Documente Academic

Documente Profesional

Documente Cultură

Practical Study of Borewell Pump

Încărcat de

Gray FullbusterDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Practical Study of Borewell Pump

Încărcat de

Gray FullbusterDrepturi de autor:

Formate disponibile

PRACTICAL STUDY OF

BOREWELL PUMPS

Borewell pumps are widely known as submersible pumps.

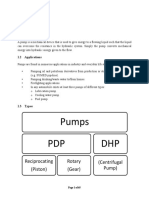

All machines are classified into two types based operation, they are:-

1. POSITIVE DISPLACEMENT MACHINE.

2. ROTODYNAMIC MACHINE/ TURBOMACHINE.

TURBOMACHINES:- It is device where energy is transferred, either from

are to the continuously flowing fluid by the DYNAMIC action of one or

more rotating blade rows.

SUBMERSIBLE PUMPS/ BOREWELL PUMPS:-

A submersible pump is a type of centrifugal pump. In 1928 it was invented

by an engineer ARMAIS ARUTUNOFF( born in Russia and then later

migrated to USA.)

The submersible pumps (SP) is renowned for high efficiency

and reliability. Made entirely of corrosion resistant stainless steel, SP

pumps are ideal for a wide variety of applications. SP pumps represent

state-of-the-art hydraulic design. Built to deliver optimum efficiency

during periods of high demand, SP pumps provide low long-term costs and

high operating reliability regardless of the application.

The SP offers high efficiency, high resistance to

sand and other abrasives, motor burnout protection, and easy maintenance.

A complete monitoring and control system is available for constant

optimization of the pumping system.

STUDY OF THE PARTS IN THE SUBMERSIBLE PUMPS:-

The main parts of a submersible water pump has the following parts:-

1. MOTOR.

2. SHAFT( with key ways).

3. WATER FILTER.

4. IMPELLER.

5. DIFFUSER.

6. CASING.

7. WASHER,HOSING,ALAN SCREWS, etc…

1. MOTOR:- The motor used in the SP is an induction type one.

The exterior of the motor is made up of stainless steel, which is a corrosive

resistant material.

Motor consists of a rotor, shaft, stator, shaft bearings and thrust

bearings and seals , safety valves etc,..

The stator contains copper windings, when the current flows through the

stator windings it produces a rotating magnetic field. Due to this rotating

magnetic field the rotor which encloses the shaft rotates.

This shaft is supported by shaft bearings and thrust bearings to

facilitate the smooth and vibration free motion of the shaft.

To prevent the motor from overheating pressure valves/ safety valves

are provided to the motor which lets the filtered water in and hot water

out the the motor. The pressure sensing mechanism is used to maintain

constant volume of coolant water inside the motor.

2. SHAFT:- The shaft is generally made up of mild steel, if high strength

is required then materials like alloy steels, nickel-chromium steels are

used.

The length of the shaft mainly depends on the horsepower and

stage of the submersible pump.

3. WATER FILTER:- A simple mesh like structure through the water

enters to the pump. It is also made up of stainless steel.

It only allows the water and blocks the entry of particles of certain size

to protect the pump against materials which can damage its functionality.

4. IMPELLER:- It is the rotating element in the SP. It transfers energy

from the motor (which drives the pump) to the water(transferring

kinetic energy) being pumped, through the shaft, in outward direction.

Impeller is firmly mounted on the shaft, which is connected to the

motor through keys, Alan screws and washers.

Impeller has backward curved blades which increases the

efficiency of the pump and reduces the flow deviation of the water.

5. DIFFUSER:- some pumps are provided with diffuser, diffuser is a set

of stationary vane which surrounds the impeller. The purpose of the

diffuser is to convert kinetic energy of the water in pressure head.

The water leaves the impeller with high velocity, this high velocity

water is made to flow through the diffuser. The diffuser vane geometry

is in such a way that it provides a increase flow area to the water, when

water flows through the diffuser this increasing flow area converts

kinetic energy of the water in pressure energy.

(diffuser does

Rotate even

When

Impeller

Rotates)

The impeller-diffuser combination is termed as one stage in submersible

water pump.

6. CASING:- it is the most important part in any turbo machine after

rotating element.

The functions of casing are :-

1. It prevents leakage of the water in the pump.

2. It takes part in the process of energy conversion.

3. It supports the other parts by holding it together.

7. HOSING, WASHERS AND ALAN SCREWS AND KEYS:-

These are some of the joining elements which are used to connect and

join the submersible water pump during its assembly.

ADVANTAGES OF SUBMERSIBLE WATER PUMPS:-

1. There is no need of suction pipe in this pump, as the whole pump is

submerged in the water, the push action of the water takes place due

pressure alone instead of the pull of water.

2. Since the whole pump is under water there is no need of priming in

case of submersible water pump.

3. There is no occurrence of cavitation in this kind of pump as there is

no suction piping here as that of normal centrifugal pump.

4. The efficiency of the pump compared to other pump is significantly

high.

5. The maintenance of this kind of pump is very easy compared to others

Disadvantages of submersible water pump:-

1. Frequent maintenance is required for this kind of pumps, as they are

always under water the outer layer corrodes with time leading to

leakage. So proper selection of materials is required while

manufacturing.

2. The cost of this pump is significantly high.

3. The other main disadvantage is that one pump does not fit all uses.

Single stage pumps are used for most home and light industrial pumping.

This includes aquarium filters, sewage pumping, or sump pumps for

drainage. Multiple stage pumps are used for anything underground, such

as water wells or oil wells.

REFERENCE:-

Place of visit: SRINIVASA ENGINEERING WORKS

CHICKBALLAPUR, NEAR RAILWAY

STATION.

Owner info:

Name: DEVARAJU.(professional in repairing

pumps and motors)

S-ar putea să vă placă și

- Submersible PumpDocument3 paginiSubmersible Pumpeddy brachoÎncă nu există evaluări

- 5 7-PumpsDocument46 pagini5 7-PumpsMohamed Rafeek GhaniÎncă nu există evaluări

- Centrifugal Pump ImpellerDocument4 paginiCentrifugal Pump ImpellerKrunal Patil100% (1)

- Mark 3 ASME Pumps PDFDocument94 paginiMark 3 ASME Pumps PDFInf IngÎncă nu există evaluări

- IWP Frequently Asked Questions BorewellDocument10 paginiIWP Frequently Asked Questions BorewelllehmanwolfÎncă nu există evaluări

- Pump Wisdom: Problem Solving for Operators and SpecialistsDe la EverandPump Wisdom: Problem Solving for Operators and SpecialistsÎncă nu există evaluări

- Centrifugal PumpsDocument5 paginiCentrifugal PumpsNimesh Gunasekera100% (1)

- Arid Land Irrigation in Developing Countries: Environmental Problems and EffectsDe la EverandArid Land Irrigation in Developing Countries: Environmental Problems and EffectsE. Barton WorthingtonÎncă nu există evaluări

- Waste Water PumpsDocument87 paginiWaste Water PumpsGrundfosEgypt100% (4)

- Centrifugal Pump ConstructionDocument39 paginiCentrifugal Pump ConstructionHaryadiÎncă nu există evaluări

- Basic Rolling Bearing TechnologyDocument75 paginiBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- PumpDocument40 paginiPumpbabulu175% (4)

- Some of The Basics You Need To Understand Centrifugal PumpsDocument16 paginiSome of The Basics You Need To Understand Centrifugal PumpsGauravÎncă nu există evaluări

- On-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20Document173 paginiOn-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20kamchorepkÎncă nu există evaluări

- FCCU Slurry Pump Selection Allaire Flowserve FCCU Galveston 2016Document11 paginiFCCU Slurry Pump Selection Allaire Flowserve FCCU Galveston 2016AgungBasoviÎncă nu există evaluări

- Functions of A PumpDocument178 paginiFunctions of A PumpKetan Sarmalkar50% (2)

- An Introduction To Pumping Equipment: Principle, Operation & MaintenanceDocument18 paginiAn Introduction To Pumping Equipment: Principle, Operation & Maintenancegowrisankar32Încă nu există evaluări

- Centrifugal Pumps CourseDocument108 paginiCentrifugal Pumps CoursefotopredicÎncă nu există evaluări

- Vertical Sump PumpDocument6 paginiVertical Sump Pumpsahildhingra100% (1)

- A Centrifugal PumpDocument10 paginiA Centrifugal PumpZain Ulabideen100% (1)

- Pump NotesDocument65 paginiPump NotesMustafa Alweshahi100% (1)

- Jet PumpsDocument7 paginiJet PumpsNazeeh Abdulrhman AlbokaryÎncă nu există evaluări

- Presentation of PumpDocument46 paginiPresentation of PumpArindam SamantaÎncă nu există evaluări

- Type DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument43 paginiType DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar Pumpkprasad_56900Încă nu există evaluări

- Boletin Non ClogDocument12 paginiBoletin Non ClogulisesgeÎncă nu există evaluări

- Flowserve PumpsDocument16 paginiFlowserve Pumpsdavidgaro12100% (1)

- Axial Flow PumpDocument4 paginiAxial Flow Pumpjonayat222100% (2)

- Selecting Centrifugal Pumps DataDocument92 paginiSelecting Centrifugal Pumps DataarvindzdenÎncă nu există evaluări

- Commpressed Air TipsDocument11 paginiCommpressed Air TipsfructoraÎncă nu există evaluări

- Radial Pump Impeller Design ExampleDocument16 paginiRadial Pump Impeller Design ExampleDon Poul JoseÎncă nu există evaluări

- Rain Water Harvesting: by Kashmir Dass BawaDocument40 paginiRain Water Harvesting: by Kashmir Dass BawaAr Ishank SuriÎncă nu există evaluări

- Reading Pump CurvesDocument4 paginiReading Pump CurvesRobert Barrett100% (1)

- Sprinkler Irrigation FinalDocument44 paginiSprinkler Irrigation FinalBirjesh Yaduvanshi100% (1)

- Centrifugal PumpDocument7 paginiCentrifugal PumpTife BakreÎncă nu există evaluări

- Sprinkler Irrigation: By: R. J. PatelDocument81 paginiSprinkler Irrigation: By: R. J. PatelDhruv DholariyaÎncă nu există evaluări

- Methods and Techniques of IrrigationDocument9 paginiMethods and Techniques of IrrigationEmmanuel Sto TomasÎncă nu există evaluări

- Tutorial Centrifugal PumpDocument14 paginiTutorial Centrifugal PumpManea GrosuÎncă nu există evaluări

- Training PumpDocument52 paginiTraining Pumparis mulyana100% (1)

- Midrange Pump Station Design RecommendationsDocument8 paginiMidrange Pump Station Design Recommendationsalan toomeyÎncă nu există evaluări

- Screw PumpDocument12 paginiScrew Pumpemilliomud100% (1)

- Pump Motor TripDocument4 paginiPump Motor TripKamal UddinÎncă nu există evaluări

- Complete Guide On New Borewell Drilling AtoZDocument6 paginiComplete Guide On New Borewell Drilling AtoZJOHN MASEFIELD100% (1)

- Marine Auxiliary Machinery: 4 Positive Displacement PumpsDocument36 paginiMarine Auxiliary Machinery: 4 Positive Displacement PumpsJoshua HicksÎncă nu există evaluări

- Spraying SystemDocument8 paginiSpraying SystemRaul FidalgoÎncă nu există evaluări

- Centrifugal Pump OverloadingDocument2 paginiCentrifugal Pump OverloadingAbdul AlimÎncă nu există evaluări

- Trouble Shooting in Vacuum PumpDocument12 paginiTrouble Shooting in Vacuum Pumpj172Încă nu există evaluări

- 1-6 Types of Pumps and FansDocument43 pagini1-6 Types of Pumps and FansCirky NadleiÎncă nu există evaluări

- Compiled by RabinDocument110 paginiCompiled by RabinRabinÎncă nu există evaluări

- Gear Pump QuestionsDocument2 paginiGear Pump QuestionsChandramohan MuruganÎncă nu există evaluări

- Design of Centrifugal Pump - ImpellerDocument18 paginiDesign of Centrifugal Pump - ImpellerRajib MandalÎncă nu există evaluări

- Centrifugal PumpDocument38 paginiCentrifugal PumpAbdullah Azzam100% (2)

- Fundamentals of Centrifugal PumpsDocument70 paginiFundamentals of Centrifugal PumpsFrancisco GarcíaÎncă nu există evaluări

- Al-Salam Higher Institute For: by Abdelaal Mohamed Khttap Cairo 2014Document28 paginiAl-Salam Higher Institute For: by Abdelaal Mohamed Khttap Cairo 2014عبدوخطابÎncă nu există evaluări

- 01 Chemical ProcessDocument333 pagini01 Chemical ProcessDavid ValladaresÎncă nu există evaluări

- Use of Rice Husk As Fuel in Process Steam BoilersDocument5 paginiUse of Rice Husk As Fuel in Process Steam BoilersHinaAmanÎncă nu există evaluări

- PUMPS 1-NotesDocument16 paginiPUMPS 1-NotesPortifer Harrison Ray Mubanga100% (1)

- PumpsDocument124 paginiPumpsantonyale90% (10)

- 400免费咨询电话:400-188-5009 400 Free consultation Tel:400-188-5009Document16 pagini400免费咨询电话:400-188-5009 400 Free consultation Tel:400-188-5009Chi Kit PhoonÎncă nu există evaluări

- FMM PDFDocument17 paginiFMM PDFOmkar LohakareÎncă nu există evaluări

- Liquid Rocket Engines Centrifugal Flow Turbo PumpsDocument124 paginiLiquid Rocket Engines Centrifugal Flow Turbo Pumpsapi-3827338100% (1)

- Pump VLR-16Document2 paginiPump VLR-16Nguyễn Hoàng PhúcÎncă nu există evaluări

- EIEPD Design CriteriaDocument125 paginiEIEPD Design CriteriaLale AğayevaÎncă nu există evaluări

- HVAC Pump Handbook, Second Edition - Access Engineering From McGraw-HillDocument7 paginiHVAC Pump Handbook, Second Edition - Access Engineering From McGraw-HillamigdalÎncă nu există evaluări

- Submersible Pump Research PaperDocument8 paginiSubmersible Pump Research Paperjcrfwerif100% (1)

- Sffeco Pumps Ul PDFDocument16 paginiSffeco Pumps Ul PDFMd.Asif Hassan Shipo100% (1)

- Pump Engineering MSRODocument2 paginiPump Engineering MSROLeonel RubioÎncă nu există evaluări

- Introduction of Pump and Mechanical SealsDocument38 paginiIntroduction of Pump and Mechanical SealsakhilakaÎncă nu există evaluări

- MT180e - V1.2Document161 paginiMT180e - V1.2Ilhamz100% (1)

- Process Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001Document15 paginiProcess Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001m4metzÎncă nu există evaluări

- Ipmg B SF DSH 1005 03Document5 paginiIpmg B SF DSH 1005 03sgh1355Încă nu există evaluări

- Staggered ImpellerDocument7 paginiStaggered ImpellerhariradhakrishnanÎncă nu există evaluări

- CH 12 Turbomachines (Compatibility Mode)Document30 paginiCH 12 Turbomachines (Compatibility Mode)abbas6063Încă nu există evaluări

- LCHS - Oil Tanker For - TPM - 1Document65 paginiLCHS - Oil Tanker For - TPM - 1zz100% (1)

- NB 50-160-169 (167) - 60m3-h. 38m. 11KW PDFDocument4 paginiNB 50-160-169 (167) - 60m3-h. 38m. 11KW PDFViệt Đặng XuânÎncă nu există evaluări

- Pptonpumpspresentedbytamanash 131003045133 Phpapp01Document26 paginiPptonpumpspresentedbytamanash 131003045133 Phpapp01Buddy EkoÎncă nu există evaluări

- API STD 610, 12ed., Jan. 2021 - Centrifugal Pumps For Petroleum, Petrochemical, and Natural Gas IndustriesDocument108 paginiAPI STD 610, 12ed., Jan. 2021 - Centrifugal Pumps For Petroleum, Petrochemical, and Natural Gas Industriesabdeslem mouloudjÎncă nu există evaluări

- Calculation and Specification of Bilge System: Design Iv Machinery System Department of Marine EngineeringDocument36 paginiCalculation and Specification of Bilge System: Design Iv Machinery System Department of Marine EngineeringAfanda Dwi R RÎncă nu există evaluări

- 1-1/2 Self-Priming Centrifugal Pumps: 888-Amt-Pump (268-7867)Document2 pagini1-1/2 Self-Priming Centrifugal Pumps: 888-Amt-Pump (268-7867)joravicaÎncă nu există evaluări

- 4.16 Clear Water High Lift Pump HouseDocument4 pagini4.16 Clear Water High Lift Pump HousePrasenjit DeyÎncă nu există evaluări

- CDLF Catalogue GuomeipumpDocument7 paginiCDLF Catalogue Guomeipumpanon_6965157Încă nu există evaluări

- Experiment 2: CPD 30302 Pilot Plant Operation 2 JULY 2018Document10 paginiExperiment 2: CPD 30302 Pilot Plant Operation 2 JULY 2018Muhammad Al-baihaqiÎncă nu există evaluări

- Oil Tanker Cargo WorkDocument12 paginiOil Tanker Cargo WorkAshutosh Singh100% (4)

- Chem ENgg Board Exam QuestionsDocument42 paginiChem ENgg Board Exam QuestionsAllyana Marie TiemsimÎncă nu există evaluări

- Pump FirePumps BDocument12 paginiPump FirePumps BAshok SrivatsanÎncă nu există evaluări

- 2CP PDFDocument8 pagini2CP PDFM Zeeshan HaiderÎncă nu există evaluări

- Importance of Right Pump SelectionDocument3 paginiImportance of Right Pump SelectionsahildhingraÎncă nu există evaluări

- T.E MechanicalDocument62 paginiT.E MechanicalhaptooorÎncă nu există evaluări