Documente Academic

Documente Profesional

Documente Cultură

QLY40使用手册

Încărcat de

Jppi Ptk0 evaluări0% au considerat acest document util (0 voturi)

134 vizualizări128 paginimobile crane

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentmobile crane

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

134 vizualizări128 paginiQLY40使用手册

Încărcat de

Jppi Ptkmobile crane

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 128

it

Ol

MTL DEAE “e7 "AY OLYA0 ABH

HPL. RECA R aE !

VA: LEH

JANIE A) SA As FULT IR AY YA AP

iS BUI 22 BEAD DR:

AP APP BER OER” BOW, Fe

Bik eA: OSE AS,

KARR, FPP ARI Hehe AE

SE TUE THR i HE Seok TEAL Be AE

Wie, DIR Bate 6

ACF ASAE ARIE NBD» TE CE AR

FEAR TU NETL, HES

AF Ae tir EEG (ER TT

SPE TR

PAPE EE SE, ASTRO

PEERALABAR ALT AEG OTL

HOPS AAS TEA TE, AP DiS

Forward

Greatly appreciate your selectively

purchasing model QLY40 Wheel Crane,

which is produced by Harbin

Engineering Machinery Manufacture Co.

Lid, with many thanks

It is considered that managers and

operators should thoroughly familiarize

the contents of this manual, safely

operates and meticulously maintains the

crane.

‘The “Cautions” in this handbook

are the important reminding to prevent

major accidents; the relative persons

should thoroughly familiarize it and must

be strictly observed to prevent crane

accident taking place, so as to

ensure safety,

The maintenance portion of,

handbook is a guide, which prolongs the

ciane use life, raise operation efficiency,

and be sure to follow regulations and

properly maintain the crane.

Owing to the reviser reasons in

design, diagrams and technical data

shown in the manual may be different to

the ones of delivering the crane to users,

and please understand to our revision.

RLEBRT

BLARRTE. Hear al EBB ARA B/E

AIS SEM & BA tht FAS HEA 1

ASI SRI AT RR PRG FTA AY

SAGA ARS AT IRMA FEB, TERIA

ZA RT DEPT EAT WIRE I

H99eAe

AP AUPE SEBLAE ZA, 9

1 Oe A GRAPH A

ti.

SEAS Dee A HE CEP MS Be

HEL" ASPET MR, JR CE BRIE

Ar fe FRM. La EI

HAMA PRIA, CAGE READIES. HAS

HRSA PGBS, AEE EM im OE

i, BEG Ce AM Aa Hi.

RA ATT HE AO UNL TAS HT

RALLIES AST HE 4 SARA TE I

24, CR. UR ASE A RAT

FER. AEP PRPS, HF

SATE BI AN AL A A Be FE

Si FUSS iA 48 TT Ms a PRY

PUREE SAA BLUE BA

Be!

FEIANIE MINUET. AldP ANE BE A

Fee, WT PBEM AE, fei

AM

i RY 8 Hae

THRE ABLES, MORRIE A BLAS 1

Important safety precautions

Most accident during the machine

operation, maintenance and repair

happens because they do not comply

with basic safety rules or did not take

preventive measures. Usually aware the

dangers previously and take effective

preventive measures can avoid accidents

happe:

Before the operation, maintenance

and repair of the machine, be sure to

carefully read and understand all

protective measures and waming signs.

Basic security measures have been

provided an overview in the manual

"Safety Precautions" section, and it also

gives descriptions where there is a

dangerous place in the operation, The

machine also has a warning label pasted

to be able to identify, prompted a special

dangerous place. In the operation, please

strictly pay attention to avoid injury to

themselves or others.

Please understand that our company

can not foresee all possible dangers, and

indicate all danger. Please conform you

and your partner’s security during the

operation and maintenance whether there

is dangerous operation tips or not in the

instruction manual. Make sure that the

maintenance methods and the program

that you choose will not cause danger to

people or damage to the erane.

Warning

Any incorrect operation,

maintenance and repair way is

dangerous, It may lead to accidents and

endanger personal safety!

Please carefully read and understand

the operating instructions first and then

operate the machine, Otherwise do not

operate the machine!

fe:

1.3 Be fe A

1.4 DRA Rie eH TE

1S (RFID OTE.

Ae FRA

2.1 HE

2.2 eBEpOR te

2.3 lem OLI aA

SSR AH

3.1 ALIA

3.2 EFA NIE A

3.3 AAPL IS HERE

3.4 FRE

3.5 CHEE

3.6 BME TEL BRE

3.7 fel: i

3.8 BAP ADHERE BET

BOR MLM

4.1 RUNDE

4.28 WRAY

BAR RAPT RIE

SAL HE G4 AD

5.2 EAB AREA ALA

5.3 See FA

5.4 HUE AS NY RL RFE

5.5 2M AEL AL

5.6 Kris Beit

ARS RUM MZRSRT

6.1 ALE

6.2 dea LIN RE

Contents

Chapters 1 Safety

1.1 General Attentions

1.2 Safety Attentions before

Operation

1.3 Operation Cautions

1.4 Cautions in Dismounting and

Transportation

1.5 Maintenance Cautions

Chapter 2 Production Introduce

2.1 Summary

2.2 Main Technical Performances

2.3 Main Structure of Crane

Chapter 3. Operating of Crane

3.1 Controlling Device of Crane

3.2 Preparation before Usage

3.3 Operation of Engine

3.4 Traveling and Driving

3.5 Outrigger Operation

3.6 Hoisting Operation

3.7 Operation after Working

3.8 Cautions of New Crane Usage

Chapter 4 Disassemble and

Assembled of Crane

4,1 Dismounting of Counter Weight

4.2 Height Change of A shape

Bracket

4.3 Assemblage and Disassemble of

Boom

4.4 Wire Rope Assemblage and

Disassemble

Chapter 5 Maintenance of Crane

5.1 Lubricating and Cooling

$.2 Bolt Tightening in Main Position

5.3 Using of Wire Ropes

5A Maintenance and Service of

Hydraulic Devices

5.5 Item for Periodic Check

5.6 Data for Service

Chapter 6 Transport and Storage of

Crane

6.1 Transport of Crane

6.2 Storage of Crane

AOD F B/S / AER BAL Instruction Manual / Safety / General Attention

B-E Ze Chapter 1 Safety

LIARS 1.1 General Attentions

11 Rata

0 BERANE 2 RPL MET 6 UTA BE

HME, TCM Ee Rw

HURT ARII.

AB A DNR Pe eh HR PE A

TES BLT.

© FACIE WN SITS. PRE TTIA. Im

WATT BAR FETT IE.

© BARREL Mk TE

Fe

HE SOE ke AE A SN AN

BBL.

+ MRAM RUT ee, AM, &

AH He HE

fe. SCO HEB Be

MAAR Ar, FEEL

TER AS

31

SIE, HSE S| te

1.1.2 CAPARBOA

+ FAG A TEMLAT LEM, CEE

BROW FT Bh ie a bY 9S

Han, SBS @

(ORME.

2 RE RH MIR a

Celis SBA b

+ ISL SBE HM 8

PHA. MRR. &

ae. pH, Bram OY

hf PE

‘e.

L113 Meee

HUET 2 BLA FE SE

ANY, CSR aby Ti) EM

RSET AE, BLP ak

ap.

1.1.1 Safety Cautions

* Keep clean of the safety label. If

damaged or lost, please buy from the

production factory and paste it again at

once

+ The operators must gain the designated

operating credentials.

+ Remember well the right method of

driving, operating, oil charging and

maintenance.

+ Keep the equipment working in

normal state throughout.

+ The crane must be working in the

range of the rated lifting performance.

+ Do not remake the crane and

otherwise, it will damage the

equipment in safety, and lead to

decrease in function and using life,

also is excluded from the guarantee.

+ Other safety cautions not written here

should also be taken notice.

1.1.2 Work clothes and_ protective

appliances

+ Must dress the work clothes suit for

operating, to avoid being caught on

controller or projective on equipment

and leading to casualty.

+ Do not dress the work clothes with

greasy dirt sticking, to avoid catching

fire

+ Put on the suitable _ protecting

appliances for operating. Such as

protecting cap, safety shoes, goggles,

dustproof mask, protecting gloves and

safety belt etc.

1.1.3 Noise protection

Should wear earmuffs or earplug

when carry out maintenance of engine

with working in the noise environment

for a long time.

SOA i/o / ATL

Instruction Manual / Safety / General Attention

1.1.4 SrPRAS EIT SRE BRIE TEL

GRE LER

Si. LAA PSP,

‘

SSRUER AMEE, SbF f{

FRE TE TS 5 We BB PRS

sen}, matteaEAL, ff I

HEAL mone!

1.1.5 S3thA fe A Bier Ra

«i we fe Mk dB

FEA BE

«HES

Te

WATT.

+ HERA

AMV TRS

+ AC SEMEL AERA DFA

TEETER.

RTA LBL kB Ae AS RAS

FEAT AAEM.

= Re ATARI Pe AE J)

2 RATE MEL Sy PA 9 8 a HB

SORE RUM

1.1.6 Jefe Ss

Fi 73 TE HHS

Os ah HO DR

Kihe

= REA

Site BBR HH

Af S.A,

HER RAD WL

AGA HINT,

TEBE Be TARE, JENS

SAMA SL.

Aldi act

ie

© IEG THERA RE 5

BAA CREE AE TA

LL eRe RT A

SESE Je AE SE A =

AE IN eA (}

BA, Sea Me i"

Pe

1.14 Forbidden operation when

physical fatigue

When operator is over fatigue,

getting ill, taking medicine or drinking,

one's energy can not concentrate, at this

moment, be sure not to operating the

crane to avoid bringing about an

accident.

1.1.5 Coordinate with common

operators before operation

+ Determine commander and command

system.

+ Determine indicate way of signal.

+ Determine the operator and

hoisting way

+ Provide assistants and determine work

method.

+ Determine crane setting locality and

ground state and then carry on

corresponding truing.

+ Check lifting load and lifting capacity.

+ Determine the prohibitory items,

matiers needing attention and safty

rules at worksi

the

1.1.6 Common operating signal

+ Signaler should transmit the signal and

indication w operator comectly.

+ The operator should obey the signal,

and besides, should pay attention to

the situation around, and whistle to

‘wam surrounding person when starting

engine and operating equipment.

1.1.7 Standing safeguard appliances

+ Should prior know the way of

emergency liaison in an accident, and

determine disposal measures.

+ Should prior know the storage site of

fire extinguisher and first-aid case;

understand the usage of them.

SOA i/o / ATL

Instruction Manual / Safety / General Attention

1.1.8 RIERA PEML IG PD

© FA AEMLIE HA, EBON SE

ASG.

JSL-4E ff Mh 9 FBLA BE

Maik A AEA

i

FA IY 26 fe eH 2s

UA UE FA EAN

RORY.

11.9 Bela AS HEM A ET PEM

PAULA PEM Dy ak 2 3 AS HH

AE, FE PBR EA iB EY

‘Bist, MARNE AN TE AEE,

fies Ie \

ial i, to

i, REISE Er

VFRHAT WOH 0

1.1.10 SHE

+ HEARED ALY

AEA THRIA

+ TEMA, MRE A, AIPA AS

HIS 5 HE Pel RE ae.

Here

MET ICBO ELEN. ASL

HOEZ INSERT.

+ SOIR RES BER POP I, MEA AY SC HE

iit. PHM ES, MEENA ae

HRI BUT HL EE AS

TRV AR AS 0

+ FUN AAA

“op ok AF ST

ere it,

i RAR

ei LE

BBA, Wilke

ARS Rie

AS. FECHA

1.1.11 Seat BE

+ AGREE

Se HM.

REM TS, MRE

BAR AEH DHE ©

AEE,

De eE A

1.1.8 No entering into working area

+ There will be in danger of accident

with someone being into scope of

work.

+ Should set up facilities to prohibit

person entering the working scope.

+ Should confirm that no person or

obstruction around the crane before

operating,

1.1.9 Operating according to the given

way

Operation mistake will result

overturn and shatter of crane, and danger

happen. Therefore, must operate

according to the given way. In addition,

shouldn't remake — the equipment

optionally, if needed, should prior consult

with manufacturing enterprises.

1.1.10 Setting up of equipment

+ Set up the crane to level state and

confirm with leveler.

+ In working, the outrigger should be

fully extended, and all outrigger floats

should contact to the ground for

suppouting the crane with the tyre

apart from ground,

+ When operating the outrigger, people

cannot near the movement part of

outrigger.

+ Outrigger float should be based on the

firm and smooth ground, If the ground

is rumny, should lay iron plate with

given strength to maintain the crane in

level state,

1.1.11 Safety devices

+ Cannot remove the safety devices

optionally in order to avoid. fatal

accident taking place

+ Understand the correct usage to ensure

that safety devices give normal

SOA i/o / ATL

Instruction Manual / Safety / General Attention

AAT He NAR HE A JE ODE AL

Pe MEE SFE II HENS HR.

GPM ia: ATES. RTT

EVRA ES. WBE AS aS. Ae OSG OR

AB TEN URIBE 8 BIR

YH.

1.1.12 Ey PB BY AER

Ey Fa MCBUIN, SAS EEA FAL

PALL. BEF, APRA

TESTE Se,

Lex BCI, WS ch Fd Be A FP HER

FANOAR. BEAR EE ATH, BE

:

by Fike, 1

Masel 4

DAS 5) RS ET 0

© ABBE LAR BEE Be

te

1.1.13 ARE Bef EDR

tee

ISLAY 2

Lea te EL Le He ik

hy VASA PR TT SSR AE

11. 14 SELES AB

© DRIAL, UTES

APLAR, MeL

fe.

+ WAAL

BAAR, AS

SUBE IN fe

Be

L115 BRU eB

“AAR LSE BHR ASE NT

ATA ESCHLAT MLAS, Mit SEC

BL API, WA EE.

«Sid PLE METAL. OP IAAT Ef

WANT AE.

+ REWRITTEN ILIA NORTE. HN.

14

function.

Check the safety devices for defected

or damaged, if abnormal, should

Maintain or replace them.

Safety devices include

limiter, lift height limiter,

indicator, boom elevation

derrick lock detent

device, ete.

moment

radius

limiter,

and warning

1.1.12 Cautions in up and down the

crane

When getting on or off the crane, if

not using handrail and footplate, or

jumping on and off the crane, may lead

to drop down accident

When getting on or off the crane,

should face to the crane and use handle

and footplate. Handle and footplate

may slip, should pay more attention

When getting on or off the crane,

should not hold the control set to avoid

accidentally operation.

Do not jump on or off the crane.

1.1.13 Operating on the seat

Should start and operate the

equipment on the seat to avoid accident

on account of accidentally operation

1.1.14 Prohibit personnel from hitching

or lifted

Prohibit hitching unconcemed person

to avoid obstructing the view and

affecting operation

Prohibit lifting people, may lead to

drop down accident.

Prevent crane turn over

f there is vibration or leaning with

the crane, may probably cause land

subsidence and fall down, and lead to

crane tum over and bring about casualty.

+ The crane should be operated and

travel on firm and smooth ground.

+ Should check the state for topography,

SOA i/o / ATL

Instruction Manual / Safety / General Attention

BER ALTRITY

+ MRA KF

ERKER

6 iS 3 fF ke

RE (0 3

teak, 8

fea, B

NTR AS 0

HLA i

JB AP

JRE ARE ER ASK

ech Tl.

Je AR SL

© SSK ANSE

= LS TAT

1.1. 16 HLS RE BE

PAARL AE feat Just, 262i el

TEMPE EER , REIL AAR A

ENE BN.

1.1.17 FBR

ie EH RS A LA

+ FAME HE. Pale, ME

RIB F 4 i j feobs«

0 BES DIT i oh Fle HT)

RUS, SHIRES DA aE

arte

0 FERALE b iA HE LER SLC EI

REF 2K

EATERS.

HERRERA IE

EMMIS» Ed

4K BR ve

Fe

+ EERE

RAS,

SEE als feb,

MERE.

LL, 18 RAE fe a Ce ART HE

© PAERAOBL, HEA.

geology, and bridge or structure of

worksite in advance.

+ In ordinary circumstances, it is not

allowed working on soft ground or

where is not strong enough. If it must

be worked on the soft ground, should

lay iron plate with enough width and

strength to firm and smooth the

ground.

Ground needed to be firmed and

smoothed:

+ Surface near cliff, roadside and deep

ditch

+ Ground of after rain

Frozen ground

Loose surface

1.1.16 Electric cable concatenation:

When working with electric power,

cable must be wired by professional

electrician according to operation

instruction, strictly forbid connecting

cable by person who is not professional

electrician.

1.1.17 Keep away from transmission

line

If crane or lift load is over close to

ansnission Line, may be dangerous (0

get an electric shock. Therefore, should

adopt measures as below to avoid it:

+ Prevent personnel near crane and the

lift load.

+ Dispose signaler, and

according to the indication,

+ Traveling under wire or working near

it, should keep a distance over 2m

Working nearby highline, should avoid

it according to relevant rules.

+ If it cannot avoid working near

transmission line, should — install

insulation protection part

operating

1.1.18 The way to deal with electric

shock

+ Operate the crane to leave away from

SOA i/o / ATL

AS BE UE fb fe) ARR a IT he

FD, WB de ts UP

TEDL AIRTEL ZHI, PTE A A IS 8

HE URS, HULL i se fe

FU ASBR IR FP UE » BRM A ELS Bi)

SE FCHE RP SL FEI RES,

SE ORAE Aa AL SB te Beth

+ HUG, MAMET. BHR

DLR, MULT HERE.

L119) Sebi BR wa = A

TENE BRR A ANCE MEIN ,

BOA ESE IA LR RANE

fea, ARES LOG

hati.

Tuk, Ze mAeth

Se i oe Fs Be

DURCH Yt

aS

1.1.20 BRA EL

PEAT TT RE LR or HARE SCPE

IAM.

He OMEN. HY PES ee

eH L.

+ KARL, BEAT

HS) 24a hii.

Har

KEE

defen.

WL A A AE AT

Tobe BRAY

afi

Ja PRA:

11. 21 ALUN EE aL

TESA TEMES, 7 RAE i At

fy fel

+ TURK, RAP ie BR, ea

PNY SE TTR A, SEALY OP a

Ky BA FEO BA AD

+ SE ROR, AAT

Instruction Manual / Safety / General Attention

electrification.

Any one cannot near to crane and lift

load to avoid secondary accident.

Before equipment interrupt, operator

should keep in the cab. If operator

must leave, should use wooden ladder

to leave equipment, or jump to blotter

from — equipment, and when

touchdown, avoid contacting the

equipment,

After accident, should check every

parts of equipment, if find abnormal,

should do to repair.

1.1.19 Avoid electrification caused by

strong electric wave

When the crane works near

broadcasting station or TV station,

electrification phenomenon may appear

to wire rope and hook

Therefore, should make hook

grounding to release electricity before

crane works

1.1.20 Forbid work in rain

In situation that it may be struck by

thunderbolt, should stop work.

Fall down the load and boom to the

ground

The operator should stop the engine,

leave away the crane and avoid at a

safety place

When restarting work after thunder,

should check equipment for burn

dilapidation, and check whether the

function is normal, whether electrical

equipment is normal. If abnormal,

should after repait it.

1.1.21 Attention in wind blowing

Work in the strong breeze, may

present. dangerous of equipment

overturn

+ The longer the boom length is, the

higher the position of lift load is, and

the lager the area of windward is, the

stronger the affect of wind will be, and

SOA i/o / ATL

Ds PORE ACE Hi 77 NOE

AIRS, BL

PA ZI A REE HE

AWE

BEI, Beith

KAR, BET

AE MEI SE FE SHE

ML, TS

Ly

“7

\

i

SAR aie

10m/s (£F 15m/s WY, BSE RIE

RLF fbi

Ore HN i

ES MANE PAE B25 GO" 6

OH TES

Wot.

@ in Fl He BH

EAU FE HAD.

DFS AR

PEP “i”

iH.

Ones aT

“Hoi” ARAS

DAM RAL.

“AA 1 VAL. 30m/s LOB iets

Pee PMS CIB Bis

OF ie 8.

Oita Fe wie MELE HAD.

OH ATT ROUT ELE “oH Ae” ALL

@ 3 4%

Bb BE” KR

OKMR

abl.

Ls 1. 22 PEMA CERT i Be A da

a LAG BR he BT BEAR

AS, UAE SSAA

«RCE ACY Ae ST

+ SEA SI BE BLA 60°

+ HEMP R TS.

FESPA RADHA a8 US TB

A" eB, JPR “ti”

{He

147

Instruction Manual / Safety / General Attention

may lead to equipment overturn or

damage.

When the boom is in max angle

without load, if taking a strong wind

facing to it, the boom will be fling and

the crane will fall down toward rear,

The wind power will have great

change with different landform. and

different ground height, so should pay

more attention to it in working.

When wind speed is more than

10nvs and below 15m/s, should stop

work and take the following steps:

@DCounter weight set facing the

wind

@The boom set up angle 60°.

@Pack up the hook completely.

@Lock the tumtable and brake the

slewing.

©Put all the control levers at the

neutral position

©Put the drums in

state.

@sStop engine.

“braking”

When wind speed is more than

1Snv/s_and below 30m/s, should stop

operating and take the following steps:

Fall the boom and the hook to the

ground.

@Lock the turntable and brake the

slewing.

@Put all the control levers at the

neutral position.

@Put the drums in “braking”

state

@Stop engine.

1.1.22 Safety precautions after

operating

After operating, should lay the crane

in safety state, if not, may lead to an

accident.

+ Lay the crane on the firm and smooth

ground.

+ Set the boom angle at 60°.

+ Lift the hook entirety.

+ Put all the brakes and lock devices at

SOA i/o / ATL

Instruction Manual / Safety / General Attention

Bi b AABN

HET AIT 2 wet LBA

TER ULAR

HP La Sy

PANTIE» BE

RAE FL 9

Pa SE EE RK

“TART HE

+1, 23 EWE SRA Ah AE

RH

AST SL 5 YM PE ER

HH LAER AYP BSE Pe RE

HE PA a UE SONAR HE ho MEE

Da BEA MEF IEF) EPA 2, DA

Se PBUH 22 AE 6

BEART” SHITE 48h

TUES AS UM. WT AS AS BR

I AF Se He A RA th» EBL

(SEAT tA, ART ARATE.

“braking” position, place the control

levers at the “neutral” position.

+ Pull out the engine key.

+ Lock all the doors and covers

1.1.23 Attentions about optional and

special equipment

Some of optional and special

equipments manufactured by other

factory do not explain in this instruction,

so should fully understand the related

content in their own instructions, to avoid

accident happened.

If it need to be installed other

special equipment which is not from our

plant, should consult with us in advance.

Because of not consulting with operation

and us to install the special equipment by

oneself that it brings about an accident or

equipment damage we will not undertake

the responsibility.

SIF MR // MET

Instruction Manual / Safety / Safety Attentions before Operation

1.2 RF REM

1.2.1 Peed ee EH

felkad, SEE AGAR eM Lt

BL. HMI. HMR AS. feleAte Be Sat

FAME HR

Path HS HL

TEES, RHR

We AT HE AT PE

dhe Jhah, Zest

EAE MEINE, BENG 4

SRE AE eT

A, Dain Ral tr

PRITAM

2 HELA

1 RELA A BEE

fh FE AG ENE AB

HO, BAA, REIN.

« BARE: TERM A. RTT RU BEMR

{OAS WEEE Aaa, EASE BELLAS

AS ATL A) BE A BAIT DBRS

ie

i PEL ah

Hi, RWI. Hi,

“He

PRT: BOE. BAB. BIE K

AGERE HEE.

33

=

TEMES AB un

HNL: ALT PH a RE

Ae. BAe

AeIMLeMA, Habe, NS )

HS.

1.2.2.2 A

BEER. BAY. ROUT. BRAKE

‘AS a a WP SeEP

if, AEE RL

Al ih

WRIA, Wh

JE Se Hf

PERL, Ti

ABIES.

1.2 Safety Attentions before

Operation

1.2.1 Safety attentions of working site

Defore operation, should first

confirm the situation of working site, the

weight of lift load, and the lift capacity of

crane, so that to adopt the best safety

precautions to operate. When operating

on the road should provide commander

and set enclosure to ensure the safety of

traffic vehicle and the pedestrian

1.2.2 Check before operation

1.2.2.1 Check every part of equipment

Inspect the crane before operation

every day, if finding abnormal should

repair it at once.

+ Safety device: moment limiter, height

limiter, radius indicator, boom

elevation limiter, derrick lock detent

and warming devices, etc.

Control devices: control levers, pedal,

switches and so on.

Brake devices: hoist brake and so on.

Wire rope: hoist wire rope, derrick

wire rope, pull rope and connect parts.

Handling sling: hook, hoist wire rope,

hook chain, sling rope, ring hook and

so on.

1.2.2.2 Cleaning equipment

Clean the greasy dirt on the

handrail, ladder, lever, pedal, floor, and

channels and so on, do not lay parts and

tools near the feet and on the channels, in

order to avoid personnel drop accident

that is caused by slipping or tripping

SIF MR // MET

Instruction Manual / Safety / Safety Attentions before Operation

1.2.2.3 TEACH DLA FEU

ORAL eA NTH. AUR

USE, CLR Sl BG

12.2.4 RRR

UAT BEEN 4 folk. BE

BOA. AT. AUG BLREL Ti. LEME

PLB OEE, HAT Be LEE

} DUR PRAT BLE EA LER

SOFT THEA ARSE HS, ACE aL A A

mH.

1.2.2.5 RR

EN DISD is PR RES Se a

BE, FAN RMP Bh ao Ee

WE, MOR HA SER UE TORE, JRE

BRE

FREE E RAAT. WYN Bett

BAA PL AD bE EB PR — fh

wy

i.

1.2.3 TT BeMERS

BEIETIIRE MER, DL O

Ti PRA A PROM

1.2.4 KARAM HEU

FV EATS SESH Sf ml AB Aes

VAG RCI AHA PES

TEEROE. BAUR. PROCES

AL Hf»

HAE NOL AE A TG

Ate

« RRR LAT

© BVA LIE AEE “28k:

“FOR” SPEIRS

fF

fe"

1.2.5 MET MALE

BERET MLE, ELA Ray HLA

YM ABE FC SP PAR AR TA LEE AE Dy

Ik, BM, SSBC EAR, Mi

KOA 75 tit DAE EBL AE 0

1.2.2.3 Clean engine surrounding

Thorough clean varied matters

surrounding the equipment to avoid the

fire

1.2.2.4 Ensure the sight

+ If the sight is not well, it will affect

safe operation. Should clean the

windowpane, lamp and back view

mirror; check whether the front lamp

and work lamp can normally light up

to ensure the good sight.

+ If finding breakage or abnormal,

should repair in time.

1.2.2.5 Ensure the safety label clean

+ Operator should read the safety label

pasted on the equipment carefully, and

operate the crane strictly according to

requires of them, in order to avoid

accident.

+ If the label damaged or lost, should

buy a new one and paste it on the same

place in time.

1.2.3 Adjusting scat

The seat should be adjusted

correctly for easy to control pedal and

lever.

1.2.4 Safety confirm before starting

engine

Confirm the following matters, and

whistle to warn the personnel around

+ Check whether the place of levers,

pedal and switches is right

+ Check whether there is obstacle and

personnel unconcemed around the

engine

+ Check whether there is part

disassembled on engine.

+ Confirm whether there is waming

board about “No Operation” and “No

Water” on engine.

1.2.5 Engine warm up operation

Warm up the engine until the

hydraulic oil is being fully done up, and

the water-thermometer begins swing, and

otherwise, when operating the crane, it

will present the phenomenon that power

SIF MR // MET

1.2.6 aR awe

Rathi wich AG Ge Whe He eH

RA. BARRA LER AS,

ROLE, SISLRIBHL.

ARBAB» ADA AMA EY

SEAR AEE. ABE IEEE AL IEE

© RAL HEL BLE ACSA A

Bie T-PD A de PS PATHE AT 6

1.2.7 PSEA DR Bea Be

PSSA DR Be eRe BE, ILD TA 2 BE

RLM IEM LRG, FTE. ey

Se REFER.

1.2.8 Re

« FEATOMRE RT, BOOTIES IU,

Ti

CRA URL, A

Ti, Bie Bae

Bi Jr HE AF

qe, DUES

PO NA WA AR fa

PE RG HA

AB

8,

1.2.9 Seite Brae

TARDE HTN AEE, CTE

MATA SE

ee

Th, MOAT. IE

SEEN HEB, Li

al He Hea LT BL

ASP AI.

Instruction Manual / Safety / Safety Attentions before Operation

decreases, work life shortens, and

function is out of order.

1.2.6 Check after starting the engine

+ After warming up, check the state of

control and safety devices through

operating unload. If finding abnormal,

should repair them at once

+ Afier starting the engine, should check

whether the display of meters, and

their operation are normal

+ The lifting work should be carried on

safety site where there is no obstacle

and other personnel around the crane

1.2.7 Farhid to release safety devices

Should confirm that safety devices

are in good order, and then start

operation. If finding abnormal, should

repair them at once.

1.2.8 Checking and

pressure of tyre

+ Before traveling operation, should

check tyre pressure, adjust suitably if

necessary,

+ When adjusting tyre pressure, do not

stand in fiont of it, should operate after

placing the guard board to avoid

casualty caused by tyre breaking and

its pauts lying out

adjusting the

1.2.9 Damage and wear of tyre

Before traveling operation, should

check tyres to confirm that there is no

damage or wear in it, if finding

abnormal, should replacing it at once.

IAEA / Be HE OO EL

1.3 BPE AUER

1.3.1 BRAEMAR,

AEM IP ats

lB ae aU PE MEALS

BAYA 6

1.3.2 SEI SRR EL

4 (eit te. Semi ee Ali

FIBER TE, ALT PBR YE SECO

Be. Bl, APE UEAT RRR

JN.

13.3 BRERA

(eden, BEA DEE Ns

BOMB SAA a, Uh

PAK

1.3.4 PEMLES ASB FE 2 a ee

PEMEI ARPES FP HER, Dh Se

The BSIFAEREI,

eg A ALLY A BE.

FROME bic

BUR TAL NHB a8 Be BH

KARL, HEL.

‘Bier Me eT.

1.3.5 Zee 8a A EL

teak

BAG ARRAS ico a eA

PE feAB ie Reka LE, Sane HE

RETA AMIE RE TEE ALE Ek. BE

ike He ESE, Ek

Th, SBR iia Th.

Instruction Manual / Safety / Operation Cautions

1.3 Uperation Cautions

1.3.1 Confirm worksite conditions

Before operation, should first

confirm state of worksite and its

surrounding; when operating, should also

notice the change around all the time to

avoid contingency happening.

13.2 Prohibit sudden operating

Suddenly operating will destroy the

stability of crane and toad, result in

contingency. So, cannot operate in

sudden starting, sudden speeding up and

sudden stopping

1.3.3 Concentrate on operation

In operating, the operator should

concentrate on, the line of sight cannot

leave signaler and lifting load in order to

avoid contingency.

13.4 Cannot

operation

Cannot leave drive seat when

operation, for fear of happening to

accident, When leaving seat, should do as

bellows:

+ Load fall to ground,

+ Operating lever is “the neutral” place

leave the seat in

Catch all breaks and lock equipments

Shut down the engine and put out the

ey.

+ Lock up door of cab,

1.3.5 Operating in scope of rated

fring capacity

mnfirm boom length, work radius

and lifting load according to the Rated

Lifting Capacity Chart, and take

operation in the scope of performance

indicated in the chart, Avoid the crane

turning over, damaged and fatal accident

caused by exceeding the performance

L

L

Fife. Fi

renee

Fit

BRAUER. ii

RE, By DLE

i 1

A

1 HT ah

Ch BM tit

RMS

atk te A

RE.

IAEA / Be HE OO EL

Instruction Manual / Safety / Operation Cautions

6 Sas ne

ABEL RETR TEE TY 5

SUR Hf HES HS AK

‘i TT

sesh Him.

BESET PILE

Wes 45 FE BE

FEMI, FFE

FEE HEHE

GUAT AEN

Sei

Bie At TY.

BE AAOEL A

BL

7 ARAN HE

PENTA BL, BGS

ETL, Bea ari

Piet PBR Ae TL.

3.8 J Se 4 MRS Wy ehh

feseiny, Me

FP ae a J EBL Le

TD, RRS

SRR oT NAMM TE, FE

LACT A HAT, MEE

ing load crashing boom

+ Avoid the lifting load crashing the

boom.

If the lifting load crash the boom and

damage it, should stop working at

once, and then use an assistant crane to

fall the boom damaged to ground,

Entrust specialty maintenance worker

to repair it.

1.3.7 Cautions about stopping engine

If want to stop engine in operating,

should put the hoisting lever to neutral

position, in order to avoid happening to

accident caused by over loading,

1.3.8 Avoid touching fraise

‘When operation, should avoid fraise

above or near the crane. If it touch fraise,

or wire rope or the load hitch fraise,

cannot try to lift the load, should try to

get rid of hook. In this way, it can avoid

the crane and the fraise dilapidation and

heavy drop, ensure operator safe

VA a / ete ET

Instruction Manual / Safety / Operation Cautions

1.3.9 Wf ASR ET ADE

VRNUL LEER. HRSA

IEE, MAHAR. eth ASE’

SURI, BRAC ACR, LRU Be ARE

Bis %

BOER,

CRUE cA, GHEE PF

TABS

8 DAA IP

1.3.10 BPR LF

TEDL:

UL AER

Bike.

Hob. HE

BM IE

WRAL, BE

sulfek, ae)

ALLE IL.

1.3.11 Jeng HEART

= HOURS _ aL

INT ESR ARIE Eh

HR PR

© TENEFRSEIM, SRNR TRAE

UAFE A PLR ANT HE

« TARSOR, SORE HE. DAT

ihe Fa RSA TAT I:

1.3. 12 HEATAL A Be RET TE

«UTA ATER. BOP RELL

BE Se HP 3d FE SE A ALR BE

SBOE WRE

« SLAM TEE, Amr

Be EE a8)

Me Sa

PRED, TIE

ME ae Inte,

ESL

1.39 The crane

countermeasure

When the crane present abnormal

noise, vibration, temperature change,

gauge abnormal, have abnormal smell, or

when fuel, hydraulic oil, coolant happen

leakage, should stop operation at once,

the crane park harbor, check causation

and repair.

abnormal

1.3.10 Insure vision

When the crane work below dusky

light should use front light and work

light. If necessary, should set other

lighting installation, for operator to see

clearly equipment and work condition. In

addition, when rain, snow and fog,

should stop operation until resume

vision.

13.11 Take countermeasure in cold

season

+ Confirm whether the safety deviecs,

hoist mechanism and brake for work

normal, if necessary, cleaning snow,

unfreezing and drying.

+ When start operation, should operate

slowly with fiactional load tw fully

‘warm-up oil, grease and so on.

+ When finish work, should take

relevant measure to avoid lift load

freeze onto the ground,

1.3.12 Cautions in assembly operation

+ In assembly operation, should operate

smoothly to avoid the accident caused

by speed changing rapidly or error

operation.

+ The working speed of assembly

operation, sometimes lower than

which of single operation; othenvise

when assembly operation is changed

into single operation, the working

speed will be quicken, should pay

more attention to it.

VA a / ete ET

Instruction Manual / Safety / Operation Cautions

1.3. A SRI TERI

FEL ATS REP ARE Hic ys iS HL

Bi, SBR rik, te, Be

1.3.14 REPRE RSE ES

ARB L2H B MAS

TARE MICAS. WET Ae AT

PAC. A UN A

MERE (ELC te ne BB YE 7 AE FR

i, ‘em CALI BE Wi He BE OR UE AT BR

fe, ASDF RL, DAT ILE

RE.

1.3.15 (PMR AER

1.3.15.1 BBA PERO

AK 4

AA 75 he 3 AY

SHI. EE

te th 7 Bs

BATAAN

=<

1.3.15.2 ZEARISITRAS FASTER

ai

TL A A HE PE HS EI PA

oy A th ot EAT

Fis AE

«LSet i i A aE

STE RA

ee

Wahi.

=» EARS MA

fe Sth i: 47° Oe

Teh, SERA SAP

> VAD

itis

1.3.16 Stik Ra aAT ae

CEMA TINRAS FTG, SHE

BRAT LAH FD ohg A

134

1.3.18 Promibit trom pushing or pulling

Joad using boom

Boom push or pull load will cause

boom to be injured, and lead to accident.

Therefore, the crane cannot operate in

other usage except lifting.

1.3.14 Cannot excessively depend on

safety

The crane has been assembled

safety devices, such as moment limiter,

height limiter, radius indicator, boom

elevation limiter, derrick lock detent and

warning devices, ete, but its capacity is a

finite, it cannot check the correct of

equipment assembly and adjusting, so

should operate the crane strictly

according to the given request, do not

excessively depend on safety devices, in

order to avoid accident.

1.3.15 Cautions in traveling

1.3.15.1 Confirm the direction of

carrier

+ Before traveling, should control the

accelerator pedal and the traveling

pedal afier confirming the direction of

cartier and the cab,

1.3.15.2 Different

cautions

+ Do not travel near the cliff or in the

soft roadside.

+ The crane should travel on the smooth

road.

+ If the ground is soft or not hard

enough, should lay sheet iron which

has certain width and strength.

+ When the crane travels on frozen

ground, antiskid measures should be

taken

ground — status

1.3.16 Prohibit travel with load

Traveling with load may cause the

crane to turn over and to be damaged

because of the vibration and road

IAEA / Be HE OO EL

Instruction Manual / Safety / Operation Cautions

NAT, FEA

BUA Sr

PHAR,

Pat, Byude ts

FARA F Take

1.3.17 (EL RG AIS) AEB PE ak DB HL

BUA SA, THR AM ASE

‘THEE.

‘Bi 8-46 J AEE A BA

BR EINT SEm OFA DAL, DAB i Hd EBL

IATA BEE {EE 6

18 eR NE

AFG. iL RR SEAL, AL

OY FE HEE HY PAR), BI 2 HE

PNNTERE » ANRC) eM is SARS SME

AT FUSE BRIE.

SEE DMG EAE S| MRT} AR, A

Sil HB 1 A A

+ PERRET LER, BO ih

DUE LAE, WA Setl Pik a LR RA

A RUE

SHS WEL HE 5

im ak 4 [al 44 jh

Be AE FH Lae

tla aS A 6

1.3.19 SEIE RRC A LE it

SE IL A SASK CE Hh de BRT 4

HOP, Di seke er PT

SARE A i TM.

1.3. 20 AV APAEWRSR EI MSE SE

SELL ALFA PEAT AT AE | «

+ SILA, WGeiaR

Ax BEE BEL Ha SRA SA PEP UT

Wee DEAE FN EE MAA A ERAS SH

OOP Re, MR a PSE Fs A aR

ii» DE FY AF BAT

Vib, HMR ae (SLANT

affecting, so cannot travel with load.

1.3.17 Cautions in slewing and backing

+ Provide commander and operating the

crane according to indicator.

Determine that no other person around

the crane

When operating the crane, should

sound the hom to warming people

around it not to enter the working

range.

1.3.18 Cautions in slewing

+ Sudden slewing, high speed slewing or

sudden stop will cause the crane to

tum over, scathe and the load to drop.

So should slew the crane slowly with

low speed.

Prohibit from drawing and hoisting

oad with slewing operation, otherwise

it will cause that the crane tum over

and damage.

When stop slewing, must lock

superstructure with turntable fixed pin,

for fear the crane accidentally slew

because of slant or winding,

Prohibit fiom applying the slewing

brake slewing,

1.3.19 Prohibit lifting load passing

above the personnel

Prohibit personnel from standing

down the lift load, for fear load drop to

cause person hurt accident.

1.3.20 Cautions in derrick

+ Prohibit from drawing load with boom

derricking

Prohibit rapidity derricking, for fear of

over load,

Do not operate near the boom max

angle. Should fall the boom slightly

from max angle, then slowly fall down

the load to avoid the boom backward

or the lift load crash it and cause

equipment to tum over or to be

damaged

VA a / ete ET

Instruction Manual / Safety / Operation Cautions

1.3.21 RPA

DLE ZE (PM Bag FA

FIA, Js Ai ICE

BETA. BAW KK,

ef MIE Zo WRI BE

WOES se TE, MTS BCR

SEMI ARE.

1.3.22 SELES

lt PASE ERT. WIZE

TMS WAT ey SABRE.

WM, A SBCROPAENI AT AE. Pk,

UAE TP OLE ABR

1.3.23 SEIZE 5| ART

RUA]

HAR, SSB

ARAMA, IFAT PBL

AS tf MRE \

fale. N,

Alt, BAG as

2B) 8 A Ha OE I a

FER AF .

1.3.24 SEER

+ PLAN

© SESE SE TAL GE AAT

HAR, DA Se AREA

FEE AS (OLE, TE

Asia HAIRS

FE Mic HH 30

Wy, Se FT yA

4644, BEBE, HF

HEART ENE 6

ih

kD ELAR

1.3.25 SIEM AYA Sk BA

Spies A Jake Mm Bea. hse

Le. BUA SECH AIRE.

= AE Re A

Ta A.

7A HL ih \

MESES, AE ”

PPL BI

HERR BREA

HEI EME TT

1.3.21 Avoid hook over hoisting

When there is no obstacle, should be

possible of shorten the boom length. If

the boom length is too longer, it may

affect the stability of lifting load, and

cause accident taking place.

1.3.22 Prohibit from lifting more loads

It cannot survey the loads condition

if lifting more than two objects, and the

loads knocked against one another may

cause accident taken place, so, once don’t

lift loads more than two.

1.3.23 Prohibit from towing the load

Towing the load crosswise or

endwise will cause equipment to tum

over or to be damaged that may cause

person hurt accident.

Therefore, should move the crane

near the load and lit it vertically.

1.3.24 Prohibit over load

+ Do not lift the load over the rated

lifting capacity. Should ascertain the

load weight in advance (© avoid the

crane turning over or damaged caused

by over load

When the overload appears in

operating, should fall the lift load

down to the ground by the hoist falling

operation of hook.

1.3.25 Prohibit

excessively

Does not lift the load overstrain when

wite rope or load is grappled by fraise,

can carry on operation after removing

from obstruction

Do not uy to lift the load burned

underground or in the sediment.

from lifting load

ARF F AR / Bee Pa HEN OE TL

tet

AN SER PARE AT A ik Tl BS Te eb

PTE.

3.26 Bik Raa

PEAS TRS, RR HT

HRS PN, Man SH AF

WEAR ATR AT PAE, ASB

iA HT HE «

BD tk 48 He

By, Se

WF BEIT, tL

BH HE

EAB BNTDEA

WERE.

=» EMRE

ASE FT

A EA RAC a,

tH Za a Boa a a A

BRA.

g

ahs

1.3.27 SMU PE NLP EI IE

“haw, fellate,

fi WOE 2 HB a IIL Be AG ED

Sik.

Lie FEMA, BEE BRETT AR

real:

Sei, gs

nemeTte NS

HTML,

ie 5 A TF

we (EL A BL

ati.

HE BORTIN, B e 2 8

PEAT BEE Me eS TAL

BURL, TEM ES DR

u

1.3.28 AE

RE pa iL ee B, ei FRE

ue a

bh be DLN peers

Alin BY

Instruction Manual / Safety / Operation Cautions

1.3.26 Avoid hook over hoist

+ If the hook is over hoisting, it will

cause hook and lift load to hit the

boom, and lead to damage the boom

and load drops down, and may person

hhurt accident happen.

Even if the hoist immovability, when

derricking downward, can also lead to

the hook is moving upward to over

hoisting,

Before anti -overhoist device working,

by the different hoom angle and lifting

Toad, the lifting load and boom

collision can also lead to the overhoist

state

1.3.27 Cautions in work radius added

When lifting the load, the work

radius will be increased; sometimes will

lead the crane to turn over because of

over load

+ Before operation, should think ahead

the benefit of work radius to set up the

work radius under prescribe or the lift

weight under prescribe,

When lifting load, work radius will be

increased because of wire rope and

backstay cable wire rope stretching,

and the load is more weight, the work

radius is increased more clearly.

1.3.28 Don't excessively release the

wire rope

Don’t excessively release the wire

rope, when hoist falling, should remain

the rope on drums at least above three

circle, for fear that wire rope falls off to

cause the load and the hook to fall down.

VA a / ete ET Instruction Manual / Safety / Operation Cautions

1.3.29 ASS PENIS ADE eT 1.3.29 Cautions in biting work

+ SEALCE EID BUREN NAEAL AVE + Check the function of hook drop

. prevented device for normal

FUSeARUe HAN AME 3A + Reduce the hoisting angle of wire

ia 7 22 SE » jE

: ‘ fein foliar efor RA rope; the angle should be under 60°.

Tersde 60" EA Fs + The hook should be located over the

+ BIRLA PRR CAEL Tift load centre of gravity, for fear of

US PE yk STE AR He DB causing load to drop or turn over

NCAT because of the departure of gravity

«AIDA HA22 EAT AEM centre.

+ Prohibit the crane from lifting load

with single wire rope

EIA AB ee RATA A NE

Instruction Manual / Safety / Cautions in Dismounting und Transportation

1.4 PPR RRB ER

Bi

1,4, 1 FE TE Wi BAD OL PP Sa A 2

fe

REL ET ALAR, SNAP AIR ME PE Me

WY, SEH TE NEHA 5

+ TEXPESALIN, BELL

BMW Fy ae eH

SUT BE, 48 Ss

FARO GHLA

AI EEE AN oe

Spite Te.

1.4.2 BARA MARE HET

CER A ARTEL, WRT EAS

Hy A WAAL AE SS FARIA.

+ REE EEN A RAS EB

‘We

AB BE VINE ER AE AE AS UE

se

3 RCM ERT

HG ALPE A MES. SEL HTT

by efit lel eat

« SILA RGEARL ED A.

PERMA LE ZW, SEAS

HLT

4.4 FD EEA

AREA AT SE HE OR Lak fT ak

Se HHL.

4 HE 7 AP AY AHL

Bey D} HR EA

I, BREA BLAS ¢

AS

PARMAR e

METAR, DRI PIS SBA

WUE 6

26D win SH HE IE

ISLE RAS 2 3 i LF

ALE, Sait Ae

1.4 Cautions in

‘Transportation

mounting and

14.1 Dismounting according to right

sequence

+ When carrying on dismounting

operation, should follow right

sequence.

When fitting the pinhole, should not

put the finger into it to avoid person

hurt accident happening,

1.4.2 Cautions in changing the height

of A-shape bracket

When changing the height of

A-shape bracket, it may probably drop or

squeezed person if unsuitably.

Do not enter into or under the A-shape

bracket

Do not pull out the fixed pin in left and

right sides of rear drawbar.

14.3 Cautions in dismounting the

counter weight

+ Park the crane on firm, smooth

ground, and insert the turntable fixed

pin

Person is forbidden to enter under the

counter weight.

Before the counter weight is

immobility, should use an assistant

crane to support it.

1.4.4 Cautions in dismounting the

boom

+ Dismounting boom should be

performed on the workbench or use an

assistant crane,

When assembling, disassemble, and

replacing the boom, operator cannot

come into boom inside or under it, for

fear that boom drop to cause person

hhurt accident.

When boom front touches to the

ground, should notice that the hoist

wire rope is not pressed, for fear of

damage ta the wire rope

EIA AB ee RATA A NE

tuction Manual / Safety / Cautions in Disny

14 and Transport

tie

(UE

‘Al

Aes ae

FOS CM, FRUIT MYRE.

multierin, SEAL Ate aL

LAT AL OG SCH SR EN Fa RE

SEMA, CB hE PBC

ADL.

Ase e, AEA LAA

WAM TANS TE AT

HRETHIRIE

45, RA HE ET

PRR I, EC oak A A

PES ULAS HORA, UL Git 2

ETE. ATs AMES

ACSBLR. HRT

HAAR.

BL a

FrMase, AS

eh

SCTE HIM S SHH I

A, 6 BREA LE BB RIS REE TAL

‘HRS BRI SoA Ty NS A IE Ho

tk Jz AOUIN ET ARSENE 1 nL ATL J

sh) DOR AE NS eA.

TEAS Lista, BAG UE TABATA

BIA, MESHES AL

HES SPR AT

PUR LER

SSCZ IER, WS.

bit, PRIMA.

AUKUR BRL. ACTS TT

+ When disassemble link pin shaft of the

boom by knocking, should not stand in

face of it to prevent the shaft fiom

flying out suddenly and cause

accident.

+ When pulling out link pin, should use

an assistant crane or a workbench with

enough supporting strength to support

the boom for fear that boom drops and

cause person accident

+ When the boom installing finished,

should check whether there are tools

or parts on the boom, and then carry

on boom hoisting operation,

1.4.5 Cautions in disassemble and

assembling of the wire rope

+ When disassembling the wire rope,

should pull out the rope by winding it

on reel for fear of causing the wire

rope deformation, disorder, relaxation

to, ete, and shorten its use life.

+ When installing the wire rope, should

make the wire rope reeling tidily along

the drum, and not allow presenting

warping of “S” form.

1.4.6 Cautions in instal

wedge

+ Check — whether the installation

direction of rope wedge is right.

tion of rope

1.4.7 Cautions in transportation

+ Should know the given weight and

size of transportation in transporting to

choose the suitable transport vehicle,

+ When transport on the highway,

should investigate the pass restrict

advance, avoid no passing caused by

limit of breadth, height, weight and so

on

+ When passing through under elevated

wire and tunnel under overpass should

keep them at a distance, for fear of

causing accident in touching or crash.

+ Should transport with low speed to

ensure safety when the road surface is

snow covering, freezing, or not

smooth.

EAE / Sec / FRONT eT

1.5 PRFEM AUER

1.5.1 SBR Bete

Ga Fem BE AH AS)

ls WA Sei AD

De A RE

1.5.2 Seite ASE

EAM TLZ HT, BEML ACBL

DEAT RAE, BETUETT UCT Me, REAR ME

TURE, REL ABE, BENT

THERE, HOR EIR.

1.5.3 CHER HS Sawer

Fa TARE Bee, HE Tai BE

MERE BH, WRAY it

TP, ATT RE SREP ICI RE

© SAMA see PA Tae Mi Eee,

FAK, ROMA ACLS AS, BU

SUVS ACID DISS , SE NTH AO

THe.

Ae Aa Fa ITE I], ON A,

FRAG, WBMES RARE IE

5.4 BREA AE

RPE TE He LAE 2 4 META ALE

FIAT 6

= ERR Ree

Ah HERR SPAM ae ALPE AE,

SBS BE A STE A AIM SEB BH fle

STE oki SHAT BUR, Bhp ik

ART GA

0 CE AMET ARPES BEET JET 1, TE:

HE, VAG EAIDE AL. HRS HE.

SLBA BE EY TA RE A

ie

6 RRA] A

FALE TED) BRAR AE 5

BAAR, WL

SSA De MAD

Ke WLR 5 es

HL, RAD.

aanene

mbes

FEAR HOARAS PEAT HEME, aR AEAT

RAS DE BRIBE BET

Ls.

Instruction Manual / Safety / Maintennance Cautions

1.5 Maintenance Cautions

1.5.1 Using the factory parts

Use former factory parts in

maintenance for fear of causing

equipment trouble.

1.5.2 Periodical check

Before using crane every day,

should check the crane, make a month

check every month and make a year

check every year, if abnormal, should

repair, adjust or replacing at once

1.5.3 Periodical replacing importance

parts

In order to ensure safety, appoint

importance parts of periodical replacing,

if no replacing may cause contingency.

Parts will age with time passing,

therefore, even if no abnormal, when it

is the time to replace parts, should

replace new parts

Even if it is not the time to replace

parts and if found abnormal, should

replace or repair either.

1.5.4 Operation cautions

The maintenance should be carried on

safety, firm and smooth ground.

Clean the needless tools and effects,

clean oil and lubricate grease to

protect operator fiom tipping or

slipping,

When opening the door or cover,

should fix them to avoid a sudden

wind hurting.

Open the door and window to change

air when maintenance indoor, for fear

of operator poisoning caused by

pollution of exhaust gas, fuel, paint

and so on.

+ Put the warning board No Operation

on the door or operating lever, for fear

of starting the engine

or moving the crane

by other person and

it will cause person

hhurt accident.

AOFM / BH / RH SBA

eM BERL

WT PE aE

fi 9B BE A OR

HSL

om

«5.5 RI REDO ADR AS

EKA RAIPUR AS FT RFE,

CAB ANA EE, We HiaAs

Ail FRAT He

MRR BLE Ie BH WIE HEAR

ADL EORHME, JEM Neils Y

Te

DAMA TE 2 ws, a

FRU RAL AL CL Pak

iy EE Se eI AR A, 9] RR

tee

QAR BEES. ACH. TL

SB A VL A aS ANT A os a Ee fl

aie

1.5.6 thls RR IRE

+ CMAP, UB be.

oT HN Be

= Hens (BE A PEAS EAE 6

1.5.7 SRIEREA RE IIE OEE

MBL RICE, AEE

HEB UIE He

MBE, DL Seth K

FRET. OR FR

“TREE A

Bike

1.5.8 HERE

IR eS th

Hea RAN WRLC

FSH SEL att. IE

Bibi A, AHEM

AS BRUISE

+ TERT RIEHL, BE

ERGO ABER IH»

Instruction Manual / Safety / Maintennance Cautions

= Operator in unprotected

circumstances, or in dust, detritus,

metal particle site, should wear

protection apparatus.

1.5.5 The Engine State in Maintenance

+ Cary on maintaining after stopping

the engine for fear of touching with

rotational parts, Otherwise, it will

cause person accident hurt by

squeezed and swept

If must maintain in engine running or

crane moving state, should operate by

over two operators, and strictly abide

the items below:

One person seats in the cab, keep

a posture which can stop engine and

crane throughout and meanwhile should

avoid touching other operating lever

which cause error operate

®The operator should avoid the

body, clothes and tools touching near the

slewing parts or turning units.

1.5.6 Brake maintenance cautions

« Should set stop dog under the tyre to

avoid crane sliding,

+ Boom should be dropped to the

ground

+ Drums and slewing device should be

broken,

1.5.7 Prohibit from approaching to

running part

When the equipment is running, do

not put hands and feet into running part,

for fear of the person accident caused by

squeezing, roller compaction and so on

1.5.8 Advert high-pressure oil

If the operator is hit by ejaculation

such as high-pressure fuel, hydraulic oil,

cover and stopper, it will cause person

hurt accident.

+ Before maintenance, should discharge

pressure of hydraulic oil line.

+ When carrying on check in

high-pressure oil leakage, should wear

EAE / Sec / FRONT eT

Instruction Manual / Safety / Maintennance Cautions

oA RMA LENT, ERT

BP PS, eA ACHE A

Ka.

1, 6.9 HAMAR DEAL HE HE

» RARAL

+ RCM Ras HT oh.

+ AMMA

Er RMR

BLP EA

PSE ea a5 Ta tH,

A FO HR a RL a

HAT.

1.5.10 AEH

SPRATT. DLT. LT LAR

BEAK FAD REE L, SAO

KGROH, BiB BME.

1.5.11 RABAAB MER BT

FERRE CURSE, SEITE a Lit

WO, WAS Ae Ge HRA TE

1.5.12 BERL ROE SL

BIE A IEDR

AB, Bit Rul ie

AIR « x

AR BE 7k BE BR

APE, DL Sait

SL

13 RTT RE OE

Bi

Bee HH BE TT aE

Dd Ses 3ST DA TEA HE

TRAST iE.

+ SARE ER 2 Ih» EAL

PAB DB ATT ME, HER aH

Ws RASHIE A URLS OR HI HA 5

1.5.14 SEIE RSL HERE A I

SRL

HEAT IN

TE OPE. SUE RES

HERES, DRE

Ls

goggle and glove, and use pasteboard

or board to check.

1.5.9 Cautions in fuel and oil filling

+ Stop the engine.

+ Do fuel filling on drafty place

+ Do not near to the open fire.

+ Screw up the cover of fuel tank and oil

tank,

+ Clean the spill fuel and oil promptly.

1.5.10 Using suitable illuminator

When check fuel, oil, battery

electrolyte, should use explosion-proof

illuminator to avoid explosion. The open

fire lighting is forbidden.

1.5.11 Cautions in maintenance of

electrical system

When maintaining the electrical

system, should cut off the cable of

battery to avoid person hurt accident

caused by fire,

1.5.12 Clean equipment cautions

Operator should wear gougle for fear

that spattering marl come into eye.

Do not splash water to the electric

parts, and avoid causing short circuit.

1.5.13 Welding paint surface cautions

Operation should be carried on drafty

place at outdoor to avoid toxic gas by

heating, and cause person hurt

+ When removing the paint coat with

grinder, the operator should wear

goggle and dustproof mask 10 avoid

pain chips and dust getting into eyes or

being breathed in body.

1.5.14 Prohibit heating hydraulic parts

and

Prohibit the operations of heating,

welding and gas cutting hydraulic parts,

EAE / Sec / FRONT eT

Instruction Manual / Safety / Maintennance Cautions

PR, PR MT AE

5.15 AVR AOE ET

«DOT BEBE Mb OR a

ETE FS

= SAU EE

SGA SUIT.

. a AE FANE HEE, ESS

AVS EF MEAD, FE SBA

ei BME SEB

ATER, (ESET

1.5, 16 EBABY ERIE

HELP PUEES i

SOUEAT

Siz APSE 0 0 SW A

2B 10%.

© EEN L AKELTE U0

© RTL.

WYSE Bak Ae he

i Ee

1.5.17 IEW

« HAAR, Bok. BERR TRA

ar RARE.

. fe tA Bee He Hd BG

AUNT TE A ET

+ ARTTIA IEA RET TAFE 2 LTA.

Rat AR HA.

. Mt tt

sonia, ea Sab

BL i 1 ly

oy THE Gas IIHT 7A AK HE,

FEIN AE ATT SH AE A.

BEAT ET AUER fe MEP BE es 5 HR

M.

pipes and around them, to avoid

person-hurt accident by pipe burst.

1.5.15 Boom maintenance cautions

+ The boom should be dropped down to

ground or shelf and then carry on

repairing,

+ When the boom is damaged, should

replace or repair it by professional

person.

+ Never weld other parts on the boom,

Otherwise, it will decrease the boom

strength and cause damage and it has

dangerous of person-hurt accident.

1.5.16 Wire rope maintenance

Replace the wire rope if having any

below:

+ The boom should be dropped down to

ground or shelf and then carry on

repairing.

+ When the boom is damaged, should

replace or repair it by professional

person.

+ Never weld other paris on the boom.

Otherwise, it will decrease the boom

strength and cause damage and it has

dangerous of person-hurt accident,

1.5.17 Right assembling wire rope

+ Cheek if the size of rope wedge, 1ope

nip and wedge is suitable for rope

diameter.

+ Check the wire rope installation

direction on drum and rope wedge

direction for right

+ Check the installation direction of rope

nip for right.

1.5.18 Avoid fire

+ Forbid smoking

maintenance.

+ Should carry on adding fuel at outside,

and stop engine, be away from the

open fire

+ In order to avoid electric spark during

filling fuel, should touch the hose

nipple to the fuel tank.

+ Polishing and welding operations

should be faraway from

inflammables,

+ Check the tube and hose for looseness

during the

EAE / Sec / FRONT eT

Instruction Manual / Safety / Maintennance Cautions

ALAR AACE A DC Rl a a, BE

APATITE AGRO Tk EA

YA HED SERA SIRE AT 1B

AF Hs ME a He BE A att

Hi TG»

AG PE CY SH LG aL

ae

PEE ABET, BALA A BRAN

HERI MUIEAR

MOAT RUE Tike

© SARE KR aE

KR RABL, FeRIF

20 Bi A ALI ik

tn ey Dae AF IK

JAY, DAEBA IT By WIRE

BenARAS BET IK

eE.

1.5.19 BRIE

FEL BIBHORAS F

paid Bove Bil.

BLA IEMA

arin. MLR

ie PRET ERIE, FA

BR OiITIE I. AS,

BE HE 6.5) oH JS FP HE

TORRE

1.5.20 (EF. PREC RAIT MOTE

SEAM HE FCI 5

BUN, AAU HAY

+ FER.

RA BARRE AE: fe. PSELAMAL

BNE SUR AEA, BETH

HRIENL, DEE

ANIA RET.

+ TAREE IAT, AS

BAG 6 lif FLT Ik

B, ese

ai.

21 FSM MERE

BEALL FCAT RES SE 1 8 HE

#4

AMA

Uns id SU BUE fL

UE A aE S| EAS BEAR S|

‘or damage, and leakage of fuel, lube

oil, and hydraulic oil. If having, should

clean and repair

Check the wiring connect piece for

damage.

Should not flush parts. with the

inflammable cleaning solution.

Operator should know the placing site

and usage of fire extinguisher in

advance.

Once fire occurs, should shut down the

engine at once, and leave the crane.

If fire can be put out at beginning,

should do it in a state of avoiding

dangerous.

1.5.19 Avoid scald

When or after the equipment is in

running, the parts and coolant liquid,

Iubricating oil, hydraulic oil are all in

high temperature state, Maintenance in

high temperature state may have scald

dangers, so should do it after full cooling.

1.5.20 Cautions on tyre using and safe

keeping

+ Should use appointed tyre.

+ Tyre pressure must attain the given

value during travel.

+ Do not overload.

+ Replacing, disassembly, repair and

assembly of tyre all need special

equipment and technology, when the

tyre need maintenance, should carry

on it by special operator.

+ When tyre storage, do not put the tyre

upright for fear of rolling or tuning

over.

1.5.21 Hauling cautions

+ Operator should cary on hauling

operation with wire rope that has

enough strength,

+ Personnel cannot enter between the

EAE / Sec / FRONT eT

ZU) 6

BEA IRIE YA AT AR, ANE

Tk.

FES] AS WEE S| EE ee — 2h

Ble

FeRAM

5.22 She ESR

HERDER EEA A ABIL, ABE

PERUALHNM, SR i Ta. WH.

«5, 23 ARIE

A BEANBOE Fl, WLS

A Sm ERIE EIR,

RIERA W RA

Ha GRAPE IASG, AS BENS al 2 FB HE

BAK.

DEE TLINS BE Lede Hk A i

file

5.24 RIES

TESERUR IE» BERS HE 8 BL

TL. THORUAE Chiat. SR EOE

Able

MIRE RABID, IPA LET BR

TE HAVES e a, aie Rea LPS

ET AOA. BURA LE AT LL

IEW ie Fe 1k.

Instruction Manual / Safety / Maintennance Cautions

hauling vehicle and the hauled vehicle.

+ Should travel at given speed, do not

suddenly speed up.

+ Tractor and erane should keep on one

line,

1.5.22 Cautions on cast off treatment

Discharge liquid should be received

with container; cannot pour it into river

and lake or make it seep through ground.

1.5.23 Air-condition maintenance

+ Do not touch refrigerant, and avoid it

entering into eyes or staining to skin

for fear of going blind or being cold

injury

+ Do not discharge cryogens to the air in

order to protect the environment.

+ When air-conditioner is discarded,

should retrieve the refrigerant that has

been charged in.

1.5.24 Cautions after maintenance

+ Check running state of equipment after

maintenance, confirm whether there is,

oil Icak, and bolts arc fastening,

+ Run the engine at low speed, carry on

operations slowly and after confirming

it is no abnormal, speed up the engine

and confirm again until the equipment

can operate nounally.

ITE AP SPB

Ro PSR

210 BR

1 PAST

QLY4O fe Hiaks HEL AL ARS ALE AL

PE FUE ca FMF Az 4b Ike BL,

JG HEO, Chie. Beit Pet AY Be

2.

EAE RETR» fe

Heals kt

FLAT LAPEER AT A DRE FR MER

Hi AWS Js VLE. KI

REAP MLIN Be RK.

ABLAD HITS

IPs

(1) It. ARN. LES APE BLED

SWAG). SAMUI. (TRAE OR

Hee

(2) 887 Bi, PFA IK eh HLH

RARE), (ER ANTE DI FS

DA.

(3) ket. REN lay 818) 9 2 FAS

es, ila ay

GQ) AHR. HRS

PURE, TE KR UREIIE HE EIN te

Ke

(5) RS EAR, SEH. AAT. A

WR Ai HE SIR SEA

pic, SEMI, PYSRS

(6) BLAU EAS IRIE

ANT 2%), det PAS. AY ANF

PRR Aire AEE BRR A OS LA A

Mh ip 2 4 He

(7) ACBL) pace Fic BE te oR PE

Hy 19m, APA Pe BE KB

HUAI AISIZ 31m.

Instruction manual / Production introduce / Summary

Chapter 2. Production

Introduce

2.1 Summary

2.1.1 Brief Introduction

The QLY40 wheel crane is a

product, which is specially developed

according to the operating characteristies

of the consumer. It is suited for handling

of cargoes at harbor, warehouse and

railway goods yard et

The crane can be operated

continuously for a long time with high

operation efficiency, its operation is easy

and flexible, and it has reliable

performance, conveniently maintain etc.

The crane has high lifting weight in

middle or large radius,

The crane is of the structural

features below:

(i)The mechanisms of hoisting,

derrick, swing, traveling are all driven

hydraulically with simple in structure and

easy for service and maintenance

(2)Motors of hoisting, derrick, and

traveling are driven by variable pump

with constant power; enable the power of

engine being fully to be utilized.

(3)The hoist and derrick brakes all is

normal applied brake, which has reliable

braking.

(4)The boom structure is a lattice

type with lightweight, satisfactory forced

situation and great hoist capability at

middle or large radius.

(5)The main force units, such as

boom, frame, outriggers, turntable,

A-shape bracket etc, are made of

high-strength steel, so the structure is

strong and reliable.

(6)The crane incorporates some

safety devices, such as_radius

indicator(with error less than 2%) , lift

limiter, boom elevation limiter, moment

limiter, derrick check pawl ete.

(7)Under the standard allocation, the

boom length of the crane is 19m, it can

also be added or subtracted in length

according to the customers and the max

ITE AP SPB

2.1.2 EHOPLIERE

AVE PLUG SEMANA 2.1 fas

108

Instruction manual / Production introduce / Summary

length is 51m

2.1.2 General view of crane

General view of erane see Fig 2.1

wo

357

a2. 1 LR

2.1.3 AROMA ER

(AEA BL A, ERY

AAPLUMTI, BAHT —KAR,

GET

— ie BE ee it ee BE

OR, AEE iE AE 2 AS SE LT AT

fe

(3) ROR BLEETE ACY. BENS

21a

Fig, 2.1 General view of the crane

2.1.3 Operating points for attention

(Routine check should be

performed before daily operation.

Besides, month check is needed once a

month, and year check is needed once a

year.

(2)Work must be performed under the

rated lifting load and appropriate radius

according to the Rated Lifting Capacities

chart.

(3)The crane must work on the

ITE AP SPB

Instruction manual / Production introduce / Summary

IL ftes

GQ) ATE A BUR RARASI, AP

REBEAT CMLL. SEAL TE A AR AR

ASIN HT ae.

() fe lett, RLY BA RA

(6) 47 Ht, RAE NA TRIE BI)

MEH.

(7) FEMA U TRIBE RS FL EEA

PRT Xe GG TEE Te» RE LE

HURKEG. AAT ek

(8) BGA 13.8 K/L,

AUCH: FTWIN, SRE PEL.

(9) FERAL BE Pith ick BE Lee ON LE

MEI, 2 ZUREE 2 RUA EAOBES. CE

RAR AGEE EMMI, DIEHL METT

(10) BEE MEIN

HEIPL L.

(11) sR Pe BP AS A

(12) ELRE EMIS» BH eI

PY A 0

(13) MPU cea, BREA

ADL.

SLA Se Hy SB

lid

(1A) AB BE FB AS, SE

IL fe MR Se Fa EL LH

a PEL A i, id

AEH KE.

(17) 25 10 CA TB 238

(18) FABRE DRE RAE

ABHE EM.

(19) HEBLAT SLIM. FA BPE

ea

(20) REBLATMRIY, FAAS me

CLG).

(21) AAT SHRI, RMA AS PE AT

(alee.

(22) BLE {he MIS WAS BB FF EAL

Saeed “ab” CBD ACBL

horizontal and firm ground.

(4)Permitted to lift load only when

the A-shape frame is extended, with it

retracted, lifting work is forbidden.

(5)The outriggers must be extended

fully in operation,

(6)When traveling, the tire pressure

must be up to the given value.

(7)Operation can be performed only

when confirming that the height limiter

and boom elevation limiter are normal,

and ensuring the rope length of the

limiter.

(8)With the wind speed exceeding

13.8 m/s, working must be stopped: If

thundering, working is prohibited.

(9)Traveling through under the

electric wire or working near it, must

keep the distance more than 2m away

from it. The crane should shun the high

voltage line in site as regulated rules with

there being high voltage line around.

(10)Should avoid the load bumping

against the crane body with lifting work,

(1)Prohibit fiom. standing in the

scope of lifting work suietly.

(12)Take notice of obstacle in the

scope of swing during working.

(13)During holding load in the air,

the operator should be forbidden to leave

the crane.

(14)Prohibit derrick downward at

high speed to avoid overload.

(15)Prohibit from — shutting

source of crane during work.

(16)Selecting the suitable boom

length according to the actual work

(17)Must use the same wire rope

with the given specifications.

(18)With boom stringer or lattice

bending, working is forbidden.

(19) With the crane traveling, be sure

to stow the boom at the due front in its

travel direction.

(20) With traveling, refuse to lift load

ina hook (including slings)

(21)Prohibit from slewing operation

when the outrigger being not extended.

(22)The radiater switch is suggested

to be still at position of Mannual control

(radiating) in summer working.

the

ITE AP SPB Instruction manual / Production introduce / Summary

(23) RP RAIL. ARIK TEES tt (23)For the detailed description on

Geis Bis JTREURIHLAESNGTEAMABIAL. (service and maintenance about engine,

ERI, BIR ER) apy hydraulic component, transmission, axle

iene IT BAILS. and moment limiter, ete, refer to the

operating instruction manual given by

manufacturing plant.

EIR EB SSH

Instruction manual / Productio

duce / Main Technical Perf

2. 2 ER BORERE

2.2.1 EBRASH

2.2.1.1 dB AME RE

2.2 Main Technical Performances

2.2.1 Main Technical Parameter

2.2.1.1 Lifting Technical Performances

7s Gieaet ©:

RKGESRH (0) ii

‘kN.m):

(Nm) 1764

Max. rated lifting moment

SEATS (im): 10

Base boom length

TRASH Ke (am). a6

Middle section length

fA CORA SCRAPE, ms 4-26

Radius (with outrigger extending )

AEE A fs

ate ve A TE 40° 75°

Scope of elevation angle

BERETA (m): vs

Max. lifting height a

MAMET (249 m/min): mass

ine speed (unload) ~

RATAN (UE HLA RL mv mi ons

Line speed (rated capacity) ~

FVEY-R RINT 1] (30°~75°) (S): >

Derricking time

(SGM CAR e/min):

(LEME CER rim) ou32

Slewing speed (unload)

2.2.1.2 47 BERG 2.2.1.2 Travel performances

Sai’ Drive type 4x2

‘fraieit Ne #3014 high-speed (km/h): 14

Traveling speed | {38 #4 low-speed (km/h): 6

TAMIR AE Max. grade abilit 20%

Jats 854% Min, turning radius (m): 93

‘eli 44 Approach angle: 10°

23:48 Leave angle: 15°

ay BL LAPSE (c/n):

‘esp A be ith TPE r/min): 2000

Engine max. speed

REI PASE eR

Instruction manual / Productio

duce / Main Technical Perform

2.2.1.3 REAR 2.2.1.3 Structure dimensions

47HRIRAS ALS Length in traveling (m): 15.5

WEAK Chassis length (m): 70

W484. 9 Chassis wide (m): 3.43

AT BK: ‘i Height in waveling (m). 39

‘AWE Axle base (m): 38

EH Wheel span (m) 24

Jt)» 3 HALF Min. ground clearance (m): 0.27

SCMMA TEESE Cm) 2

Outriggers longitudinal span

SCHELL Gn): 62

Outriggers extended width

Fe Pbl14 64 Rear slewing radius (m): 3.56

ARS PBC eh ACE BS (my:

Horizontal range between boom lower hinge point to 1.055

center of swing

HORE PEER ALIASES (m): La90

Range between boom lower hinge point to ground

Front suspension (m): 1.770

Rear overhang (m): 1346

2214 RRSR 2.2.1.4 Weight parameter

THERA (19m FY) (0): 383

General weight in traveling (boom length 21m)

HUAN 47 Front axle (1): 178

20.5

EIB PA

Instruction manual / Productio

duce / Main Technical Perf

B/E RE

2.2.2 OHCHE NESE

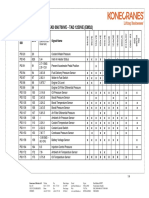

2.2.2 Rated lifting capacities

{OOF SER VE LAL Rte Be Rated lifting capacities with outriggers

SPL units t

De {89 KEE Boom length (m)

Radius 10 13 16 19 22 25 28 at

4 40.0

4.5 35.0 34.5

5 32.5 31.0 29.0 29.0

6 30.0 28.0 25.0 25.0 23.0

7 24.0 24.0 22.5 22.5 20.0 19.0 16.8

8

9

10

12

14

16

1B

20 47 45 3.8 37

22 3.9 3.2 3.1

24 26 | 27

26 2.2

A EB AP Ae eA SB FR

> SCARE Hh ACBL A 5 PE BR a

(IN, AICTE.

2A AA SCI MEIN, BOLE ERE ACT «

S.de ee aS, aE

442 ANT

Caution:

1. The capacities enclosed with bold line

are limited by mechanical strength, the

rest are based on crane stability, so the

overload is not permitted.

Enable the crane to hold the level state

when it is working with outriggers.

3. The capacities specified in the list

include the weight of the hook, it weights

442kg

IPI Pm eR,