Documente Academic

Documente Profesional

Documente Cultură

Vertical Drum Separator Calculation Sheet

Încărcat de

eka resmana100%(2)100% au considerat acest document util (2 voturi)

572 vizualizări2 paginiThis document provides calculations for the design of a vertical drum separator with demister used in a geothermal power plant. It includes process data like flow rates and operating conditions. Nozzle sizes are calculated based on criteria like velocity and density. Drum diameter is determined considering demister diameter and critical vapor velocity. Vessel height is designed to provide minimum specified holding times between sections. Final dimensions like length to diameter ratio and volumes are reported.

Descriere originală:

Scrubber & Demister Sizing

Titlu original

Scrubber and Demister Sizing - Form 2

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLSX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides calculations for the design of a vertical drum separator with demister used in a geothermal power plant. It includes process data like flow rates and operating conditions. Nozzle sizes are calculated based on criteria like velocity and density. Drum diameter is determined considering demister diameter and critical vapor velocity. Vessel height is designed to provide minimum specified holding times between sections. Final dimensions like length to diameter ratio and volumes are reported.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

100%(2)100% au considerat acest document util (2 voturi)

572 vizualizări2 paginiVertical Drum Separator Calculation Sheet

Încărcat de

eka resmanaThis document provides calculations for the design of a vertical drum separator with demister used in a geothermal power plant. It includes process data like flow rates and operating conditions. Nozzle sizes are calculated based on criteria like velocity and density. Drum diameter is determined considering demister diameter and critical vapor velocity. Vessel height is designed to provide minimum specified holding times between sections. Final dimensions like length to diameter ratio and volumes are reported.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

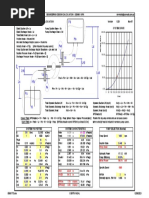

Vertical Drum Separator Calculation Sheet (with Demister)

Item No. & Service Name ; Scrubber (V-200) Prepared by Page

Provision of FEED Consultant Services on Small Scale Geothermal

Project No. ; Date 1 of 2

Power Plant Dieng

1. Process data Total volume: 666 ft3 NOTES

Operating pressure psig 142

Operating temperature o

F 354 16 inch gas out

gas liquid mixture (Design)

Weight flow lb/hr 179,479 1,720 199,318 8.0 ft

15 ''

Density lb/ft3 0.31 54.30 17.87

Design Margin % 10 10 - 6 ''

Design Volumetric flow ft3/h 10,139 0.000485 10,139

2. Nozzle design 3.53ft/s , vapor

48 ''

Sizing Basis Nozzle Sizing

ρv² Velocity min. ID Selected ID Cal. ρv² Cal. Vel Selected ND

(lb/ft-s²) (ft/s) (inch) (inch) (lb/ft-s²) (ft/s) (inch) 16 inch 4.63ft/s

Inlet mixture 6706 - 14.5503 16 4586.2 127.22 16 Feed nozzle liquid droplet

Outlet gas 2500 - 19.0242 16 4996.7 127.22 16

Outlet liquid - 3.9 0.6714 3 - 0.2 3 Holding 10.6 ft

3. Diameter for vapor section with demister HHLL 36 '' V (ft³) t (min)

Recommend Selected HLL 30 '' 25.13 43.29

Velocity constant, K

ft/s 0.18~0.35 0.35

(reference only, for Vc)

Demister constant, Kd ft/s - 0.35 58 ''

Over sizing (for diameter) % < 30 10 NLL 24 '' 50.27 86.58

Demister diameter ft 6.99 6.63

Drum diameter ft 7.69 8.00

Ud, designed velocity of vapor ft/s 3.83 3.53 LLL 18 ''

Vc, critical velocity of vapor ft/s 4.63 4.63 LLLL 12 '' 25.13 43.29

Drum dia.(reference only, without demister) ft 6.99 8.00 T.L 0 50.27 86.58

4. Vessel Height Recommend

Selected

calcul Recomm.

Total height ft 8.5 10.6 10.6 3 inch liq. out

Top TL-Demister top inch 14.4 15.0 15 127 : Input of General and Process Data

Demister thickness NOTE1 inch 6.0 6.0 6 112 : Trial and error calculation to meet minimum requirement of

Demister bottom-top of inlet nozzle inch 39.4 40.0 40 106 Project specification

Inlet nozzle diameter inch 16.0 16.0 16 66

Btm of inlet nozzle - HHLL inch 14.0 14.0 14 50 Min. requirement (Process Design Basis)

HHLL- HLL (holding time) 2 min. inch 0.1 6.0 6 36 HHLL~HLL ; OK 2 minute (minimum 6 inch)

HLL-LLL (holding time) 6 min. inch 0.4 12.0 12 30 HLL~LLL ; OK 6 minutes (minimum 12 inch)

LLL- LLLL (holding time) 2 min. inch 0.1 6.0 6 18 LLL~LLLL ; OK 2 minute (minimum 6 inch)

LLLL-BOV inch 12.0 12.0 12 12 LLLL~btm TL ; OK minimum 12 inch

5. Vessel L/D ratio 1.07 1.32 1.32

Volume (Shell / Shell+Head) ft3 384.6 503.6 532.0 666.0

Vertical Drum Separator Calculation Sheet (with Demister)

Item No. & Service Name ; Demister (V-201) Prepared by Page

Provision of FEED Consultant Services on Small Scale Geothermal

Project No. ; Date 1 of 2

Power Plant Dieng

1. Process data Total volume: 666 ft3 NOTES

Operating pressure psig 139

Operating temperature o

F 352 16 inch gas out

gas liquid mixture (Design)

Weight flow lb/hr 179,479 1,720 199,318 8.0 ft

15 ''

Density lb/ft3 0.31 54.30 17.87

Design Margin % 10 10 - 6 ''

Design Volumetric flow ft3/h 10,139 0.000485 10,139

2. Nozzle design 3.53ft/s , vapor

48 ''

Sizing Basis Nozzle Sizing

ρv² Velocity min. ID Selected ID Cal. ρv² Cal. Vel Selected ND

(lb/ft-s²) (ft/s) (inch) (inch) (lb/ft-s²) (ft/s) (inch) 16 inch 4.63ft/s

Inlet mixture 6706 - 14.5503 16 4586.2 127.22 16 Feed nozzle liquid droplet

Outlet gas 2500 - 19.0242 16 4996.7 127.22 16

Outlet liquid - 3.9 0.6714 3 - 0.2 3 Holding 10.6 ft

3. Diameter for vapor section with demister HHLL 36 '' V (ft³) t (min)

Recommend Selected HLL 30 '' 25.13 43.29

Velocity constant, K

ft/s 0.18~0.35 0.35

(reference only, for Vc)

Demister constant, Kd ft/s - 0.35 58 ''

Over sizing (for diameter) % < 30 10 NLL 24 '' 50.27 86.58

Demister diameter ft 6.99 6.63

Drum diameter ft 7.69 8.00

Ud, designed velocity of vapor ft/s 3.83 3.53 LLL 18 ''

Vc, critical velocity of vapor ft/s 4.63 4.63 LLLL 12 '' 25.13 43.29

Drum dia.(reference only, without demister) ft 6.99 8.00 T.L 0 50.27 86.58

4. Vessel Height Recommend

Selected

calcul Recomm.

Total height ft 8.5 10.6 10.6 3 inch liq. out

Top TL-Demister top inch 14.4 15.0 15 127 : Input of General and Process Data

Demister thickness NOTE1 inch 6.0 6.0 6 112 : Trial and error calculation to meet minimum requirement of

Demister bottom-top of inlet nozzle inch 39.4 40.0 40 106 Project specification

Inlet nozzle diameter inch 16.0 16.0 16 66

Btm of inlet nozzle - HHLL inch 14.0 14.0 14 50 Min. requirement (Process Design Basis)

HHLL- HLL (holding time) 2 min. inch 0.1 6.0 6 36 HHLL~HLL ; OK 2 minute (minimum 6 inch)

HLL-LLL (holding time) 6 min. inch 0.4 12.0 12 30 HLL~LLL ; OK 6 minutes (minimum 12 inch)

LLL- LLLL (holding time) 2 min. inch 0.1 6.0 6 18 LLL~LLLL ; OK 2 minute (minimum 6 inch)

LLLL-BOV inch 12.0 12.0 12 12 LLLL~btm TL ; OK minimum 12 inch

5. Vessel L/D ratio 1.07 1.32 1.32

Volume (Shell / Shell+Head) ft3 384.6 503.6 532.0 666.0

S-ar putea să vă placă și

- API 650 Tank Design CalculationDocument8 paginiAPI 650 Tank Design Calculationmail_younes659283% (29)

- Scrubber Design SheetDocument11 paginiScrubber Design Sheetganeshdhage100% (1)

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design Separatorsgrabetty100% (3)

- Scrubber Design (Packed Column)Document10 paginiScrubber Design (Packed Column)alinaveed198367% (3)

- LNG Design StandardDocument41 paginiLNG Design Standardamirlng100% (1)

- LP Separator SizingDocument81 paginiLP Separator SizingNadia BahloulÎncă nu există evaluări

- Vertical Separator SizingDocument4 paginiVertical Separator SizingnemprrÎncă nu există evaluări

- Demister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: DateDocument3 paginiDemister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: Daterakesh3487100% (2)

- Separator Design Guide PDFDocument36 paginiSeparator Design Guide PDFAdam RizkyÎncă nu există evaluări

- Master - Three Phase Horizontal Separator Rev 0Document6 paginiMaster - Three Phase Horizontal Separator Rev 0Naeem HussainÎncă nu există evaluări

- HCL Scrubber DesignDocument5 paginiHCL Scrubber DesignManish0301198375% (4)

- Equipment - Sizing (Update) - Pacf2-Rev. ADocument52 paginiEquipment - Sizing (Update) - Pacf2-Rev. AAnonymous AtAGVssJÎncă nu există evaluări

- Metal Loss & Geometry InspectionsDocument43 paginiMetal Loss & Geometry Inspectionseka resmanaÎncă nu există evaluări

- 220cmr112 General O&M LNG Plan FacilitiesDocument12 pagini220cmr112 General O&M LNG Plan Facilitieseka resmanaÎncă nu există evaluări

- AutoPIPE Training WorkbookDocument189 paginiAutoPIPE Training Workbookeka resmanaÎncă nu există evaluări

- Senarai Kontraktor Pendawaian SesbDocument14 paginiSenarai Kontraktor Pendawaian SesbFizree AriesÎncă nu există evaluări

- Experiment #1 (Formal Lab Report)Document11 paginiExperiment #1 (Formal Lab Report)Niui NagarÎncă nu există evaluări

- Norcold 6162Document41 paginiNorcold 6162w4445555100% (1)

- PLN CNG Process CalculationDocument14 paginiPLN CNG Process CalculationViqiÎncă nu există evaluări

- Fuel Gas ScrubberDocument2 paginiFuel Gas ScrubberToyin100% (3)

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDocument4 paginiVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezÎncă nu există evaluări

- Knock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet NozzleDocument11 paginiKnock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet Nozzlejazeel alaviÎncă nu există evaluări

- Boiling Up Rate For Batch DistillationDocument4 paginiBoiling Up Rate For Batch DistillationKanhaiyalal PatilÎncă nu există evaluări

- Scrubber DesignDocument11 paginiScrubber Designsaji kumar0% (1)

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 paginiEIND 3184 15 Liquid Flash Vessel SizingzamijakaÎncă nu există evaluări

- All Sep CalcDocument22 paginiAll Sep Calcbharathscds100% (3)

- Half Pipe Coil AgitatedDocument1 paginăHalf Pipe Coil AgitatedNITINÎncă nu există evaluări

- Separator (1) Sizing Spread SheetsDocument21 paginiSeparator (1) Sizing Spread SheetsSteve WanÎncă nu există evaluări

- 2phase Separator Size 2010 VerAADocument22 pagini2phase Separator Size 2010 VerAAAnonymous a4Jwz14WÎncă nu există evaluări

- 2 Phase VerticalDocument4 pagini2 Phase VerticalJAZEEL ALAVIÎncă nu există evaluări

- Three Phase Separator Sizing (Double Weir 2)Document3 paginiThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- Maz - Design - Separator Capacity EvaluationDocument5 paginiMaz - Design - Separator Capacity EvaluationNaeem HussainÎncă nu există evaluări

- 3phase Separator Size 2010 VerADocument24 pagini3phase Separator Size 2010 VerACristina BarbulescuÎncă nu există evaluări

- 2 Phase Vertical Separator Sizing Calculation-AUHDocument26 pagini2 Phase Vertical Separator Sizing Calculation-AUHMike Dukas100% (1)

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pagini3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisÎncă nu există evaluări

- G01 20 VD 101 (Sizing Sheet) 3 PhaseDocument6 paginiG01 20 VD 101 (Sizing Sheet) 3 PhaseWickyÎncă nu există evaluări

- Experienced Based Rules of Chemical EngineeringDocument33 paginiExperienced Based Rules of Chemical Engineeringintania66Încă nu există evaluări

- Vessel Weight CheckDocument8 paginiVessel Weight ChecknileshÎncă nu există evaluări

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 paginiPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoÎncă nu există evaluări

- Venturi Scrubber Theory & ExperimentDocument6 paginiVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- PUMP CALCULATION SHEETDocument4 paginiPUMP CALCULATION SHEETMuhammad BilalÎncă nu există evaluări

- Technical Design Principles for Liquid Ring Vacuum PumpsDocument18 paginiTechnical Design Principles for Liquid Ring Vacuum PumpsAgung SiswahyuÎncă nu există evaluări

- Gas Line Size-1Document12 paginiGas Line Size-1svnaik14Încă nu există evaluări

- Heat Exchanger Rating Calc SheetDocument14 paginiHeat Exchanger Rating Calc SheetSatria 'igin' Girindra NugrahaÎncă nu există evaluări

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 paginiSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierÎncă nu există evaluări

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe la EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentÎncă nu există evaluări

- Piping Pressure Drop and Pump SizingDocument3 paginiPiping Pressure Drop and Pump SizingElias EliasÎncă nu există evaluări

- HEAT EXCHANGER SPECIFICATION SHEETDocument1 paginăHEAT EXCHANGER SPECIFICATION SHEETHudaFiHayyatÎncă nu există evaluări

- Hydraulic Calculations MudpumpDocument1 paginăHydraulic Calculations MudpumpSudish BhatÎncă nu există evaluări

- Caso de Studio Xchanger 1Document5 paginiCaso de Studio Xchanger 1fabianÎncă nu există evaluări

- 215-DDR Balkassar Deep-1a, 27.11.23Document2 pagini215-DDR Balkassar Deep-1a, 27.11.23Syed HumzaÎncă nu există evaluări

- 12 - Hydraulic Calculations & MudpumpDocument1 pagină12 - Hydraulic Calculations & MudpumpJunaid MateenÎncă nu există evaluări

- Hydraulic Calc by VassDocument1 paginăHydraulic Calc by VassKyzak K. KeorkÎncă nu există evaluări

- Gas-Gas Exchanger DatasheetDocument3 paginiGas-Gas Exchanger DatasheetidilfitriÎncă nu există evaluări

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 paginiDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTOROÎncă nu există evaluări

- Gas Chiller DatasheetDocument2 paginiGas Chiller DatasheetidilfitriÎncă nu există evaluări

- Gas Chiller Datasheet PDFDocument2 paginiGas Chiller Datasheet PDFidilfitriÎncă nu există evaluări

- Liquid - Gas Phase SizingDocument12 paginiLiquid - Gas Phase Sizingeke23Încă nu există evaluări

- KSB MIL Controls Limited Valve Specification SheetDocument2 paginiKSB MIL Controls Limited Valve Specification SheetPablo TorresÎncă nu există evaluări

- Cementing Job Model 001Document6 paginiCementing Job Model 001islam atifÎncă nu există evaluări

- Heat Exchanger Specification SheetDocument32 paginiHeat Exchanger Specification SheetWijayantoÎncă nu există evaluări

- 2400-05-DTS-005cooling TowerDocument19 pagini2400-05-DTS-005cooling TowerEmran NazirÎncă nu există evaluări

- 240-05-DTS-000 Fire Water PumpDocument19 pagini240-05-DTS-000 Fire Water PumpEmran NazirÎncă nu există evaluări

- 240-05-DTS-XXX Flare StackDocument18 pagini240-05-DTS-XXX Flare StackEmran NazirÎncă nu există evaluări

- 100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorDocument1 pagină100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorSonya LoveraÎncă nu există evaluări

- Tank Pressure During Pump OutDocument1 paginăTank Pressure During Pump OutRexx MexxÎncă nu există evaluări

- 084 AT507X - Stylesheet PDFDocument1 pagină084 AT507X - Stylesheet PDFLeonardo BarriosÎncă nu există evaluări

- SizingDocument4 paginiSizingAlberto ReyesÎncă nu există evaluări

- Foam Pig TDW PDFDocument2 paginiFoam Pig TDW PDFeka resmanaÎncă nu există evaluări

- PIPEMILL - Piping Engineering, Design and Analysis: Pipe Wall Thickness Calculation To Asme B31.3 (2012) para 304.1.2Document1 paginăPIPEMILL - Piping Engineering, Design and Analysis: Pipe Wall Thickness Calculation To Asme B31.3 (2012) para 304.1.2eka resmanaÎncă nu există evaluări

- 02 - Heat ExchangersDocument88 pagini02 - Heat ExchangersDana GuerreroÎncă nu există evaluări

- NPSH calculations for suction systemsDocument9 paginiNPSH calculations for suction systemsrajkamal_eÎncă nu există evaluări

- Pipe Flow Friction Factor CalculationsDocument11 paginiPipe Flow Friction Factor CalculationsVictor ValenciaÎncă nu există evaluări

- Allowable Pipe WeightDocument8 paginiAllowable Pipe Weighteka resmanaÎncă nu există evaluări

- Calculating Centrifugal Chiller Condenser LoadsDocument49 paginiCalculating Centrifugal Chiller Condenser Loadseka resmana100% (1)

- PN13 ConstructabilityDocument7 paginiPN13 ConstructabilityTeniozo_MesdwardÎncă nu există evaluări

- 02 - Heat ExchangersDocument88 pagini02 - Heat ExchangersDana GuerreroÎncă nu există evaluări

- Steam CompositionDocument2 paginiSteam Compositioneka resmanaÎncă nu există evaluări

- PSF Project Execution Plan for Physical Sciences FacilityDocument54 paginiPSF Project Execution Plan for Physical Sciences FacilityihllhmÎncă nu există evaluări

- AutoPIPE V8i Standard Vs Advanced Vs NuclearDocument3 paginiAutoPIPE V8i Standard Vs Advanced Vs NuclearZoranÎncă nu există evaluări

- AG 606 - 1997 Prep Safety & Operating Plan Gas Networks PDFDocument20 paginiAG 606 - 1997 Prep Safety & Operating Plan Gas Networks PDFeka resmanaÎncă nu există evaluări

- INCO TermsDocument1 paginăINCO TermscypraegeanÎncă nu există evaluări

- Honeywell Notifier 2017Document56 paginiHoneywell Notifier 2017eka resmanaÎncă nu există evaluări

- OE Spec MTU16V2000DS1100 3B 50Hz 1 15Document7 paginiOE Spec MTU16V2000DS1100 3B 50Hz 1 15eka resmanaÎncă nu există evaluări

- Paper09 Zamriahmad Petronas PmuDocument28 paginiPaper09 Zamriahmad Petronas PmugengiskahnÎncă nu există evaluări

- Design Practice - Piping Supports Design PDFDocument36 paginiDesign Practice - Piping Supports Design PDFeka resmanaÎncă nu există evaluări

- Pigging System for Dense Slurry PipelineDocument4 paginiPigging System for Dense Slurry Pipelineeka resmanaÎncă nu există evaluări

- Pipe Reducer StandardDocument3 paginiPipe Reducer StandardSyifa Alfi HabibiÎncă nu există evaluări

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocument1 paginăEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007Încă nu există evaluări

- WRI Manual of Standard Practice 109497Document38 paginiWRI Manual of Standard Practice 109497Maximiliano Rivas AlferoÎncă nu există evaluări

- Compressed Gas Cryogenic HoseDocument4 paginiCompressed Gas Cryogenic Hoseeka resmanaÎncă nu există evaluări

- View TendDocument8 paginiView Tendeka resmanaÎncă nu există evaluări

- Mains Supply: Noadswood Science, 2012Document16 paginiMains Supply: Noadswood Science, 2012LailaÎncă nu există evaluări

- Synchronous Machine DesignDocument35 paginiSynchronous Machine DesigndiptiÎncă nu există evaluări

- Universiti Malaysia Pahang: Faculty of Mechanical EngineeringDocument13 paginiUniversiti Malaysia Pahang: Faculty of Mechanical EngineeringFirdaus IliasÎncă nu există evaluări

- Calculation of Safe Bearing Capacity as per IS 6403 - 1981Document11 paginiCalculation of Safe Bearing Capacity as per IS 6403 - 1981navneet3bawaÎncă nu există evaluări

- Phys 16 21 Module 2 Thermal ExpansionDocument15 paginiPhys 16 21 Module 2 Thermal ExpansionLarkTrebligÎncă nu există evaluări

- 4-Cyclones HandoutDocument18 pagini4-Cyclones HandoutfatimaÎncă nu există evaluări

- LNG ConverstionTableDocument7 paginiLNG ConverstionTableLeite AddyÎncă nu există evaluări

- Westinghouse Lighting Fisher-Pierce 6600A Series Photocontrol Spec Sheet 12-59Document4 paginiWestinghouse Lighting Fisher-Pierce 6600A Series Photocontrol Spec Sheet 12-59Alan MastersÎncă nu există evaluări

- RAJIV RANJAN SINHA IP 09 SR No. 09Document15 paginiRAJIV RANJAN SINHA IP 09 SR No. 09rajeev ranjanÎncă nu există evaluări

- Autochangeover in Power PlantsDocument18 paginiAutochangeover in Power PlantsSukant BhattacharyaÎncă nu există evaluări

- 4 - Fact Sheet PVC2200B enDocument2 pagini4 - Fact Sheet PVC2200B enAhmedreyad35Încă nu există evaluări

- Fundamental of Electronics Engineering Lab (EC-211)Document2 paginiFundamental of Electronics Engineering Lab (EC-211)ragvshahÎncă nu există evaluări

- KU SPH 101 Electricity and Magnetism 1 NotesDocument107 paginiKU SPH 101 Electricity and Magnetism 1 NotesCallum Fallen100% (1)

- M3aa M2aa M2va M3va 2004Document82 paginiM3aa M2aa M2va M3va 2004Lance AyoubÎncă nu există evaluări

- Power Supply RepairDocument4 paginiPower Supply RepairterezkiÎncă nu există evaluări

- Model: PF15-Pro Helmer Scientific, Noblesville, Indiana: Technical Data Sheet High-Performance, Platelet AgitatorDocument2 paginiModel: PF15-Pro Helmer Scientific, Noblesville, Indiana: Technical Data Sheet High-Performance, Platelet AgitatorVishnu Premkumar (SmartCal)Încă nu există evaluări

- What Is An Injection Moulding MachineDocument3 paginiWhat Is An Injection Moulding MachineNIKHIL PATHADEÎncă nu există evaluări

- BahanKuliah 2BDocument74 paginiBahanKuliah 2BAsep RÎncă nu există evaluări

- Fiche Technique Jinko JKM300 320M 60H V A2 enDocument2 paginiFiche Technique Jinko JKM300 320M 60H V A2 enfarfarfifi3Încă nu există evaluări

- June 2014 (R) QP - Unit 1 Edexcel Physics A-LevelDocument28 paginiJune 2014 (R) QP - Unit 1 Edexcel Physics A-LevelArun MosesÎncă nu există evaluări

- Emi Unit 4Document2 paginiEmi Unit 4Murali KrishnaÎncă nu există evaluări

- Method of Equivalencing For A Large Wind Power Plant With Multiple Turbine RepresentationDocument11 paginiMethod of Equivalencing For A Large Wind Power Plant With Multiple Turbine RepresentationAlberto JimenezÎncă nu există evaluări

- Dynamics of Machinery Question PapersDocument22 paginiDynamics of Machinery Question PapersMohan Babu S0% (1)

- Sustainable Energy Management and Green EngineeringDocument35 paginiSustainable Energy Management and Green EngineeringSamuel GarciaÎncă nu există evaluări

- High-Voltage Sf6 Gas Insulated Busbars (Gil) : Field of ApplicationDocument2 paginiHigh-Voltage Sf6 Gas Insulated Busbars (Gil) : Field of ApplicationT D MeenakshiÎncă nu există evaluări

- Heat 4Document4 paginiHeat 4Kasar nagib 2002Încă nu există evaluări

- Internal Combustion Engine Heat Release Calculation Using Single Zone and CFD 3D Numerical ModelsDocument12 paginiInternal Combustion Engine Heat Release Calculation Using Single Zone and CFD 3D Numerical ModelsPinsteritÎncă nu există evaluări