Documente Academic

Documente Profesional

Documente Cultură

P.O.Box 261 Owings Mills, MD 21117 USA

Încărcat de

Renny Devassy0 evaluări0% au considerat acest document util (0 voturi)

6 vizualizări1 paginăt17

Titlu original

t17u

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentt17

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

6 vizualizări1 paginăP.O.Box 261 Owings Mills, MD 21117 USA

Încărcat de

Renny Devassyt17

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

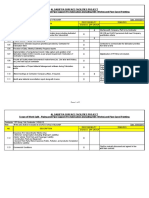

M ARYLAND METRI C S

P.O.Box 261 Owings Mills, MD 21117 USA

(410)358-3130 (800)638-1830 Faxes: (410)358-3142 (800)872-9329

http://mdmetric.com techinfo@mdmetric.com

TECHNICAL INFORMATION and DATA

Materials for bolts, screws and studs

Property Materials Chemical composition limits Tempering

class and treatment (check analysis) % tempe-

rature

C P S B9) °C

min. max. max. max. max. min.

3.61) – 0,20 0,05 0,06 0,003

4.61) – 0,55 0,05 0,06 0,003

4.81) Carbon steel –

5.61) 0,153) 0,55 0,05 0,06 0,003

5.81) – 0,55 0,05 0,06 0,003

6.81)

8.82) Carbon steel with additives 0,153) 0,40 0,035 0,035

(e.g. Boron or Mn or Cr), 0,003 425

quenched and tempered or

Carbon steel quenched 0,253) 0,55 0,035 0,035

and tempered

9.8 Carbon steel with additives 0,153) 0,35 0,035 0,035

(e.g. Boron or Mn or Cr), 0,003 425

quenched and tempered or

Carbon steel quenched 0,253) 0,55 0,035 0,035

and tempered

10,9 4) Carbon steel with additives 0,153) 0,35 0,035 0,035

(e.g. Boron or Mn or Cr), 0,003 340

quenched and tempered

10.9 5) Carbon steel 0,253) 0,55 0,035 0,035

quenched and tempered or

Carbon steel with additives 0,203) 0,55 0,035 0,035

(e.g. Boron or Mn or Cr), 425

quenched and tempered or

Alloy steel quenched and 0,203) 0,55 0,035 0,035 0,003

tempered7)

12.9 5), 6) Alloy steel quenched and 0,283) 0,50 0,035 0,035 0,003 380

tempered7)

1) Free cutting steel is allowed for these property classes with the following maximum sulfur, phosphorus and

lea contents:

sulfur 0,34%; phosphorus 0,11%; lead 0,35%.

2) For nominal diameters above 20 mm the steels specified for property classe 10.9 may be necessary in

order to achieve sufficient hardenability.

3) In case of plain carbon boron alloyed steel with a carbon content below 0,25% (ladle analysis), the

minimum manganese content shall be 0,6% for property class 8.8 and 0,7% for 9.8 and 10.9.

4) Products shall be additionally identified by underlining the symbol of the property class.

5) For the materials of these property classes, it is intended that there should be a sufficient hardenability to

ensure a structure consisting of aproximately 90% martensite in the core of the threaded sections for the

fasteners in the “as-hardened” condition before tempering.

6) A metallographically detectable white phosphorous enriched layer is not permitted for property class 12.9

on surfaces subjected to tensile stress.

7) This alloy steel shall contain at least one of the following elements in the minimum quantity given:

chromium 0,30%, nickel 0,30%, molybdenum 0,20%, vanadium 0,10%. Where elements are specified in

combinations of two, three or four and have alloy contents less than those given above the limit value to be

applied for classification is 70% of the sum of the individual limit values shown above for the two, three or

four elements concerned.

9) Boron content can reach 0,005% providing that non-effective boron is controlled by titanium and/or

aluminium additions.

T 17 copyright 1998 Maryland Metrics All rights reserved

S-ar putea să vă placă și

- Astm A449Document1 paginăAstm A449Vitor Rigueira de GodoyÎncă nu există evaluări

- Coefficient of Friction Reference Table - Engineer's HandbookDocument4 paginiCoefficient of Friction Reference Table - Engineer's Handbooksafaozhan100% (1)

- Welding Filler Metals For Power Plant EngineeringDocument20 paginiWelding Filler Metals For Power Plant EngineeringShoaib AhmedÎncă nu există evaluări

- Structural Plate Astm A36: Plates, Shapes, and Sheet PilingDocument4 paginiStructural Plate Astm A36: Plates, Shapes, and Sheet Pilingeko kusumoÎncă nu există evaluări

- 888DFHD - 1000kva. Fuel ConsumptionDocument3 pagini888DFHD - 1000kva. Fuel ConsumptionRenny DevassyÎncă nu există evaluări

- Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Carbon, Commercial, Drawing, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument8 paginiSteel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Carbon, Commercial, Drawing, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthIsaac ZTÎncă nu există evaluări

- Chemical Composition Limit (Cast Analysis, %) Tempering Temperature Property Class Material and Heat TreatmentDocument1 paginăChemical Composition Limit (Cast Analysis, %) Tempering Temperature Property Class Material and Heat TreatmentAhmed Saber NassarÎncă nu există evaluări

- 6 Materials: ISO 898-1:2009 (E)Document4 pagini6 Materials: ISO 898-1:2009 (E)Dasith SithiraÎncă nu există evaluări

- Resistance class selection guide for connection screws and studsDocument2 paginiResistance class selection guide for connection screws and studsengfaridmalkÎncă nu există evaluări

- Kapitel 01 DINO Techn TeilDocument12 paginiKapitel 01 DINO Techn TeilAkshay /TEAM-DÎncă nu există evaluări

- Hot-rolled carbon steel data sheetDocument7 paginiHot-rolled carbon steel data sheetwulfgang66Încă nu există evaluări

- Kapitel 01 DINO Techn TeilDocument12 paginiKapitel 01 DINO Techn TeilLê Đức BảoÎncă nu există evaluări

- Titanium Alloys and Their PropertiesDocument14 paginiTitanium Alloys and Their PropertiesMarno PrinslooÎncă nu există evaluări

- Kapitel 01 DINO Techn TeilDocument12 paginiKapitel 01 DINO Techn TeilPetros IosifidisÎncă nu există evaluări

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 paginiApplicable Standards: ASTM A792 ASTM A792 EN10215ersinÎncă nu există evaluări

- Mat 07000-07149 200411Document5 paginiMat 07000-07149 200411Ronaldo Bandeira RodriguesÎncă nu există evaluări

- Requerimientos ABS Pruebas MecanicasDocument7 paginiRequerimientos ABS Pruebas MecanicasGilberto ZamudioÎncă nu există evaluări

- Extracto Norma ASTM A792Document2 paginiExtracto Norma ASTM A792Christian Latorre VielmaÎncă nu există evaluări

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pagini36CrB4 Rod - Wire Rev4 PDFKarthi KeyanÎncă nu există evaluări

- Chemical PropertiesDocument1 paginăChemical PropertiesDanny TriwibowoÎncă nu există evaluări

- ASTM A234 2010 (No Oficial)Document10 paginiASTM A234 2010 (No Oficial)Santiago Loría NavaÎncă nu există evaluări

- Electric Arc Furnace SimulationDocument38 paginiElectric Arc Furnace SimulationGilang Hermawan100% (1)

- Rules For Materials and Welding 2021 AmendmentsDocument29 paginiRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCÎncă nu există evaluări

- Fundamentals of Fabrication WeldingDocument22 paginiFundamentals of Fabrication WeldingKevinÎncă nu există evaluări

- 02.classifications and SpecificationsDocument8 pagini02.classifications and SpecificationsShendi Kiki PratamaÎncă nu există evaluări

- Specification for Precipitation-Hardening Nickel Alloy BarsDocument9 paginiSpecification for Precipitation-Hardening Nickel Alloy BarsrbagriÎncă nu există evaluări

- As1548 Pt46onrlo l20 August2010bDocument3 paginiAs1548 Pt46onrlo l20 August2010bchoopoÎncă nu există evaluări

- Chloride Thresholds by Steel TypeDocument21 paginiChloride Thresholds by Steel Typeshameeka100% (1)

- THERMO-OPTICAL PROPERTIES OF MATERIALSDocument2 paginiTHERMO-OPTICAL PROPERTIES OF MATERIALSMariela BaigorriaÎncă nu există evaluări

- Astm A36 Asme Sa36Document3 paginiAstm A36 Asme Sa36Mohamed IsmailÎncă nu există evaluări

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 paginiAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamÎncă nu există evaluări

- Astm-A519 - 06Document13 paginiAstm-A519 - 06claudiaÎncă nu există evaluări

- DIN 17174 SEAMLESS STEEL TUBES FOR LOW TEMP USEDocument7 paginiDIN 17174 SEAMLESS STEEL TUBES FOR LOW TEMP USEdjmattmÎncă nu există evaluări

- AISI 304 Vs 304L Stainless Steel Properties (UNS S30403) Difference Between 304 and 304L (SS304L)Document6 paginiAISI 304 Vs 304L Stainless Steel Properties (UNS S30403) Difference Between 304 and 304L (SS304L)masoodkamalÎncă nu există evaluări

- Astm A653a 653M 4Document1 paginăAstm A653a 653M 4Barbado BlancoÎncă nu există evaluări

- Forging BasicsDocument9 paginiForging BasicsAl EnggÎncă nu există evaluări

- ASME BPVC - II.A-2017 SA-182/SA-182M: Table 2Document1 paginăASME BPVC - II.A-2017 SA-182/SA-182M: Table 2rajeshÎncă nu există evaluări

- A N D High-Cycle Fatigue Properties of Various Steels Specified in Jis For Machine Structural USEDocument12 paginiA N D High-Cycle Fatigue Properties of Various Steels Specified in Jis For Machine Structural USEKadek Santiari DewiÎncă nu există evaluări

- New 4340 Alloy SteelDocument3 paginiNew 4340 Alloy Steeljimmy julian pava vargasÎncă nu există evaluări

- Application of High Strength Microalloyed Steel in A New Automotive CrankshaftDocument8 paginiApplication of High Strength Microalloyed Steel in A New Automotive Crankshaftsinan alqassabÎncă nu există evaluări

- Design & Process of Steel Bloom: Manganese Chromium TungstenDocument10 paginiDesign & Process of Steel Bloom: Manganese Chromium Tungstenulul farichinÎncă nu există evaluări

- JIS G 4051 (Translation)Document7 paginiJIS G 4051 (Translation)haharameshÎncă nu există evaluări

- ASTM A789 Duplex Stainless TubingDocument10 paginiASTM A789 Duplex Stainless Tubingmathew holeyÎncă nu există evaluări

- B 928 - 03 - Qjkyoc1sruq - PDFDocument11 paginiB 928 - 03 - Qjkyoc1sruq - PDF이동욱Încă nu există evaluări

- Milling Speeds and FeedsDocument1 paginăMilling Speeds and FeedsirinaÎncă nu există evaluări

- Specification Guide: Chrome High Temp Fittings & FlangesDocument4 paginiSpecification Guide: Chrome High Temp Fittings & FlangesAdrian EspinosaÎncă nu există evaluări

- Astm A449Document2 paginiAstm A449RicÎncă nu există evaluări

- A 490M - 03 - Qtq5me0tukveDocument8 paginiA 490M - 03 - Qtq5me0tukveAnderson VelandiaÎncă nu există evaluări

- Alloy Steel Castings Table 1Document16 paginiAlloy Steel Castings Table 1takumi_zÎncă nu există evaluări

- Tabla de MaterialesDocument2 paginiTabla de MaterialesAlan Mauricio InsaustiÎncă nu există evaluări

- Spring Grade 52cr4mo2v ChemicalDocument1 paginăSpring Grade 52cr4mo2v ChemicalSujin SujiÎncă nu există evaluări

- How To Get High Quality Boiler TubesDocument7 paginiHow To Get High Quality Boiler TubesYaneYangÎncă nu există evaluări

- CastMaterials E00510Document6 paginiCastMaterials E00510samir basuniÎncă nu există evaluări

- ZXDocument6 paginiZXPedro SilvaÎncă nu există evaluări

- ASTM A519-96 Seamless Carbon & Alloy Steel Mech TubingDocument12 paginiASTM A519-96 Seamless Carbon & Alloy Steel Mech TubingJoe ScopeliteÎncă nu există evaluări

- Ferrous - Non Ferrous AlloysDocument199 paginiFerrous - Non Ferrous AlloysRehan AfzalÎncă nu există evaluări

- Duplex Stainless SteelDocument17 paginiDuplex Stainless SteelthunderÎncă nu există evaluări

- ASTM A325 Specification GuideDocument3 paginiASTM A325 Specification GuideHector BalderaÎncă nu există evaluări

- Din 17177-79Document8 paginiDin 17177-79savanÎncă nu există evaluări

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonÎncă nu există evaluări

- Project price list for painting worksDocument67 paginiProject price list for painting worksRenny DevassyÎncă nu există evaluări

- OGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Document14 paginiOGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Renny DevassyÎncă nu există evaluări

- 1250 kVA Generator Specs and Performance DataDocument8 pagini1250 kVA Generator Specs and Performance DataRenny DevassyÎncă nu există evaluări

- Tubular Products From Special MetalsDocument26 paginiTubular Products From Special Metalskaveh-bahiraeeÎncă nu există evaluări

- WPS Alloy 625 Strip With Flux EST 236Document1 paginăWPS Alloy 625 Strip With Flux EST 236Renny DevassyÎncă nu există evaluări

- 0400GF Amerlock 400 GF PDS PDFDocument4 pagini0400GF Amerlock 400 GF PDS PDFRenny DevassyÎncă nu există evaluări

- Lincoln Electric ESW Strip Cladding GuideDocument26 paginiLincoln Electric ESW Strip Cladding GuideRenny DevassyÎncă nu există evaluări

- Responsibility Matrix For Shop Piping WorksDocument5 paginiResponsibility Matrix For Shop Piping WorksRenny DevassyÎncă nu există evaluări

- Soudokay Strip Cladding - PrincipesDocument31 paginiSoudokay Strip Cladding - PrincipesRenny DevassyÎncă nu există evaluări

- Weldingguide ENGDocument518 paginiWeldingguide ENGBoris Kozjan0% (1)

- Cummins C350D5 Diesel Generator Data SheetDocument3 paginiCummins C350D5 Diesel Generator Data SheetasdthuÎncă nu există evaluări

- Cummins C900D5 Diesel Generator Data Sheet PDFDocument3 paginiCummins C900D5 Diesel Generator Data Sheet PDFpurushmicroÎncă nu există evaluări

- 0400GF Amerlock 400 GF PDSDocument4 pagini0400GF Amerlock 400 GF PDSRenny DevassyÎncă nu există evaluări

- Garnet IDocument3 paginiGarnet IRenny DevassyÎncă nu există evaluări

- HEMI Cryo Brochure 6 PageDocument6 paginiHEMI Cryo Brochure 6 PageRenny DevassyÎncă nu există evaluări

- Ratnamani - Manufacturing RangeDocument2 paginiRatnamani - Manufacturing RangeRenny DevassyÎncă nu există evaluări

- Tubular Products From Special MetalsDocument26 paginiTubular Products From Special Metalskaveh-bahiraeeÎncă nu există evaluări

- Tubular Products From Special MetalsDocument26 paginiTubular Products From Special Metalskaveh-bahiraeeÎncă nu există evaluări

- Cummins C350D5 Diesel Generator Data SheetDocument3 paginiCummins C350D5 Diesel Generator Data SheetasdthuÎncă nu există evaluări

- Cummins C350D5 Diesel Generator Data SheetDocument3 paginiCummins C350D5 Diesel Generator Data SheetasdthuÎncă nu există evaluări

- 1250 kVA Genset SpecificationsDocument8 pagini1250 kVA Genset SpecificationsRenny DevassyÎncă nu există evaluări

- Compressible Cake Constant Pressure ProfileDocument9 paginiCompressible Cake Constant Pressure ProfileClarence AG YueÎncă nu există evaluări

- Cummins C350D5 Diesel Generator Data SheetDocument3 paginiCummins C350D5 Diesel Generator Data SheetasdthuÎncă nu există evaluări

- Cummins C900D5 Diesel Generator Data Sheet PDFDocument3 paginiCummins C900D5 Diesel Generator Data Sheet PDFpurushmicroÎncă nu există evaluări

- Inspection Certificate EN 10204 PDFDocument0 paginiInspection Certificate EN 10204 PDFkronos39zeusÎncă nu există evaluări

- Cummins C350D5 Diesel Generator Data SheetDocument3 paginiCummins C350D5 Diesel Generator Data SheetasdthuÎncă nu există evaluări

- FILTRACIONDocument14 paginiFILTRACIONantoniojaviermaciasÎncă nu există evaluări

- Friction Factor Formulas For CheresourcesDocument4 paginiFriction Factor Formulas For CheresourcesHarjasa AdhiÎncă nu există evaluări

- T 71 UDocument1 paginăT 71 URenny DevassyÎncă nu există evaluări

- Astm A 335Document5 paginiAstm A 335Jamil SalmanÎncă nu există evaluări

- Standar Elektroda PDFDocument182 paginiStandar Elektroda PDFFakhar WindratamaÎncă nu există evaluări

- PD Cen Iso - TR 15608 - 2013Document16 paginiPD Cen Iso - TR 15608 - 2013Jan-Paul100% (1)

- A Mechanical Aspect of Borides Formed On The AISI 440C Stainless SteelDocument6 paginiA Mechanical Aspect of Borides Formed On The AISI 440C Stainless SteelSergio Fernando Resendiz PerezÎncă nu există evaluări

- Dimensions and tolerances of circlesDocument8 paginiDimensions and tolerances of circlesibouÎncă nu există evaluări

- Steels - Carbon Steels, Mild Steel, Carbon-Manganese Steels, Alloys Steels, Low-Alloy Steels and Micro-Alloy SteelsDocument2 paginiSteels - Carbon Steels, Mild Steel, Carbon-Manganese Steels, Alloys Steels, Low-Alloy Steels and Micro-Alloy SteelsHoangÎncă nu există evaluări

- Aws D3.5-93PV PDFDocument8 paginiAws D3.5-93PV PDFwalter091011Încă nu există evaluări

- TOTIME End Mill (2019-2020) ★定価のみ★最新20190501Document26 paginiTOTIME End Mill (2019-2020) ★定価のみ★最新20190501Anonymous ltmd7gPBÎncă nu există evaluări

- Astm A387 387MDocument3 paginiAstm A387 387MkartsoftÎncă nu există evaluări

- Acero Inoxidable SA 455Document3 paginiAcero Inoxidable SA 455Carlos PosadaÎncă nu există evaluări

- ASTM Piping Codes PDFDocument6 paginiASTM Piping Codes PDFdablu kumarÎncă nu există evaluări

- Explomet PolandDocument6 paginiExplomet PolandLucian CiprianÎncă nu există evaluări

- Overview of Pressure Vessel Design-Instructor's Guide (Carucci)Document137 paginiOverview of Pressure Vessel Design-Instructor's Guide (Carucci)Kittipong PhakakarnÎncă nu există evaluări

- Types of Steel-Grades of SteelDocument7 paginiTypes of Steel-Grades of SteelmabroukÎncă nu există evaluări

- Unit 5 Engineering Alloy Steels DesignationDocument52 paginiUnit 5 Engineering Alloy Steels DesignationYobsan BushuraÎncă nu există evaluări

- Alloying Elements in MetalsDocument22 paginiAlloying Elements in MetalsKenty BoydonÎncă nu există evaluări

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 paginiASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroÎncă nu există evaluări

- Ferrous Alloy Types and PropertiesDocument72 paginiFerrous Alloy Types and PropertiesSneha Kriti100% (3)

- Metal Properties, Characteristics, Uses, and Codes: Subcourse Edition OD1643 7Document97 paginiMetal Properties, Characteristics, Uses, and Codes: Subcourse Edition OD1643 7Albert ArominÎncă nu există evaluări

- Norma Astm A255Document26 paginiNorma Astm A255Moisés Oliveira100% (3)

- Basic Metallurgy For Welding and Fabricating ProfessionalsDocument190 paginiBasic Metallurgy For Welding and Fabricating ProfessionalsdaemsalÎncă nu există evaluări

- 18 Ni (200) MaragingDocument22 pagini18 Ni (200) MaragingsunsirÎncă nu există evaluări

- Catalogo Brossard ParafusosDocument0 paginiCatalogo Brossard ParafusosMarco ViniciusÎncă nu există evaluări

- Microalloyed Steels: Ironmaking & Steelmaking September 2015Document46 paginiMicroalloyed Steels: Ironmaking & Steelmaking September 2015haribabu ampoluÎncă nu există evaluări

- A325MDocument8 paginiA325MmsbarretosÎncă nu există evaluări

- MATERIALS ENGINEERING FUNDAMENTALSDocument16 paginiMATERIALS ENGINEERING FUNDAMENTALSWanasisYenantaÎncă nu există evaluări

- PMI MASTER SMART Determination of Ferrous AlloysDocument22 paginiPMI MASTER SMART Determination of Ferrous AlloysAbhinandan ChatterjeeÎncă nu există evaluări

- Pressure VesselsDocument25 paginiPressure Vesselsmohammed alaa eldinÎncă nu există evaluări