Documente Academic

Documente Profesional

Documente Cultură

Protect Steel Surfaces in Acidic Environments

Încărcat de

Juanda Mardohar Dantec SitompulDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Protect Steel Surfaces in Acidic Environments

Încărcat de

Juanda Mardohar Dantec SitompulDrepturi de autor:

Formate disponibile

Product Data

HEMPADUR 37620

37620: BASE 37629: CURING AGENT 97620

Description: HEMPADUR 37620 is a two-component, amine cured phenolic epoxy paint, which cured to provide

excellent resistance to acidic environments.

Recommended use: For corrosion protection of steel in atmospheric acidic environments such as electrowinning plants,

coking works, pickling shops, electroplating plants, dye mills, wood-pulp works, tanneries and oil

refineries. Not intended for continuous contact or immersion with acidic solutions.

Service temperature: Ambient temperature in acidic environments.

Availability: Not included in Group Assortment. Availability subject to special agreement.

PHYSICAL CONSTANTS:

Shade nos/Colours: 11621*/ Grey. see REMARKS overleaf

Finish: Glossy

Volume solids, %: 100

Theoretical spreading rate: 4 m2/l [160.4 sq.ft./US gallon] - 250 micron/10 mils

Flash point: 128 °C [262.4 °F]

Specific gravity: 1.3 kg/litre [11.1 lbs/US gallon]

Dry to touch: 6 approx. hour(s) 20°C/68°F

Fully cured: 7 day(s) , 20°C/68°F. see REMARKS overleaf

VOC content: 48 g/l [0.4 lbs/US gallon]

Shelf life: 1 year (25°C/77°F) from time of production. Depending on storage conditions, mechanical stirring may

be necessary before usage.

- *other shades according to assortment list.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: 37620

Mixing ratio: BASE 37629: CURING AGENT 97620

2:1 by volume

Application method: Airless spray / Brush (touch up)

Thinner (max.vol.): Do not dilute.

Pot life: 40 minute(s) , 20°C/68°F or 30 minutes , 30°C/86°F.

Nozzle orifice: 0.015 - 0.017 "

Nozzle pressure: 250 bar [3625 psi]

(Airless spray data are indicative and subject to adjustment)

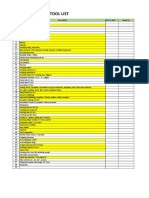

Cleaning of tools: HEMPEL'S TOOL CLEANER 99610

Indicated film thickness, dry: 250 micron [10 mils] see REMARKS overleaf

Indicated film thickness, wet: 250 micron [10 mils]

Overcoat interval, min: According to specification.

Overcoat interval, max: According to specification.

-

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: January 2018 Page: 1/2

Product Data

HEMPADUR 37620

SURFACE PREPARATION: New steel: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive blasting to Sa 2½ (ISO 8501-1:2007).

Minimum surface profile corresponding to Rugotest No. 3, BN11a, Keane-Tator Comparator, 5.5 G/S,

or ISO Comparator Coarse (G) - or as per specification for the subsequent coat(s). Otherwise

according to specification. After blasting, clean the surface carefully from abrasives and dust.

Feather edges to sound and intact areas. Dust off residues. Touch up to full film thickness.

APPLICATION CONDITIONS: Use only where application and curing can proceed at temperatures above: 10°C/50°F. The steel

temperature must never drop below this limit until full curing has taken place. The temperature of

the paint itself must be above 15°C/59°F, best results are obtained at 17-23°C/62-73°F. Apply only on a

dry and clean surface with a temperature above the dew point to avoid condensation. In confined

spaces provide adequate ventilation during application and drying.

See separate APPLICATION INSTRUCTIONS

PRECEDING COAT: HEMPADUR 37620

SUBSEQUENT COAT: HEMPADUR 37620

REMARKS:

Colours/Colour stability: May attain a reddish shade in very acidic environments. This is a common feature of all 100% solids

novolac epoxy products and has no detrimental effect on performance.

Overcoating intervals: If the maximum overcoating interval is exceeded, roughening of the surface is necessary to ensure

intercoat adhesion.

Note: HEMPADUR 37620 For professional use only.

ISSUED BY: HEMPEL A/S 3762011621

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: January 2018 Page: 2/2

S-ar putea să vă placă și

- Heavy-Duty Epoxy Coating Product DataDocument2 paginiHeavy-Duty Epoxy Coating Product DataKhyle Laurenz DuroÎncă nu există evaluări

- Pds Hempadur Glass Flake 35851 En-GbDocument2 paginiPds Hempadur Glass Flake 35851 En-GbIlham NugrohoÎncă nu există evaluări

- HempadurDocument2 paginiHempadurLuciano SalituriÎncă nu există evaluări

- Pds Hempadur Glass Flake 35851 En-GbDocument2 paginiPds Hempadur Glass Flake 35851 En-Gbkalpesh parmarÎncă nu există evaluări

- Product DataDocument2 paginiProduct DataegomoÎncă nu există evaluări

- PDS HEMPADUR EASY 47700 en GBDocument3 paginiPDS HEMPADUR EASY 47700 en GBharshana divankaÎncă nu există evaluări

- Pds Hempel's 174de En-GbDocument2 paginiPds Hempel's 174de En-GbMark InnesÎncă nu există evaluări

- Pds Hemparea DTM 55973 En-GbDocument2 paginiPds Hemparea DTM 55973 En-GbFreddy Carl FredricksenÎncă nu există evaluări

- Hempadur 85531 PDFDocument2 paginiHempadur 85531 PDFvitharvan0% (1)

- HEMPADUR 15400: DescriptionDocument2 paginiHEMPADUR 15400: Descriptionherysyam1980Încă nu există evaluări

- HEMPADUR 15400: DescriptionDocument2 paginiHEMPADUR 15400: Descriptionherysyam1980Încă nu există evaluări

- Hempel Shopprimer 15890ZSDocument2 paginiHempel Shopprimer 15890ZSAnuar SalehÎncă nu există evaluări

- PDS Hempatex Hi-Build 46370 en-GBDocument2 paginiPDS Hempatex Hi-Build 46370 en-GBRauf AliyevÎncă nu există evaluări

- Hempadur Quattro InglesDocument3 paginiHempadur Quattro InglesElizabeth Maria Bazán MoralesÎncă nu există evaluări

- PDS Hempadur Hi-Build 45200 en-GBDocument2 paginiPDS Hempadur Hi-Build 45200 en-GBvitharvanÎncă nu există evaluări

- PDS en-GB 45751Document2 paginiPDS en-GB 45751Anuar SalehÎncă nu există evaluări

- PDS Hempadur 35560 en-GBDocument2 paginiPDS Hempadur 35560 en-GBErwin MalmsteinÎncă nu există evaluări

- Hempadur 15570 15570 En-GbDocument2 paginiHempadur 15570 15570 En-GbgabyorÎncă nu există evaluări

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 paginiPDS Hempadur Multi-Strength 45753 en-GBJosip LasanÎncă nu există evaluări

- Pds Hempadur Spray-Guard 35490 En-GbDocument2 paginiPds Hempadur Spray-Guard 35490 En-GbVijayaraghavan SrinivasamurthiÎncă nu există evaluări

- Hempadur XP 87550: DescriptionDocument2 paginiHempadur XP 87550: DescriptionEngTamer50% (4)

- PDS Hempadur 45883Document2 paginiPDS Hempadur 45883Fredy Xavier DomínguezÎncă nu există evaluări

- PDS Hempadur Mio 47950Document2 paginiPDS Hempadur Mio 47950VIKAS DAHIYA0% (2)

- Paint Specification HamadourDocument2 paginiPaint Specification HamadourAbdul Majid LodhiÎncă nu există evaluări

- PDFDocument2 paginiPDFMuhammad AsifÎncă nu există evaluări

- PDS HEMPATEX ENAMEL 56360 en-GB PDFDocument2 paginiPDS HEMPATEX ENAMEL 56360 en-GB PDFMohamed ChelfatÎncă nu există evaluări

- Hempathane Hs 55610 55610 En-GbDocument2 paginiHempathane Hs 55610 55610 En-GbfaizalÎncă nu există evaluări

- Product Data: Hempadur Multi-Strength 35530Document2 paginiProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarÎncă nu există evaluări

- Pds Hempadur 35900 En-GbDocument2 paginiPds Hempadur 35900 En-Gbluisbarrios104Încă nu există evaluări

- Product Data for HEMPATHANE HS 55610 Protective CoatingDocument3 paginiProduct Data for HEMPATHANE HS 55610 Protective CoatingAnonymous HPlNDhM6ejÎncă nu există evaluări

- Pds Hempel's Silicone Acrylic 56940 En-GbDocument2 paginiPds Hempel's Silicone Acrylic 56940 En-GbsenthilkumarÎncă nu există evaluări

- HEMPADUR MULTI-STRENGTH 35530 BlackDocument2 paginiHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaÎncă nu există evaluări

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 paginiPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- Hempadur Fast Dry 17410 En-GbDocument2 paginiHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaÎncă nu există evaluări

- Hempadur Zinc 17360Document2 paginiHempadur Zinc 17360Krishna Vacha100% (1)

- Fast-Drying Epoxy Primer DataDocument2 paginiFast-Drying Epoxy Primer Datadkdkdkdkdkdk_Încă nu există evaluări

- Hempaprime Multi 500 Summer 45950Document3 paginiHempaprime Multi 500 Summer 45950omar alkarabliehÎncă nu există evaluări

- Pds Hempel's Silicone Aluminium 56914 En-GbDocument2 paginiPds Hempel's Silicone Aluminium 56914 En-GbMatej ZirdumÎncă nu există evaluări

- 151SGDocument2 pagini151SGdcsamaraweeraÎncă nu există evaluări

- Product Data: Hempel'S 15asgDocument2 paginiProduct Data: Hempel'S 15asgwahyu0% (1)

- Hempadur 15590Document2 paginiHempadur 15590Yosses Sang NahkodaÎncă nu există evaluări

- PDS Hempadur Fast Dry 15560 en-GBDocument2 paginiPDS Hempadur Fast Dry 15560 en-GBErwin MalmsteinÎncă nu există evaluări

- Hempadur 15570Document2 paginiHempadur 15570Edwin HarrisÎncă nu există evaluări

- PDS Hempathane HS 55610 en-GBDocument3 paginiPDS Hempathane HS 55610 en-GBalouisÎncă nu există evaluări

- HEMPADUR SPEED-DRY ZP 500 Product Data SheetDocument3 paginiHEMPADUR SPEED-DRY ZP 500 Product Data SheetDHANOOPÎncă nu există evaluări

- Defend 740Document2 paginiDefend 740Mohamed NouzerÎncă nu există evaluări

- Hempadur 85530Document2 paginiHempadur 85530kumarnowabuÎncă nu există evaluări

- PdsDocument3 paginiPdsEnrico SaviraÎncă nu există evaluări

- GP Primeguard 235Document1 paginăGP Primeguard 235Krunal RudaniÎncă nu există evaluări

- HEMPATEX HI-BUILD 46410 Product Data SheetDocument2 paginiHEMPATEX HI-BUILD 46410 Product Data SheetMohamed ChelfatÎncă nu există evaluări

- PDS HEMPATHANE FAST DRY 55750 en-GBDocument2 paginiPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawÎncă nu există evaluări

- Pds Hempel's Silicone Aluminium 56910 En-GbDocument2 paginiPds Hempel's Silicone Aluminium 56910 En-GbjakelowÎncă nu există evaluări

- Product Data: HEMPADUR 85671Document2 paginiProduct Data: HEMPADUR 85671EngTamerÎncă nu există evaluări

- Product DataDocument2 paginiProduct DatapoerwntiÎncă nu există evaluări

- Creative Resin: Easy techniques for contemporary resin artDe la EverandCreative Resin: Easy techniques for contemporary resin artÎncă nu există evaluări

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- Detailers Dictionary Volume 2: The Industry StandardDe la EverandDetailers Dictionary Volume 2: The Industry StandardÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Tool ListDocument2 paginiTool ListJuanda Mardohar Dantec SitompulÎncă nu există evaluări

- 4008-ReCYN Project Roster - Hima-Juanda-Agung - Rev1Document4 pagini4008-ReCYN Project Roster - Hima-Juanda-Agung - Rev1Juanda Mardohar Dantec SitompulÎncă nu există evaluări

- Feed Pump Alignment Checklist PDFDocument1 paginăFeed Pump Alignment Checklist PDFJuanda Mardohar Dantec SitompulÎncă nu există evaluări

- FatigueDocument38 paginiFatigueManoj KulkarniÎncă nu există evaluări

- Feed Pump Alignment Checklist PDFDocument1 paginăFeed Pump Alignment Checklist PDFJuanda Mardohar Dantec SitompulÎncă nu există evaluări

- Feed Pump Alignment Checklist PDFDocument1 paginăFeed Pump Alignment Checklist PDFJuanda Mardohar Dantec SitompulÎncă nu există evaluări

- Smith Copper SS Weld Fittings - Price ListDocument14 paginiSmith Copper SS Weld Fittings - Price ListMohammed Jaffar AdnanÎncă nu există evaluări

- GMK6300L Product Guide Imperial PDFDocument28 paginiGMK6300L Product Guide Imperial PDFAlexis Serrano AlavidÎncă nu există evaluări

- 1.piping Systems On ShipsDocument2 pagini1.piping Systems On ShipsJuanda Mardohar Dantec SitompulÎncă nu există evaluări

- GMK6300L Product Guide Imperial PDFDocument28 paginiGMK6300L Product Guide Imperial PDFAlexis Serrano AlavidÎncă nu există evaluări

- GMK6300L Product Guide Imperial PDFDocument28 paginiGMK6300L Product Guide Imperial PDFAlexis Serrano AlavidÎncă nu există evaluări

- Offshore IndustryDocument44 paginiOffshore IndustryJuanda Mardohar Dantec SitompulÎncă nu există evaluări

- AST - Study GuideDocument174 paginiAST - Study Guiderongweius100% (4)

- Application Form Total Scholarship 2010Document4 paginiApplication Form Total Scholarship 2010Juanda Mardohar Dantec SitompulÎncă nu există evaluări

- Higher Algebra - Hall & KnightDocument593 paginiHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 paginiHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- SEO-Optimized Manual Section TitleDocument25 paginiSEO-Optimized Manual Section Title100regÎncă nu există evaluări

- Work Policy On Hepatitis BDocument3 paginiWork Policy On Hepatitis BPauline Mae AranetaÎncă nu există evaluări

- Prolonged Labor Diagnosis and ManagementDocument8 paginiProlonged Labor Diagnosis and ManagementMadhu Sudhan PandeyaÎncă nu există evaluări

- COMPRE EXAM Power and Industrial No ChoicesDocument8 paginiCOMPRE EXAM Power and Industrial No ChoicesDhey Ortega ManahanÎncă nu există evaluări

- Rosen 48V 200AH LiFePo4 Battery-PowerwallDocument5 paginiRosen 48V 200AH LiFePo4 Battery-Powerwallgihan_maÎncă nu există evaluări

- ARDS and Resp Failure by SardarDocument53 paginiARDS and Resp Failure by SardarQashqar & GB FolksÎncă nu există evaluări

- Business Project Weight LossDocument18 paginiBusiness Project Weight Lossshubh_bra100% (1)

- Rope Access Inspection GuidebookDocument44 paginiRope Access Inspection GuidebookShaik Mohamed100% (2)

- Mindray Resona7 Sapphire Edition 40325ADocument2 paginiMindray Resona7 Sapphire Edition 40325AHanna FettahÎncă nu există evaluări

- Gantt ChartDocument4 paginiGantt ChartWM IskandarÎncă nu există evaluări

- Feeder-Breaker BrochureDocument4 paginiFeeder-Breaker BrochurekrisezhilÎncă nu există evaluări

- Rain Water HarvestingDocument120 paginiRain Water HarvestingShreyas DeshpandeÎncă nu există evaluări

- Community Directory (May 2023)Document32 paginiCommunity Directory (May 2023)The Livingston County NewsÎncă nu există evaluări

- 10 1039@c5ob00173kDocument33 pagini10 1039@c5ob00173kAlex FÎncă nu există evaluări

- Metals and Its Alloys MCQDocument2 paginiMetals and Its Alloys MCQsrj sÎncă nu există evaluări

- Aspek Mediko Etiko LegalDocument45 paginiAspek Mediko Etiko LegalIra WarouwÎncă nu există evaluări

- Marin 10112017Document28 paginiMarin 10112017Robert SterlingÎncă nu există evaluări

- School and Community RelationsDocument8 paginiSchool and Community RelationsWendell HernandezÎncă nu există evaluări

- Motor Octane Number of Spark-Ignition Engine Fuel: Standard Test Method ForDocument56 paginiMotor Octane Number of Spark-Ignition Engine Fuel: Standard Test Method ForAMANDA BARRERA100% (1)

- Employee pay slip detailsDocument1 paginăEmployee pay slip detailsAmar Rajput58% (12)

- Fd35t9 Fd35t2 ServiceDocument116 paginiFd35t9 Fd35t2 ServicePyae Phyoe AungÎncă nu există evaluări

- Is The 'Next Friend' The Best FriendDocument5 paginiIs The 'Next Friend' The Best Friendarushi agarwalÎncă nu există evaluări

- Working Capital ManagementDocument2 paginiWorking Capital ManagementSatyender Kumar JainÎncă nu există evaluări

- Article - 1001293 Controling FoulingDocument9 paginiArticle - 1001293 Controling FoulingDavid Diaz PadillaÎncă nu există evaluări

- Waterways Summer 2013Document76 paginiWaterways Summer 2013Waterways MagazineÎncă nu există evaluări

- Group1 ReportersDocument4 paginiGroup1 ReportersNoraisa PatadonÎncă nu există evaluări

- Tablet CoatingDocument33 paginiTablet CoatingJames YenchoÎncă nu există evaluări

- Wound CleansingDocument5 paginiWound CleansingNur Siyah 3BÎncă nu există evaluări

- Clinical Management GuidelineDocument246 paginiClinical Management GuidelineKyaw Htet KhaingÎncă nu există evaluări

- Test Bank For Mauk Gerontological Nursing 2nd EditionDocument36 paginiTest Bank For Mauk Gerontological Nursing 2nd Editionsiccaganoiddz6x98% (48)