Documente Academic

Documente Profesional

Documente Cultură

Vibration Analysis Iso Cat I DLPDF PDF

Încărcat de

cesarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vibration Analysis Iso Cat I DLPDF PDF

Încărcat de

cesarDrepturi de autor:

Formate disponibile

Mobius Institute

Vibration Analysis Distance Learning

ISO Cat I & ASNT Level I Vibration Analysis

Mobius Institute offers distance learning courses for vibration analysis at the

Category I, II and III level, identical to the instructor-led courses we teach globally.

You can learn at your own pace, with assistance from an instructor, and optionally

take a certification examination at the end of the course.

This 32 hour course is the ideal starting place for new vibration analysts, people

collecting vibration data, and those who want a better understanding of vibration

analysis and condition monitoring. The course exceeds the ISO 18436-2 Category I

standard and meets the ASNT Level I Recommended Practice.

Are you ready to get started in vibration analysis and condition monitoring? You will

enjoy this course!

You will come away with a solid understanding of why we monitor the condition of

rotating machinery (and other critical assets), the importance of improved reliability,

and how the vibration can be successfully measured and analyzed to provide an early

warning of a wide range of fault conditions. You won’t come away as an expert;

that’s what our more advanced courses are for. But you will know enough to make a

valuable contribution to an existing program; be in a position to start a new

program; determine if you should implement a program at your site; or better

understand the program that exists in your plant.

Distance Learning benefits

If the high cost of travel and accommodation and the time away from your family

and work has stopped you from receiving the training that you need, then you

should consider our distance learning courses.

At the time and pace that works best for you, you can take our lessons and learn in a

very similar way to attendees of our classroom courses. This approximately four day

course is available for three months online from the time your register.

Video lessons

Each video has been carefully created and edited so that you receive the full benefit

exactly as you would in a live class – without the distractions. You will see the

instructor talking and see the presentations, animations and simulators being used in

high resolution. You can pause, replay or forward the video so that you can review

any topic as many times as you need. All you need is a good Internet connection and

monitor (1024x768 or better) and you will be ready to start learning.

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

In addition to the lessons, we present hands-on videos that show a variety of

vibration analyzers being used to perform a range of tests.

Mobius makes learning about vibration analysis unique. We use 3D animations, Flash

simulations, and numerous software simulators that completely demystify vibration

analysis. While vibration training courses have traditionally been very theoretical,

difficult to understand, (and boring), you will be captivated by the Mobius Training

methods, and you will enjoy our practical approach. You will take away skills that

you can immediately apply to your job, and you will truly understand what you are

doing. When senior vibration analysts attend our classes they often say “if only I

could have learned this way when I got started” – well, now you can!

Certification

The course follows ISO 1836-2

and ASNT SNT-TC-1A

Recommended Practice for

training and certification of

Category I or Level I vibration

analysts.

Examinations for certification

are offered as an option at

the end of the course.

All Mobius certified analysts receive personalized logos with their certification

number and name for their own professional use. Mobius Institute also maintains a

listing of all certified analysts on mobiusinstitute.com and provides each analyst with

a personal webpage.

Who should attend?

If you have been performing vibration analysis for less than one year, or if you have

been collecting vibration readings and leaving the analysis to another person, then

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

this course is for you. This course is also designed for reliability engineers, PdM

program managers, and other maintenance staff who would like to understand

condition monitoring with a focus on vibration analysis, and take the ISO or ASNT

exam. You will come away from the course with a solid understanding of:

The benefits of performing condition monitoring and improving reliability

The condition monitoring technologies: acoustic emission, infrared analysis

(thermography), oil analysis, wear particle analysis, motor testing

How machines work – via supplementary self-study using the “Equipment

Knowledge” section

Why vibration measurements can tell you about the condition of the

machine

How to collect good, repeatable measurements

What the Fmax, resolution, averaging and other analyzer settings mean

How to analyze vibration spectra, and the basics of fault diagnosis:

unbalance, misalignment, looseness, rolling element bearings faults,

resonance, and other conditions

An introduction to setting alarm limits

Course Description

Duration: 3 months covering 32 hours of Cat I / Level I, Optional Certification

Examination: 2 hours, Invigilation required, 70% Passing Grade

The Introductory Vibration Analysis course is intended for personnel who are new to

vibration monitoring and analysis, and for personnel who have limited vibration

analysis experience. The course focuses on periodic, single channel data collection

and analysis for condition based maintenance programs. A foundation is established

for in-depth understanding of spectrum and waveform relationships. This is the ideal

starting place for new vibration analysts, people collecting vibration data, and those

who want a better understanding of vibration analysis and condition monitoring.

You will come away from this course with a very good understanding of the

fundamentals; you will understand how to take good measurements (and

understand the importance of repeatability); and you will be ready to begin

analyzing vibration spectra. Topics covered include:

Maintenance Practices

First you are taught why we perform vibration analysis, and how it fits into the

maintenance plan. We also emphasize the benefits of condition based maintenance

and a reliability centered approach.

What is breakdown maintenance and when should it be employed?

What is preventive (calendar based) maintenance, and what are its major

flaws?

What is predictive (condition based) maintenance, and what are its benefits?

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

What is proactive (reliability centered) maintenance, and what are its

benefits?

We use a Flash simulator that demonstrates the relationship between

“infant mortality”, breakdown modes, and common maintenance practices –

you may be surprised about what you will learn about preventive

maintenance.

Condition monitoring

Next we summarize vibration analysis and describe five other technologies that can

be utilized to determine the health of rotating machinery, and other key assets such

as switchgear, insulators, compressed air systems, and others. These topics are

summarized in order to give the attendee a working knowledge of each technology.

Acoustic emission (ultrasound):

What is acoustic emission?

What can it tell you about rotating machinery?

How to you detect leaks and electrical faults?

How can it be used to detect bearing faults?

We use a simulator to demonstrate visually and audibly how acoustic

emission tests are performed.

Thermography:

What is thermography?

How can it be used to detect faults in mechanical and electrical equipment?

What is emissivity, and how does it affect the accuracy of the

measurements?

What are the key qualities of thermal imaging cameras?

In addition to lots of thermal images, we have a number of Flash simulations

that clarify the effect of emissivity and environmental conditions on the test

results.

Oil analysis:

How can it be used to check if the machine has a fault condition,

How can you test if the lubricant is “fit for purpose”?

What do viscosity, cleanliness, particle count, and other tests tell you?

Wear particle analysis:

How are the tests performed?

How can you learn about the nature of wear?

How can you determine which components are wearing?

How does it differ from conventional oil analysis?

Motor testing:

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

What are the most common types of faults?

What can motor current analysis tell you?

What other test types tell you about the condition of the rotor, stator, and

insulation?

Vibration analysis:

Quick introduction to vibration analysis

Spectrum versus overall level readings

Walk-around versus on-line monitoring versus protection systems

We use a number of samples of real data, and an excellent simulator that

demonstrates the limitations of the overall level meter (that follows ISO

standards). You won’t believe your ears!

Principles of vibration

Now we get into the details of understanding vibration terminology and basic

theory. This is the first time that the simulators will make a huge difference to your

understanding of the topics covered. You will see exactly where the waveform

comes from, how the spectrum is created, and why machines generate different

frequencies.

Introduction to vibration measurement

A quick introduction to the accelerometer and displacement probes

A quick introduction to the vibration waveform (via live displays)

We use a simulator and an analyzer that displays live vibration from an

accelerometer. We use another simulator to show real data from machines

with faults

An introduction to the time waveform

What is the time waveform?

How does it change with higher and lower frequency

What is frequency and period?

How does it change with amplitude

What are rms, peak and peak-peak?

What happens when the vibration includes multiple frequencies and

amplitudes?

We use a great simulator to demonstrate where the waveform comes from.

We utilize a virtual dial indicator and a strip-chart recorder. You will never

wonder what a waveform is again.

An introduction to the spectrum

What is the spectrum, and what does “FFT” mean

How can a spectrum be used to separate each source of vibration into a

graph that highlights the different frequencies of vibration

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

We use a fantastic simulator that totally demystifies the spectrum. The

spectrum and waveforms are shown in an interactive, 3D simulation. We get

our biggest “ah, ha!” moments here.

An introduction to forcing frequencies

Using units of orders instead of Hz or CPM.

Calculating forcing frequencies

Identifying shaft speed

Blade and vane passing frequencies, bearing frequencies, gearmesh

frequencies, and more

Gear and belt driven machines (multiple shafts with different turning

speeds)

We utilize a couple of great simulators that are used to illustrate how to

calculate forcing frequencies. In one case, you drag and drop machine icons

to calculate all of the frequencies from the machine.

Explaining the different vibration units

What is the difference between acceleration, velocity and displacement?

When would you use each type of unit?

How to convert between each type of unit?

We have two simulators that demonstrate the relationship between these

three parameters. One demonstrates a car and the change in displacement,

velocity and acceleration as it is driven in different ways. And the second

simulator shows how the displacement, velocity and acceleration change

with frequency.

A brief introduction to phase

What is phase (in-phase, out of phase, phase angle)?

Why is it important in vibration analysis?

How is it measured with a single-channel analyzer, two-channel analyzer,

and strobe?

While our simple phase simulator provides a clear demonstration of the

phase difference between two fans, the simulator that demonstrates phase

measurement collection is incredibly popular. You can drag the optical

tachometer onto a virtual machine, and then move the sensor on the

machine to see the phase readings. It can also demonstrate two-channel

and strobe measurements. You have to see it to believe it.

Data acquisition

The next major topic covered is data acquisition. A vibration analysis program will

fail unless the vibration readings are collected correctly. They must be collected from

the correct location on the machine, and they must be collected the same way each

and every time – and that includes the operating conditions of the machine (speed

and load). The Category I vibration analyst should not be the person who decides

how the analyzer should be set up, nor should she/he decide where the

measurements should be taken. However, given that some programs do not have a

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

Category II analyst available, (and it is always important for every vibration analyst to

understand these issues), we do discuss these important points in this section of the

course. Many of the recommendations for measurement locations, analyzer setups

and more come from the ISO standards and the Mobius Recommended Practice.

A quick review of data acquisition

How do we measure vibration?

The non-contact eddy current displacement probe

The velocity probe

The accelerometer

Just wait until you see the 3D animations of the accelerometers, velocity

sensors, and proximity probes.

Where to place the sensor on the machine

A sensible approach

Understanding axial, radial, vertical, and horizontal readings

Do you really need to measure in three axes?

What does one axis tell you that another will not?

A quick introduction to mounting the accelerometer and surface preparation

Comparing handheld probes, magnetic mounts, and quick connect mounts

The 3D animations will highlight the important differences

What do you do if you cannot access the desired measurement point?

Naming conventions

Where is position “1” on the machine?

What does “MNDE” mean?

What are “routes” and how do you create them?

Downloading, following, and uploading routes

Why should you record your field observations when you are in the field

(and why should you listen to the vibration during data collection)?

Recognizing bad data (and deciding what you should do if you get bad data)

Signal processing

This section will take you through a quick tour of the operation of your data

collector/analyzer, explaining some of the terms you will encounter. The analyzer

requires settings to be established for your measurements such as the type and

number of averages, the window type, the Fmax limit, the low frequency high pass

filter setting, and the lines of resolution. This section is not intended to make you an

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

expert; just make you aware of the importance of each setting, and how they will

each impact the measurement quality.

A quick tour of your analyzer

Fmax and lines of resolution (LOR)

The importance of selecting the correct Fmax and lines of resolution?

Spectral averaging

What does averaging do, and why is it important?

You will see a number of simulators that make this potentially complicated topic very

easy to understand. Instead of using overly technical terms and boring slides, the

simulators demonstrate exactly what these settings do, and why they are so

important. You get to see and hear the vibration, and see the final spectra – with

correct and incorrect settings.

Vibration analysis

Now we get into the spectrum analysis process (we will also mention the benefits of

enveloping, time waveform and phase analysis, but you have to wait until Category II

before you learn more about those methods). In this section you will learn how the

spectra can be displayed to determine if a fault condition exists. We discuss a

number of the most common fault conditions, all supported with excellent 3D

animations that demonstrate how the components move when the condition exists.

After this section is complete you should feel very confident that spectrum analysis

can be used to detect these faults, and you will have greater confidence in your

ability to utilize spectrum analysis.

The spectrum analysis process

Four steps to success

The ISO standard

What is resonance – a quick introduction

How does it affect your machines and your measurements

Our resonance movies and simulator will open your eyes to the hidden

threat that lives in every one of your machines and structures.

Diagnosing common fault conditions

Unbalance

Misalignment

Looseness

Rolling element bearing wear

Common electric motor faults

Common pump, fan and compressor faults

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

Mobius Institute

Common belt drive and gearbox faults

Just wait until you see the 3D animations, and the software simulators of the

bearings and gearbox. You will understand exactly why the fault conditions

exist. The special Mobius Institute pen, mouse pad, and pocket reference

guide will help you to remember all of the rules in the future.

Setting alarm limits

One of the keys to a successful vibration analysis programs is the establishment of

good alarm limits. In truth, very few programs have good alarm limits… In this

section we explain how the band alarm and envelope (mask) alarm systems work,

and how you can establish the limits. It is not the job of the Category I analyst to

establish alarm limits, but it is important to understand the challenges involved, and

the important, of setting good alarm limits.

The ISO standard for setting alarms

How to use them

Their limitations

Band alarms

How they can be used to warn you of changes in vibration level

How they can aid your analysis process

Their limitations

Envelope alarms

How they can be used to warn you of changes in vibration level

Their limitations

Using the machine modeler simulator, you will see how the envelope alarms and

band alarms can be established on any machine that you can describe.

Registration

To register for a Mobius Institute course, go to our website at

www.mobiusinstitute.com to see the current calendar of courses and dates online, or

just call one of our sales representatives in N. America at 877.550.3400.

DL Vibration Analysis Cat I Understandable Training … Respected Certification

DLCATI 100310 www.mobiusinstitute.com

www.preditec.com

www.preditec.com

info@preditec.com

+34 976 200 969

S-ar putea să vă placă și

- Understand Vibration Analysis Training in 40 CharactersDocument6 paginiUnderstand Vibration Analysis Training in 40 CharacterscesarÎncă nu există evaluări

- Vibration Analysis Iso Cat III DLPDFDocument8 paginiVibration Analysis Iso Cat III DLPDFWisnuÎncă nu există evaluări

- Iso 18436 Category III Vibration Analyst TrainingDocument4 paginiIso 18436 Category III Vibration Analyst Trainingmaria alejandraÎncă nu există evaluări

- ISO 18436 Category I Vibration Analyst TrainingDocument4 paginiISO 18436 Category I Vibration Analyst TrainingDean LofallÎncă nu există evaluări

- Vibration Analysis Category I (Level 1)Document9 paginiVibration Analysis Category I (Level 1)Choochart ThongnarkÎncă nu există evaluări

- Va Cat III - Velosi A4Document4 paginiVa Cat III - Velosi A4shahbaz akramÎncă nu există evaluări

- ISO 18436 Category III Vibration Analyst TrainingDocument4 paginiISO 18436 Category III Vibration Analyst TrainingDean LofallÎncă nu există evaluări

- Vibration Analysis - Iso Cat II Asnt Level II 1331196230Document3 paginiVibration Analysis - Iso Cat II Asnt Level II 1331196230tylerdurdaneÎncă nu există evaluări

- ISO 18436 Category II Vibration Analyst TrainingDocument4 paginiISO 18436 Category II Vibration Analyst TrainingDean Lofall0% (1)

- Vibration Analysis ISO II + ASNT Level IIDocument5 paginiVibration Analysis ISO II + ASNT Level IIDonald VasquezÎncă nu există evaluări

- Vibration Analysis Iso Cat I Asnt Level I 1305326781 PDFDocument7 paginiVibration Analysis Iso Cat I Asnt Level I 1305326781 PDFVasile NicolauÎncă nu există evaluări

- Vibration Analysis Training: ISO Category II + ASNT Level IIDocument3 paginiVibration Analysis Training: ISO Category II + ASNT Level IIBrent HardeoÎncă nu există evaluări

- Mobius Training Cat IIDocument10 paginiMobius Training Cat IISuhartomt33% (3)

- Vibration Analysis Training & Certification Courses by Predict InstituteDocument7 paginiVibration Analysis Training & Certification Courses by Predict InstitutefaisalÎncă nu există evaluări

- Vibration Analyis Course Information 2020 PDFDocument6 paginiVibration Analyis Course Information 2020 PDFramy thaerÎncă nu există evaluări

- Mobius Institute Vibration BrochureDocument21 paginiMobius Institute Vibration Brochurechris strieglÎncă nu există evaluări

- Time Waveform Analysis CourseDocument4 paginiTime Waveform Analysis CourseDean LofallÎncă nu există evaluări

- VibMatters Current Issue PDFDocument16 paginiVibMatters Current Issue PDFjuancgr77Încă nu există evaluări

- Pdfcoffee.com Mobius Training Cat II PDF FreeDocument10 paginiPdfcoffee.com Mobius Training Cat II PDF FreeArkajyoti DharÎncă nu există evaluări

- Csi Ds TrainingandcertifDocument20 paginiCsi Ds TrainingandcertifElvis Alberto Rodriguez BravoÎncă nu există evaluări

- Mobius Institute Ultrasound Brochure June 2022Document10 paginiMobius Institute Ultrasound Brochure June 2022nino16041973Încă nu există evaluări

- ISO 18436 Category IV Vibration Analyst TrainingDocument4 paginiISO 18436 Category IV Vibration Analyst TrainingDean Lofall0% (1)

- Pruftechnik Training Courses Calendar 2012Document13 paginiPruftechnik Training Courses Calendar 2012sithulibraÎncă nu există evaluări

- 2020 Training Courses BrochureDocument7 pagini2020 Training Courses BrochurehasnaÎncă nu există evaluări

- Gearbox Vibration Analysis - Analysis Techniques: The Peril of Wall Chart' AnalystsDocument18 paginiGearbox Vibration Analysis - Analysis Techniques: The Peril of Wall Chart' AnalystsRICARDO OLIVEROÎncă nu există evaluări

- Vibration Training Brochure - 2018Document24 paginiVibration Training Brochure - 2018Madhan KannanÎncă nu există evaluări

- VibMatters Current Issue PDFDocument20 paginiVibMatters Current Issue PDFPedada AdityaÎncă nu există evaluări

- ISO Category II PDFDocument1 paginăISO Category II PDFArif FadilahÎncă nu există evaluări

- Machinery Fault Diagnosis and Signal Processing Course OverviewDocument16 paginiMachinery Fault Diagnosis and Signal Processing Course OverviewAdeoti OladapoÎncă nu există evaluări

- Gearbox Vibration Analysis - Forcing Frequencies: 16 Things Many Vibration Analysts Don't Do (But They Should)Document19 paginiGearbox Vibration Analysis - Forcing Frequencies: 16 Things Many Vibration Analysts Don't Do (But They Should)Pedro RosaÎncă nu există evaluări

- Training Schedule RegisterDocument9 paginiTraining Schedule RegisterahmedÎncă nu există evaluări

- 2011 Training Schedule VIDocument24 pagini2011 Training Schedule VIHarold AlconzÎncă nu există evaluări

- 10 Steps To Successful Explicit Dynamic AnalysisDocument6 pagini10 Steps To Successful Explicit Dynamic AnalysisEquitus EngÎncă nu există evaluări

- 4X Diagnostics 2017 Courses PDFDocument6 pagini4X Diagnostics 2017 Courses PDFHero VinothÎncă nu există evaluări

- Shock and Vibration Overview Ebook PDFDocument69 paginiShock and Vibration Overview Ebook PDFAna Isabel PradoÎncă nu există evaluări

- 8 Endaq Shock Vibration Overview Ebook Guía Rápida VibracionesDocument69 pagini8 Endaq Shock Vibration Overview Ebook Guía Rápida VibracionesAndres Felipe Rodriguez JimenezÎncă nu există evaluări

- 73 - Vibration Training Brochure 2016Document22 pagini73 - Vibration Training Brochure 2016satfasÎncă nu există evaluări

- Vibration Matters June 2017Document15 paginiVibration Matters June 2017mara2proletaÎncă nu există evaluări

- VA - Vibration BrochureDocument5 paginiVA - Vibration BrochureQuoc LeHoaiÎncă nu există evaluări

- Automatic Diagnosis: Guide For Maintenance Supervisors & Reliability EngineersDocument15 paginiAutomatic Diagnosis: Guide For Maintenance Supervisors & Reliability EngineersKaiser46Li206Încă nu există evaluări

- Summer Training Report: Maharaja Surajmal Institute of TechnologyDocument35 paginiSummer Training Report: Maharaja Surajmal Institute of TechnologyHarsh JhaÎncă nu există evaluări

- Training CatalogDocument35 paginiTraining Catalogkarthikeyan1992Încă nu există evaluări

- TDS1 12.x Lesson TranscriptDocument28 paginiTDS1 12.x Lesson Transcriptkirangangadari527Încă nu există evaluări

- Instructional Planning: Curriculum GuideDocument14 paginiInstructional Planning: Curriculum GuideANTHONY GAMBOAÎncă nu există evaluări

- Iso 18436Document2 paginiIso 18436knsvel20000% (3)

- Control Sensors Module Code 6EJ518Document15 paginiControl Sensors Module Code 6EJ518Umer EhsanÎncă nu există evaluări

- 2030 Student GuideDocument326 pagini2030 Student GuideZach Brownfield100% (1)

- Exfo Catalog Be-An-Expert-Training enDocument16 paginiExfo Catalog Be-An-Expert-Training enAbdulmoied OmarÎncă nu există evaluări

- Instructor Manual (5G-Small Cell Deployment Training)Document258 paginiInstructor Manual (5G-Small Cell Deployment Training)elmoustaphaelÎncă nu există evaluări

- Vibration Analysis TrainingDocument2 paginiVibration Analysis TrainingVeeresh Nayak VeereshÎncă nu există evaluări

- Getting Approval To Deliver Managing Safely v5Document6 paginiGetting Approval To Deliver Managing Safely v5eastÎncă nu există evaluări

- Managing Safely course delivers safety training successDocument6 paginiManaging Safely course delivers safety training successZahid KamalÎncă nu există evaluări

- Workplace Ergonomics ProgramDocument16 paginiWorkplace Ergonomics ProgramKoutuk MogerÎncă nu există evaluări

- Reliability, Maintenance, Integrity & Inspection Engineering - Best PracticesDocument4 paginiReliability, Maintenance, Integrity & Inspection Engineering - Best Practiceselif demirelÎncă nu există evaluări

- Behaviour Based SafetyDocument3 paginiBehaviour Based SafetyOmesh K SharmaÎncă nu există evaluări

- REAL TIME SLEEP DROWSINESS DETECTION ProDocument15 paginiREAL TIME SLEEP DROWSINESS DETECTION ProYash NehraÎncă nu există evaluări

- Debugging Playbook: System Testing, Error Localization, And Vulnerability RemediationDe la EverandDebugging Playbook: System Testing, Error Localization, And Vulnerability RemediationÎncă nu există evaluări

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningDe la EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningEvaluare: 4.5 din 5 stele4.5/5 (2)

- Service Desk Analyst Bootcamp: Maintaining, Configuring And Installing Hardware And SoftwareDe la EverandService Desk Analyst Bootcamp: Maintaining, Configuring And Installing Hardware And SoftwareÎncă nu există evaluări

- Hacking with Kali: Practical Penetration Testing TechniquesDe la EverandHacking with Kali: Practical Penetration Testing TechniquesEvaluare: 4 din 5 stele4/5 (6)

- Vibration Shakers 2Document5 paginiVibration Shakers 2aal_shurafaÎncă nu există evaluări

- Condition monitoring and predictive maintenance in mining using vibration analysisDocument4 paginiCondition monitoring and predictive maintenance in mining using vibration analysisaal_shurafaÎncă nu există evaluări

- Electrical Safety QuizDocument2 paginiElectrical Safety QuizRehman MuzaffarÎncă nu există evaluări

- Machine Vibration TutorialDocument12 paginiMachine Vibration TutorialabhishekÎncă nu există evaluări

- Accelerometer - SKF CMSS 2200 Data Sheet of CurveDocument2 paginiAccelerometer - SKF CMSS 2200 Data Sheet of Curveaal_shurafa0% (1)

- Probe Mounting RequirementsDocument1 paginăProbe Mounting Requirementsaal_shurafaÎncă nu există evaluări

- Hi-903 Hardy Shaker: Installation ManualDocument33 paginiHi-903 Hardy Shaker: Installation Manualaal_shurafaÎncă nu există evaluări

- IvibeDocument2 paginiIvibeaal_shurafaÎncă nu există evaluări

- Brochure Noria TrainingDocument24 paginiBrochure Noria Trainingaal_shurafa100% (1)

- Save $20K Monthly on Oil CostsDocument12 paginiSave $20K Monthly on Oil CostsJose ChuchulloÎncă nu există evaluări

- Machine Vibration TutorialDocument12 paginiMachine Vibration TutorialabhishekÎncă nu există evaluări

- Noria Training CatalogDocument28 paginiNoria Training Catalogaal_shurafaÎncă nu există evaluări

- AP Physics B - Waves and SoundDocument17 paginiAP Physics B - Waves and SoundshaheerdurraniÎncă nu există evaluări

- Mobius Vibration Analysis Global Skill ShortageDocument8 paginiMobius Vibration Analysis Global Skill Shortageaal_shurafaÎncă nu există evaluări

- Waves Unit Catch A Wave!Document35 paginiWaves Unit Catch A Wave!aal_shurafaÎncă nu există evaluări

- Waves and Sound Waves in WaterDocument6 paginiWaves and Sound Waves in Wateraal_shurafaÎncă nu există evaluări

- Alignment Standard Press ReleaseDocument2 paginiAlignment Standard Press Releaseaal_shurafaÎncă nu există evaluări

- Introduction To VibrationDocument9 paginiIntroduction To Vibrationaal_shurafaÎncă nu există evaluări

- Cm5043 Why SKF-MCMDocument1 paginăCm5043 Why SKF-MCMaal_shurafaÎncă nu există evaluări

- CM2012 Optical Phase Kit From SKFDocument2 paginiCM2012 Optical Phase Kit From SKFaal_shurafaÎncă nu există evaluări

- AME Flow Chart for Freshmen to Senior Year Course SequenceDocument1 paginăAME Flow Chart for Freshmen to Senior Year Course Sequenceaal_shurafaÎncă nu există evaluări

- Exhibitor Overview For 2014 VIDocument1 paginăExhibitor Overview For 2014 VIaal_shurafaÎncă nu există evaluări

- Don BentleyDocument1 paginăDon Bentleyaal_shurafaÎncă nu există evaluări

- CM3035 MCM Accel Enveloping Enveloped Acceleration With The Mechanical Condition Monitor (MCM)Document2 paginiCM3035 MCM Accel Enveloping Enveloped Acceleration With The Mechanical Condition Monitor (MCM)aal_shurafa0% (1)

- Certificate Conformity Saudi Arabia ExportDocument1 paginăCertificate Conformity Saudi Arabia Exportaal_shurafaÎncă nu există evaluări

- 2013 Certification Handbook - FINAL - 020613Document28 pagini2013 Certification Handbook - FINAL - 020613DanielAvellanedaÎncă nu există evaluări

- Differential Expansion TCM 12-21465Document4 paginiDifferential Expansion TCM 12-21465aal_shurafa100% (1)

- A1016-Rotate 4 Pages Brochure WebDocument4 paginiA1016-Rotate 4 Pages Brochure Webaal_shurafaÎncă nu există evaluări

- IIR Rotate 13 Final AgendaDocument2 paginiIIR Rotate 13 Final Agendaaal_shurafaÎncă nu există evaluări

- HP EliteBook 2540P Compal LA-5251P Swatch-UMA Rev 0.9 SchematicsDocument47 paginiHP EliteBook 2540P Compal LA-5251P Swatch-UMA Rev 0.9 SchematicsRama MamethÎncă nu există evaluări

- Autonomous Vehicles RRLDocument8 paginiAutonomous Vehicles RRLDominique LopenaÎncă nu există evaluări

- Chap5 - Samsung LTE-LSM Overview and PracticeDocument221 paginiChap5 - Samsung LTE-LSM Overview and Practiceabhay100% (2)

- Chlorination General SpecsDocument8 paginiChlorination General Specsraghuwanshi12Încă nu există evaluări

- Hive Nano 2 Hub User GuideDocument6 paginiHive Nano 2 Hub User GuideLuis Armando Campos BarbaÎncă nu există evaluări

- PCS-9705 Bcu - V1.00Document29 paginiPCS-9705 Bcu - V1.00Bharath ErÎncă nu există evaluări

- L1+L2+L3-Project Integration Management2Document45 paginiL1+L2+L3-Project Integration Management2MASOUDÎncă nu există evaluări

- Better Ansible Network Automation With Roles and Custom ModulesDocument22 paginiBetter Ansible Network Automation With Roles and Custom Modulesstanislaw.jachuraÎncă nu există evaluări

- Search Engine MarketingDocument7 paginiSearch Engine Marketingyuvaraj321321Încă nu există evaluări

- Students' Attitudes Towards Science and Expectations of Science Related CareersDocument37 paginiStudents' Attitudes Towards Science and Expectations of Science Related CareersFitriyani SaparangÎncă nu există evaluări

- Curriculum PDFDocument5 paginiCurriculum PDFstephen villaruzÎncă nu există evaluări

- Android Studio Cookbook - Sample ChapterDocument21 paginiAndroid Studio Cookbook - Sample ChapterPackt Publishing100% (1)

- Smart Automated Irrigation System Seminar ReportDocument30 paginiSmart Automated Irrigation System Seminar ReportSCOC53 Parth NegiÎncă nu există evaluări

- DevLIVE PresentationDocument53 paginiDevLIVE PresentationGeneva LozadaÎncă nu există evaluări

- Vivado Basic TutorialDocument30 paginiVivado Basic Tutorial8885684828Încă nu există evaluări

- Radio Shack 20-314 Aka Pro-79 Scanner Owners ManualDocument52 paginiRadio Shack 20-314 Aka Pro-79 Scanner Owners Manualeh2677Încă nu există evaluări

- Social Media Marketing in IndiaDocument23 paginiSocial Media Marketing in IndiaYash MandaliaÎncă nu există evaluări

- Electrical Safety Analyzer: 6Huylfh0DqxdoDocument52 paginiElectrical Safety Analyzer: 6Huylfh0Dqxdoservice serviceÎncă nu există evaluări

- Azure FundamentalsDocument5 paginiAzure FundamentalsRamziÎncă nu există evaluări

- TQMDocument2 paginiTQMMahaveer SepatÎncă nu există evaluări

- Spare Parts Reliance Taxiway Edge L 861tlDocument22 paginiSpare Parts Reliance Taxiway Edge L 861tlMarcelo DilerniaÎncă nu există evaluări

- Logistics and Supply Chain Management Unit-3Document24 paginiLogistics and Supply Chain Management Unit-3AkhiÎncă nu există evaluări

- Social Media Safety TipsDocument5 paginiSocial Media Safety TipsIthran IthranÎncă nu există evaluări

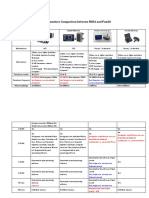

- Main Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayDocument3 paginiMain Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayAsep RifkyÎncă nu există evaluări

- Serial IO and Data CommunicationDocument25 paginiSerial IO and Data Communicationapi-3724082100% (8)

- Hoosier Tire Midwest-PlymouthDocument2 paginiHoosier Tire Midwest-PlymouthAkbar SatrioÎncă nu există evaluări

- IIT Bombay Spoken Tutorials For ICT Training in Schools: Value To The SchoolDocument2 paginiIIT Bombay Spoken Tutorials For ICT Training in Schools: Value To The SchoolmanaliÎncă nu există evaluări

- PM Range Brochure - NORELDocument4 paginiPM Range Brochure - NORELESUSTENTALÎncă nu există evaluări

- Course Guide - Legal Instruments For The Protection of ChildrenDocument4 paginiCourse Guide - Legal Instruments For The Protection of ChildrenSherwin Buenavente SulitÎncă nu există evaluări

- PAPSCU Toolkit PDFDocument81 paginiPAPSCU Toolkit PDFIzelia Montes Aballe MaquilingÎncă nu există evaluări