Documente Academic

Documente Profesional

Documente Cultură

Da 950092 001

Încărcat de

munnaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Da 950092 001

Încărcat de

munnaDrepturi de autor:

Formate disponibile

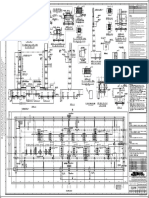

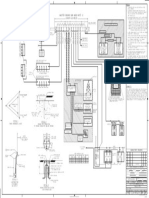

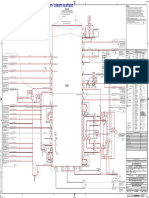

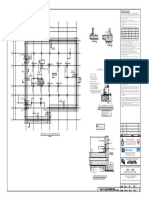

DA-950092 001 00 M88 X NOTES:

REV. NO. SHT. NO. DRAWING NUMBER INDEX PLANT NO. 1. CP DESIGNER SHALL SPECIFY THE SIZE, NUMBER AND

DISTRIBUTION OF ANODES FOR EACH INSTALLATION.

2. CUT CABLE TO REQUIRED LENGTH, REMOVE 75mm OF

PILE INSULATION FROM BOTH ENDS. THERMITE WELD CABLE

LEG SEE DETAIL-7 SEE DETAIL-7 ENDS TO MILD STEEL PLATES 38mm WIDE BY 100mm

LONG. WELD THE STEEL PLATES TO THE ANODE CORE.

SEE NOTE 5 SEE NOTE 5

PILE 6 REMOVE ALL WELD SLAG SPLATTER, SHARP EDGES AND

TYP. BURRS. ENSURE SURFACE IS CLEAN AND DRY BEFORE

TYP. TYP.

3 APPLYING COATING ON THE ANODE CORE, STEEL

PILE LEG PLATES AND BARE CABLE SECTIONS.

ANODE (TYP.) A A A A

3. AFTER SECURING THE BARE SECTIONS OF THE ANODE

SEE DETAIL-1 OR CABLE THROUGH THE SPLIT BOLT, TACK WELD THE

1 2 45^ 45^

CABLE TO THE CHANNEL CLAMP.

45^ 45^

ANODE (TYP.) 4. AFTER TIGHTENING THE SETSCREWS TO MAKE METAL

16 TYPICAL 16 TYPICAL

SEE DETAIL-1 CABLE TO TOTAL CONTACT BETWEEN THE SCREW TIPS

BOND CABLE 17 16 AND THE PILE STRUCTURES, TIGHTEN THE JAM JUTS

SEE DETAIL-5 17 TYPICAL BOND CABLE 17 TYPICAL ANODE TO LOCK THE SETSCREWS IN PLACE.

ANODE (TYP.) AND NOTES 7 & 8 15 SEE DETAIL-5 CLAMP

15 7 OR 6 5. COAT ANODE CLAMP ASSEMBLY PER SUADI ARAMCO

SEE DETAIL-1 & NOTES 7 & 8 SPECIFICATION APCS-19.

6

6 SECTION A-A 6. WHEN THE EXISTING GALVANIC ANODES ARE NEARLY

CONSUMED, REMOVE AND REPLACE THEM WITH ANODES

OF SIMILAR SIZE AND DIMENSIONS.

PLAN PLAN

7. WHENEVER THE ANODE CLAMP ASSEMBLY CAN BE

INSTALLED NEAR AN EXISTING PILE MOUNTED GALVANIC

TYPICAL 3 LEG TYPICAL 4 LEG TYPICAL 6 LEG ANODE, WELD A CABLE END TO THE CHANNEL SUPPORT

AND WET WELD THE OTHER CABLE END TO THE ANODE

PLATFORM PLATFORM PLATFORM SUPPORT BRACKET OF THE EXISTING ANODE WHEN THE

MEAN SEA ANODE CLAMP ASSEMBLY IS INSTALLED. BOTH WELDS

10 OR 11

LEVEL

TYPICAL DISTRIBUTION OF ANODES AT SEA BED CAN BE WET WELDED IF DESIRED. DO NOT WET WELD

ON THE PILE LEG. COAT ALL BARE PARTS OF THE

100 CHANNEL 8

PILE-MOUNTED ASSEMBLY AND ANODE CORE.

SEE DETAIL-6 6" CHANNEL 9

& NOTE 6 8. BEFORE PROCEEDING WITH ANY SUBSEA WET WELDING,

CONSULT WITH THE CSD WELDING ENGINEER FOR

PROPER PROCEDURS.

3/4 "-10 NUTS 25 23 24 22 9. CLEAN (BRUSH) JACKET MEMBERS FROM ANY MARINE

PIPELINE RISER (SEE NOTE 9)

TYPICAL (SEE NOTE 9) GROWTH AT THE CLAMP LOCATIONS.

22

10. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS

OTHERWISE NOTED.

CHANNEL CLAMP ASSEMBLY 11. ANODE CABLES TO BE ATTACHED TO EXISTING ANODE

(SEE DETAILS-2, 3 & 9) BRACKETS.

SEE NOTE 9 6 12. MOUNT THE ANODES ON SUITABLE PALLETS TO ELEVATE

SEE DETAIL-7

THEM FROM THE MUDLINE. REFER TO LIBRARY DRAWING

1

(TYPICAL)

NO. DA-950094, SHT. 001. SECURE THE ANODES ON THE

SET SCREWS

OR

3 GRATINGS THROUGH THE ANODE CORES. COAT ALL BARE

3505mm FOR 1245 LBS.

SEE NOTE-4

ALUMINUM ALLOY

2845mm FOR 560 LBS.

AREAS OF THE ANODE CORES AND ASSOCIATED METALLIC

2

COMPONENTS OF THE MOUNTING ASSEMBLY WITH SPLASH

ALUMINUM ALLOY

SEE DETAIL-1 ZONE COMPOUND.

3353mm FOR 1245 LBS.

1829

2743mm FOR 560 LBS.

1702

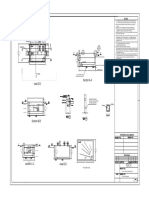

DETAIL-9 13. MOUNT THE CHANNEL CLAMP ASSEMLY ON THE

LOWEST HORIZONTAL BRACING, CSOSS MEMBERS, OR

ANODE CABLE CONNECTOR

1 OR 2 OR 3 SUITABLE SIZE OF VERTICAL SUPPORT PILES.

SEE DETAIL-3 & NOTE-3

SEE NOTES

GROUT BAG 6 & 8

SEE DETAIL-7

(TYPICAL)

MATERIAL LIST

LOWEST HORIZONTAL CODE AMS NUMBER DESCRIPTION

BRACING ANODE CABLES 1 17-851-031 ANODE: GALVALUM III; 254 KG.

ANODE LAID ON SEA SEE DETAIL-5

2 17-851-053 ANODE: GALVALUM III; 565 KG.

BED UNDER PILE STRUCTURE 3 17-851-400 ANODE: GALVALUM III; 126 KG.

6

SEE NOTE 1 12-336-225

GROUT BAG 4 BAR: FLAT; STEEL; 10x100 ( 3/8 "x4")

5 12 13 TYP.

6 5 12-336-120 BAR: FLAT; STEEL; 6x38 ( 1/4 "x1 1/2 ")

6 75 x 6 6 12-336-140 BAR: FLAT; STEEL; 6x76 ( 1/4 "x3")

ANODES INSTALLED

6 7 12-336-150 BAR: FLAT; STEEL; 6x100 ( 1/4 "x4")

WELD EACH END

ON THE SEA BED SEE NOTE-2 8 12-435-612 CHANNEL: STEEL; 100 (4")

5 TYP.

6 7 100 x 6 9 12-435-638 CHANNEL: STEEL; 150 (6"x8.2)

BOND CABLE 10 01-167-217 PIPE: STEEL; 9.53 mm W.T.; 2 1/2 "

12

SEE DETAIL-5 15

DETAIL-6

11 01-167-410 PIPE: STEEL; 8.56 mm W.T.; 4"

SEE DETAIL 5 1 2 AND NOTES

O.D. OF PIPE +200 BOND CABLE

7 & 8 SEE DETAIL-5 15

ALTERNATIVE PILE 12 09-612-345 COATING: ANTI-CORROSIVE

13 15-525-200 STRAP: NYLON;483 mm LONG

75 DRILL & TAP FOR 100 AND NOTES MOUNTED ANODE 14 10-206-826 BOLT: HEX. HD.; 3/4 "-10; 203 mm LONG

1/2 " UNC 7 & 8

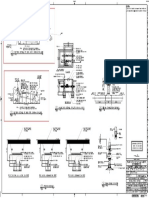

DETAIL-1

38

38

2 HOLES C 305 MIN. PILE 305 PILE 15 17-858-792 CABLE: HMWPE; NO. 2/0 AWG.

13

(SEE NOTES 2, 12 & 13) 16 11-525-862 SET SCREW: 1/2 "-13 x 1 3/4 " LG.

17 10-579-017 NUT: JAM; 1/2 " -13

18 12-435-645 CHANNEL: STEEL ; 150 (6" x 13)

ELEVATION ELEVATION 19 11-525-866 SET SCREW: 1/2 "-13 x 3" LG

38

38

20 14-114-472 TAP SPLIT-BOLT 1/2 "-13 STUD

5

DRILL 20mm DIA.

THERMITE WELD

PILE MOUNTED ANODE PILE MOUNTED ANODE 21 12-337-780 BAR: STEEL; ROUND; 19mm( ) DIA.

3/4 "

4 HOLES 15

3/4 " UNC 254 AND 565 KG. WT. 22 10-579-027 NUT: 3/4 "-10

126 KG. WT. 23 47-821-025 WASHER: ROUND PLAIN, 3/4 " BOLT

O.D./2+200mm

200

SEE NOTE 3 SEE NOTE 3 24 10-826-477 LOCK WASHER: SHAKERPROOF, 3/4 " BOLT

38 21

38

25 08-466-805 SPRING: 800 LB/IN DEFLECTION

O.D. OF PIPE

22

100

12

R=

PIPE

14 25 23 24 22

DRILL & TAP 30

1/

18

1/2

6

FOR 1/2 " UNC

2

O.D.

EACH SIDE

O.

EXISTING ANODE

D

19

.

x x

DETAIL-2 x x

x

x

x

x

45^

x x

4 45^ EXISTING BRACKET

DETAIL-4

76

x x

4

C B 19 x

x

x x

x

x ANODE CABLE FORMERLY STD. DWG. AA-036409; SHT. 001; REV. 05

CHANNEL SUPPORT x x

18 x

x

x

x (SEE NOTES 2 & 11)

SEE DETAIL-2 xx xxxx xxx xx xxx xxx xxx x

x x x xxx

x x x xx

xxxx xxx

C xx x x

6M 1 OR 3

6 OR 7 6 OR 7

STEEL LUGS

NEW ANODE

WELDED 4

305

DETAIL-5 TO CLAMPS

6

6 WELD BOTTOM 14 REV.

CLAMP 6 OR 7 NO.

DATE BY JO/EWO DESCRIPTION CHKD. CERT. APPD.

C B JAM NUT

TWO NUTS

x

x

x

HORIZONTAL BRACING SAUDI ARABIAN OIL COMPANY

x

JAM NUT x

x

x

x

x

x

EDSD

x NONE

x DRAWN BY W.E.DAGHSTANI CHECKED BY SCALE:

SET SCREW 20 20 TAP

19 17 1/2 " -13 NUTS TAP SPLIT BOLT

6.00" 6 OR 7 JACKET LEG DATE STARTED

02-10-99

DATE COMPLETED

02-10-99

SEE VIEW BB SPLIT-BOLT x x

x x

x x OPR’G. DEPT. ENG. DEPT.

x x

x x

x x

x x

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx APP’D. FOR CONST.

THIS DRAWING IS NOT TO BE USED FOR CERTIFIED

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED BY DATE

2.157"

ALTERNATIVE HORIZONTAL CATHODIC PROTECTION

0.437"

25 23 24 22

DETAIL-3 BRAZE BRAZE GUSSET PLATES

WELDED AS SHOWN

4 MEMBER MOUNTED ANODE GALVANIC ANODES REPLACEMENT ON

254 AND 126 KG. WT. OFFSHORE STRUCTURES

VIEW B-B 0.343"

DETAIL-7 LIB. DWG. SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

SECTION C-C

M88 X DA-950092 001 00

Saudi Aramco 2615 ENG. (3/91)

CADD-02

Copyright©Saudi Aramco 2009. All rights reserved.

S-ar putea să vă placă și

- Gas AbDocument14 paginiGas AbJackielyn EugenioÎncă nu există evaluări

- TWPH Rev - 5Document1 paginăTWPH Rev - 5pravinmishra1245Încă nu există evaluări

- Pre Welding ChecklistDocument2 paginiPre Welding Checklistmunna100% (3)

- Clinical Micro Lab Safety & QA IntroDocument8 paginiClinical Micro Lab Safety & QA IntroDayledaniel SorvetoÎncă nu există evaluări

- Mechanical Intro 17.0 M08 Eigenvalue Buckling and SubmodelingDocument34 paginiMechanical Intro 17.0 M08 Eigenvalue Buckling and SubmodelingAlexander NarváezÎncă nu există evaluări

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 paginăSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikÎncă nu există evaluări

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 paginăSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikÎncă nu există evaluări

- Aa 038607 001Document1 paginăAa 038607 001hai sunÎncă nu există evaluări

- Aa 038605 001Document1 paginăAa 038605 001hai sunÎncă nu există evaluări

- (0030) Salman Town Solar Project Solar SMDBDocument6 pagini(0030) Salman Town Solar Project Solar SMDBSavio SunnyÎncă nu există evaluări

- Batching Plant Architectural DrawingDocument1 paginăBatching Plant Architectural DrawingTaposh Paul100% (1)

- Design Criteria Wall Types:: Dininig Room 9'-6" CEILINGDocument1 paginăDesign Criteria Wall Types:: Dininig Room 9'-6" CEILINGIamJace C.Încă nu există evaluări

- A29 P LTG Va 240416 003 - 00 PDFDocument1 paginăA29 P LTG Va 240416 003 - 00 PDFbillÎncă nu există evaluări

- A005 Stan Deck FRDocument1 paginăA005 Stan Deck FRkecalli.restauranteÎncă nu există evaluări

- Ea-679798 001 0000Document1 paginăEa-679798 001 0000engrabbas75Încă nu există evaluări

- View-U View-A View-B View-C: Reference DrawingsDocument1 paginăView-U View-A View-B View-C: Reference DrawingsAnonymous BZQOJwWIh6Încă nu există evaluări

- 13.8kV Auto Bus Transfer Scheme Panel OverviewDocument1 pagină13.8kV Auto Bus Transfer Scheme Panel OverviewAnonymous BZQOJwWIh6Încă nu există evaluări

- Revised valve piping and instrumentation drawingDocument1 paginăRevised valve piping and instrumentation drawingMohamed Wasim ShaikhÎncă nu există evaluări

- GA Drawings for ProcurementDocument19 paginiGA Drawings for ProcurementRAJESHWARÎncă nu există evaluări

- AjhDocument1 paginăAjhbillÎncă nu există evaluări

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 pagină4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiÎncă nu există evaluări

- K H110984004V00Document1 paginăK H110984004V00Anonymous X3PnFL6Încă nu există evaluări

- Parent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTDocument9 paginiParent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTmoneyphotocopyshopÎncă nu există evaluări

- H041675001V00Document1 paginăH041675001V00Mohammed IrfanÎncă nu există evaluări

- Tab Riy Me SD DR SFL 104aDocument1 paginăTab Riy Me SD DR SFL 104aamostafacandpegÎncă nu există evaluări

- Floor Pattern Layout 1: Masterpiece Asia Properties IncDocument7 paginiFloor Pattern Layout 1: Masterpiece Asia Properties Incerwin leeÎncă nu există evaluări

- Decoke Drum Piping and Instrumentation DiagramDocument1 paginăDecoke Drum Piping and Instrumentation DiagramJovit BeaÎncă nu există evaluări

- M1.1 Moja HvacDocument1 paginăM1.1 Moja HvacArchDynamics01100% (1)

- Uci Mce Stru D S-20.6Document1 paginăUci Mce Stru D S-20.6Thanh Đạt NguyễnÎncă nu există evaluări

- Test Meter Unit 310-90-FM-0050: Saudi Arabian Oil CompanyDocument1 paginăTest Meter Unit 310-90-FM-0050: Saudi Arabian Oil Companyamit sharmaÎncă nu există evaluări

- Sa128563 0004 0003Document1 paginăSa128563 0004 0003Gavriel NgÎncă nu există evaluări

- Train - C - DG10-PIT Plan & SectionsDocument1 paginăTrain - C - DG10-PIT Plan & Sectionsحسن صالح حسن المياحيÎncă nu există evaluări

- PD 0158 SM 06Document1 paginăPD 0158 SM 06FAIZAN AHMEDÎncă nu există evaluări

- Elevation: Saudi Arabian Oil CompanyDocument1 paginăElevation: Saudi Arabian Oil CompanyDomie Neil Bucag SalasÎncă nu există evaluări

- Ha431892003v0f1 (Cable Routing Details)Document1 paginăHa431892003v0f1 (Cable Routing Details)Malik MalikÎncă nu există evaluări

- Aa 036391 001Document1 paginăAa 036391 001Mohammed IrfanÎncă nu există evaluări

- Heat Pumps On Roof Level (1: 100) : Fan ScheduleDocument1 paginăHeat Pumps On Roof Level (1: 100) : Fan ScheduleSelloÎncă nu există evaluări

- Notes:: Packaged Rooftop Units Schedule Split System Schedule (Heat Pump) Sand Trap Louver ScheduleDocument1 paginăNotes:: Packaged Rooftop Units Schedule Split System Schedule (Heat Pump) Sand Trap Louver SchedulemohammedÎncă nu există evaluări

- NCGM XX XX D Aec DR 930 1103Document1 paginăNCGM XX XX D Aec DR 930 1103yusufuÎncă nu există evaluări

- SIDEWALK DETAILS 5Document1 paginăSIDEWALK DETAILS 5atiq0592Încă nu există evaluări

- NCGM XX XX D Aec DR 930 1103Document1 paginăNCGM XX XX D Aec DR 930 1103yusufuÎncă nu există evaluări

- Detailed column and footing reinforcement notesDocument1 paginăDetailed column and footing reinforcement notesom RakseÎncă nu există evaluări

- Detail Section Detail: NotesDocument1 paginăDetail Section Detail: NotesMohamed RamadanÎncă nu există evaluări

- Ohtl Route and Profile. Rev.0 - Part-3-1Document1 paginăOhtl Route and Profile. Rev.0 - Part-3-1Hassan H AlshokyÎncă nu există evaluări

- C RA-620208 002 B 961 A310: Ground Floor Firefighting Part Plan 1Document1 paginăC RA-620208 002 B 961 A310: Ground Floor Firefighting Part Plan 1muthuvelaaÎncă nu există evaluări

- Steam Surface Condenser A10-E-2001: Saudi Arabian Oil CompanyDocument1 paginăSteam Surface Condenser A10-E-2001: Saudi Arabian Oil CompanyzhangÎncă nu există evaluări

- Notes:: Typical Installation DrawingDocument1 paginăNotes:: Typical Installation DrawingAbu Anas M.SalaheldinÎncă nu există evaluări

- CTW320 Msy 00 El Abd 5002 05Document1 paginăCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehÎncă nu există evaluări

- Sa128563 0002 0004Document1 paginăSa128563 0002 0004Gavriel NgÎncă nu există evaluări

- DRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanyDocument1 paginăDRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanybillÎncă nu există evaluări

- SaudiAramco ladder designDocument1 paginăSaudiAramco ladder designDomie Neil Bucag SalasÎncă nu există evaluări

- Plumbing fixture tags and notesDocument1 paginăPlumbing fixture tags and notespaul kioiÎncă nu există evaluări

- (R4) Details of Mother Slab PDFDocument1 pagină(R4) Details of Mother Slab PDFsurya prakashÎncă nu există evaluări

- Construction: Uk ElectricalDocument1 paginăConstruction: Uk ElectricalEdward AveryÎncă nu există evaluări

- MRT M&E Drawing4Document1 paginăMRT M&E Drawing4qinxuekunÎncă nu există evaluări

- Wa-345225 0002 0000Document1 paginăWa-345225 0002 0000Gavriel NgÎncă nu există evaluări

- 18 Ocs General Assemblies OverlapDocument36 pagini18 Ocs General Assemblies OverlapMounikaÎncă nu există evaluări

- DrawingDocument1 paginăDrawingahmedÎncă nu există evaluări

- General notes for construction drawingsDocument1 paginăGeneral notes for construction drawingsmhazarath murariÎncă nu există evaluări

- RCC BEAM AND SLAB DETAILSDocument1 paginăRCC BEAM AND SLAB DETAILSdipesh sharmaÎncă nu există evaluări

- Stair Plans and ElevationsDocument1 paginăStair Plans and ElevationsMohamedÎncă nu există evaluări

- SaudiAramco electrical installation guidelinesDocument1 paginăSaudiAramco electrical installation guidelinescherif yahyaouiÎncă nu există evaluări

- Column Schedule1Document1 paginăColumn Schedule1dipesh sharmaÎncă nu există evaluări

- Saic P 3105Document2 paginiSaic P 3105munnaÎncă nu există evaluări

- Saic W 2090Document2 paginiSaic W 2090munnaÎncă nu există evaluări

- Saic RT 2009Document3 paginiSaic RT 2009munnaÎncă nu există evaluări

- Saic W 2011Document3 paginiSaic W 2011munnaÎncă nu există evaluări

- Satip X 400 01Document11 paginiSatip X 400 01munnaÎncă nu există evaluări

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONDocument24 paginiSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONmunnaÎncă nu există evaluări

- Satr P 3206Document6 paginiSatr P 3206munnaÎncă nu există evaluări

- Satip M 100 10Document10 paginiSatip M 100 10munnaÎncă nu există evaluări

- Satr J 6510Document7 paginiSatr J 6510munnaÎncă nu există evaluări

- Saic P 3105Document2 paginiSaic P 3105munnaÎncă nu există evaluări

- Satr J 2001Document1 paginăSatr J 2001munnaÎncă nu există evaluări

- Saic W 2090Document2 paginiSaic W 2090munnaÎncă nu există evaluări

- Saic RT 2007Document9 paginiSaic RT 2007munnaÎncă nu există evaluări

- Saudi Aramco Glass Inspection PlanDocument10 paginiSaudi Aramco Glass Inspection PlanmunnaÎncă nu există evaluări

- Saic F 2024Document2 paginiSaic F 2024munnaÎncă nu există evaluări

- Satip Q 001 03Document10 paginiSatip Q 001 03munnaÎncă nu există evaluări

- Satip M 100 07Document10 paginiSatip M 100 07munnaÎncă nu există evaluări

- Saic F 2025Document8 paginiSaic F 2025munnaÎncă nu există evaluări

- Architectural Painting Works Ins ChecklistDocument2 paginiArchitectural Painting Works Ins Checklistmunna100% (1)

- Saudi Aramco Foamed Asphalt Inspection PlanDocument10 paginiSaudi Aramco Foamed Asphalt Inspection PlanmunnaÎncă nu există evaluări

- Schedule I Company Attachment IDocument1 paginăSchedule I Company Attachment ImunnaÎncă nu există evaluări

- Schedule S Attachment IDocument1 paginăSchedule S Attachment ImunnaÎncă nu există evaluări

- Additional Requirements for Saudi Aramco ProjectDocument27 paginiAdditional Requirements for Saudi Aramco Projectmunna100% (2)

- Sampleq Practice Exam d11 2002Document22 paginiSampleq Practice Exam d11 2002Michael J Chandik0% (1)

- Schedule C - Attachment 01Document50 paginiSchedule C - Attachment 01munnaÎncă nu există evaluări

- Schedule FDocument5 paginiSchedule FmunnaÎncă nu există evaluări

- Saep 61 PDFDocument21 paginiSaep 61 PDFmunnaÎncă nu există evaluări

- Saep 42Document11 paginiSaep 42munnaÎncă nu există evaluări

- Saep 55Document12 paginiSaep 55munnaÎncă nu există evaluări

- Blower Door Testing Passive Houses: Guidelines For ofDocument20 paginiBlower Door Testing Passive Houses: Guidelines For ofAndie AviÎncă nu există evaluări

- BC 2.2 Ok PDFDocument16 paginiBC 2.2 Ok PDFsatydevsinghnegiÎncă nu există evaluări

- Organic Chemistry Structural EffectsDocument3 paginiOrganic Chemistry Structural EffectsOrlando Angelo Cerezo100% (2)

- Turbidity StandardsDocument18 paginiTurbidity StandardsRizky Cahya PutraÎncă nu există evaluări

- Flexider Heat-Exchangers FLDocument1 paginăFlexider Heat-Exchangers FLMiya NanaÎncă nu există evaluări

- Analysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhaDocument6 paginiAnalysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhakumarÎncă nu există evaluări

- Carbon, Hydrogen, and Nitrogen in Coke: Instrument: CHN628Document2 paginiCarbon, Hydrogen, and Nitrogen in Coke: Instrument: CHN628Making IronÎncă nu există evaluări

- D3039 3039MDocument12 paginiD3039 3039MMariana CarvalhoÎncă nu există evaluări

- Cysteine HPLC MethodDocument6 paginiCysteine HPLC MethodYuxiong HuangÎncă nu există evaluări

- Science3 STC-QC 3rd Trimestral ExamDocument14 paginiScience3 STC-QC 3rd Trimestral ExamMarilouSodeVillaÎncă nu există evaluări

- Comparison Study of Conventional Hot-Water and Microwave Blanching at Different Timetemperaturepower Combinations On The Quality of Potatoes.Document72 paginiComparison Study of Conventional Hot-Water and Microwave Blanching at Different Timetemperaturepower Combinations On The Quality of Potatoes.DavldSmith100% (1)

- Capacitors: An OverviewDocument60 paginiCapacitors: An OverviewKish ShenoyÎncă nu există evaluări

- Um Ga250al Ga400al Eng 0350941Document40 paginiUm Ga250al Ga400al Eng 0350941jackyt09Încă nu există evaluări

- MidSem 2016Document2 paginiMidSem 2016avi0341Încă nu există evaluări

- Confident EngineeringDocument9 paginiConfident EngineeringvalentineÎncă nu există evaluări

- A. Karimi - Kinetic Studies and Reactor ModelingpdfDocument24 paginiA. Karimi - Kinetic Studies and Reactor ModelingpdfPetronela CozmaÎncă nu există evaluări

- Tig Welding W19 12 3 LSiDocument2 paginiTig Welding W19 12 3 LSiKoen BidlotÎncă nu există evaluări

- Angewandte Chemie Intl Edit - 2021 - Jeong - Rapid Access To Ordered Mesoporous Carbons For Chemical Hydrogen StorageDocument9 paginiAngewandte Chemie Intl Edit - 2021 - Jeong - Rapid Access To Ordered Mesoporous Carbons For Chemical Hydrogen StorageHanfeng ZhouÎncă nu există evaluări

- SIKA Concrete Repair Site HandbookDocument24 paginiSIKA Concrete Repair Site HandbookkeesinvongÎncă nu există evaluări

- 22 Aptitude Pipes Cisterns PDFDocument13 pagini22 Aptitude Pipes Cisterns PDFDivya patidarÎncă nu există evaluări

- Prediction of Thrust Force and Torque in Drilling On Aluminium AlloyDocument7 paginiPrediction of Thrust Force and Torque in Drilling On Aluminium Alloyanilsamuel0077418Încă nu există evaluări

- Sika Plast 257Document3 paginiSika Plast 257HasithaÎncă nu există evaluări

- Homework 4 NewDocument4 paginiHomework 4 NewnooraÎncă nu există evaluări

- 37PHTOCHEMICALDHEEBAJCPRDocument7 pagini37PHTOCHEMICALDHEEBAJCPRRifantyÎncă nu există evaluări

- New Edition 2021 - 2022 Chemistry Lab ManualDocument115 paginiNew Edition 2021 - 2022 Chemistry Lab ManualBack UpÎncă nu există evaluări

- RedoxDocument14 paginiRedoxsaraÎncă nu există evaluări

- MIL control valves for process industriesDocument8 paginiMIL control valves for process industriesGovarthanan GopalanÎncă nu există evaluări