17.1M 2017 Sample PQTR FormDocument1 paginăD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaÎncă nu există evaluări

- Wps For Ss 304Document3 paginiWps For Ss 304Sajit PillaiÎncă nu există evaluări

- WPQ WeldCanada PDFDocument1 paginăWPQ WeldCanada PDFAhmad DanielÎncă nu există evaluări

- Aws d1.5 PQRDocument2 paginiAws d1.5 PQRjacquesmayolÎncă nu există evaluări

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pagini163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 paginiWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniÎncă nu există evaluări

- WPS-PQR (Aws D.1.1 - 2015)Document3 paginiWPS-PQR (Aws D.1.1 - 2015)Ivan Garzon100% (1)

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 paginăWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Wps Magi Tig Exemple PDFDocument6 paginiWps Magi Tig Exemple PDFJaime PatrónÎncă nu există evaluări

- BPV IX-16-3 QW-283 - ButteringDocument1 paginăBPV IX-16-3 QW-283 - ButteringyutweldingÎncă nu există evaluări

- PWPS DonpyDocument1 paginăPWPS DonpyANDINTA MUDA YUSUFÎncă nu există evaluări

- Welding Procedure Specification - TemplateDocument2 paginiWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationDocument1 paginăMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghÎncă nu există evaluări

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 paginiWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupÎncă nu există evaluări

- Sch. SAE 3000 PsiDocument19 paginiSch. SAE 3000 PsiWilson JustinoÎncă nu există evaluări

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pagini(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023Încă nu există evaluări

- Datasheet StrainerDocument4 paginiDatasheet StrainerTommy ArjanggiÎncă nu există evaluări

- Asme Ix - : ProcedureDocument11 paginiAsme Ix - : ProcedureMohammed Elmodathir Ali100% (1)

- Circumferential Welders LiteratureDocument6 paginiCircumferential Welders LiteratureMohammed Elmodathir AliÎncă nu există evaluări

- Laser WeldingDocument129 paginiLaser WeldingMohammed Elmodathir AliÎncă nu există evaluări

- User Manual For Threading and Tapping: Dyson CentreDocument10 paginiUser Manual For Threading and Tapping: Dyson CentreMohammed Elmodathir AliÎncă nu există evaluări

- Understanding WPS & PQRDocument18 paginiUnderstanding WPS & PQRMohammed Elmodathir AliÎncă nu există evaluări

- Training Program Required For MIG/MAG: 1. Day MIG/MAGDocument7 paginiTraining Program Required For MIG/MAG: 1. Day MIG/MAGMohammed Elmodathir AliÎncă nu există evaluări

- Electron Beam Welding BasicsDocument1 paginăElectron Beam Welding BasicsMohammed Elmodathir AliÎncă nu există evaluări

- Datasheet For Steel Grades Structure Steel 30crmnsiaDocument2 paginiDatasheet For Steel Grades Structure Steel 30crmnsiaMohammed Elmodathir AliÎncă nu există evaluări

- Tig ParametersDocument4 paginiTig ParametersMohammed Elmodathir AliÎncă nu există evaluări

- Investigation Into Electron Beam WeldingofheavysectionsDocument4 paginiInvestigation Into Electron Beam WeldingofheavysectionsMohammed Elmodathir AliÎncă nu există evaluări

- 1.PPT II Plastics Processing Technology II 20 222 wtb2654Document1 pagină1.PPT II Plastics Processing Technology II 20 222 wtb2654Raj ThakurÎncă nu există evaluări

- Membrane SystemDocument16 paginiMembrane SystemAulia syafiraÎncă nu există evaluări

- U-Seal /Z-Seal Casing Seals: For Cased CrossingsDocument4 paginiU-Seal /Z-Seal Casing Seals: For Cased CrossingsChegg ChemÎncă nu există evaluări

- Na2Xfgby 2 X (10-300) MM 0.6/1 KVDocument4 paginiNa2Xfgby 2 X (10-300) MM 0.6/1 KVHajie OmenÎncă nu există evaluări

- Observation On Quality Aspects 083Document3 paginiObservation On Quality Aspects 083Moorthy NaveenÎncă nu există evaluări

- Etea 2019Document7 paginiEtea 2019Izhar RahmanÎncă nu există evaluări

- Detailed Lesson Plan in ScienceDocument9 paginiDetailed Lesson Plan in ScienceRedMoonLightÎncă nu există evaluări

- Aggregate Impact ValueDocument8 paginiAggregate Impact ValueAnonymous KpLy2NeÎncă nu există evaluări

- Wire Rope Assemblies Catalog PDFDocument40 paginiWire Rope Assemblies Catalog PDFEduÎncă nu există evaluări

- Chemistry - Ionic Equilibrium DPPDocument6 paginiChemistry - Ionic Equilibrium DPPmy missionÎncă nu există evaluări

- Professional Skill Development Activities (PSDA) Topic: Practical Application Ideas and Case Studies On Aircraft Composite StructureDocument12 paginiProfessional Skill Development Activities (PSDA) Topic: Practical Application Ideas and Case Studies On Aircraft Composite StructureAkas SinghÎncă nu există evaluări

- P S CL K Ca: F3 First Term RevisionDocument6 paginiP S CL K Ca: F3 First Term Revisionjonas hoÎncă nu există evaluări

- Cryogenic Ball Milling - A Key For Elemental Analysis of Plastic-Rich Automotive Shedder ResidueDocument9 paginiCryogenic Ball Milling - A Key For Elemental Analysis of Plastic-Rich Automotive Shedder ResidueyeisonÎncă nu există evaluări

- Sea Water DesalinationDocument4 paginiSea Water Desalinationsisiliaprenaly100% (1)

- Bollhoff Quicksert Expansion InsertsDocument4 paginiBollhoff Quicksert Expansion InsertsAce Industrial SuppliesÎncă nu există evaluări

- Jafurah Field Development - Export Pipelines (PACKAGE #5) : CONTRACT No. 6600050457 / BI No. 10-14329Document60 paginiJafurah Field Development - Export Pipelines (PACKAGE #5) : CONTRACT No. 6600050457 / BI No. 10-14329SahityaÎncă nu există evaluări

- THHNDocument2 paginiTHHNanon-136032Încă nu există evaluări

- TDS S330Document2 paginiTDS S330Iridian Cano CeronÎncă nu există evaluări

- Homemade Bandsaw Plans YouTube PDFDocument3 paginiHomemade Bandsaw Plans YouTube PDFsanosyÎncă nu există evaluări

- Journal of Dental Research: Water Absorption and Water Solubility of Soft Lining Materials For Acrylic DenturesDocument6 paginiJournal of Dental Research: Water Absorption and Water Solubility of Soft Lining Materials For Acrylic DenturesANJALI TMU StudentÎncă nu există evaluări

- Types of Magnesium Treatment Processes PDFDocument2 paginiTypes of Magnesium Treatment Processes PDFAdrià BorregoÎncă nu există evaluări

- Xuper 2240Document2 paginiXuper 2240Ashis Kumar MohantyÎncă nu există evaluări

- Aluminium AlloyDocument17 paginiAluminium AlloyPrasanth PÎncă nu există evaluări

- Defects - Faults and Remedies of Warping - Textile LearnerDocument4 paginiDefects - Faults and Remedies of Warping - Textile LearnerGOWTHAM CHANDRUÎncă nu există evaluări

- En 12875 5 2006Document8 paginiEn 12875 5 2006Yuttapong LimphaiboonÎncă nu există evaluări

- Concreting Plan: Bauxite Export Project, Guinea - CC - 006Document3 paginiConcreting Plan: Bauxite Export Project, Guinea - CC - 006Gibbs Per70% (10)

- Masterseal 591: Cement Based Fast Setting Mortar For Plugging Active Water LeakageDocument3 paginiMasterseal 591: Cement Based Fast Setting Mortar For Plugging Active Water LeakageDeepak JoyÎncă nu există evaluări

- CONCRETE12121NEWSSDocument22 paginiCONCRETE12121NEWSSMae Coleen LaynoÎncă nu există evaluări

- Solar System Quick Guide-TanzaniaDocument16 paginiSolar System Quick Guide-Tanzaniasos santa anitaÎncă nu există evaluări

- DatabaseDocument112 paginiDatabaseamirulamirÎncă nu există evaluări