Documente Academic

Documente Profesional

Documente Cultură

New Seminar PDF

Încărcat de

9730389172vijaypatoleTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

New Seminar PDF

Încărcat de

9730389172vijaypatoleDrepturi de autor:

Formate disponibile

SAVITRIBAI PHULE PUNE UNIVERSITY

ACKNOWLEDGEMENT

A seminar project is a golden opportunity for learning and self-

development. I consider myself very lucky and honored to have so many

wonderful people who lead me through in completion of the project.

First of all I would like to thank my parents who are my true

inspiration .It is all their love and hard work which makes it possible for

me to study and work without any hardships.

My grateful thanks to Prof. Ramesh Rudrapati, who inspire me of being

busy with his duties, took time out to hear, guide and keep me on correct

path .A humble thank you sir.

Prof. N S Biradar,HOD, monitored my progress and arranged all

facilities. I chose this moment to acknowledge his contribution gratefully.

Last but not the least there were so many who shared valuable info that

helped me in successful completion of this report.

Tushar Diwate

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

SAVITRIBAI PHULE PUNE UNIVERSITY

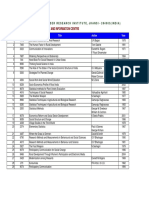

INDEX

SR. CONTENTS PAGE

NO NO

1 Introduction 1

2 Literature Review 2

3 Journal Bearing 4

4 Friction in journal bearing 6

4.1 Friction coefficient in journal bearing 6

4.2 Pressure in journal bearing 7

4.3 Effect of oil pressure and groove position on fluid 8

friction

4.4 And torque of journal bearing 8

Methodology for determining coefficient of

friction and torque analysis 8

4.4.1 Journal bearing test rig 11

Experimental result

4.4.2

5 Lubrication in journal bearing 14

Gas lubrication 14

5.1 Effects of gas lubrication on frictional behavior of 14

bearing 15

5.2 Optimal parameters 16

Advantages and disadvantages of gas lubrication 17

5.3 Palm oil and mineral oil 17

Evaluate the effect of curved surface in wear and

5.4 friction

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

SAVITRIBAI PHULE PUNE UNIVERSITY

6 Conclusion 20

7 References 21

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

SAVITRIBAI PHULE PUNE UNIVERSITY

LIST OF FIGURES

Fig.1 Journal bearing

Fig.2 Journal bearing

Fig.3 Pressure distribution schematic representation

Fig.4 (a) Journal bearing test rig and (b) bearing attached with pressure

sensors

Fig.5 Frictional force sensors

Fig 6 (a) Frictional force of 500 rpm of 10 KN and (b) Frictional force at

500 rpm of

15 KN for different oil inlet pressure and groove locations.

Fig.7(a) Frictional force of 800 rpm of 10 KN and (b)Frictional force at

800 rpm of

15 KN for different oil inlet pressure and groove locations.

Fig.8(a) Bearing torque at 500 rpm of 10 KN and (b)Bearing torque at

500 rpm of

15 KN for different oil inlet pressure and groove locations.

Fig.9(a) Bearing torque at 800 rpm of 10 KN and (b)Bearing torque at

800 rpm of

15 KN for different oil inlet pressure and groove locations

Fig.10 (a)Friction Coefficient for 500 and 800 rpm at 10 kN and

(b) 15 kN for different oil inlet pressures and groove locations.

Fig.11 Interaction plot for coefficient of friction.

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

SAVITRIBAI PHULE PUNE UNIVERSITY

Fig.12 Mean of SN ratio for coefficient of friction. The optimal design

parameters are shown by a red circle.

Fig.13 A confirmation test results by comparing (a) the coefficient of

friction and (b) Scanning Electron Microscopy (SEM) of worn

surfaces on a ball under air and N2-gas lubricated conditions using

optimal design parameters.

Fig.14 From left to right (a) four-ball tester working concept to (b)

schematic modified single ball (upper side) and level of lubricant put into

ballcup/ curve surface.

Fig.15 Represented a) ABS Curve surface structure (CSS) before

experimental b) ABS CSS after experiment using lubricant and c) ABS

CSS after experiment without lubricant.

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

SAVITRIBAI PHULE PUNE UNIVERSITY

List Of tables

Table.1 Details of test bearing dimensions, lubricant properties and

operating parameters

Table.2 Experimental condition on the modified single ball tribotest.

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

SAVITRIBAI PHULE PUNE UNIVERSITY

ABSTRACT

Journal Bearings are used in a large number of critical positions in

automotive internal combustion engines and contribute a major

contribution to the total friction power losses in these engines. Due to the

worldwide effort to reduce CO2 emissions, automotive manufacturers

investigate the remaining potential for friction reduction also in the

journal bearings , which leads to severe operating conditions due to the

lower viscosity lubricants. These reasons motivate in addition the reliable

and accurate simulation of operating conditions and friction power losses

in journal bearings. Also the efforts are made in the direction of

lubrication of these type of bearings with conventional type of fluids

along with non conventional type of fluids and gasses to minimize the

friction losses.

JSPM’S IMPERIAL COLLEGE OF ENGINEERING AND RESEARCH, MECHANICAL

ENGINEERING

S-ar putea să vă placă și

- Gas Chromatography: Principles, Techniques, and ApplicationsDe la EverandGas Chromatography: Principles, Techniques, and ApplicationsÎncă nu există evaluări

- Front Page NalramDocument11 paginiFront Page NalramJeyakumar NÎncă nu există evaluări

- An Experimental Study of Simple Savonius Wind Turbine With Semi Elliptical Blade ProfileDocument49 paginiAn Experimental Study of Simple Savonius Wind Turbine With Semi Elliptical Blade ProfileMr. T. Micha Premkumar Assistant Professor II - MECHÎncă nu există evaluări

- Synopsis On Rehabilitation and Retrofiting of StructureDocument5 paginiSynopsis On Rehabilitation and Retrofiting of StructuresnehrozÎncă nu există evaluări

- Influence of Volute Surface Roughness On The Performance of A Centrifugal PumpDocument4 paginiInfluence of Volute Surface Roughness On The Performance of A Centrifugal PumpHayderAlSamawiÎncă nu există evaluări

- Analysis of A Hydrogen Fueled PDFDocument71 paginiAnalysis of A Hydrogen Fueled PDFAlok KumarÎncă nu există evaluări

- Alternate Fuels For IC EnginesDocument58 paginiAlternate Fuels For IC Enginesgowtham shettyÎncă nu există evaluări

- TRIL2013 by GuoDocument21 paginiTRIL2013 by GuoKailash TauckoorÎncă nu există evaluări

- Study of Turbine Blade RoughnessDocument118 paginiStudy of Turbine Blade RoughnessSIVA KAVYAÎncă nu există evaluări

- C PumpDocument100 paginiC PumpAmmar Ahmad50% (2)

- AeroDocument73 paginiAeroLakshman KumarÎncă nu există evaluări

- Comparative Study of The Tribological Properties of The Swashplate Axial Piston Pump For Different Materials of The Valve Plate On Different Load ApplicationsDocument11 paginiComparative Study of The Tribological Properties of The Swashplate Axial Piston Pump For Different Materials of The Valve Plate On Different Load ApplicationsEditor IJTSRDÎncă nu există evaluări

- Seminar Report - ThomasDocument36 paginiSeminar Report - ThomasAU 13-ELDHØSE BÅBUÎncă nu există evaluări

- Statistical Model For Effect of PolymerDocument69 paginiStatistical Model For Effect of PolymerDidier BellonÎncă nu există evaluări

- An Experimental Investigation On Tribological BehaDocument6 paginiAn Experimental Investigation On Tribological BehaRameshkumar R100% (1)

- 10.1016@0022 48989490020 5Document10 pagini10.1016@0022 48989490020 5ParthÎncă nu există evaluări

- Final Project New ReportDocument57 paginiFinal Project New Report4NM17ME118 Pradyumna BhatÎncă nu există evaluări

- Two Stroke PetrolDocument93 paginiTwo Stroke PetrolPrince Tiwari DETL 27Încă nu există evaluări

- Design and Fabrication of The Efficient Composite Spur GearDocument15 paginiDesign and Fabrication of The Efficient Composite Spur GearMithra SriÎncă nu există evaluări

- Batch 15 Thesis 4Document65 paginiBatch 15 Thesis 4Mugesh Mugesh SÎncă nu există evaluări

- 1 s2.0 S0043164818316739 MainDocument8 pagini1 s2.0 S0043164818316739 MainMert Can AKTAYÎncă nu există evaluări

- Draft Report A10Document37 paginiDraft Report A10AkashÎncă nu există evaluări

- UDP Final ReportDocument47 paginiUDP Final Reporthairin33% (3)

- MILAN FINAL YEAR REPORT EditDocument56 paginiMILAN FINAL YEAR REPORT EditrekhaÎncă nu există evaluări

- Manufacture and Testing of Jet Engines:case Study of AL31FP EngineDocument76 paginiManufacture and Testing of Jet Engines:case Study of AL31FP EngineSi thu AungÎncă nu există evaluări

- Optimization of A Hydraulic Mixing NozzleDocument65 paginiOptimization of A Hydraulic Mixing NozzleGeorge PircalabuÎncă nu există evaluări

- Universidade Estadual de Campinas Faculdade de Engenharia MecânicaDocument62 paginiUniversidade Estadual de Campinas Faculdade de Engenharia MecânicaGabriel AraujoÎncă nu există evaluări

- 314b PDFDocument70 pagini314b PDFSiva baalanÎncă nu există evaluări

- STUDYOFAL31FPENGINEMANUFACTURINGASSEMBLYANDTESTINGDocument76 paginiSTUDYOFAL31FPENGINEMANUFACTURINGASSEMBLYANDTESTINGamir hosseinÎncă nu există evaluări

- STUDYOFAL31 FPENl GINEMANUFACTURINGASSEMBLYANDTESTINGDocument76 paginiSTUDYOFAL31 FPENl GINEMANUFACTURINGASSEMBLYANDTESTINGRohit GujralÎncă nu există evaluări

- Subgrade Soil Stabilization Through The Introduction of Goetextile & Natural Coir Fibre AlternativelyDocument50 paginiSubgrade Soil Stabilization Through The Introduction of Goetextile & Natural Coir Fibre AlternativelyPrince FerdousÎncă nu există evaluări

- Effect Mechanism and Quantitative Analysis of Injector Faults On Diesel Engine PerformanceDocument22 paginiEffect Mechanism and Quantitative Analysis of Injector Faults On Diesel Engine Performancefabio1199Încă nu există evaluări

- Partial ResearchDocument60 paginiPartial Researchrizki hidayatÎncă nu există evaluări

- Manufacture and Testing of Jet Engines:case Study of AL31FP EngineDocument76 paginiManufacture and Testing of Jet Engines:case Study of AL31FP EnginealokÎncă nu există evaluări

- A Study On The Effect of Out-Of-Roundness of Drum Brake Rotor On The Braking Force Using The Finite Element MethodDocument36 paginiA Study On The Effect of Out-Of-Roundness of Drum Brake Rotor On The Braking Force Using The Finite Element MethodКонстантин ХорошийÎncă nu există evaluări

- Tribology in Industry: H.K. Trivedi, D.V. BhattDocument10 paginiTribology in Industry: H.K. Trivedi, D.V. BhattAwais RazzaqÎncă nu există evaluări

- UKP19ME071 PeeyushDocument38 paginiUKP19ME071 Peeyushathul manojÎncă nu există evaluări

- Turbine Manufacturing B.H.E.L., Haridwar: An Industrial Training Report ONDocument41 paginiTurbine Manufacturing B.H.E.L., Haridwar: An Industrial Training Report ONraspberry piÎncă nu există evaluări

- PDF DatastreamDocument97 paginiPDF DatastreamNguyên KhôiÎncă nu există evaluări

- A Laboratory Study On Use of Bitumen Emulsion in Gravel RoadDocument49 paginiA Laboratory Study On Use of Bitumen Emulsion in Gravel RoadNehaSinghÎncă nu există evaluări

- Roga 2019 J. Phys. Conf. Ser. 1276 012041Document12 paginiRoga 2019 J. Phys. Conf. Ser. 1276 01204119951A2117 TANGUTOORI HARSHITH RAJÎncă nu există evaluări

- PDF Merger 2023 05 16 19 23 27771Document68 paginiPDF Merger 2023 05 16 19 23 27771MonishaÎncă nu există evaluări

- Sae Technical Paper Series: Takao Yokoyama, Yoshiyuki Hayashi, Katsuyuki Osako and Yoshimi KomatsuDocument9 paginiSae Technical Paper Series: Takao Yokoyama, Yoshiyuki Hayashi, Katsuyuki Osako and Yoshimi Komatsusirajul_musthafaÎncă nu există evaluări

- Fault Analysis of The Axial Piston PumpDocument33 paginiFault Analysis of The Axial Piston PumpSatyabrat Gaan100% (3)

- Optimal Design of Swept, Leaned and Skewed Blades in A Transonic Axial CompressorDocument11 paginiOptimal Design of Swept, Leaned and Skewed Blades in A Transonic Axial Compressorramnadh803181Încă nu există evaluări

- Amin Bagrezale PDFDocument5 paginiAmin Bagrezale PDFJavier E. Guerrero ArrietaÎncă nu există evaluări

- Banty Kashyapbhel Training Report File-1Document41 paginiBanty Kashyapbhel Training Report File-1Banty KashyapÎncă nu există evaluări

- Final Report ABSTRACT f254Document7 paginiFinal Report ABSTRACT f254AnandÎncă nu există evaluări

- Nambi Rajan Mini ReportDocument45 paginiNambi Rajan Mini ReportNambi RajanÎncă nu există evaluări

- FABRICATION AND MECHANICAL CHARACTERIZATION OF SANDWICH COMPOSITE ReportDocument52 paginiFABRICATION AND MECHANICAL CHARACTERIZATION OF SANDWICH COMPOSITE ReportAkhil Garlapati100% (1)

- Project Report 3Document70 paginiProject Report 3DhinakaranÎncă nu există evaluări

- Factors Affecting Strength of Reactive Powder ConcreteDocument8 paginiFactors Affecting Strength of Reactive Powder Concretesanjithr619Încă nu există evaluări

- Mechanical Engineering Noor Syaffynas Yusoff 10469Document78 paginiMechanical Engineering Noor Syaffynas Yusoff 10469ROMEO Y PALETA FLORESTAÎncă nu există evaluări

- Training Report FINAL0000 RajatDocument50 paginiTraining Report FINAL0000 Rajatrajat sharmaÎncă nu există evaluări

- Final Report Air Brake Using Exhaust GasesDocument25 paginiFinal Report Air Brake Using Exhaust GasesHarris RoyÎncă nu există evaluări

- Plasma CoatingDocument9 paginiPlasma Coatingavm4343Încă nu există evaluări

- Folleto LCCDocument74 paginiFolleto LCCGerman DiBaccoÎncă nu există evaluări

- Influence of Durability On Mechanical Properties of PQC Mix: A DissertationDocument10 paginiInfluence of Durability On Mechanical Properties of PQC Mix: A DissertationMr. Jitender KumarÎncă nu există evaluări

- Anwesh Project 1Document33 paginiAnwesh Project 1sunil kumarÎncă nu există evaluări

- B.E Degree End Semester Practical Examination 16AE8901 - Project Work Viva VoceDocument27 paginiB.E Degree End Semester Practical Examination 16AE8901 - Project Work Viva Voce17101801 HICET - STUDENT AEROÎncă nu există evaluări

- Media Framing of Terrorism, Implications For Public Opinion, Civil Liberties, and Counterterrorism PoliciesDocument22 paginiMedia Framing of Terrorism, Implications For Public Opinion, Civil Liberties, and Counterterrorism PoliciesGillian Adams100% (1)

- 1875 Patent On Earth BatteriesDocument22 pagini1875 Patent On Earth Batteriesjoetylor100% (1)

- Scientific MethodDocument9 paginiScientific Methoduzma sagheer janjuaÎncă nu există evaluări

- Virtual Laboratory Based Guided Inquiry: Viscosity ExsperimentsDocument8 paginiVirtual Laboratory Based Guided Inquiry: Viscosity ExsperimentsPutu IndraÎncă nu există evaluări

- CE 162 LAB #3 Particle Analysis of Soil (Hydrometer Analysis)Document11 paginiCE 162 LAB #3 Particle Analysis of Soil (Hydrometer Analysis)Angel Umali Gacutan100% (4)

- Cornell Notes Read AlongDocument4 paginiCornell Notes Read AlonggrantgoodyÎncă nu există evaluări

- Eksperimen Sains KSSM f4Document18 paginiEksperimen Sains KSSM f4NOR ATIKA IDAYU BINTI ABDUL KADIRÎncă nu există evaluări

- Characteristics, Strengths, Weaknesses and Kinds of Quantitative ResearchDocument18 paginiCharacteristics, Strengths, Weaknesses and Kinds of Quantitative ResearchNikkaa XOXÎncă nu există evaluări

- 1.2 Scientific InquiryDocument15 pagini1.2 Scientific InquiryHilma SuryaniÎncă nu există evaluări

- Freud'S Studies: On CocaineDocument33 paginiFreud'S Studies: On CocaineRichard KleinÎncă nu există evaluări

- Module 3Document2 paginiModule 3Jared OlegarioÎncă nu există evaluări

- ThinkLikeaFreakTG PDFDocument24 paginiThinkLikeaFreakTG PDFArturo VelázquezÎncă nu există evaluări

- SC F1 - Chapter 7Document10 paginiSC F1 - Chapter 7Azrul EffindiÎncă nu există evaluări

- Methods of Research LyceumDocument11 paginiMethods of Research LyceumJesseca Jean Aguilar Sepillo100% (1)

- Acid Rain Lab ReportDocument4 paginiAcid Rain Lab Reportapi-320765978Încă nu există evaluări

- Mastering Statistical Quality Control With MinitabDocument7 paginiMastering Statistical Quality Control With MinitabBrian PrestonÎncă nu există evaluări

- Hypothesis-Driven Development: Instructions & Template For Peer-Reviewed AssignmentDocument5 paginiHypothesis-Driven Development: Instructions & Template For Peer-Reviewed AssignmentMuhammad El-FahamÎncă nu există evaluări

- Radiotracer ApplicationsDocument291 paginiRadiotracer ApplicationsIrwan JanuarÎncă nu există evaluări

- Caribe - Michel CamiloDocument18 paginiCaribe - Michel CamiloJonathan FonsecaÎncă nu există evaluări

- The Mystery and Secret of The Great Pyramid by Joe ParrDocument6 paginiThe Mystery and Secret of The Great Pyramid by Joe ParrCIDNOV100% (6)

- Fat Tony 1Document12 paginiFat Tony 1ZerohedgeÎncă nu există evaluări

- Listofbooksforwebsite PDFDocument187 paginiListofbooksforwebsite PDFਕੁਮਾਰ ਸੰਜੀਵ0% (1)

- Assignment No. 1: Q.1 Explain Briefly Each Source of Knowledge and Discuss Which Source Is Most Important and Why?Document29 paginiAssignment No. 1: Q.1 Explain Briefly Each Source of Knowledge and Discuss Which Source Is Most Important and Why?Faheem Elahi FomeÎncă nu există evaluări

- MEM661 - Destructive Test (Bend Test)Document20 paginiMEM661 - Destructive Test (Bend Test)FIefa100% (2)

- I. Context and Rationale: Review of Related LiteratureDocument3 paginiI. Context and Rationale: Review of Related Literaturecarmena b. orisÎncă nu există evaluări

- Two Phase Pressure Drop & Flooding Characyeristics in A Horizontal Vertical Pulsed Seive Plate ColumnDocument11 paginiTwo Phase Pressure Drop & Flooding Characyeristics in A Horizontal Vertical Pulsed Seive Plate ColumnSnehasish Barman RoyÎncă nu există evaluări

- The Startup Real BookDocument38 paginiThe Startup Real BookAndreSantanaÎncă nu există evaluări

- Thesis Champorrado RollsDocument31 paginiThesis Champorrado Rollsjohn torresÎncă nu există evaluări

- Operational DefinitionsDocument3 paginiOperational Definitionsdhiva27Încă nu există evaluări