Documente Academic

Documente Profesional

Documente Cultură

Quality Tools Cause and Effect Diagram

Încărcat de

Raj SekarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Quality Tools Cause and Effect Diagram

Încărcat de

Raj SekarDrepturi de autor:

Formate disponibile

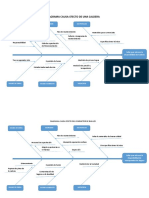

Quality Tools

Cause and Effect Diagram

Measurement Materials Method

Work place not properly

Light colored can easily capture secured(Floor cleaning not

properly done)

Stain removal become diffcult White gloves not handled by

process in low GSM fabrics operators

Lack off WIP lets to stain garment

by way off handling

Problem Statement

HANDLING STAIN

Precaution Method not used Not properly covered during shift

Properly end

Other garments dust partical are

No awarness to operator for Machine maintainance not done

deposited in light colored

handling garments properly

garments due to poor Suction

Environment Manpower Machine

Quality Tools

Cause and Effect Diagram

Measurement Materials Method

No checklist created for oil

Light colored

leakage in machines

Stain removal diffcult in low Machine service not done

GSM properly b/w time intervals

Oil stain visiblity will more

vigiliant when comapred to Dark

colored garments

Problem Statement

OIL STAIN

Precaution Method not used

Properly(Check oil leakage in Due to poor maintaince

M/C by manually by operator)

No awarness to operator for Oil leakage not calibrated/

handling garments notified properly

Environment Manpower Machine

Quality Tools

Cause and Effect Diagram

Measurement Materials Method

Low GSM lets to diffcult in sewing Not following Guide properly

Improper Handling of fabric while

sewing(Pull & push method)

Problem

Statement

OPEN SEAM

Machine RPM to be re calibrated

Proper time settings

Improper thread tension(Loose/

No awarness of checking method

Tight tension)

Due to Improper machine

By passing self checking method

settings(Pressure bar, Feed dog etc)

Environment Manpower Machine

S-ar putea să vă placă și

- Absorption Costing and The Concept of Job Order: Hammad Javed Vohra, FCCADocument23 paginiAbsorption Costing and The Concept of Job Order: Hammad Javed Vohra, FCCAUrooj MustafaÎncă nu există evaluări

- Input: Fishbone Diagram TemplateDocument4 paginiInput: Fishbone Diagram TemplateHamza KhalidÎncă nu există evaluări

- Topic 2 - 7 QC ToolsDocument68 paginiTopic 2 - 7 QC ToolsFikri ZdinÎncă nu există evaluări

- Project Traffic Light SystemDocument17 paginiProject Traffic Light SystemAnonymous h8XzQqz8rÎncă nu există evaluări

- Assignment 6 MDocument2 paginiAssignment 6 MMuhammad Saad KamalÎncă nu există evaluări

- Corrective Action Report (CAR) : Fish Bone AnalysisDocument2 paginiCorrective Action Report (CAR) : Fish Bone AnalysisFarrukh Jamil100% (1)

- DHUDocument12 paginiDHUSukram HembromÎncă nu există evaluări

- Analysis of Sewing Defects and Control IJPTE-V7I2P10420200710-95083-1vdx52v-with-cover-page-v2Document8 paginiAnalysis of Sewing Defects and Control IJPTE-V7I2P10420200710-95083-1vdx52v-with-cover-page-v2Abdul Mateen TahirÎncă nu există evaluări

- Fishbone DiagramDocument3 paginiFishbone DiagramQuality Dept AsiaÎncă nu există evaluări

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 paginiWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerÎncă nu există evaluări

- 4Ms' & AN I - CMV Matrix: Man Machine Material Method InformationDocument12 pagini4Ms' & AN I - CMV Matrix: Man Machine Material Method InformationZia AbidiÎncă nu există evaluări

- Measurement System AnalysisDocument44 paginiMeasurement System AnalysisMahender Kumar100% (4)

- Caldera causa-efecto diagrama mantenimiento fallasDocument2 paginiCaldera causa-efecto diagrama mantenimiento fallasDaniel Will Morales GuerreroÎncă nu există evaluări

- Method Statement SM Shimaaaaaaaaa-1Document17 paginiMethod Statement SM Shimaaaaaaaaa-1suaidah shimaÎncă nu există evaluări

- Risk Assessment-2021Document2 paginiRisk Assessment-2021Mayur KhalatkarÎncă nu există evaluări

- Risk Assessment SheetDocument4 paginiRisk Assessment Sheetfuturecolor7Încă nu există evaluări

- CAPA Incomplete Part MixDocument16 paginiCAPA Incomplete Part MixRohtash fastnerÎncă nu există evaluări

- Monitoring Environmental Impacts and Mitigation MeasuresDocument4 paginiMonitoring Environmental Impacts and Mitigation MeasuresAlvin OrtizÎncă nu există evaluări

- Fishbone Diagram: (Regarding Case Presented in Class On 14 Nov.18)Document1 paginăFishbone Diagram: (Regarding Case Presented in Class On 14 Nov.18)Anonymous sTlPd6VVRÎncă nu există evaluări

- Operations Management Managing Global Supply Chains 1st Edition Venkataraman Solutions Manual 1Document23 paginiOperations Management Managing Global Supply Chains 1st Edition Venkataraman Solutions Manual 1kristen100% (54)

- Causes of Dehydration Package Failure: Process MachineDocument1 paginăCauses of Dehydration Package Failure: Process MachineIbn MasrÎncă nu există evaluări

- Construction Equipment Telematics Service ManagementDocument2 paginiConstruction Equipment Telematics Service Managementluca nicoliniÎncă nu există evaluări

- item analysisDocument4 paginiitem analysisMarycris LopezÎncă nu există evaluări

- Garment QA ConceptsDocument119 paginiGarment QA ConceptsMila IcuzÎncă nu există evaluări

- Dr. Katsutoshi Toda 5 1Document23 paginiDr. Katsutoshi Toda 5 1Mihir RanaÎncă nu există evaluări

- Tool Wear Monitoring Using Artificial Neural Network Based On Extended Kalman Filter Weight Updation With Transformed Input PatternsDocument14 paginiTool Wear Monitoring Using Artificial Neural Network Based On Extended Kalman Filter Weight Updation With Transformed Input Patternspurushothaman sinivasanÎncă nu există evaluări

- FishDocument1 paginăFishQaiser IqbalÎncă nu există evaluări

- About The Company/ Organisational Structure: Plant ManagerDocument4 paginiAbout The Company/ Organisational Structure: Plant Managerparash rajÎncă nu există evaluări

- Maintenance Patterns and Fmea AnalysisDocument11 paginiMaintenance Patterns and Fmea AnalysisAdaaÎncă nu există evaluări

- Textile Process FlowchartDocument10 paginiTextile Process FlowchartAnik RajbongshiÎncă nu există evaluări

- 1.flange Thickness US & OSDocument4 pagini1.flange Thickness US & OSVasanth KumarÎncă nu există evaluări

- STANDARD OPERATING PROCEDURE FOR FABRIC STOREDocument8 paginiSTANDARD OPERATING PROCEDURE FOR FABRIC STOREAnkita SinghÎncă nu există evaluări

- Program Needs: Analysis By: Reviewed byDocument3 paginiProgram Needs: Analysis By: Reviewed bysajidkaleemÎncă nu există evaluări

- RA For Hvac Duct InstallationDocument10 paginiRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- UAQ 2nd Assignment (Pooja Kumari)Document14 paginiUAQ 2nd Assignment (Pooja Kumari)Reena VermaÎncă nu există evaluări

- Fishbone DiagramDocument2 paginiFishbone DiagramMai HươngÎncă nu există evaluări

- SMT Generic Control PlanDocument2 paginiSMT Generic Control Plansmtdrkd81% (21)

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 paginiKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganÎncă nu există evaluări

- Lamination Training GuideDocument2 paginiLamination Training GuideMATTHEW MUNGAIÎncă nu există evaluări

- Quality Control Management T3 B2Document30 paginiQuality Control Management T3 B2NurMohammad SarderÎncă nu există evaluări

- Che - Lesson6 - NanomaterialsDocument3 paginiChe - Lesson6 - NanomaterialsBren Jousef BayhonÎncă nu există evaluări

- Quality CircleDocument49 paginiQuality CircleAbdul Wahid AnsariÎncă nu există evaluări

- Shifting Gears E Book by CalibroMeasure EquipmentsDocument11 paginiShifting Gears E Book by CalibroMeasure EquipmentsCADISTCÎncă nu există evaluări

- Control Plan for Leanmap.com Case ManufacturingDocument1 paginăControl Plan for Leanmap.com Case ManufacturingWixi MundoÎncă nu există evaluări

- Quality Control & Quality ToolsDocument15 paginiQuality Control & Quality ToolsHadi Ahamed LipuÎncă nu există evaluări

- TCI Operations Training Program - GET: A Production & Equipment Management ToolDocument59 paginiTCI Operations Training Program - GET: A Production & Equipment Management Toolminingnova2Încă nu există evaluări

- Technology For ReinforcementDocument2 paginiTechnology For ReinforcementVasant KothariÎncă nu există evaluări

- Week 12Document6 paginiWeek 12SılaÎncă nu există evaluări

- Plantilla Xls Diagrama de IshikawaDocument1 paginăPlantilla Xls Diagrama de IshikawaIsmael Morales PuenteÎncă nu există evaluări

- POSTER_Four_gaps_in_PSM_Rev_FDocument1 paginăPOSTER_Four_gaps_in_PSM_Rev_FJinyoung ChoiÎncă nu există evaluări

- PFMEA Reference Card PDFDocument2 paginiPFMEA Reference Card PDFRajesh Yadav100% (5)

- Atac 113 Pfmea R10 IatfDocument50 paginiAtac 113 Pfmea R10 IatfAzlan MustaphaÎncă nu există evaluări

- Experimental: International Journal of Textile Science 2015, 4 (6) : 119-136 121Document1 paginăExperimental: International Journal of Textile Science 2015, 4 (6) : 119-136 121Black SoulÎncă nu există evaluări

- Customer Complinat - SadhuDocument2 paginiCustomer Complinat - SadhuPANKAJ JAISWALÎncă nu există evaluări

- Mano de Obra Método Materiales: Sistema Producto SoyaDocument2 paginiMano de Obra Método Materiales: Sistema Producto SoyaCecilia Muñoz OcegueraÎncă nu există evaluări

- Stencil Testing & Cleaning: Process DetailDocument2 paginiStencil Testing & Cleaning: Process DetailAkhilesh KushwahaÎncă nu există evaluări

- Fabric inspection flowchartDocument1 paginăFabric inspection flowchartMd.Sadequl IslamÎncă nu există evaluări

- 001 Influences - On - Measuring - ResultsDocument1 pagină001 Influences - On - Measuring - ResultsThamizhmani VÎncă nu există evaluări

- How To Do Focuses ImprovementDocument39 paginiHow To Do Focuses Improvementashutoshpal21Încă nu există evaluări

- Monitoring sheet for special washer manufacturingDocument2 paginiMonitoring sheet for special washer manufacturingHarsh KachhawaÎncă nu există evaluări

- Cutting SopDocument2 paginiCutting SopRaj SekarÎncă nu există evaluări

- Cutting SopDocument2 paginiCutting SopRaj SekarÎncă nu există evaluări

- CTS Cutting and Sewing (VI) - CTS - NSQF-3Document37 paginiCTS Cutting and Sewing (VI) - CTS - NSQF-3Raj SekarÎncă nu există evaluări

- Codes LaundryDocument172 paginiCodes LaundrymashaÎncă nu există evaluări

- SOP Sewing Machine SafetyDocument3 paginiSOP Sewing Machine SafetyRaj SekarÎncă nu există evaluări

- CTS Cutting and Sewing (VI) - CTS - NSQF-3Document37 paginiCTS Cutting and Sewing (VI) - CTS - NSQF-3Raj SekarÎncă nu există evaluări

- TMP 841704 RL 2023-03-13 Relieving LetterDocument1 paginăTMP 841704 RL 2023-03-13 Relieving Letterxop0887Încă nu există evaluări

- MIT6 003S10 FrontDocument11 paginiMIT6 003S10 Frontclique_devÎncă nu există evaluări

- Action and Budget Plan For The Boys Scouts of The PhilippinesDocument2 paginiAction and Budget Plan For The Boys Scouts of The PhilippinesJohn Paul ViñasÎncă nu există evaluări

- Char Chapori Sahitya ParishadDocument2 paginiChar Chapori Sahitya ParishaddescataÎncă nu există evaluări

- Case Study Series by Afterschoool - The Great Hotels of BikanerDocument24 paginiCase Study Series by Afterschoool - The Great Hotels of BikanerKNOWLEDGE CREATORSÎncă nu există evaluări

- L5 Isomerism 3Document16 paginiL5 Isomerism 3Cheng FuÎncă nu există evaluări

- Eslit-Vinea-LA 03 Task #1-4Document11 paginiEslit-Vinea-LA 03 Task #1-4darkÎncă nu există evaluări

- All India CW Pricelist Wef 01.05.2021Document6 paginiAll India CW Pricelist Wef 01.05.2021Sameer PadhyÎncă nu există evaluări

- C15 DiagranmaDocument2 paginiC15 Diagranmajose manuel100% (1)

- Mercado - 10 Fabrikam Investments SolutionDocument3 paginiMercado - 10 Fabrikam Investments SolutionMila MercadoÎncă nu există evaluări

- List of Steel Products Made in The UK PDFDocument120 paginiList of Steel Products Made in The UK PDFAntonio MarrufoÎncă nu există evaluări

- Corporations Defined and FormedDocument16 paginiCorporations Defined and FormedSheryn Mae AlinÎncă nu există evaluări

- Ball Bearings 1Document17 paginiBall Bearings 1ManicharanÎncă nu există evaluări

- Gec220 Assignment 2Document5 paginiGec220 Assignment 2precious omokhaiyeÎncă nu există evaluări

- Chapter 7, 8, 9Document11 paginiChapter 7, 8, 9Rubilyn IbarretaÎncă nu există evaluări

- Sbi Home Loan InfoDocument4 paginiSbi Home Loan InfoBhargavaSharmaÎncă nu există evaluări

- Tutorial Letter 101/3/2018: Internal Auditing: Theory & PrinciplesDocument39 paginiTutorial Letter 101/3/2018: Internal Auditing: Theory & PrinciplesSAMANTHAÎncă nu există evaluări

- Introduction To Computer Graphics: Version 1.3, August 2021Document456 paginiIntroduction To Computer Graphics: Version 1.3, August 2021Sharan K.KÎncă nu există evaluări

- 10 Questions About Independent ReadingDocument4 pagini10 Questions About Independent ReadingdewiÎncă nu există evaluări

- Automatic Transaxle System GuideDocument23 paginiAutomatic Transaxle System GuideChristian Linares AbreuÎncă nu există evaluări

- GCAF Online Inspector Practice ExamDocument5 paginiGCAF Online Inspector Practice Examcamwills2100% (1)

- Sample COBOL ProgramsDocument35 paginiSample COBOL Programsrahul tejÎncă nu există evaluări

- Syllabus: Android Training Course: 1. JAVA ConceptsDocument6 paginiSyllabus: Android Training Course: 1. JAVA ConceptsVenkata Rao GudeÎncă nu există evaluări

- What Is InterpolDocument5 paginiWhat Is InterpolJimmy Jr Comahig LapeÎncă nu există evaluări

- ChE 4110 Process Control HW 1Document6 paginiChE 4110 Process Control HW 1MalloryÎncă nu există evaluări

- ATV600 - Communication - Parameters - EAV64332 - V1.3Document46 paginiATV600 - Communication - Parameters - EAV64332 - V1.3Sugeng WahyudiÎncă nu există evaluări

- 3.1. Optical Sources - LED - FOC - PNP - February 2022 - NewDocument49 pagini3.1. Optical Sources - LED - FOC - PNP - February 2022 - NewyashÎncă nu există evaluări

- The Government-Created Subprime Mortgage Meltdown by Thomas DiLorenzoDocument3 paginiThe Government-Created Subprime Mortgage Meltdown by Thomas DiLorenzodavid rockÎncă nu există evaluări

- Porter 5 ForcesDocument44 paginiPorter 5 ForcesSwapnil ChonkarÎncă nu există evaluări

- Index and Sections Guide for Medical DocumentDocument54 paginiIndex and Sections Guide for Medical DocumentCarlos AndrésÎncă nu există evaluări