Documente Academic

Documente Profesional

Documente Cultură

Department of Chemical Engineering (IIT Delhi)

Încărcat de

Vaidh Prakash Choudhary0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări1 paginăThe student is working on a project to study the role of catalyst support in tri-reforming of methane. During the reporting period, the student researched catalyst recipes and novel supports discussed in recent literature. Plans were made to synthesize MgAl2O4 and MgAl2O4 with ZrO2 supports, and load them with Ni and Rh for testing. Future work includes simulating the reaction, characterizing synthesized catalysts, and conducting experiments while analyzing products online using GC-FID. The supervisor's feedback on performance was satisfactory.

Descriere originală:

fortnight

Titlu original

Fortnight 2

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe student is working on a project to study the role of catalyst support in tri-reforming of methane. During the reporting period, the student researched catalyst recipes and novel supports discussed in recent literature. Plans were made to synthesize MgAl2O4 and MgAl2O4 with ZrO2 supports, and load them with Ni and Rh for testing. Future work includes simulating the reaction, characterizing synthesized catalysts, and conducting experiments while analyzing products online using GC-FID. The supervisor's feedback on performance was satisfactory.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări1 paginăDepartment of Chemical Engineering (IIT Delhi)

Încărcat de

Vaidh Prakash ChoudharyThe student is working on a project to study the role of catalyst support in tri-reforming of methane. During the reporting period, the student researched catalyst recipes and novel supports discussed in recent literature. Plans were made to synthesize MgAl2O4 and MgAl2O4 with ZrO2 supports, and load them with Ni and Rh for testing. Future work includes simulating the reaction, characterizing synthesized catalysts, and conducting experiments while analyzing products online using GC-FID. The supervisor's feedback on performance was satisfactory.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Department of Chemical Engineering (IIT Delhi)

B.Tech. Major Project Part-1 / Part-II (CLD 411/412/413/414/415)

Fortnight Report No.: FR1/FR2/FR3/FR4/FR5/FR6 (tick the right one) Date: 23/08/2019

Student Name: Amit Entry No.: 2016CH10077 Group No.: 4

Choudhary

Project Title: Role of Support in Tri-Reforming of Methane

Objectives:

Comparative Analysis of the effect of support on TRM and Optimizing the CO/H2

ratio to 1:2.

Summary of work done:

During the past week, focus was on the recipe of catalyst synthesis and the novel catalysts

discussed in recent literature.

Discussion with Prof. K.K. Pant Sir highlighted that in the industries sintering of the catalyst at

high temperatures is observed which results in the h < 0.01, resulting in a diffusion limited

reaction. So, support design becomes important parameter. Literature review gives the loading of

the active material in the range of 5-15%. So, planning to wet impregnate the catalyst with active

material using suitable nitrate salts. In addition to that, also thinking to load about 0.1% of Rh

along with Ni (at 8,12,15%).

Synthesis of support – MgAl2O4 with and without Zirconia (ZrO2) at different composition. For

this, MgCO3 can be calcined to yield MgO and it can be dry mixed with the Alumina. For other

one, one can calcine the Zirconia-nitrate hexahydrate first and use MgO and Alumina. After this

the mixture can be calcined at different rates (800oC for 10hr OR 1000oC for 8hr). The catalyst

structure can then be studied using the XRD data. The best support can then be loaded with the

active metal. To prevent the formation of Hydrotalcites, we would keep the concentration of MgO

less than that of the Alumina.

For the case of Thermodynamic analysis, taking into account the Boudouard reaction for the

deposition of the carbon (becomes important at higher temperature), along with the tri-reforming

reaction, the WGS reaction and the decomposition of methane and the hydrolysis and oxidation

of the C-deposited.

We also looked for the MgIn2O4 as a catalyst, the literature gives an inverse spinel structure

which is quite similar to the MgAl2O4. Therefore, the experimentation will begin from coming

Wednesday. This discussion is left with Pant Sir to proceed with MgAl2O4 or MgIn2O4 for the

case of novelty of support.

Future plan:

Simulate the tri-reforming reaction on MATLAB to understand its thermodynamic analysis.

Synthesize the catalyst with and without Zirconia in the support to understand the differences in

performance. Characterization of support via XRD. Then loaded catalyst characterization by XRD,

SEM_EDX, TEM, TGA, CO2-TPD and BET-Surface Area techniques.

Run the experiments with controlled flow of the gases (flue gas, Oxygen, Methane & Steam).

Analyze the results online using GC-FID and get the conversion.

Comments on Performance: Satisfactory Average Unsatisfactory

(to be filled up by BTP supervisor or his nominee in case supervisor is out of station)

Name of Supervisor: Signature of Supervisor:

S-ar putea să vă placă și

- 1995 S320 S420 S500 Owner's Manual Edition C PDFDocument153 pagini1995 S320 S420 S500 Owner's Manual Edition C PDFnpachecorecabarrenÎncă nu există evaluări

- Air Pollution - Maximum Mixing Depth and Ventilation CoefficientDocument3 paginiAir Pollution - Maximum Mixing Depth and Ventilation Coefficientgabinuang275% (8)

- Double Effect EvaporatorDocument9 paginiDouble Effect EvaporatorVaidh Prakash ChoudharyÎncă nu există evaluări

- Chem 1211 Lab ReportDocument9 paginiChem 1211 Lab Reportansleybarfield0% (1)

- IJHE Article in Press-2Document9 paginiIJHE Article in Press-2vthiagu90_267718230Încă nu există evaluări

- Jurnal 3 FixDocument9 paginiJurnal 3 FixfransescatomasilaÎncă nu există evaluări

- کنفرانس2Document6 paginiکنفرانس2Maryam S MotallebipourÎncă nu există evaluări

- Enhancement Low Temperature NH3 SCR Activity of The Fe MN Mo - 2023 - MolecularDocument11 paginiEnhancement Low Temperature NH3 SCR Activity of The Fe MN Mo - 2023 - MolecularDana MateiÎncă nu există evaluări

- Ijaret 06 10 020Document16 paginiIjaret 06 10 020IAEME PublicationÎncă nu există evaluări

- Ali Pour 2014Document6 paginiAli Pour 2014Marcus NguyễnÎncă nu există evaluări

- Fabrication of Ag Po /tio Composite and Its Photodegradation of Formaldehyde Under Solar RadiationDocument9 paginiFabrication of Ag Po /tio Composite and Its Photodegradation of Formaldehyde Under Solar Radiationcesafilho.idtÎncă nu există evaluări

- Chem Select 2020, 5, 3805-3814Document1 paginăChem Select 2020, 5, 3805-3814Malaya SahooÎncă nu există evaluări

- Download Morphology Effect Of Mno2 Promoter To The Catalytic Performance Of Pt Toward Methanol Electrooxidation Reaction Yuan Yuan Feng Gui Hua Song Qiang Zhang Jian Ning Lv Xi Yu Hu Yu Long He Xin full chapterDocument30 paginiDownload Morphology Effect Of Mno2 Promoter To The Catalytic Performance Of Pt Toward Methanol Electrooxidation Reaction Yuan Yuan Feng Gui Hua Song Qiang Zhang Jian Ning Lv Xi Yu Hu Yu Long He Xin full chapterwilliam.farmer998100% (15)

- J Ijhydene 2018 06 123Document12 paginiJ Ijhydene 2018 06 123Wassachol SumarasinghaÎncă nu există evaluări

- Methane Steam Reforming On Supported Nickel, Effect of Nickel Content For Product HydrogenDocument8 paginiMethane Steam Reforming On Supported Nickel, Effect of Nickel Content For Product HydrogenChikaÎncă nu există evaluări

- Engineering Pt-Mn2O3 Interface To Boost Selective Oxidation of Ethylene Glycol To Glycolic AcidDocument11 paginiEngineering Pt-Mn2O3 Interface To Boost Selective Oxidation of Ethylene Glycol To Glycolic Acid63011373Încă nu există evaluări

- Zhao 2004Document7 paginiZhao 200463011273Încă nu există evaluări

- Sedighi 2015Document7 paginiSedighi 2015Amir RahbariÎncă nu există evaluări

- Chemical Engineering Science 228 (2020) 115967 - JhonyDocument11 paginiChemical Engineering Science 228 (2020) 115967 - JhonyJhony Ramos GarciaÎncă nu există evaluări

- SBA-15 Support SynthesizingDocument13 paginiSBA-15 Support SynthesizingmarviÎncă nu există evaluări

- 3 - Intermetallic Compounds of Ni and Ga As Catalysts For The Synthesis of MethanolDocument12 pagini3 - Intermetallic Compounds of Ni and Ga As Catalysts For The Synthesis of Methanoltunganh1110Încă nu există evaluări

- Chem Select 2020, 5, 3805-3814Document10 paginiChem Select 2020, 5, 3805-3814Malaya SahooÎncă nu există evaluări

- M Urashima 2016Document7 paginiM Urashima 2016Paulo Ernesto MarcheziÎncă nu există evaluări

- Full Length Article: SciencedirectDocument12 paginiFull Length Article: SciencedirectAmir RahbariÎncă nu există evaluări

- Catalysts 10 01240 v2Document24 paginiCatalysts 10 01240 v2Khalil SukurÎncă nu există evaluări

- Catalytic Effect of Lead Oxide Nano-And Microparticles On Thermal Decomposition Kinetics of Energetic Compositions Containing Tegdn/Nc/DagDocument12 paginiCatalytic Effect of Lead Oxide Nano-And Microparticles On Thermal Decomposition Kinetics of Energetic Compositions Containing Tegdn/Nc/DagSabri AeroChemÎncă nu există evaluări

- Electrocatalysis 2 VTDocument11 paginiElectrocatalysis 2 VTvthiagu90_267718230Încă nu există evaluări

- 7 цитирований Impregnation vs. sol-gel and sol-gel-plasma dispersion of nickel nanoparticles over Al2O3 employed in combined dry reforming and partial oxidation of greenhouse gases to syngasDocument16 pagini7 цитирований Impregnation vs. sol-gel and sol-gel-plasma dispersion of nickel nanoparticles over Al2O3 employed in combined dry reforming and partial oxidation of greenhouse gases to syngasПитон КиришевскийÎncă nu există evaluări

- Dry ReformingDocument13 paginiDry ReformingDana MateiÎncă nu există evaluări

- Studies On Heat and Mass Transfer Limitations in Oxidative Dehydrogenation of Ethane Over CR O /al O CatalystDocument8 paginiStudies On Heat and Mass Transfer Limitations in Oxidative Dehydrogenation of Ethane Over CR O /al O CatalystKapil KhandelwalÎncă nu există evaluări

- One-Pot Hydrothermal Synthesis, Characterization, and Electrochemical Properties of Rgo/Mnfe2O4 NanocompositesDocument8 paginiOne-Pot Hydrothermal Synthesis, Characterization, and Electrochemical Properties of Rgo/Mnfe2O4 NanocompositesjhenyÎncă nu există evaluări

- 21 цитирование Sequential impregnation vs. sol-gel synthesized NiAl2O3-CeO2 nanocatalyst for dry reforming of methane Effect of synthesis method and support promotionDocument10 pagini21 цитирование Sequential impregnation vs. sol-gel synthesized NiAl2O3-CeO2 nanocatalyst for dry reforming of methane Effect of synthesis method and support promotionПитон КиришевскийÎncă nu există evaluări

- Electrochimica ActaDocument11 paginiElectrochimica ActaMarco MarcoÎncă nu există evaluări

- Accepted Manuscript: ApsuscDocument30 paginiAccepted Manuscript: ApsuscAminÎncă nu există evaluări

- Experimental Paper15 AugDocument16 paginiExperimental Paper15 AugAhmad AliÎncă nu există evaluări

- Thiagu IJHE 1Document11 paginiThiagu IJHE 1vthiagu90_267718230Încă nu există evaluări

- Multilateral Characterization For Industrial Ziegler-Natta Catalysts Toward Elucidation of Structure-Performance RelationshipDocument8 paginiMultilateral Characterization For Industrial Ziegler-Natta Catalysts Toward Elucidation of Structure-Performance RelationshipahsanbasherÎncă nu există evaluări

- Preparation and Characterization of Supported Ce - TB Mixed Oxide For Use in TWC CatalystsDocument11 paginiPreparation and Characterization of Supported Ce - TB Mixed Oxide For Use in TWC CatalystsMarcus VSÎncă nu există evaluări

- Applied Catalysis A: GeneralDocument9 paginiApplied Catalysis A: GeneralCatur Budi KusumoÎncă nu există evaluări

- Xaba 2020Document37 paginiXaba 2020Shubhangi ShrivastawaÎncă nu există evaluări

- Maier 2011Document14 paginiMaier 2011raharjo1608Încă nu există evaluări

- 10 1016@j Apsusc 2020 147047Document23 pagini10 1016@j Apsusc 2020 147047Daniel MontalvoÎncă nu există evaluări

- Journal of CO2 Utilization: Cong Shi, Sha Wang, Xiang Ge, Shengxiang Deng, Bin Chen, Jun ShenDocument19 paginiJournal of CO2 Utilization: Cong Shi, Sha Wang, Xiang Ge, Shengxiang Deng, Bin Chen, Jun Shenfarah al-sudaniÎncă nu există evaluări

- Impreso - Leido - 2000 - Siodmiak - Frenking - Korkin - Ini Reacts CVD Ta2O5 TaCl5 H2O Ab Initio StuDocument10 paginiImpreso - Leido - 2000 - Siodmiak - Frenking - Korkin - Ini Reacts CVD Ta2O5 TaCl5 H2O Ab Initio Stuphdeza2000Încă nu există evaluări

- PrecursorsDocument4 paginiPrecursorssimonwadelinÎncă nu există evaluări

- Liu 2015Document24 paginiLiu 2015chintz BhatÎncă nu există evaluări

- Applied Catalysis A: General: P. Sangeetha, K. Shanthi, K.S. Rama Rao, B. Viswanathan, P. SelvamDocument6 paginiApplied Catalysis A: General: P. Sangeetha, K. Shanthi, K.S. Rama Rao, B. Viswanathan, P. SelvamJoha BetancurÎncă nu există evaluări

- 13 - Chapter 6 PDFDocument8 pagini13 - Chapter 6 PDFVenice JaceÎncă nu există evaluări

- Reichenbach 2018Document7 paginiReichenbach 2018Neha NegiÎncă nu există evaluări

- J Ijhydene 2018 04 208Document10 paginiJ Ijhydene 2018 04 208KASHVINWARMA A/L BASKARANÎncă nu există evaluări

- The Facilitating Effect of Sulfide Treatment Coupled So - 2024 - Journal of TheDocument11 paginiThe Facilitating Effect of Sulfide Treatment Coupled So - 2024 - Journal of TheDana MateiÎncă nu există evaluări

- Peyman I 2016Document10 paginiPeyman I 2016peymanÎncă nu există evaluări

- Intrinsic Kinetics of Dimethyl Ether Synthesis From SyngasDocument7 paginiIntrinsic Kinetics of Dimethyl Ether Synthesis From SyngasJayeshÎncă nu există evaluări

- Surface Modi Cation of Magnesium Hydroxide and Its Application in Flame Retardant Polypropylene CompositesDocument9 paginiSurface Modi Cation of Magnesium Hydroxide and Its Application in Flame Retardant Polypropylene CompositesDany HdzÎncă nu există evaluări

- Cat and SelectivitiesDocument5 paginiCat and SelectivitiesadamÎncă nu există evaluări

- Modelling and Simulation of A Fluidized Bed Reactor For Minimum Ammonium Nitrate and Reduction of Nox EmissionsDocument11 paginiModelling and Simulation of A Fluidized Bed Reactor For Minimum Ammonium Nitrate and Reduction of Nox EmissionsMekar MeinaÎncă nu există evaluări

- Mechanistic Investigation of Methane Steam Reforming Over Ce-Promoted Ni/SBA-15 CatalystDocument12 paginiMechanistic Investigation of Methane Steam Reforming Over Ce-Promoted Ni/SBA-15 CatalystDanCosminÎncă nu există evaluări

- Kinetic Model Development For Steam PyroDocument8 paginiKinetic Model Development For Steam PyroAyuanda PutriÎncă nu există evaluări

- 10 цитирований Elucidating the impact of Ni and Co loading on the selectivity of bimetallic NiCo catalysts for Dry Reforming of MethaneDocument35 pagini10 цитирований Elucidating the impact of Ni and Co loading on the selectivity of bimetallic NiCo catalysts for Dry Reforming of MethaneПитон КиришевскийÎncă nu există evaluări

- in Situ Growth of Cop Wrapped by Carbon Nanoarray Like Architecture Onto Nitrogen Doped Ti3C2 PT Based Catalyst For Efficient Methanol Oxidation W Zhan L Ma M Gan Full ChapterDocument34 paginiin Situ Growth of Cop Wrapped by Carbon Nanoarray Like Architecture Onto Nitrogen Doped Ti3C2 PT Based Catalyst For Efficient Methanol Oxidation W Zhan L Ma M Gan Full Chapterdaniel.taylor716100% (7)

- Journal of Hazardous Materials: Zhong Wan, Jianlong WangDocument12 paginiJournal of Hazardous Materials: Zhong Wan, Jianlong WangLucia Medina PimentelÎncă nu există evaluări

- Carbon 06 00052Document17 paginiCarbon 06 00052Elbahi DjaalabÎncă nu există evaluări

- 1 - E Ect of Metal Dispersion and Support Structure ofDocument12 pagini1 - E Ect of Metal Dispersion and Support Structure offarah al-sudaniÎncă nu există evaluări

- Scikit Learn Cheat Sheet PythonDocument1 paginăScikit Learn Cheat Sheet PythonNitesh ChaurasiyaÎncă nu există evaluări

- FortnightDocument1 paginăFortnightVaidh Prakash ChoudharyÎncă nu există evaluări

- ProcessDocument38 paginiProcessVaidh Prakash ChoudharyÎncă nu există evaluări

- Department of Chemical Engineering (IIT Delhi)Document1 paginăDepartment of Chemical Engineering (IIT Delhi)Vaidh Prakash ChoudharyÎncă nu există evaluări

- Subject ApptitudeDocument54 paginiSubject ApptitudeVaidh Prakash ChoudharyÎncă nu există evaluări

- Interfacial EngineeringDocument45 paginiInterfacial EngineeringVaidh Prakash ChoudharyÎncă nu există evaluări

- LH325Document3 paginiLH325Vaidh Prakash ChoudharyÎncă nu există evaluări

- CHDocument2 paginiCHDebottamSarkarÎncă nu există evaluări

- AwardsDocument1 paginăAwardsVaidh Prakash ChoudharyÎncă nu există evaluări

- Flow RateDocument3 paginiFlow RateVaidh Prakash ChoudharyÎncă nu există evaluări

- Gate Syllabus Chemical-EngineeringDocument12 paginiGate Syllabus Chemical-EngineeringVaidh Prakash ChoudharyÎncă nu există evaluări

- pc10 DataDocument3 paginipc10 DataVaidh Prakash ChoudharyÎncă nu există evaluări

- Sportech'19 Infra Proposal 2018Document26 paginiSportech'19 Infra Proposal 2018Vaidh Prakash ChoudharyÎncă nu există evaluări

- CVL100 Minor2 2017-18 Sem2-1Document3 paginiCVL100 Minor2 2017-18 Sem2-1Vaidh Prakash ChoudharyÎncă nu există evaluări

- RDL AssignmentDocument7 paginiRDL AssignmentVaidh Prakash ChoudharyÎncă nu există evaluări

- CVL100 L5 q1 1819Document1 paginăCVL100 L5 q1 1819Vaidh Prakash ChoudharyÎncă nu există evaluări

- L 2: Environmental Impact AssessmentDocument34 paginiL 2: Environmental Impact AssessmentVaidh Prakash ChoudharyÎncă nu există evaluări

- CRE-2 After Minor 1Document32 paginiCRE-2 After Minor 1Vaidh Prakash ChoudharyÎncă nu există evaluări

- Solution Manual - Chemical Process Control by StephanopoulosDocument177 paginiSolution Manual - Chemical Process Control by StephanopoulosVaidh Prakash ChoudharyÎncă nu există evaluări

- CVL100 L5 q1 1819Document1 paginăCVL100 L5 q1 1819Vaidh Prakash ChoudharyÎncă nu există evaluări

- Formula Sheet: Basic Trigonometric IdentitiesDocument4 paginiFormula Sheet: Basic Trigonometric Identitieschetan temkarÎncă nu există evaluări

- Lab 3.1 - Configuring and Verifying Standard ACLsDocument9 paginiLab 3.1 - Configuring and Verifying Standard ACLsRas Abel BekeleÎncă nu există evaluări

- Teaching Tactics and Teaching Strategy: Arthur W. Foshay'Document4 paginiTeaching Tactics and Teaching Strategy: Arthur W. Foshay'Ahmed DaibecheÎncă nu există evaluări

- TitleDocument142 paginiTitleAmar PašićÎncă nu există evaluări

- PS1Document2 paginiPS1Nitesh Kumar DubeyÎncă nu există evaluări

- Mechanism of Muscle ContractionDocument24 paginiMechanism of Muscle Contractionfisika100% (1)

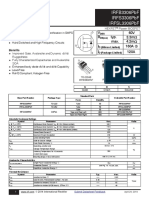

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 paginiIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligÎncă nu există evaluări

- A Tutorial On Spectral Sound Processing Using Max/MSP and JitterDocument16 paginiA Tutorial On Spectral Sound Processing Using Max/MSP and Jittertramazio0% (1)

- DocuDocument77 paginiDocuDon'tAsK TheStupidOnesÎncă nu există evaluări

- Microporous and Mesoporous Materials: SciencedirectDocument8 paginiMicroporous and Mesoporous Materials: SciencedirectAssyakurÎncă nu există evaluări

- NumpyDocument23 paginiNumpymuzammil jawedÎncă nu există evaluări

- DA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFDocument329 paginiDA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFrindy_bilhaniÎncă nu există evaluări

- Solution To QuestionsDocument76 paginiSolution To QuestionsVipul AggarwalÎncă nu există evaluări

- Laboratory Manual: BTY351 Plant Biotechnology LaboratoryDocument40 paginiLaboratory Manual: BTY351 Plant Biotechnology LaboratoryRetik KoulÎncă nu există evaluări

- 307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionDocument12 pagini307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionCARLOS LIMADAÎncă nu există evaluări

- Allison 1,000 & 2,000 Group 21Document4 paginiAllison 1,000 & 2,000 Group 21Robert WhooleyÎncă nu există evaluări

- Periodic Table and AtomsDocument5 paginiPeriodic Table and AtomsShoroff AliÎncă nu există evaluări

- Data Mining ConceptsDocument175 paginiData Mining ConceptsNikolya SmirnoffÎncă nu există evaluări

- AlgebraDocument66 paginiAlgebraOliseyenum Precious ChukuemekeÎncă nu există evaluări

- EXP.2 Enzyme Extraction From BacteriaDocument3 paginiEXP.2 Enzyme Extraction From BacteriaLinhNguyeÎncă nu există evaluări

- Siemens Micromaster 440 Manual PDFDocument312 paginiSiemens Micromaster 440 Manual PDFGustavo Barrera100% (1)

- More Practice Multiple ChoiceDocument3 paginiMore Practice Multiple ChoiceHiÎncă nu există evaluări

- Polya Problem Solving StrategiesDocument12 paginiPolya Problem Solving StrategiesGwandaleana VwearsosaÎncă nu există evaluări

- Cheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESDocument2 paginiCheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESThomas ThomasÎncă nu există evaluări

- Chapter 1 IntroductionDocument49 paginiChapter 1 IntroductionGemex4fshÎncă nu există evaluări

- 3yr-Astro-Properies of StarsDocument35 pagini3yr-Astro-Properies of StarsBharath V YÎncă nu există evaluări

- Creating Attachments To Work Items or To User Decisions in WorkflowsDocument20 paginiCreating Attachments To Work Items or To User Decisions in Workflowselampe100% (1)

- College of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurDocument24 paginiCollege of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurPooja SahuÎncă nu există evaluări