Documente Academic

Documente Profesional

Documente Cultură

AI Hempadur AvantGuard

Încărcat de

Amol GoleDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

AI Hempadur AvantGuard

Încărcat de

Amol GoleDrepturi de autor:

Formate disponibile

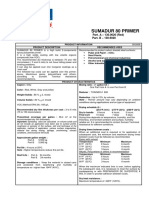

Application Instructions

HEMPADUR AvantGuard 550

1734G: BASE 1734U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 750

1736G: BASE 1736U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 770

17382: BASE 17388 WITH CURING AGENT 98384/

Hempadur Avantguard 860

17990: BASE 17999 with CURING AGENT 98384

For product description, refer to product data sheet HEMPADUR AvantGuard 550 / HEMPADUR AvantGuard 750 / HEMPADUR

AvantGuard 770 / Hempadur Avantguard 860

Scope: These Application Instructions cover surface preparation, application equipment and application details for

HEMPADUR AvantGuard 550, HEMPADUR AvantGuard 750, HEMPADUR AvantGuard 770.and

HEMPADUR AvantGuard 860

Steel work (PSPC): The steel shall preferably be Rust Grade A or B according to ISO 8501-1. The use of steel with Rust

Grade C requires tighter inspection of surface profile after blasting as well as of possible salt

contamination.

The steel surface shall be thoroughly prepared so that the coating achieves an even distribution at the

specified nominal dry film thickness of 50 - 100 micron (please refer to the specifications) and has

adequate adhesion. The final steel condition including welds and edges shall conform to preparation

grade P2, ISO 8501-3: “Preparation of steel substrates before application of paints and related products -

Visual assessment of surface cleanliness”.

Surface preparation: General: In order to obtain best performance, abrasive blast cleaning is recommended.

Abrasive blasting/abrasive sweep blasting: Before blasting any deposits of grease or oil must be removed

from the steel surface with a suitable detergent followed by high pressure fresh water cleaning. Minor spots of

oil/grease may be cleaned with thinner and clean rags - avoid smearing out the contamination. Possible

alkali weld deposits, chemicals used for testing of welds, soap residues from the pressure testing must be

removed by fresh water hosing. Abrasive blasting to Sa 2½ (ISO 8501-1:2007) with a sharp-edged surface

profile corresponding to Rugotest No. 3, BN10a-b, Keane-Tator Comparator, 2.0 G/S, 2 S, or ISO

Comparator, Medium (G).

Spot-repairs: Clean damaged areas thoroughly by power tool cleaning to minimum St 3 or by abrasive

blasting to minimum Sa 2, preferably Sa 2½. As an alternative, water jetting to minimum Wa 2 (ISO 8501-

4:2006) may be used or according to specification. A flash rust degree of maximum M (atmospheric

exposure) (ISO 8501-4:2006) is acceptable before application. Feather edges to sound and intact areas.

Brush off loose material. Touch up to full film thickness.

As for all primers improved surface preparation will improve the performance of HEMPADUR AvantGuard 550,

HEMPADUR AvantGuard 750 HEMPADUR AvantGuard 770.and HEMPADUR AvantGuard 860.

Compatibility: HEMPADUR AvantGuard 550, HEMPADUR AvantGuard 750 and HEMPADUR AvantGuard 770

may be used in connection with other generic paint systems. Contact HEMPEL for further information.

Application equipment: Recommended airless spray equipment:

Pump ratio: min 45:1

Pump output: 12 litres/minute (theoretical)

Input pressure: min. 6 bar/90 psi

Spray hoses: max. 100 metres/300 feet, ½” internal diameter

max. 30 metres/100 feet, 3/8" internal diameter

max. 6 metres/20 feet, 1/4" internal diameter

Filter: minimum mesh size 250 µm/ 10 mil

Regular surfaces: Complicated surfaces (and touch up):

Nozzle size: .017"-.021” Nozzle size: .017"-.021”

Fan angle: 60° Fan angle: 40°

Issued: February 2018 Page: 1/5

Application Instructions

HEMPADUR AvantGuard 550

1734G: BASE 1734U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 750

1736G: BASE 1736U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 770

17382: BASE 17388 WITH CURING AGENT 98384/

Hempadur Avantguard 860

17990: BASE 17999 with CURING AGENT 98384

After finishing the application, clean the equipment immediately with HEMPEL’S TOOL CLEANER 99610.

Note: Increasing hose diameter may ease paint flow thereby improving the spray fan. If longer hoses are

necessary it may be necessary to raise the pump ratio to 60:1, maintaining the high output capacity of the

pump.

Alternatively up to approximately 5-10% THINNER 08450 may be added, but thinning must be done with

care as the maximum obtainable film thickness is reduced significantly by over-thinning.

Spray application: Film-build/continuity: With this paint material applied in one coat a continuous, pinhole-free paint film

should be obtained. An application technique which will ensure good film formation on all surfaces should

be adopted. It is very important to use nozzles of the correct size, not too big, and to have a proper,

uniform distance of the spray gun to the surface, 30-50 cm should be aimed at. Furthermore, great care

must be taken to cover edges, openings, rear sides of stiffeners etc. Thus, on these areas application of a

stripe coat will therefore be good painting practice. To obtain good and steady atomizing, the viscosity of

the paint must be suitable and the spray equipment must be sufficient in output pressure and capacity. At

high working temperatures, use of extra thinner may be necessary to avoid dust-spray.

The paint layer must be applied homogeneously and close to the specification, even though this product

has high tolerance to high dry film thickness.

The finished coating must appear as a homogeneous film and irregularities such as dust, dry spray,

abrasives, should be remedied.

Pot life: Pot life is dependent on temperature – please refer to the tables below for pot life data for a 10 litre mix.

For HEMPADUR AvantGuard 550 1734G

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Pot life 8h 6h 5.5 h 3h 1h 1h

h = hour(s)

For HEMPADUR AvantGuard 750 1736G

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Pot life 8h 5h 5h 4h 3h 1.5 h

h = hour(s)

For HEMPADUR AvantGuard 770 17382

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Pot life 8h 7h 7h 7h 6h 5h

h = hour(s)

For Hempadur Avantguard 860 17990

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Pot life 8h 7h 7h 6h 6h 5h

h = hour(s

Drying times*: For HEMPADUR AvantGuard 550 1734G (60 micron / 2.4 mils)

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Surface dry 50 m 30 m 10 m 10 m 10 m 5m

Through dry 21 h 6h 3.5 h 1.5 h 1h 0.5 h

m = minute(s), h = hour(s)

Issued: February 2018 Page: 2/5

Application Instructions

HEMPADUR AvantGuard 550

1734G: BASE 1734U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 750

1736G: BASE 1736U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 770

17382: BASE 17388 WITH CURING AGENT 98384/

Hempadur Avantguard 860

17990: BASE 17999 with CURING AGENT 98384

For HEMPADUR AvantGuard 750 1736G (60 micron / 2.4 mils)

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Surface dry 50 m 30 m 10 m 10 m 10 m 5m

Through dry 21 h 5h 3.5 h 1.5 h 1h 0.5 h

m = minute(s), h = hour(s)

For HEMPADUR AvantGuard 770 17382 (60 micron / 2.4 mils)

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Surface dry 90 m 60 m 30 m 10 m 10 m 5m

Through dry 51 h 9h 6h 3h 2h 1h

m = minute(s), h = hour(s)

For Hempadur Avantguard 860 17990 (60 micron / 2.4 mils)

Temperature -10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Surface dry 150 m 60 m 30 m 15 m 10 m 5m

Through dry 18 h 8h 4h 3h 2h 1h

m = minute(s), h = hour(s)

* Drying times vary with film thickness.

Overcoating interval: HEMPADUR AvantGuard 550 1734G (60 micron /2.4 mils):

Surface temperature

Environment

-10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Min Max Min Max Min Max Min Max Min Max Min Max

Overcoating with HEMPADUR

Mild 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Medium 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Severe 4h 56 d 2h 42 d 1.5 h 28 d 1h 14 d 45 m 7 d 30 m 3 d

Overcoating with HEMPATHANE

Mild 4h 90 d 2h 90 d 1.5 h 60 d 1h 30 d 45 m 14 d 30 m 7 d

Medium 4h 56 d 2h 42 d 1.5 h 28 d 1h 14 d 45 m 7 d 30 m 3 d

Severe 4h 20 d 2h 15 d 1.5 h 10 d

5d 1h

45 m 2.5 d 30 m 1 d

d = day(s); m = minute(s), h = hour(s)

*Depending on actual local conditions, the long maximum overcoating intervals may vary.

Contact HEMPEL for more information.

HEMPADUR AvantGuard 750 1736G (60 micron /2.4 mils):

Surface temperature

Environment

-10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Min Max Min Max Min Max Min Max Min Max Min Max

Overcoating with HEMPADUR

Mild 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Medium 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Issued: February 2018 Page: 3/5

Application Instructions

HEMPADUR AvantGuard 550

1734G: BASE 1734U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 750

1736G: BASE 1736U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 770

17382: BASE 17388 WITH CURING AGENT 98384/

Hempadur Avantguard 860

17990: BASE 17999 with CURING AGENT 98384

Severe 4h 90 d 2h 90 d 1.5 h 60 d 1h 30 d 45 m 14 d 30 m 7 d

Overcoating with HEMPATHANE

Mild 4h 90 d 2h 90 d 1.5 h 60 d 1h 30 d 45 m 14 d 30 m 7 d

Medium 4h 56 d 2h 42 d 1.5 h 28 d 1h 14 d 45 m 7 d 30 m 3 d

Severe 4h 20 d 2h 15 d 1.5 h 10 d

5d 1h 45 m 2.5 d 30 m 1 d

d = day(s); m = minute(s), h = hour(s)

*Depending on actual local conditions, the long maximum overcoating intervals may vary.

Contact HEMPEL for more information.

HEMPADUR AvantGuard 770 17382 (60 micron /2.4 mils):

Surface temperature

Environment

-10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Min Max Min Max Min Max Min Max Min Max Min Max

Overcoating with HEMPADUR

Mild 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Medium 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Severe 4h 90 d 2h 90 d 1.5 h 60 d 1h 30 d 45 m 14 d 30 m 7 d

d = day(s); m = minute(s), h = hour(s)

Hempadur Avantguard 860 17990 (60 micron /2.4 mils):

Surface temperature

Environment

-10°C/14°F 0°C/32°F 10°C/50°F 20°C/68°F 30°C/86°F 40°C/104°F

Min Max Min Max Min Max Min Max Min Max Min Max

Overcoating with HEMPADUR

Mild 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Medium 4h Ext.* 2h Ext.* 1.5 h Ext.* 1h Ext.* 45 m Ext.* 30 m Ext.*

Severe 4h 90 d 2h 90 d 1.5 h 60 d 1h 30 d 45 m 14 d 30 m 7 d

d = day(s); m = minute(s), h = hour(s)

*Depending on actual local conditions, the long maximum overcoating intervals may vary.

Contact HEMPEL for more information.

Maximum overcoating intervals:

If the maximum overcoating interval is exceeded, whatever the subsequent coat, roughening of the

surface is necessary to ensure optimum intercoat adhesion or in the case of overcoating with coatings

other than HEMPADUR, apply a (thin) additional coat of a HEMPADUR quality within the following

directions for overcoating:

• Long overcoating intervals:

A completely clean surface is mandatory to ensure intercoat adhesion, especially in the case of

long overcoating intervals. Any dirt, oil and grease have to be removed with e.g. suitable

detergent followed by high pressure fresh water cleaning. Salts are to be removed by fresh water

hosing.

• Any degraded surface layer, as a result of a long exposure period, must be removed as

well. Water jetting may be relevant to remove any degraded surface layer and may also replace

the above-mentioned cleaning methods when properly executed. Consult HEMPEL for specific

advice if in doubt.

Issued: February 2018 Page: 4/5

Application Instructions

HEMPADUR AvantGuard 550

1734G: BASE 1734U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 750

1736G: BASE 1736U WITH CURING AGENT 97043/

HEMPADUR AvantGuard 770

17382: BASE 17388 WITH CURING AGENT 98384/

Hempadur Avantguard 860

17990: BASE 17999 with CURING AGENT 98384

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Material Safety Data Sheets and follow all local or national safety regulations. Avoid

inhalation, avoid contact with skin and eyes, and do not swallow. Take precautions against possible risks

of fire or explosions as well as protection of the environment. Apply only in well ventilated areas.

Issued by: HEMPEL A/S – 1734G19840/1736G19840/1738210830/1799019840

These Application Instructions supersede those previously issued.

For explanations, definitions and scope see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data

sheet represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the

actual conditions of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise

expressly agreed in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence,

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as

recommended above, on the overleaf or otherwise. Product data are subject to change without notice and become void five years from the date of issue.

Issued: February 2018 Page: 5/5

S-ar putea să vă placă și

- Hempel AI - English - 1736GDocument5 paginiHempel AI - English - 1736GM. Zaki RahmaniÎncă nu există evaluări

- For Product Description, Refer To Product Data Sheet HEMPADUR Avantguard 550 / Hempadur Avantguard 750 / Hempadur Avantguard 770 / Hempadur Avantguard 860Document5 paginiFor Product Description, Refer To Product Data Sheet HEMPADUR Avantguard 550 / Hempadur Avantguard 750 / Hempadur Avantguard 770 / Hempadur Avantguard 860Vishnu MohanÎncă nu există evaluări

- HEMPADUR AvantGuard product data sheetDocument4 paginiHEMPADUR AvantGuard product data sheetJuan EstebanÎncă nu există evaluări

- HEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetDocument3 paginiHEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetAnuar SalehÎncă nu există evaluări

- Profile Requirements: 30 75 in Case of Full or Partial Blast CleaningDocument3 paginiProfile Requirements: 30 75 in Case of Full or Partial Blast CleaningIsabelo AbaoÎncă nu există evaluări

- 130.0020 - Sumadur 80 PrimerDocument2 pagini130.0020 - Sumadur 80 Primerhelioxavier2Încă nu există evaluări

- PDS Hempaprime Multi 500 Winter en-GBDocument2 paginiPDS Hempaprime Multi 500 Winter en-GBFreddyÎncă nu există evaluări

- MS GF 35870 en-GBDocument2 paginiMS GF 35870 en-GBLinnie McleodÎncă nu există evaluări

- PDS Hempadur Fast Dry 15560 en-GBDocument2 paginiPDS Hempadur Fast Dry 15560 en-GBErwin MalmsteinÎncă nu există evaluări

- PDS Hempaprime Multi 500 Summer en-GBDocument2 paginiPDS Hempaprime Multi 500 Summer en-GBFreddyÎncă nu există evaluări

- HEMPADUR SPEED-DRY ZP 500 Product Data SheetDocument3 paginiHEMPADUR SPEED-DRY ZP 500 Product Data SheetDHANOOPÎncă nu există evaluări

- PDS Hempadur Multi-Strength 35842 en-GBDocument2 paginiPDS Hempadur Multi-Strength 35842 en-GBIfrahimÎncă nu există evaluări

- Product Data Sheet for HEMPADUR 85671 Epoxy CoatingDocument3 paginiProduct Data Sheet for HEMPADUR 85671 Epoxy CoatingvitharvanÎncă nu există evaluări

- HEMPADUR ZINC 15360 15360 en-GB PDFDocument2 paginiHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinÎncă nu există evaluări

- Ai Hempel's Hs Gas Pipe Coating 87831 EnglishDocument2 paginiAi Hempel's Hs Gas Pipe Coating 87831 EnglishNarendraÎncă nu există evaluări

- Hempadur Zinc 17360Document2 paginiHempadur Zinc 17360Bang OchimÎncă nu există evaluări

- Sigmashield 880Document6 paginiSigmashield 880Vijay KumarÎncă nu există evaluări

- Pds Hempadur 35900 En-GbDocument2 paginiPds Hempadur 35900 En-Gbluisbarrios104Încă nu există evaluări

- HEMPADUR 47182 47182 en-GB PDFDocument3 paginiHEMPADUR 47182 47182 en-GB PDFwilfran villegasÎncă nu există evaluări

- 68 HsDocument3 pagini68 HsAsociacion Mexicana para la Prevencion de las EnfermedadesÎncă nu există evaluări

- SGP 880 HS Antifouling Paint Protects Hulls Up to 90 MonthsDocument2 paginiSGP 880 HS Antifouling Paint Protects Hulls Up to 90 MonthsAlvaro Iparraguirre NavarroÎncă nu există evaluări

- 200hs UkDocument4 pagini200hs UkAhmed IbrahimÎncă nu există evaluări

- Sigmaprime® 200 Series: Product Data SheetDocument7 paginiSigmaprime® 200 Series: Product Data SheetkaleshÎncă nu există evaluări

- New Guard Coatings Group Protects with Epoxy PrimersDocument8 paginiNew Guard Coatings Group Protects with Epoxy PrimersshunanlatheefÎncă nu există evaluări

- Product DataDocument2 paginiProduct DatapoerwntiÎncă nu există evaluări

- Amercoat 68HS Zinc Rich Epoxy CoatingDocument3 paginiAmercoat 68HS Zinc Rich Epoxy CoatingAlberto Rosa MarÎncă nu există evaluări

- Amercoat 68HSDocument7 paginiAmercoat 68HSVijay KumarÎncă nu există evaluări

- Sigmacover 280 (Primer) For HDG SurfaceDocument6 paginiSigmacover 280 (Primer) For HDG SurfaceRauf AliyevÎncă nu există evaluări

- Hempadur 15553 two-component epoxy primerDocument2 paginiHempadur 15553 two-component epoxy primerachusanachuÎncă nu există evaluări

- APCS-20A HempelDocument10 paginiAPCS-20A HempelarjunmohananÎncă nu există evaluări

- Pds Hempadur 15590 En-GbDocument2 paginiPds Hempadur 15590 En-Gbyasararafat12010Încă nu există evaluări

- Intercure 200HS: Rapid Recoat EpoxyDocument4 paginiIntercure 200HS: Rapid Recoat EpoxySubham SahuÎncă nu există evaluări

- Hi - Temp 900Document5 paginiHi - Temp 900bhavesh solankiÎncă nu există evaluări

- 870 UkDocument4 pagini870 UkAhmed IbrahimÎncă nu există evaluări

- Amercoat 78HBDocument6 paginiAmercoat 78HBVijay KumarÎncă nu există evaluări

- Amercoat 68hsvocDocument6 paginiAmercoat 68hsvocVijay KumarÎncă nu există evaluări

- Eh6280 (HS)Document2 paginiEh6280 (HS)anminsungÎncă nu există evaluări

- Epoxy Finish Coat Protects Steel StructuresDocument2 paginiEpoxy Finish Coat Protects Steel StructuresRifat AzadÎncă nu există evaluări

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 paginiPDS Hempadur Multi-Strength 45753 en-GBJosip LasanÎncă nu există evaluări

- Amercoat 68 HsDocument7 paginiAmercoat 68 HsdharamgurnaniÎncă nu există evaluări

- Pds Hempadur Multi-Strength GF 35870 En-GbDocument3 paginiPds Hempadur Multi-Strength GF 35870 En-GbThines KumarÎncă nu există evaluări

- Hempadur Avantguard 550Document2 paginiHempadur Avantguard 550Anuar SalehÎncă nu există evaluări

- PDS en-GB 45751Document2 paginiPDS en-GB 45751Anuar SalehÎncă nu există evaluări

- Interline 850 PDFDocument4 paginiInterline 850 PDFaqeelÎncă nu există evaluări

- HempelDocument2 paginiHempelAnuar SalehÎncă nu există evaluări

- Hempadur Fast Dry 17410 En-GbDocument2 paginiHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaÎncă nu există evaluări

- High-Zinc Epoxy Primer Product DataDocument2 paginiHigh-Zinc Epoxy Primer Product DatasizmaruÎncă nu există evaluări

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 paginiHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- 770 UkDocument4 pagini770 UkAhmed IbrahimÎncă nu există evaluări

- Hempadur 15553Document2 paginiHempadur 15553EngTamerÎncă nu există evaluări

- HEMPADUR PRIMER 15300 Product Data SheetDocument3 paginiHEMPADUR PRIMER 15300 Product Data SheetvitharvanÎncă nu există evaluări

- Hempadur 15130Document2 paginiHempadur 15130MuthuKumarÎncă nu există evaluări

- Intershield803 MDSDocument4 paginiIntershield803 MDSSahanÎncă nu există evaluări

- E Program Files An ConnectManager SSIS TDS PDF Interfine 629 Eng A4 20151012Document4 paginiE Program Files An ConnectManager SSIS TDS PDF Interfine 629 Eng A4 20151012Theophilus ThistlerÎncă nu există evaluări

- AI Hempadur Spray-Guard 35490 English PDFDocument4 paginiAI Hempadur Spray-Guard 35490 English PDFKhyle Laurenz Duro0% (1)

- Interline 850+ds+eng PDFDocument4 paginiInterline 850+ds+eng PDFMohamed NouzerÎncă nu există evaluări

- Soldering electronic circuits: Beginner's guideDe la EverandSoldering electronic circuits: Beginner's guideEvaluare: 4.5 din 5 stele4.5/5 (9)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Extended Abstract Ana FernandesDocument10 paginiExtended Abstract Ana FernandesVukasin LisaninÎncă nu există evaluări

- Measuring Soil Infiltration RatesDocument2 paginiMeasuring Soil Infiltration RatesAmol GoleÎncă nu există evaluări

- ConnectionDocument3 paginiConnectionAmol GoleÎncă nu există evaluări

- Material Safety Data SheetDocument4 paginiMaterial Safety Data SheetAmol Gole50% (4)

- Annexture 1-MG - STAAD.Document5 paginiAnnexture 1-MG - STAAD.Amol GoleÎncă nu există evaluări

- CV761 04 Traffic Loading and VolumeDocument52 paginiCV761 04 Traffic Loading and VolumeBhaskerBanu100% (1)

- Amol Gole - Resume - 20181112Document3 paginiAmol Gole - Resume - 20181112Amol GoleÎncă nu există evaluări

- Permissible Stress Level of Brick Masonry Under Compressive Cyclic LoadingDocument7 paginiPermissible Stress Level of Brick Masonry Under Compressive Cyclic LoadingAmol GoleÎncă nu există evaluări

- STAAD - PRO - Single PoleDocument2 paginiSTAAD - PRO - Single PoleAmol GoleÎncă nu există evaluări

- Structural design calculation for switchgear panel base frameDocument3 paginiStructural design calculation for switchgear panel base frameAmol GoleÎncă nu există evaluări

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document6 paginiTable of Material Properties For Structural Steel S235, S275, S355, S420Amol GoleÎncă nu există evaluări

- Col DesignDocument3 paginiCol DesignAmol GoleÎncă nu există evaluări

- Land Conservation and Restoration Report - Yachini Project (Eng Version)Document28 paginiLand Conservation and Restoration Report - Yachini Project (Eng Version)Amol GoleÎncă nu există evaluări

- The 20 Ultimate 20 Pullout 20 Capacity 20 of 20 Anchors 20 in 20 Frictional 20 SoilsDocument18 paginiThe 20 Ultimate 20 Pullout 20 Capacity 20 of 20 Anchors 20 in 20 Frictional 20 SoilsAmol GoleÎncă nu există evaluări

- 14 330SoilClassification PDFDocument40 pagini14 330SoilClassification PDFMartin Andrade100% (2)

- SHALLOW FOUNDATIONS March 19Document61 paginiSHALLOW FOUNDATIONS March 19Amol GoleÎncă nu există evaluări

- UnoffDocument31 paginiUnoffHeang BorinÎncă nu există evaluări

- Land Conservation and Restoration Report - Yachini Project (Eng Version)Document28 paginiLand Conservation and Restoration Report - Yachini Project (Eng Version)Amol GoleÎncă nu există evaluări

- 1 s2.0 S2452321617303232 MainDocument8 pagini1 s2.0 S2452321617303232 MainAmol GoleÎncă nu există evaluări

- British Steel Sections Datasheets PDFDocument18 paginiBritish Steel Sections Datasheets PDFAmol GoleÎncă nu există evaluări

- SHALLOW FOUNDATIONS March 19Document61 paginiSHALLOW FOUNDATIONS March 19Amol GoleÎncă nu există evaluări

- Mechanical and Physcial Properties of Fibre Cement Board PDFDocument5 paginiMechanical and Physcial Properties of Fibre Cement Board PDFanhnguyenhaiÎncă nu există evaluări

- 390x90x190 Hollow Block 7.5 N MM2Document1 pagină390x90x190 Hollow Block 7.5 N MM2Amol GoleÎncă nu există evaluări

- Screed ConcreteDocument3 paginiScreed ConcreteAmol GoleÎncă nu există evaluări

- Receipt PDFDocument1 paginăReceipt PDFAmol GoleÎncă nu există evaluări

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 paginiHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Bending Strength of Deep Corrugated Steel Panels PDFDocument34 paginiBending Strength of Deep Corrugated Steel Panels PDFAmol GoleÎncă nu există evaluări

- MCR GA Commented PDFDocument1 paginăMCR GA Commented PDFAmol GoleÎncă nu există evaluări

- Screed ConcreteDocument3 paginiScreed ConcreteAmol GoleÎncă nu există evaluări

- Annexture 2 - Grade Slab Design (Egyptian Code)Document4 paginiAnnexture 2 - Grade Slab Design (Egyptian Code)Amol GoleÎncă nu există evaluări

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsDocument10 paginiEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangÎncă nu există evaluări

- Chalk & TalkDocument6 paginiChalk & TalkmathspvÎncă nu există evaluări

- Kevin Chiu - Solving Procrastination v1.1Document2 paginiKevin Chiu - Solving Procrastination v1.1TêteHauteÎncă nu există evaluări

- 10 ExtSpringsDocument27 pagini10 ExtSpringsresh27Încă nu există evaluări

- Motorship Oct 2023Document56 paginiMotorship Oct 2023Sahil PakhaliÎncă nu există evaluări

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDocument9 paginiKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanÎncă nu există evaluări

- Application of EbwDocument11 paginiApplication of Ebwsuman kumarÎncă nu există evaluări

- Mini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler ModulesDocument2 paginiMini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler Moduleslejlas77Încă nu există evaluări

- Capacitor BanksDocument49 paginiCapacitor BanksAmal P RaviÎncă nu există evaluări

- Writing Emails Part 1 Informal British English Teacher Ver2Document7 paginiWriting Emails Part 1 Informal British English Teacher Ver2Madalina MandiucÎncă nu există evaluări

- Report Card of Army Public School StudentDocument2 paginiReport Card of Army Public School StudentRama KrishnaÎncă nu există evaluări

- CA 1 - Đề thi AV5 - CLC - Made - efDocument5 paginiCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenÎncă nu există evaluări

- Carl Rogers, Otto Rank, and "The BeyondDocument58 paginiCarl Rogers, Otto Rank, and "The BeyondAnca ElenaÎncă nu există evaluări

- Tiger AnddragonDocument61 paginiTiger AnddragonAdil SiddiquiÎncă nu există evaluări

- Get Started On Creating Your Event Budget:: If You Decide To Build Your Own Start by Creating A Few ColumnsDocument4 paginiGet Started On Creating Your Event Budget:: If You Decide To Build Your Own Start by Creating A Few ColumnsGeomarkPaalaMortelÎncă nu există evaluări

- Computers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiDocument12 paginiComputers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiQuỳnh NguyễnÎncă nu există evaluări

- Planning Dirty FrameworkDocument62 paginiPlanning Dirty FrameworkHoàng Hoa Dương100% (1)

- Advances in X-Ray Analysis - Volume 33 - 1989Document685 paginiAdvances in X-Ray Analysis - Volume 33 - 1989CVÎncă nu există evaluări

- Acer Veriton S480G Service ManualDocument90 paginiAcer Veriton S480G Service ManualAndreea Georgiana ChirilaÎncă nu există evaluări

- Explosive Ordnance DisposalDocument13 paginiExplosive Ordnance DisposalZelwisÎncă nu există evaluări

- Curriculum Vitae: Name: Mobile: EmailDocument3 paginiCurriculum Vitae: Name: Mobile: EmailRākesh RakhiÎncă nu există evaluări

- Exoskeleton Power Requirements Based on Human BiomechanicsDocument54 paginiExoskeleton Power Requirements Based on Human Biomechanicsja2ja1Încă nu există evaluări

- Five Sheets For Technology PlanDocument16 paginiFive Sheets For Technology Planapi-200984070Încă nu există evaluări

- Samsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingDocument47 paginiSamsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingOuadghiri Badre Ddine50% (2)

- Veiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inDocument8 paginiVeiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inYakov Mario QuinterosÎncă nu există evaluări

- Configure NTP, OSPF, logging and SSH on routers R1, R2 and R3Document2 paginiConfigure NTP, OSPF, logging and SSH on routers R1, R2 and R3Lars Rembrandt50% (2)

- CA Ashish Dewani - Resume-1Document2 paginiCA Ashish Dewani - Resume-1Payal JainÎncă nu există evaluări

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDocument7 paginiPlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteÎncă nu există evaluări

- CP QB PT-3 Harish KumarDocument3 paginiCP QB PT-3 Harish KumarVISHNU7 77Încă nu există evaluări

- Clinical TeachingDocument29 paginiClinical TeachingJeonoh Florida100% (2)