Documente Academic

Documente Profesional

Documente Cultură

Tower: Sample 13: Pressure Vessel Engineering

Încărcat de

Sivi NallamothuTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tower: Sample 13: Pressure Vessel Engineering

Încărcat de

Sivi NallamothuDrepturi de autor:

Formate disponibile

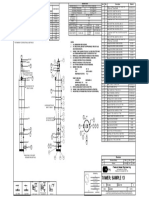

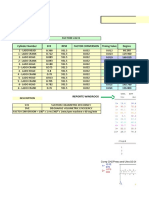

NOZZLE SCHEDULE DESIGN DATA Item Qty Description Material

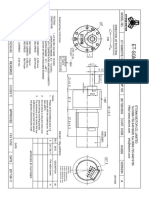

DESIGN CODE ASME VIII DIV.I 2007 ED. 2008 ADD. Head, 2:1 Elliptical - 85.5000" OD, 1.5000" SF,

NOZZLE WELDS INTERNAL PRESSURE: 150 PSI @ 550°F 1 1 SA-516 Gr.70

COMPONENTS 0.7500" Nom., 0.6250" MAF

EXTERNAL PRESSURE 15 PSI @ 550°F 2 1 Shell: 84" ID x 0.625" THK x 98" LG. SA-516 Gr.70

MARK SIZE QTY. SERVICE TYPE Nt EXT. PROJ. INT. PROJ. 41 42 43

HYDROTEST PRESSURE: 195 PSI @ 70°F

M1 24" 1 MANWAY II 1 12.4375" 0 0.375" 0.375" - 13,23,34 MDMT: -20°F @ 150 PSI 3 1 Shell: 84" ID x 0.625" THK x 98" LG. SA-516 Gr.70

M2 24" 1 MANWAY II 1 12.0256" 0 0.375" 0.625" - 13,25,33 CORROSION 4 1 Shell: 84" ID x 0.625" THK. x 59" LG. SA-516 Gr.70

M3 24" 1 MANWAY II 1 16.50" 0 0.375" 0.375" - 13,23,32 0.125"

ALLOWANCE: Conical Shell: 0.875" THK x 120.25" ID to 84" ID, 120"

M4 18" 1 MANWAY III 1 3.25" 2.00" 0.5" 0.5" 0.5" 26,35 PWHT: NO 5 1 SA-516 Gr.70

LG

N1 8" 1 DRAIN II 0.5 0.50" 0 0.375" 0.375" 0.625" 16,27,31,30,38 RADIOGRAPHY: RT-2 6 1 Shell: 0.875" THK x 120.25" ID x 88" LG SA-516 Gr.70

N2 6" 1 PROCESS I 0.719 6.4375" 0 0.375" - - 12,21 IMPACT TESTING: NONE EXEMPTION: UCS-66

7 1 Shell: 0.875" THK x 120.25" ID x 144" LG SA-516 Gr.70

N3 2" 1 PROCESS I 0.344 6.4375" 0 0.25" - - 17,24 SEISMIC CODE: IBC-2006 WIND CODE: IBC-2006

N4 4" 1 PROCESS I 0.674 12.937" 0 0.375" - - 14,29 SERVICE: - CAPACITY: 28,515 GAL (US). 8 1 Shell: 0.875" THK x 120.25" ID x 72" LG SA-516 Gr.70

N5 2" 1 PROCESS I 0.344 8.125" 0 0.25" - - 17,20 FLOODED Conical Shell: 0.875" THK x 120.25" ID to 36.25" ID,

WEIGHT EMPTY: 80,261 LBS. 251,260 LBS. 9 1 SA-516 Gr.70

N6 4" 1 PROCESS I 0.337 6.50" 0 0.25" - - 18,19 WEIGHT: 100" LG

N7 6" 1 PROCESS I 0.719 14.124" 0 0.1875" - - 15,22 10 1 Shell: 0.375" THK x 36.25" ID x 104" LG SA-516 Gr.70

SO 16" 1 SKIRT OPENING III 1 3.25" 2.00" 0.375" 0.5" 0.375" 28,36 Head, 2:1 Elliptical - 37.0000" OD, 1.5000" SF,

11 1 SA-516 Gr.70

0.3750" Nom., 0.3125" MAF

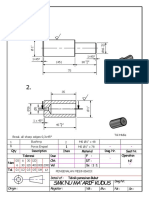

* FOR MANWAY COVER DETAILS, SEE PAGE 2 NOTES:

12 1 Flange, B16.5 RFWN - 300#, 6.00 NPS SA-105

1. ALL DIMENSIONS ARE IN INCHES

2. ALL WELDS SHALL BE NEAT IN APPEARANCE, FREE OF SLAG 13 3 Flange, B16.5 RFWN - 300#, 24.00 NPS SA-105

AND OTHER DEFECTS. 14 1 Flange, B16.5 RFWN - 300#, 4.00 NPS SA-105

3. VESSEL TO BE CLEANED OF SCALE, OIL, WELD SPLATTER AND

15 1 Flange, B16.5 RFWN - 300#, 6.00 NPS SA-105

ALL FOREIGN MATERIAL PRIOR TO HYDROSTATIC TEST.

4. REMOVE ALL SHARP EDGES ON NOZZLES (1/8" MIN. RADIUS) 16 1 Flange, B16.5 RFWN - 300#, 8.00 NPS SA-105

N7

5. ALL NOZZLES TO BE SUPPORT NOMINAL LOADS ONLY, 17 2 Flange, B16.5 RFWN - 300#, 2.00 NPS SA-105

903.857 11 FLANGES CONFORM TO B16.5 STANDARDS.

10 18 1 Flange, B16.5 RFWN - 300#, 4.00 NPS SA-105

883 6. REPAD TO HAVE MIN. 1/8" TELLTALE HOLE.

7. ALL FITTINGS CONFORM TO B16.9 STANDARDS. 19 1 Pipe: 4" SCH80 x 3.5" LG SA-106 Gr.B

835 N6 M3 841

8. SEISMIC TO IBC-2006: 20 1 Pipe: 2" SCH160 x 5.75" LG SA-106 Gr.B

37.00

Ss:2.0 S1: 1.0 21 1 Pipe: 6" SCH160 x 8" LG SA-106 Gr.B

779 N5 784

Cat:I SITE CLASS: B

.50 FROM BOTTOM 22 1 Pipe: 6" SCH160 x 8" LG SA-106 Gr.B

RESPONSE FACTOR: 3 TL:3

OF RING TO SEAM 38 23 2 Plate: 24" OD x 1" THK x 9"LG SA-516 Gr.70

698.375 M2 9 WIND TO IBC-2006: 24 1 Pipe: 2" SCH160 4.3125" LG SA-106 Gr. B

679 V: 90 MPH EXPOSURE: C

41 25 1 Plate: 24" OD x 1" THK x 9"LG SA-516 Gr.70

IMPORTANCE: 1.15 Kd:1

DAMPING COEFFICIENT: 0.024 26 1 Pipe: 18" OD x 1" THK x 5" LG SA-516 Gr.70

.500 FROM TOP OF 9. RFWN FLANGE BORE TO MATCH HOST PIPE. 27 1 Pipe: 8" SCH80 x 48" LG. SA-106Gr.B

RING TO SEAM 8

10. VESSEL TO BE HYDROTESTED IN HORIZONTAL POSITION.

N4 561 28 1 Plate: 16.25" OD x 1" THK x 5" LG SA-516 Gr.70

11. ANCHOR BOLTS FOR BASE RING TO BE SA-193 B7 MATERIAL.

29 1 Pipe: 4" SCHXXS x 10.875" LG SA-106 Gr.B

30 1 8" SCH40 Pipe x 15.4642" LG SA-106 Gr.B

122.00

7

31 1 SR Elbow, B16.9 - SCH40, 8.00 NPS SA-234 WPB

32 1 Repad: 28" OD x 24" ID x 0.375" THK SA-516 Gr.70

6

33 1 Repad: 30.5309" OD x 24" ID x 0.75" THK SA-516 Gr.70

.50 FROM BOTTOM OF

375 RING TO SEAM 34 1 Repad: 28" OD x 24" ID x 0.625" THK SA-516 Gr.70

40

35 1 Repad: 23.5" OD x 16.25" ID x 1" THK SA-516 Gr.70

5 36 1 Repad: 21" OD x 16.25" ID x 1" THK SA-516 Gr.70

N3 360° 37 1 Repad: 12.625" OD x 8.625" ID x 0.5" THK SA-516 Gr.70

255 .50 FROM BOTTOM 352° 38 1 Ring: 0.375 x 2 FLAT BAR SA-36

39 17.5 N4

OF RING TO SEAM

39 1 Ring: 0.5 x 5 FLAT BAR SA-36

M2 270° 90° N1 N5 M3 40 1 Ring: 0.625 x 6 FLAT BAR SA-36

4 41 1 Ring: 0.5 x 5 FLAT BAR SA-36

136 M1

3 235° 42 1 Skirt: 84" ID x 0.75" THK x 90.62" LG SA-516 Gr.70

N6 43 1 Base Ring: 101" OD x 81" ID x 1.625" THK SA-516 Gr.70N

86 N3 85.75 210°

2 180°

N2 53 N2 44 1 Top Ring: 101" OD x 85.5" ID x 1.625" THK SA-516 Gr.70N

M1

45 24 Guesset: 12" x 7.75" x 0.375" THK SA-516 Gr.70

0 0 1 M4

SO N1 45.50

23.500 58.62 M4

42

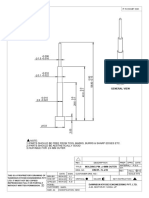

SEE PAGE 2 FOR SKIRT

AND BASE RING DETAILS 44 45 43 Revision

Rev. Revision History Date Drw. Chk.

0 Release 2015/09/28 MCT BEM

Pressure Vessel Engineering

Eng 120 Randall Drive, Suite B

Waterloo, ON, Canada, N2V 1C6

Certified by Title

A XX

S

M

E

(N am e of M anufacturer)

150 PSI @ 550°F

M ax. allow able w orkin g pressure (M AW P)

TOWER: SAMPLE 13

TYPE II TYPE III TYPE I 15 PSI @ 550°F

W M ax. allow able external w orkin g pressure Size Job ID Drawing No. Revision

41 RT-2

41 -20°F @ 150 PSI C PVE-3602 3602d-1 R0 0

Nozzle

42

Nozzle

41

Nozzle

42 M in . D esig n M etal Tem perature (M D M T)

Shell Scale Material Sheet

Shell Outside SERIAL

Shell

M anufacturer's seria l num ber 1:128 See BOM 1 OF 3

43 XX 2016

UW-16.1 (q) mod with

CRN Year built This drawing and the information herein is confidential, and must not be reproduced

Circ. Weld Long Weld UW-16.1 (q) mod inside projection UW-16.1 (c) or used in any way without the written permission of Pressure Vessel Engineering Ltd.

S-ar putea să vă placă și

- #REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionDocument31 pagini#REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionSivi NallamothuÎncă nu există evaluări

- #REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionDocument31 pagini#REF! #REF!: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4th EditionSivi NallamothuÎncă nu există evaluări

- Data Well CalculationsDocument6 paginiData Well Calculationsfaraj100% (1)

- Mechanical - Method of StatementDocument21 paginiMechanical - Method of StatementSEA ROCK TECHNICALÎncă nu există evaluări

- Gaston Engineering Drawings 100 GDocument25 paginiGaston Engineering Drawings 100 GPaul MatquisÎncă nu există evaluări

- IBR Design Calculations - FinalDocument6 paginiIBR Design Calculations - Finalshazan100% (1)

- IBR Design Calculations - FinalDocument6 paginiIBR Design Calculations - Finalshazan100% (1)

- Davit CalcDocument4 paginiDavit CalcrustamriyadiÎncă nu există evaluări

- Davit CalcDocument4 paginiDavit CalcrustamriyadiÎncă nu există evaluări

- PV ProcessDocument48 paginiPV Processkisan singhÎncă nu există evaluări

- Asce 7-10Document20 paginiAsce 7-10Julio OrozcoÎncă nu există evaluări

- CLG816C Service Manual 201404000-EN PDFDocument423 paginiCLG816C Service Manual 201404000-EN PDFJusto Paniagua100% (1)

- Interview QuestionDocument27 paginiInterview Questionsivacwi75% (4)

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 paginiSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishÎncă nu există evaluări

- EXternal ITP PDFDocument8 paginiEXternal ITP PDFjaineranaÎncă nu există evaluări

- BS 5041-3-1975 Fire Hydrant Systems EquipmentDocument10 paginiBS 5041-3-1975 Fire Hydrant Systems EquipmentTrần Khắc ĐộÎncă nu există evaluări

- Seismic Load AnalysisDocument99 paginiSeismic Load AnalysisMANDARAW100% (1)

- Underground Storage Tanks SystemsDocument32 paginiUnderground Storage Tanks Systemswferry27Încă nu există evaluări

- Static Pressure CalculationDocument1 paginăStatic Pressure CalculationMohsin ShaikhÎncă nu există evaluări

- Ref: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionDocument5 paginiRef: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionSivi NallamothuÎncă nu există evaluări

- Ref: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionDocument5 paginiRef: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionSivi NallamothuÎncă nu există evaluări

- Catalogo National e Intercambiable Julio 2019Document708 paginiCatalogo National e Intercambiable Julio 2019JhonFerneyBohorquezSaldarriagaÎncă nu există evaluări

- PTE Practice LinksDocument6 paginiPTE Practice LinksSalman Akram0% (1)

- 7029120023Document1 pagină7029120023Roderick Pinto100% (1)

- Pip Vefv1100 - 07Document45 paginiPip Vefv1100 - 07shaffeti100% (1)

- Stainless SteelDocument51 paginiStainless Steelcristian111111Încă nu există evaluări

- Norsok Material Data Sheet (M-630r2)Document77 paginiNorsok Material Data Sheet (M-630r2)karuna346Încă nu există evaluări

- Safety Valve Sizing Calculations As Per IBR 1950Document2 paginiSafety Valve Sizing Calculations As Per IBR 1950santoshmane2389% (9)

- IBR CalculationsDocument20 paginiIBR CalculationsSivi NallamothuÎncă nu există evaluări

- En 16129Document142 paginiEn 16129hasan noah0% (1)

- Manual de Servicio y Usuario OriginalDocument60 paginiManual de Servicio y Usuario OriginalluisÎncă nu există evaluări

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisDocument8 paginiGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysisgpskumar22Încă nu există evaluări

- Gixxer250 Naked-2021Document91 paginiGixxer250 Naked-2021juan pablo resrepo nieto100% (3)

- 3602 Drawing R0Document1 pagină3602 Drawing R0dhaktodesatyajitÎncă nu există evaluări

- FP1.0 Engineering Data A-C Pumps 8100Document12 paginiFP1.0 Engineering Data A-C Pumps 8100Christian FernandezÎncă nu există evaluări

- Brush Pressure 2016 PDFDocument21 paginiBrush Pressure 2016 PDFMarvinÎncă nu există evaluări

- Wwt1 Ws - Tyre - Fix 1 5600 80.6kg: Panel Height Wall Panel Project Quantity Panel WeightDocument6 paginiWwt1 Ws - Tyre - Fix 1 5600 80.6kg: Panel Height Wall Panel Project Quantity Panel WeightRizky LssÎncă nu există evaluări

- Threaded RodDocument1 paginăThreaded RodDhanu goswamiÎncă nu există evaluări

- Pdu - SMP T-11.wo# 20 - MRN, 30-08-2022Document9 paginiPdu - SMP T-11.wo# 20 - MRN, 30-08-2022Putra NugrahaÎncă nu există evaluări

- ET-SGM37FE-1222 (20170810003-H16035) ModelDocument1 paginăET-SGM37FE-1222 (20170810003-H16035) Modelruta0405Încă nu există evaluări

- Electrical Specifications: Sma Female 2 PlacesDocument1 paginăElectrical Specifications: Sma Female 2 PlacesThanh Son NguyenÎncă nu există evaluări

- Material Take Off: For Construction Dept.: Engineering Section: Construction EngineeringDocument7 paginiMaterial Take Off: For Construction Dept.: Engineering Section: Construction EngineeringabdiÎncă nu există evaluări

- Super Capacitor Starcap 1.0 5.5VDocument9 paginiSuper Capacitor Starcap 1.0 5.5VMehmood AhmadÎncă nu există evaluări

- AssyDocument1 paginăAssyArief FibonacciÎncă nu există evaluări

- Base Magnetica 6306-1020Document1 paginăBase Magnetica 6306-1020Martin Andre AlburquequeÎncă nu există evaluări

- Cabin Engine Mount Special Final 2016Document24 paginiCabin Engine Mount Special Final 2016Eduardo SantanaÎncă nu există evaluări

- Tire-Fond ReliableDocument1 paginăTire-Fond ReliablelavignenoeÎncă nu există evaluări

- Hardware PDFDocument44 paginiHardware PDFMabel FrancisÎncă nu există evaluări

- Side View PIN Crimp Ring: Recommended Cable Stripping Dimensions RG-58 Cable Consma007-R58 Assembly InstructionsDocument1 paginăSide View PIN Crimp Ring: Recommended Cable Stripping Dimensions RG-58 Cable Consma007-R58 Assembly Instructionsmyfutn-re8512Încă nu există evaluări

- 8-375 Cone Buster Junk MillDocument1 pagină8-375 Cone Buster Junk MillrahulÎncă nu există evaluări

- Timing Open Valve Compressor - Jusepin 12 - 1030Document8 paginiTiming Open Valve Compressor - Jusepin 12 - 1030jose luis rattiaÎncă nu există evaluări

- Operation Bulletin Style: BCG 7 STYLE Name Foam Padded Des: Molded Parameters IED 600 100% 79% 17 Est Time SAMDocument10 paginiOperation Bulletin Style: BCG 7 STYLE Name Foam Padded Des: Molded Parameters IED 600 100% 79% 17 Est Time SAMgouthamShetty DÎncă nu există evaluări

- Sample OB Sheet by Online Clothing StudyDocument2 paginiSample OB Sheet by Online Clothing Studyali azamÎncă nu există evaluări

- 250S15-S28 Solidworks Cad File: Sealed 1/4" Plug Do Not Scale Drawing 1 1Document2 pagini250S15-S28 Solidworks Cad File: Sealed 1/4" Plug Do Not Scale Drawing 1 1Marius BudauÎncă nu există evaluări

- Dowell Hal. BJ: Diacel LWL Halad-9 D-20 (GEL) HALAD-22A HALAD-413 R3 HALAD-344 GasstopDocument9 paginiDowell Hal. BJ: Diacel LWL Halad-9 D-20 (GEL) HALAD-22A HALAD-413 R3 HALAD-344 GasstopRio DarianoÎncă nu există evaluări

- Mict Berth 6 Project: Weight of Sample, Gram: Original: Sampled At: Oven Dry: Sampled By: Wash Oven Dry: Tested byDocument2 paginiMict Berth 6 Project: Weight of Sample, Gram: Original: Sampled At: Oven Dry: Sampled By: Wash Oven Dry: Tested bySvnshine TanÎncă nu există evaluări

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: PULLEY Ø165x70Document1 paginăGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: PULLEY Ø165x70Arief FibonacciÎncă nu există evaluări

- Cover Housing: All Sharp Edges C0.3-0.5Document1 paginăCover Housing: All Sharp Edges C0.3-0.5Arief FibonacciÎncă nu există evaluări

- Eye ClinicDocument9 paginiEye ClinicMohiuddin AhmedÎncă nu există evaluări

- 3.5mm AudioDocument1 pagină3.5mm AudiodfsdafÎncă nu există evaluări

- Slide RetainerDocument4 paginiSlide RetainerJesus Tadeo Rodriguez ChavezÎncă nu există evaluări

- Measurement Value - Eng-1Document9 paginiMeasurement Value - Eng-1Md chotuÎncă nu există evaluări

- GRIN Rod Lenses - Numerical Aperture 0.5: DownloadDocument2 paginiGRIN Rod Lenses - Numerical Aperture 0.5: DownloadveronicaÎncă nu există evaluări

- Resistors PDFDocument1 paginăResistors PDFwillian GaldinoÎncă nu există evaluări

- iSV2 60TR 48V400ADocument1 paginăiSV2 60TR 48V400AdimitriÎncă nu există evaluări

- Pompa Oval: All Sharp Edges C0.3-0.5Document1 paginăPompa Oval: All Sharp Edges C0.3-0.5Arief FibonacciÎncă nu există evaluări

- 12 TerminalDocument1 pagină12 Terminalgrhvg_mct8224Încă nu există evaluări

- K-511-V, FLW SWTDocument2 paginiK-511-V, FLW SWTamir shokrÎncă nu există evaluări

- Series 218: Data Sheet Data SheetDocument2 paginiSeries 218: Data Sheet Data Sheetm3y54mÎncă nu există evaluări

- SMK Nu Ma'Arif Kudus: Seat Nr. F: DT: Item 1 DWN Qty Description 1 Material Operation N7 Dwg. NRDocument1 paginăSMK Nu Ma'Arif Kudus: Seat Nr. F: DT: Item 1 DWN Qty Description 1 Material Operation N7 Dwg. NRBenny LaentÎncă nu există evaluări

- Piston Seals: Technical DetailsDocument4 paginiPiston Seals: Technical DetailsRPINILLA (EICO S.A.)Încă nu există evaluări

- APT001-D-DWG-ME-001 - Drawing Production Separator (V-100A-B-C) - 0 - IFBDocument2 paginiAPT001-D-DWG-ME-001 - Drawing Production Separator (V-100A-B-C) - 0 - IFBRoy RahadianÎncă nu există evaluări

- Hybrid Stepper Motors 24HS SeriesDocument4 paginiHybrid Stepper Motors 24HS SeriesMike ChanÎncă nu există evaluări

- Bolts ConnectionDocument3 paginiBolts Connectionrizwanjawaid.meenaÎncă nu există evaluări

- Cooling Fan Drive ASSY. - s220Document3 paginiCooling Fan Drive ASSY. - s220David PalashÎncă nu există evaluări

- BOM For Pig Launcher ReceiverDocument11 paginiBOM For Pig Launcher ReceivermeetÎncă nu există evaluări

- Molding Pin-4mm OuterDocument1 paginăMolding Pin-4mm Outerchirag guptaÎncă nu există evaluări

- L60 DatasheetDocument1 paginăL60 DatasheetSEISE AEROÎncă nu există evaluări

- Z Modifier (Poulos)Document5 paginiZ Modifier (Poulos)Prashanth Talkad RajagopalÎncă nu există evaluări

- Na 9287Document1 paginăNa 9287Hưng TrươngÎncă nu există evaluări

- Consuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs WeightDocument1 paginăConsuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs Weightswaran autoqaÎncă nu există evaluări

- Consuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs WeightDocument1 paginăConsuption Raw Material Items Name No. Qty. Gross W Scrap Genrate Net Pcs Weightswaran autoqaÎncă nu există evaluări

- Quotation: Quote InformationDocument3 paginiQuotation: Quote InformationMauricio OrtizÎncă nu există evaluări

- CC 2020-20-221-330 Ml. Envase Sin Litografia - InglesDocument1 paginăCC 2020-20-221-330 Ml. Envase Sin Litografia - InglesMarcelo MartinezÎncă nu există evaluări

- Calculo Diametro OriginalDocument43 paginiCalculo Diametro OriginalLizandro GuerreroÎncă nu există evaluări

- Gross AmountDocument2 paginiGross AmountRaees JunaidÎncă nu există evaluări

- Ibr Calc - 1.5 X 300 WCBDocument2 paginiIbr Calc - 1.5 X 300 WCBamit amityÎncă nu există evaluări

- Jai Ganesh Ibr-Design Chapter-1Document10 paginiJai Ganesh Ibr-Design Chapter-1Sivi NallamothuÎncă nu există evaluări

- G 011244954Document6 paginiG 011244954Gopal RamalingamÎncă nu există evaluări

- Isa Maharashtra Inteq Magazine July2012Document21 paginiIsa Maharashtra Inteq Magazine July2012ganeshanÎncă nu există evaluări

- Reg. 1 Short Title, Extent, Application and Commencement:: Chapter-1Document15 paginiReg. 1 Short Title, Extent, Application and Commencement:: Chapter-1Sivi NallamothuÎncă nu există evaluări

- AISC Shapes TablesDocument64 paginiAISC Shapes TablesJose ManuelÎncă nu există evaluări

- Flange FVC DataDocument36 paginiFlange FVC DataachillesntroyÎncă nu există evaluări

- Momin 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012050Document11 paginiMomin 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012050Sivi NallamothuÎncă nu există evaluări

- Catalog C v5Document80 paginiCatalog C v5Sivi NallamothuÎncă nu există evaluări

- PED Guidelines EN v1.6Document263 paginiPED Guidelines EN v1.6Sivi NallamothuÎncă nu există evaluări

- Uniform Building Code Volume 21997Document545 paginiUniform Building Code Volume 21997raymond100% (1)

- Article - Screw Threads DesignDocument7 paginiArticle - Screw Threads DesignjdfdfererÎncă nu există evaluări

- Incoloy Alloy 800Document12 paginiIncoloy Alloy 800mehdipoorÎncă nu există evaluări

- Parker 919 Series HosesDocument1 paginăParker 919 Series Hosesanoop9079Încă nu există evaluări

- North Hydro Company Profile-2015Document13 paginiNorth Hydro Company Profile-2015Jarus YdenapÎncă nu există evaluări

- Sodium Leak Through Pin HolesDocument9 paginiSodium Leak Through Pin HolesAvinash ChittellaÎncă nu există evaluări

- C ST A106 GRB Pipe Pressure Rating Charts Rev Dec 2012Document4 paginiC ST A106 GRB Pipe Pressure Rating Charts Rev Dec 2012Allison MoraisÎncă nu există evaluări

- OKS Clamp-On Buffer Ultrasonic Flow TransducersDocument18 paginiOKS Clamp-On Buffer Ultrasonic Flow Transducerssmit6954Încă nu există evaluări

- BSC Aircraft MainDocument35 paginiBSC Aircraft MainAyem perumalÎncă nu există evaluări

- Hanger Soportes - Mason IndustriesDocument16 paginiHanger Soportes - Mason IndustriesolivaresjhonÎncă nu există evaluări

- Lession 1 Materials and Sanitary Features of The Dairy EquipmentDocument77 paginiLession 1 Materials and Sanitary Features of The Dairy EquipmentRajat Jain100% (1)

- Road Concreting Design Criteria DrawingsDocument7 paginiRoad Concreting Design Criteria DrawingsUreshiii AnimeÎncă nu există evaluări

- EHB en File 10.7.3 Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Document2 paginiEHB en File 10.7.3 Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Rene ParedeschaconÎncă nu există evaluări

- Fisher Easy-Drive 200L: Scope of ManualDocument32 paginiFisher Easy-Drive 200L: Scope of Manualclaudinei alves fonsecaÎncă nu există evaluări

- Specijalne SpecifikacijeDocument33 paginiSpecijalne SpecifikacijeMarija SchmidtÎncă nu există evaluări

- Preliminary Estimate Iihr-Rkvy-Hybrid Vegetables Seed Production Project (Polyhouse)Document11 paginiPreliminary Estimate Iihr-Rkvy-Hybrid Vegetables Seed Production Project (Polyhouse)kajale_shrikant2325Încă nu există evaluări

- PUZ-ZM35-71V K H A Service Manual OCH653 PDFDocument112 paginiPUZ-ZM35-71V K H A Service Manual OCH653 PDFDiogo RosaÎncă nu există evaluări

- Air Conditioner: Owner'S ManualDocument40 paginiAir Conditioner: Owner'S ManualKanagaraj RaviÎncă nu există evaluări

- PDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressDocument40 paginiPDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressVũ Văn QuangÎncă nu există evaluări

- BQ AllDocument86 paginiBQ AllLi LiuÎncă nu există evaluări

- Sonic Drilling For Site Characterization and The Installation of Subsurface Monitoring DevicesDocument11 paginiSonic Drilling For Site Characterization and The Installation of Subsurface Monitoring DevicesWilliam VasquezÎncă nu există evaluări

- Appendix 37 D (Table-1)Document74 paginiAppendix 37 D (Table-1)stephin k jÎncă nu există evaluări