Documente Academic

Documente Profesional

Documente Cultură

Steel Rod System - Guide Specification

Încărcat de

Shino UlahannanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Steel Rod System - Guide Specification

Încărcat de

Shino UlahannanDrepturi de autor:

Formate disponibile

HALFEN USA Inc.

March 2012

8521 FM 1976

P.O. Box 547

Converse, TX 78109

Toll Free 800-423-9140

Fax 888-277-1695

Website www.halfenusa.com

E-mail info@halfenusa.com

Product Guide Specification

Specifier Notes: This product guide specification is written according to the Construction Specifications

Institute (CSI) 3-Part Format, including MasterFormat, SectionFormat, and PageFormat, as described

in The CSI Construction Specifications Practice Guide.

This section must be carefully reviewed and edited by the Architect or Engineer to meet the

requirements of the project and local building code. Coordinate this section with other specification

sections and the Drawings. Delete all “Specifier Notes” after editing this section.

Section numbers are from MasterFormat 2011 Update.

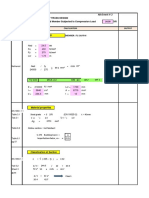

SECTION 05 17 00

STEEL ROD SYSTEM

Specifier Notes: This section covers Halfen Anchoring Systems “DETAN” steel tension and

compression rod system. Consult Halfen USA for assistance in editing this section for the specific

application.

PART 1 GENERAL

1.1 SECTION INCLUDES

Specifier Notes: Edit the following for the specific application.

A. [Stainless steel] [Carbon steel] rod system.

1. Tension rods.

2. Couplers.

3. Anchor discs.

4. Fork connectors.

5. Connecting plates.

6. Compression rods.

Halfen DETAN Steel

Rod System 05 17 00 - 1

1.2 RELATED REQUIREMENTS

Specifier Notes: Edit the following list of related sections as necessary. Limit the list to sections with

specific information that the reader might expect to find in this section, but is specified elsewhere.

A. Section 05 12 00 – Structural Steel Framing.

B. Section 05 15 00 – Wire Rope Assemblies.

C. Section 05 50 00 – Metal Fabrications.

D. Section 13 31 00 – Fabric Structures.

E. Section 13 34 13 – Glazed Structures.

1.3 REFERENCE STANDARDS

Specifier Notes: List standards referenced in this section, complete with designations and titles. Delete

standards not included in the edited section. Including a standard in this list does not require

compliance with that standard.

A. ASTM A572/A572M – Standard Specification for High-Strength Low-Alloy Columbium-

Vanadium Structural Steel.

B. ASTM A666 – Standard Specification for Annealed or Cold-Worked Austenitic Stainless Steel

Sheet, Strip, Plate, and Flat Bar.

C. ASTM A694/A694M – Standard Specification for Carbon and Alloy Steel Forgings for Pipe

Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service.

D. DIN 10088-2 – Stainless Steels - Part 2: Technical Delivery Conditions for Sheet/Plate and Strip

of Corrosion Resisting Steels for General Purposes.

E. DIN EN 10025 – Hot Rolled Products of Structural Steels.

F. EN 10293 – Steel Castings for General Engineering Uses.

1.4 PREINSTALLATION MEETINGS

Specifier Notes: Edit preinstallation meetings as necessary. Delete if not required.

A. Convene preinstallation meeting [1 week] [2 weeks] before start of work of this section.

B. Require attendance of parties directly affecting work of this section, including Contractor,

Architect, Engineer, installer, and manufacturer’s representative.

C. Review materials, installation, field quality control, protection, and coordination with other work.

Halfen DETAN Steel

Rod System 05 17 00 - 2

1.5 SUBMITTALS

Specifier Notes: Edit submittal requirements as necessary. Delete submittals not required.

A. Comply with Section 01 33 00 – Submittal Procedures.

B. Product Data: Submit manufacturer’s product data, including installation instructions.

C. Shop Drawings: Submit manufacturer’s shop drawings, detailing installation procedures,

including layout, dimensions and placement of tension rods, couplers, anchor discs, fork

connectors, connection plates, and compression rods.

D. Warranty Documentation: Submit manufacturer’s standard warranty.

1.6 QUALITY ASSURANCE

A. Manufacturer’s Qualifications:

1. Capable of providing field service representation during installation.

2. Capable of providing permanent quality control on the product.

B. Installer’s Qualifications: Installer experienced in performing work of this section.

1.7 DELIVERY, STORAGE, AND HANDLING

A. Ordering: Comply with manufacturer’s ordering instructions and lead time requirements to

avoid construction delays.

B. Delivery and Acceptance Requirements: Deliver materials to site in manufacturer’s original,

unopened containers and packaging, with labels clearly identifying product name and

manufacturer.

C. Storage and Handling Requirements:

1. Store and handle materials in accordance with manufacturer’s instructions.

2. Keep materials in manufacturer’s original, unopened containers and packaging until

installation.

3. Store materials in clean, dry area protected from weather.

4. Protect materials and finish during storage, handling, and installation to prevent damage.

PART 2 PRODUCTS

2.1 MANUFACTURER

A. Halfen USA Inc., 8521 FM 1976, P.O. Box 547, Converse, TX 78109. Toll Free 800-423-9140.

Fax 888-277-1695. www.halfenusa.com. info@halfenusa.com.

2.2 MATERIALS

A. Rod System: Halfen “DETAN” rod system.

Halfen DETAN Steel

Rod System 05 17 00 - 3

1. Stainless Steel System: “DETAN-E”.

a. Tension Rods:

1) Material: Stainless steel, A4, Type 316 with 355 MPa (51,500 psi) yield

strength [DIN 10088-2] [ASTM A666].

2) Finish: [Electropolished] [Hand polished].

Specifier Notes: System design load capacities vary with the system diameter. Load capacities are

available from 8.5 to 170.3 kN (1,460 to 38,208 lbs). Refer to system data sheets for size/capacity

relationships.

3) Diameter: [6 mm (1/4 inch)] [8 mm (5/16 inch)] [10 mm (3/8 inch)] [12 mm

(1/2 inch)] [16 mm (5/8 inch)] [20 mm (13/16 inch)] [24 mm (15/16 inch)] [27

mm (1-1/16 inches)] [30 mm (1-3/16 inches)].

Specifier Notes: Minimum system lengths are dependent on rod diameter. Maximum one-rod system

lengths are also dependent on rod diameter. Refer to system data sheets for minimum and maximum

system lengths. The critical length manufacturer requires is called “system length,” defined as length

from C.L. of left pin to C.L. of right pin.

4) Length: [190 mm (7-1/2 inches)] [______ mm (______ inches)].

b. Couplers: 139 mm (5-1/2 inches).

1) Material: Stainless steel with 235 MPa (34,000 psi) minimum yield strength

[DIN 10088-2] [ASTM A666].

Specifier Notes: Coupler lengths and diameters are specific to the system rod size. Ensure

appropriate coupler size is specified for the system.

2) Diameter: [6 mm (1/4 inch)] [______ mm (______ inches)].

3) Length: [34 mm (1-5/16 inches)] [______ mm (______ inches)].

c. Anchor Discs:

1) Material: Stainless steel A4 with 235 MPa (34,000 psi) minimum yield strength

[DIN 10088-2] [ASTM A666].

2) Number of Rod Connections: [2] [______] [8] [______].

Specifier Notes: Anchor disc diameters are specific to the system rod size. Ensure appropriate

diameter is specified for the system.

3) Diameter: [73 mm (2-7/8 inches)] [______ mm (______ inches)].

d. Fork Connectors:

1) Material: Stainless steel, A4 with 460 MPa (66,000 psi).

Specifier Notes: Connecting plates are not manufactured as part of the DETAN system. They must be

fabricated and obtained from other manufacturers in accordance with DETAN catalog dimensions and

geometry.

e. Connecting Plates:

Halfen DETAN Steel

Rod System 05 17 00 - 4

1) Material: Stainless steel, Type [304] [316] [______] with 205 MPa (30,000

psi) minimum yield strength, ASTM A666 [Finned for welding to steelwork] [T-

brackets for bolting to structure] [______].

Specifier Notes: Plate thickness, pin diameter, edge distance, and minimum plate width are specified

on the component data sheets and are specific to each system size. Ensure these tolerances are

adhered to for connecting plate design.

2) [6 mm (1/4 inch)] [______ mm (______ inches)] thick, [6.5 mm (1/4 inch)]

[______ mm (______ inches)] hole diameter, [9 mm (3/8 inch)] [______ mm

(______ inches)] edge distance, [18 mm (11/16 inch)] [______ mm (______

inches)] minimum width.

2. Carbon Steel System: “DETAN-S460”.

a. Tension Rods:

Specifier Notes: Tension rods with diameters less than or equal to 12 mm are of S355 carbon steel.

All larger sizes will be S460 carbon steel.

1) Material: Carbon steel [S355, DIN EN 10025, ASTM A694] [S460, DIN EN

10025, ASTM A572] [______].

2) Finish: [Mill finish] [Hot-dip galvanized] [______].

Specifier Notes: System design load capacities vary with the system diameter. Load capacities are

available from 7.5 to 2,695 kN (1,670 to 605,790 lbs). Refer to system data sheets for size/capacity

relationships.

3) Diameter: [10 mm (3/8 inch)] [12 mm (1/2 inch)] [16 mm (5/8 inch)] [20 mm

(13/16 inch)] [24 mm (15/16 inch)] [27 mm (1-1/16 inches)] [30 mm (1-3/16

inches)] [36 mm (1-7/16 inches)] [42 mm (1-5/8 inches)] [48 mm (1-7/8

inches)] [52 mm (2-1/16 inches)] [56 mm (2-3/16 inches)] [60 mm (2-3/8

inches)] [76 mm (3 inches)] [85 mm (3-3/8 inches)] [95 mm (3-3/4 inches)].

Specifier Notes: Minimum system lengths are dependent on rod diameter. Maximum one-rod system

lengths are also dependent on rod diameter. Refer to system data sheets for minimum and maximum

system lengths. The critical length the manufacturer requires is called “system length,” defined as

length from C.L. of left pin to C.L. of right pin.

4) Length: [250 mm (9-7/8 inches)] [______ mm (______ inches)].

b. Couplers:

1) Material: Dacrometized, carbon steel, Grade S355 with 355 MPa (51,000 psi)

minimum yield strength, DIN EN 10025.

Specifier Notes: Coupler lengths and diameters are specific to the system rod size. Ensure

appropriate coupler size is specified for the system.

2) Diameter: [10 mm (3/8 inch)] [______ mm (______ inches)].

Halfen DETAN Steel

Rod System 05 17 00 - 5

3) Length: [40 mm (1-9/16 inches)] [______ mm (______ inches)].

c. Anchor Discs:

1) Material: Hot-dip galvanized, carbon steel, Grade S355 with 355 MPa (51,000

psi) minimum yield strength, ASTM A572.

Specifier Notes: Anchor discs may be used to expand the span of the system or as central connection

points for structures requiring cross bracing. A maximum of 8 rods may be connected to each anchor

disc.

2) Number of Rod Connections: [2] [______] [8] [______].

Specifier Notes: Anchor disc diameters are specific to the system rod size. Ensure appropriate

diameter is specified for the system.

3) Diameter: [120 mm (4-3/4 inches)] [______ mm (______ inches)].

d. Fork Connectors:

Specifier Notes: The following sentence applies to fork connectors on systems with rod diameters less

than or equal to 12 mm (1/2 inch).

1) Material: Dacrometized, forged, S355J2 carbon steel, DIN EN 10025.

Specifier Notes: The following sentence applies to fork connectors on systems with rod diameters

greater than 12 mm (1/2 inch).

2) Material: Dacrometized, cast steel, G20 Mn5+QT, EN 10293.

Specifier Notes: Connecting plates are not manufactured as part of the DETAN system. They must be

fabricated and obtained from other manufacturers in accordance with DETAN catalog dimensions and

geometry.

e. Connecting Plates:

1) Material: [ASTM A572, Grade 50] [ASTM A572, Grade 60] [______].

2) [Finned for welding to steelwork] [T-brackets for bolting to structure] [______].

Specifier Notes: Plate thickness, pinhole diameter, edge distance, and minimum plate width are

specified on the component data sheets and are specific to each system size. Ensure these tolerances

are adhered to for connecting plate design.

3) [8 mm (5/16 inch)] [______ mm (______ inches)] thick, [9.5 mm (3/8 inch)]

[______ mm (______ inches)] hole diameter, [15 mm (9/16 inch)] [______ mm

(______ inches)] edge distance, [28 mm (1-1/8 inch)] [______ mm (______

inches)] minimum width.

Halfen DETAN Steel

Rod System 05 17 00 - 6

Specifier Notes: DETAN compression rods consist of large diameter tubes, reduced at each end for

use with standard DETAN fork connectors. These rods are designed to order.

3. Compression Rods: “DETAN”.

a. Material: [Carbon steel, S355J2, ASTM A694] [Stainless steel, ASTM A666].

b. Diameter: ______ mm (______ inches).

Specifier Notes: The critical length manufacturer requires is called “system length,” defined as length

from C.L. of left pin to C.L. of right pin.

c. Rod Length: ______ mm (______ inches).

PART 3 EXECUTION

3.1 EXAMINATION

A. Examine area to receive bracing for compliance with installation clearances.

B. Verify substrate conditions are acceptable for product installation.

C. Notify Architect of conditions that would adversely affect installation.

D. Do not begin installation until unacceptable conditions are corrected.

3.2 INSTALLATION

A. Install rod system in accordance with manufacturer’s instructions at locations indicated on the

Drawings.

B. Fully screw rod system locknut on rod until rod markings are not visible.

C. Screw fork connector on tension rod to required system length.

D. Screw locknut back toward fork connector until locked.

E. Install snap rings with snap-ring pliers on each side of pin in fork connector.

F. Position connection plates to not subject rod system to bending.

G. Align and position forks in same plane.

1. Maximum Misalignment: 0.5 degrees.

3.3 FIELD QUALITY CONTROL

A. Inspections:

1. Inspect completed rod system for proper locknut screw-in depth, after installation and

before final acceptance.

Halfen DETAN Steel

Rod System 05 17 00 - 7

2. Report component damage to Architect and manufacturer.

3. Ensure markings on rods are covered by locknut to achieve minimum screw-in depth.

3.4 PROTECTION

A. Protect installed rod system from damage during construction.

B. Touch-up damage to factory-applied finishes using appropriate materials and techniques.

END OF SECTION

Halfen DETAN Steel

Rod System 05 17 00 - 8

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- VCCT For Abaqus PDFDocument14 paginiVCCT For Abaqus PDFFelipe Dornellas SilvaÎncă nu există evaluări

- Acoustic Emission Testing Method: Questions AnswersDocument22 paginiAcoustic Emission Testing Method: Questions AnswersSadhasivam Velu100% (2)

- Fuselage DesignDocument4 paginiFuselage DesignIndra FurwitaÎncă nu există evaluări

- 5.15 Swing Barrier v.1.0Document190 pagini5.15 Swing Barrier v.1.0rfvz6sÎncă nu există evaluări

- Decking (Composite & 2 Layers Reinf)Document41 paginiDecking (Composite & 2 Layers Reinf)Than Than SoeÎncă nu există evaluări

- Ccip Ec2 BridgesDocument140 paginiCcip Ec2 BridgesnuÎncă nu există evaluări

- ASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteDocument5 paginiASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteOmid DeldarÎncă nu există evaluări

- BS en 10130 2006Document16 paginiBS en 10130 2006Phong TongÎncă nu există evaluări

- 2 DR BTM FRZR - cs1400Document40 pagini2 DR BTM FRZR - cs1400Marcella RossiÎncă nu există evaluări

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pagini26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- Rolling ProcessDocument17 paginiRolling ProcessRavichandran GÎncă nu există evaluări

- EN1886Document4 paginiEN1886ramesh100% (1)

- Properties and applications of metals and their alloysDocument8 paginiProperties and applications of metals and their alloyspandianvijaybharathiÎncă nu există evaluări

- Aircraft Structures II LabDocument15 paginiAircraft Structures II Labproxymo10% (1)

- Catalogue Modulo En-20372 PDFDocument32 paginiCatalogue Modulo En-20372 PDFflorinÎncă nu există evaluări

- 5 6138727946501751075Document3 pagini5 6138727946501751075Xkarr RastaÎncă nu există evaluări

- C-31 - Defence Colony - Terrace Garden ProposalDocument7 paginiC-31 - Defence Colony - Terrace Garden ProposalDevangie Shrivastava100% (1)

- Corosion Assignment FullDocument104 paginiCorosion Assignment FullVelavan KÎncă nu există evaluări

- Aux Boiler Startup ChecklistDocument4 paginiAux Boiler Startup ChecklistAmaresh NayakÎncă nu există evaluări

- Bridge Elastomeric Bearing PadsDocument10 paginiBridge Elastomeric Bearing PadsShwanÎncă nu există evaluări

- Sports-Cote Pro PUDocument2 paginiSports-Cote Pro PURahul KalathingalÎncă nu există evaluări

- TDS - Bronco Pre HDPE Membrane (S)Document3 paginiTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniÎncă nu există evaluări

- Princesa Bridge Narrative ReportDocument9 paginiPrincesa Bridge Narrative ReportRodelo OngÎncă nu există evaluări

- Aropol LP 67400Document2 paginiAropol LP 67400Ahmed ZamanÎncă nu există evaluări

- TE 1 Notes PDFDocument196 paginiTE 1 Notes PDFfatigue puttaÎncă nu există evaluări

- SOMDocument431 paginiSOMPradeepvenugopalÎncă nu există evaluări

- Lani 7060 - ASTM D5034Document1 paginăLani 7060 - ASTM D5034Serdar KaçamerÎncă nu există evaluări

- Aditi VosDocument1 paginăAditi VosXELIXCELINÎncă nu există evaluări

- DESIGN OF SHALLOW FOUNDATIONS FOR BUILDINGSDocument19 paginiDESIGN OF SHALLOW FOUNDATIONS FOR BUILDINGSJule LobresÎncă nu există evaluări

- Chemical Engineering Test QuestionsDocument1 paginăChemical Engineering Test Questionsjake dionisioÎncă nu există evaluări