Documente Academic

Documente Profesional

Documente Cultură

Trays 180204143412

Încărcat de

ravi20070 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări19 paginiColumn Trays

Titlu original

trays-180204143412

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentColumn Trays

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

19 vizualizări19 paginiTrays 180204143412

Încărcat de

ravi2007Column Trays

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 19

TRAYS

BUBBLE CAP TRAYS

SIEVE TRAYS

VALVE TRAYS

PARAMETERS FOR TRAY DESIGN

STRUCTURED PACKAGING

TRAYS VS PACKAGING

To provide liquid holdup in order to achieve the

proper vapor-liquid mass transfer that the distillation

process requires for separation.

The function of a tray is to facilitate contact between

the vapour phase and liquid phase so that mass

transfer between the two phases can take place.

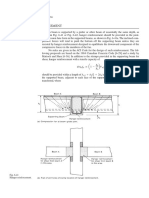

Each tray can be considered as being made up of

three sections: weir, bubbling area, and downcomer.

The function of a weir is to maintain a desired liquid level

on the tray.

Downcomers are used to guide liquid flow from an upper

tray to a lower tray.

The bubbling area is the place where vapour-liquid

contact takes place. Vapour flows through the openings on

the tray from below, and into the liquid flowing across the

tray, forming a foaming, turbulent mixture.

In the simplest design, sieves are provided for vapour-

liquid contact.

Alternatively, valves or bubble-caps may be used.

During this foaming process, a high interfacial area for

efficient vapour-liquid mass transfer is produced.

Trays are supported in a vessel by means of support rings

or beams.

On the operating principles, there are three common types

of trays:

1. Sieve

2. Valve

3. Bubble-cap

Riser or chimney fitted over each hole, and a cap that

covers the riser.

The cap is mounted so that there is a space between riser

and cap to allow the passage of vapour.

Vapour rises through the chimney and is directed

downward by the cap, finally discharging through slots in

the cap, and finally bubbling through the liquid on the

tray.

Sieve trays are simply metal plates with holes in them.

Vapour passes straight upward through the liquid on the

plate.

The arrangement, number and size of the holes are design

parameters.

Perforations are covered by liftable caps.

Vapour flows lifts the caps, thus self creating a flow area

for the passage of vapour.

The lifting cap directs the vapour to flow horizontally into

the liquid, thus providing better mixing than is possible in

sieve trays.

Cost

Bubble-caps are appreciably more expensive than sieve or

valve trays

The relative cost will depend on the material of

construction used.

Due to its simple design, sieve trays are normally the

cheapest.

Operating Range

Bubble-cap trays have a positive liquid seal and can

therefore operate efficiently at very low vapour rates.

Sieve trays rely on the flow of vapours through the holes

to hold the liquid on the tray, thus cannot operate at very

low vapour rates.

Valve trays are intended to give greater flexibility than

sieve trays at a lower cost than bubble-caps.

Thus, bubble-cap trays have the widest operating range,

followed by valve tray, and sieve tray.

Pressure Drop

This factor will be important in vacuum operations.

The tray pressure drop will depend on the detailed design

of the tray, but in general, sieve trays give the lowest

pressure drop, followed by valves, with bubble-caps giving

the highest.

Maintenance

For dirty services, bubble-caps are not suitable as they are

most susceptible to plugging.

Sieve trays are the easiest to clean.

SUMMARY

Sieve trays are the cheapest and are satisfactory for most

applications.

Valve trays should be considered if the specified turndown

ratio cannot be met with sieve trays.

Bubble-caps should only be used where very low vapour

rates have to be handled and a positive liquid seal is

essential at all flow rates.

Structured packing is formed from corrugated sheets of

perforated embossed metal or wire gauze.

The result is a very open honeycomb structure with

inclined flow channels giving a relatively high surface

area but with very low resistance to gas flow.

The surface enhancements have been chosen to maximize

liquid spreading.

These characteristics tend to show significant

performance benefits in low pressure and low irrigation

rate applications.

A tray column that is facing throughput problems may be

de-bottlenecked by replacing a section of trays with

packings. This is because:

packings provide extra inter-facial area for liquid-vapour

contact

efficiency of separation is increased for the same column

height

packed columns are shorter than trayed columns

Packed columns are called continuous-contact columns

while trayed columns are called staged-contact columns

because of the manner in which vapour and liquid are

contacted.

[1] R. Perry, D. Green and R. Perry, Perry's Chemical

Engineers' Handbook. New York: McGraw-Hill, 2008.

[2] Distillation Tray Fundamentals. Cambridge University

Press, 2009.

[3] A. Górak and Z. Olujic, Distillation. 2014.

[4]E. Ludwig, Applied Process Pesign for Chemical and

Petrochemical Plants. Houston, Tex. [u.a.]: Gulf Publ, 1997.

THANKS TO ALL OF YOU

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Introduction To Microelectronics FabricationDocument53 paginiIntroduction To Microelectronics FabricationEmilio Pardo EstebanÎncă nu există evaluări

- Ucs-66 MDMTDocument14 paginiUcs-66 MDMTravi2007Încă nu există evaluări

- PotentiometryDocument48 paginiPotentiometryapi-19959578Încă nu există evaluări

- ISO 10110 Optical Drawing StandardsDocument17 paginiISO 10110 Optical Drawing Standardskalvino314Încă nu există evaluări

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocument7 pagini6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007Încă nu există evaluări

- Crude Distillation UnitsDocument44 paginiCrude Distillation UnitsKalai SelvanÎncă nu există evaluări

- SpiraxSarco-B2-Steam Engineering Principles and Heat TransferDocument186 paginiSpiraxSarco-B2-Steam Engineering Principles and Heat Transferdanenic100% (4)

- DSC MachineDocument7 paginiDSC Machineravi2007Încă nu există evaluări

- Coated Pipe ChecklistDocument1 paginăCoated Pipe Checklistravi2007Încă nu există evaluări

- DSC Beginners GuideDocument9 paginiDSC Beginners GuidelumineurÎncă nu există evaluări

- Types of DistillationDocument6 paginiTypes of Distillationravi2007Încă nu există evaluări

- Preliminary Distillation of Crude Oil 25Document19 paginiPreliminary Distillation of Crude Oil 25ravi2007Încă nu există evaluări

- DSC Beginners GuideDocument9 paginiDSC Beginners GuidelumineurÎncă nu există evaluări

- Effect of Chemical Elements in Steel PDFDocument2 paginiEffect of Chemical Elements in Steel PDFbill_lee_242Încă nu există evaluări

- Corrosion BasicsDocument3 paginiCorrosion Basicsravi2007Încă nu există evaluări

- 21 Chemical Elements and Effects On Steel Mechanical Properties - LinkedInDocument8 pagini21 Chemical Elements and Effects On Steel Mechanical Properties - LinkedInravi2007Încă nu există evaluări

- 21 Chemical Elements and Effects On Steel Mechanical Properties - LinkedInDocument8 pagini21 Chemical Elements and Effects On Steel Mechanical Properties - LinkedInravi2007Încă nu există evaluări

- Section 4 PDFDocument3 paginiSection 4 PDFElMacheteDelHuesoÎncă nu există evaluări

- Caustic Embrittlement - Causes and PreventionDocument2 paginiCaustic Embrittlement - Causes and Preventionravi2007Încă nu există evaluări

- Corrosion BasicsDocument3 paginiCorrosion Basicsravi2007Încă nu există evaluări

- Pressure Vessels, Spherical Pressure Vessels (Pressure Spheres), Cylindrical Pressure Vessels and Dished EndsDocument4 paginiPressure Vessels, Spherical Pressure Vessels (Pressure Spheres), Cylindrical Pressure Vessels and Dished Endsravi2007Încă nu există evaluări

- Dished End Manufacturing For BeginnersDocument7 paginiDished End Manufacturing For Beginnersravi2007Încă nu există evaluări

- Dished EndsDocument2 paginiDished Endsravi2007Încă nu există evaluări

- Guide To Welding ElectrodesDocument10 paginiGuide To Welding Electrodesravi2007Încă nu există evaluări

- Dished EndsDocument2 paginiDished Endsravi2007Încă nu există evaluări

- Pressure Vessels, Spherical Pressure Vessels (Pressure Spheres), Cylindrical Pressure Vessels and Dished EndsDocument4 paginiPressure Vessels, Spherical Pressure Vessels (Pressure Spheres), Cylindrical Pressure Vessels and Dished Endsravi2007Încă nu există evaluări

- Hydrostatic Pressure Tests ASME Pressure VesselsDocument3 paginiHydrostatic Pressure Tests ASME Pressure Vesselsravi2007Încă nu există evaluări

- Manufacturing of Dish End PDFDocument48 paginiManufacturing of Dish End PDFravi2007Încă nu există evaluări

- How Critical Is MDMT in Vessel Designing - EnventureDocument2 paginiHow Critical Is MDMT in Vessel Designing - Enventureravi2007Încă nu există evaluări

- Explosive PDFDocument40 paginiExplosive PDFravi2007Încă nu există evaluări

- How Critical Is MDMT in Vessel Designing - EnventureDocument2 paginiHow Critical Is MDMT in Vessel Designing - Enventureravi2007Încă nu există evaluări

- Specific Requirement of Material SlectionDocument5 paginiSpecific Requirement of Material Slectionravi2007Încă nu există evaluări

- 6-12-0001 Rev 6 General Spec For Pressure VesselsDocument15 pagini6-12-0001 Rev 6 General Spec For Pressure Vesselsravi2007Încă nu există evaluări

- Pipeline ParametersDocument4 paginiPipeline Parametersazhagu duraiÎncă nu există evaluări

- MappingDocument13 paginiMappingAzzah NazÎncă nu există evaluări

- 2.2 Moist Air PropertiesDocument9 pagini2.2 Moist Air PropertiesMark MoraÎncă nu există evaluări

- 关于HANGERDocument3 pagini关于HANGERNEOÎncă nu există evaluări

- Experiment No (4) Torque and Angular Acceleration of A FlywheelDocument4 paginiExperiment No (4) Torque and Angular Acceleration of A FlywheelNihad MohammedÎncă nu există evaluări

- Structural Acoustics Tutorial-Part 2 Sound-StructuDocument20 paginiStructural Acoustics Tutorial-Part 2 Sound-StructuSomeSneakyBoiÎncă nu există evaluări

- Liquid Sensing Using Active Feedback Assisted Planar Microwave ResonatorDocument3 paginiLiquid Sensing Using Active Feedback Assisted Planar Microwave ResonatorhesoyamyecgaaaÎncă nu există evaluări

- Self-Healing Concrete With Crystalline AdmixtureDocument8 paginiSelf-Healing Concrete With Crystalline AdmixtureAlexander HierroÎncă nu există evaluări

- Calculation of Pipe Friction LossDocument33 paginiCalculation of Pipe Friction LossEyob AdÎncă nu există evaluări

- Subject Name: Physics Subject Code: 214: Question Id: 1Document31 paginiSubject Name: Physics Subject Code: 214: Question Id: 1AmanÎncă nu există evaluări

- Microsoft Word - No-14 6084 Red Insulating VarnishDocument3 paginiMicrosoft Word - No-14 6084 Red Insulating VarnishA PadmanathanÎncă nu există evaluări

- Vibration Testing of Small Satellites: Part 2: Test Configuration, Fixtures, and InstrumentationDocument12 paginiVibration Testing of Small Satellites: Part 2: Test Configuration, Fixtures, and InstrumentationYoussef wagdyÎncă nu există evaluări

- Assignment 1Document2 paginiAssignment 1Sandip Thakur0% (1)

- ChemicalEq DroppersDocument13 paginiChemicalEq DroppersUtkarsh SharmaÎncă nu există evaluări

- Powershift TransmissionDocument6 paginiPowershift TransmissionSuprastowo Bin SarinoÎncă nu există evaluări

- NosaDocument9 paginiNosaosaroboÎncă nu există evaluări

- Development and Characterization of Mixed EmulgelDocument41 paginiDevelopment and Characterization of Mixed EmulgelJeevan KhanalÎncă nu există evaluări

- Atomic Absorption SpectrometryDocument64 paginiAtomic Absorption Spectrometryanilrockzzz786Încă nu există evaluări

- T2 Skript CH 4Document26 paginiT2 Skript CH 4Muhammad SaleemÎncă nu există evaluări

- Vibration Absorbers: Scan This QR CodeDocument4 paginiVibration Absorbers: Scan This QR CodeThanhÎncă nu există evaluări

- GRAVITATIONAL CONCENTRATION (Autosaved)Document14 paginiGRAVITATIONAL CONCENTRATION (Autosaved)Cristiano RonaldoÎncă nu există evaluări

- Five Essentials of Gel Refrigerant Design and Specification PDFDocument10 paginiFive Essentials of Gel Refrigerant Design and Specification PDFtantibaÎncă nu există evaluări

- SpillwayDocument18 paginiSpillwayRaju ShresthaÎncă nu există evaluări

- Chapter 3-Thermodynamics FinalDocument20 paginiChapter 3-Thermodynamics Finalgsudhanta1604Încă nu există evaluări

- CFD Computational of A Supersonic Flow Past Axisymetric Nozzle Boattail With Jet Exhaust PDFDocument1 paginăCFD Computational of A Supersonic Flow Past Axisymetric Nozzle Boattail With Jet Exhaust PDFmojicapÎncă nu există evaluări

- Chapter 011Document2 paginiChapter 011Zaid juttÎncă nu există evaluări