Documente Academic

Documente Profesional

Documente Cultură

QCS Flap Valves

Încărcat de

Arun KumarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QCS Flap Valves

Încărcat de

Arun KumarDrepturi de autor:

Formate disponibile

QCS 2014 Section 08: Drainage Works Page 17

Part 05: Valves, Penstocks and Appurtenances

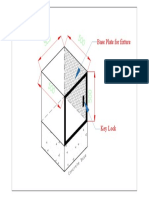

5.13 FLAP VALVES

5.13.1 Flap Valves (General Purpose)

1 The seat shall be one-piece cast iron conforming to BS EN 1561 Grade 250 with a raised

section around the perimeter of the waterway opening to provide the seat. The raised

section shall provide a seating plane diverging, top to bottom, from the plane of the mounting

flange to assist in positive closure of the cover. The seat shall be shaped to provide two

bosses extending above the top of the waterway opening for mounting the top pivot lugs.

Pivot lug bosses shall be drilled and tapped for mounting studs. The flap shall be designed

to be either butted to the face of a wall or to the outlet flange of a discharge pipe. The flaps

LL

shall be operable at a head of 10 m.

2 The cover shall be one-piece cast iron conforming to BS EN 1561 Grade 250 with

.W

necessary reinforcing ribs, with a lifting eye for manual operation, and with bosses to provide

a pivot point connection with the links. Bosses shall be designed to place the hinge bolts in

double shear when gate is assembled.

O

3 Each pivot lug shall be one-piece cast iron. Lugs shall have double bosses to place the top

C

hinge bolts in double shear when they are assembled through the links. The lugs shall be

adjustable in the horizontal plane without removal of the cover from the gate links. The

ES

adjustment shall allow the top pivots to be moved toward the gate seat for reduced sensitivity

of the cover, or moved away from the gate seat to provide opening with a minimum

differential head. Two studs shall be used to connect each pivot to the gate seat.

C

VI

4 The links connecting the cover and pivot lugs shall be one-piece heavy duty cast iron. Each

link shall be provided with bronze bushings at each pivot point. The bottom of the links shall

be provided with an adjusting screw to properly align seating faces on the cover with respect

R

to the seat. The links shall be designed to limit the double hinge action, preventing the cover

SE

from rotating sufficiently to become wedged in the open position.

5 Cast iron work shall be coated before delivery with a bituminous compound as specified in

Clause 8.5.16.2 of QCS.

AL

5.13.2 Flap Valves for Sea Water Applications

D

1 Flap valves frames including fixings for sea water and other aggressive applications shall be

O

of stainless steel conforming to BS 970 Part 1. Sealing faces shall be phosphor bronze

conforming to BS 2874.

M

R

2 Flap valves manufactured from corrosion resistant materials will also be acceptable for

general purpose applications.

TE

3 Flap valves above 1500 mm square shall be of the double door type.

IN

4 Doors shall be of reinforced natural rubber compound of sufficient flexibility to maintain an

efficient seal under minimal seating head conditions.

5 Door hinges shall be continuous across the full width of the door and manufactured from

homogeneous polypropylenes, polyurethane or similar non-ageing material.

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Coupling DatasheetDocument1 paginăCoupling DatasheetArun KumarÎncă nu există evaluări

- Trade Catalogue PDFDocument66 paginiTrade Catalogue PDFArun KumarÎncă nu există evaluări

- Fun City-Model PDFDocument1 paginăFun City-Model PDFArun KumarÎncă nu există evaluări

- Trade Catalogue PDFDocument66 paginiTrade Catalogue PDFArun KumarÎncă nu există evaluări

- Electricty Wiring Code 2018Document98 paginiElectricty Wiring Code 2018aneesÎncă nu există evaluări

- AnnexureG PDFDocument1 paginăAnnexureG PDFArun KumarÎncă nu există evaluări

- GRP Enclosure PDFDocument1 paginăGRP Enclosure PDFArun KumarÎncă nu există evaluări

- GRP Enclosure PDFDocument1 paginăGRP Enclosure PDFArun KumarÎncă nu există evaluări

- Hamad International Airport: 00 03.02.19 Issued For Construction He AtmbcmDocument11 paginiHamad International Airport: 00 03.02.19 Issued For Construction He AtmbcmArun KumarÎncă nu există evaluări

- Vendor ListDocument2 paginiVendor ListArun KumarÎncă nu există evaluări

- Section 10 Victor Stands and Substation Works Bill No. 4 Division 26 ElectricalDocument4 paginiSection 10 Victor Stands and Substation Works Bill No. 4 Division 26 ElectricalArun KumarÎncă nu există evaluări

- Advanced Actuators Limited Prequalification Dossier FOR: Electro-Hydraulic Actuators AND Hydraulic SystemsDocument1 paginăAdvanced Actuators Limited Prequalification Dossier FOR: Electro-Hydraulic Actuators AND Hydraulic SystemsArun KumarÎncă nu există evaluări

- Packing ListDocument1 paginăPacking ListArun KumarÎncă nu există evaluări

- Material List Confirmation of Nikko (Malaysia) GRP TankDocument3 paginiMaterial List Confirmation of Nikko (Malaysia) GRP TankArun KumarÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CT VT Basics SonnenbergDocument71 paginiCT VT Basics SonnenbergAnonymous OCDJg17Z67% (3)

- Valerie Tillard Murder: Probable CauseDocument11 paginiValerie Tillard Murder: Probable CauseLeigh EganÎncă nu există evaluări

- Model CV QLDocument6 paginiModel CV QLMircea GiugleaÎncă nu există evaluări

- Chapter 2 Body CoordinationDocument25 paginiChapter 2 Body CoordinationnanarahmannaimÎncă nu există evaluări

- Cardiovascular SystemDocument100 paginiCardiovascular SystemTerence ValdehuezaÎncă nu există evaluări

- Minibeasts Differentiated Reading Comprehension ActivityDocument15 paginiMinibeasts Differentiated Reading Comprehension Activitymariam helmyÎncă nu există evaluări

- Long Term LiabilitiesDocument21 paginiLong Term Liabilitiesnioriatti8924Încă nu există evaluări

- LMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnDocument4 paginiLMA An. I-Sem 1-Engleza LEC-The Category of Aspect & Aspect 3-Reedited OnIlie IonelÎncă nu există evaluări

- wk8 Nursing Care of A Family When A Child Has An Immune Disorders Part 2Document32 paginiwk8 Nursing Care of A Family When A Child Has An Immune Disorders Part 2claire yowsÎncă nu există evaluări

- Introduction To Psychology (2022)Document642 paginiIntroduction To Psychology (2022)hongnhung.tgdd2018Încă nu există evaluări

- Barista Coffee Company LTDDocument3 paginiBarista Coffee Company LTDGanesh AnandÎncă nu există evaluări

- JETIR1904787Document3 paginiJETIR1904787RONAL SALAS CONTRERASÎncă nu există evaluări

- HC-33 Maximum Moisture Hair Styling Gel PDFDocument2 paginiHC-33 Maximum Moisture Hair Styling Gel PDFdianaÎncă nu există evaluări

- LEEDDocument161 paginiLEEDjeruelÎncă nu există evaluări

- Employement ExchangeDocument22 paginiEmployement ExchangeNeelam ThakurÎncă nu există evaluări

- Manualevu VheDocument60 paginiManualevu VheThariqÎncă nu există evaluări

- Tle - H.E.-Cookery: Quarter 2 - Module 2: Prepare Salad DressingDocument26 paginiTle - H.E.-Cookery: Quarter 2 - Module 2: Prepare Salad DressingRodel Camposo88% (25)

- BPT Notes Applied PsychologyDocument36 paginiBPT Notes Applied PsychologyVivek Chandra0% (1)

- Vision Medilink Product DetailsDocument4 paginiVision Medilink Product DetailsRaj SekarÎncă nu există evaluări

- Chapter 8 Sensation and PerceptionDocument66 paginiChapter 8 Sensation and Perceptionapi-726122866Încă nu există evaluări

- Pin ContentDocument20 paginiPin ContentSwetha100% (2)

- DMD 2018 Stem and Non Stem Checklist Effective 2020-2021Document8 paginiDMD 2018 Stem and Non Stem Checklist Effective 2020-2021Elle DyÎncă nu există evaluări

- 21 Day Level Up Challenge My PathDocument52 pagini21 Day Level Up Challenge My PathDavid Stark100% (1)

- PF700 Components Replacement (Frame 7)Document56 paginiPF700 Components Replacement (Frame 7)Jael molano avilaÎncă nu există evaluări

- Whisper 500 Spec SheetDocument1 paginăWhisper 500 Spec Sheetfranco cuaylaÎncă nu există evaluări

- The Relationship Between Date of Birth and IndividDocument13 paginiThe Relationship Between Date of Birth and IndividAnonymous ktNyZTÎncă nu există evaluări

- Conditional Type 0Document16 paginiConditional Type 0marore100% (1)

- Research News: Sedimentation Velocity of Solids in Finite Size VesselsDocument4 paginiResearch News: Sedimentation Velocity of Solids in Finite Size VesselskorangaprakashÎncă nu există evaluări

- 250 Watt Solar Panel SpecificationsDocument2 pagini250 Watt Solar Panel Specificationsfopoku2k20% (1)

- Screw Take-Up Device Ur1 Ur7: Conveyor ComponentsDocument1 paginăScrew Take-Up Device Ur1 Ur7: Conveyor ComponentsDxFxÎncă nu există evaluări