Documente Academic

Documente Profesional

Documente Cultură

PDS Stopaq Wrapping Band

Încărcat de

Sinan A AzizTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PDS Stopaq Wrapping Band

Încărcat de

Sinan A AzizDrepturi de autor:

Formate disponibile

PRODUCT DATA SHEET

STOPAQ® WRAPPINGBAND CZHT

Product properties of Stopaq® Wrappingband CZHT

Product Information Colour Green

A)

®

Thickness 2.0 ± 0.2 mm [80 ± 8 mils]

Product description: Stopaq Wrappingband CZHT is a high temperature Density 1.5 ± 0.1 g/cm³ [12.5 ± 0.8 lbs/gal] (ISO 1183-1)

corrosion preventing wrap material adhering extremely well to steel and factory Temperature ranges Buried and immersed conditions:

applied pipeline coatings like PP, Liquid Epoxies and FBE. It is very suitable for

Operational: -45°C [-49°F] to +95°C [+203°F]

use on buried and immersed pipes, for use on pipes and risers in offshore

Atmospheric and CUI conditions:

atmospheric conditions, and for use on pipes susceptible for corrosion under

insulation. Operational: -45°C [-49°F] to +120°C [+248°F]

A)

Glass transition temp. ≤ - 65°C [-85°F]

A)

Stopaq® Wrappingband CZHT is a non-toxic, cold-applied, prefabricated wrap Crystallization temp. Temperature test range -100°C to +170°C

coating, based on a compound containing non-crystalline, low-viscosity, non- No evidence of crystallization

crosslinked (fully amorphous), pure homopolymer Polyisobutene. Holiday detection No holidays at 15 kV A)

A)

Drip resistance Tested 48h @ +155°C [+293°F]

No dripping of compound

®

Stopaq Wrappingband CZHT is viscous at the indicated operating temperatures.

Due to its liquid nature it has a set of unique properties, like cold-flow into all Peel tests before and Tested on carbon steel (St 3, Sa 2½) and 304 stainless

irregularities of the substrate, and self-healing of the complete coating system. The after accelerated steel, and on plant coatings PP, FBE, and liquid epoxy.

compound does not cure and is unable to build up internal stress. Stopaq® ageing tests

Wrappingband CZHT is fully resistant to water, salt spray and UV-radiation, and Before ageing A)

has a low gas- and water vapour permeability. Peel strength:

@+23°C [+73°F] ≥ 0.2 N/mm [≥ 18 oz/in]

Stopaq® Wrappingband CZHT requires application of a polymeric outerwrap like @+95°C [+203°F] ≥ 0.05 N/mm [≥ 4.6 oz/in]

Stopaq® Outerwrap HTPP or Stopaq® High Impact Shield HT. This improves

impact and indentation resistance of the coating system and supports the self- After thermal ageing for 100 days at +115°C [+239°F] A)

healing ability of small damages like dents and cuts. Optionally an additional Peel strength ≥ 0.2 N/mm [≥ 18 oz/in]

mechanical protective layer can be applied on top like Stopaq® Polyester, Stopaq®

Vinylester or Stopaq® Outerglass Shield XT. After hot water immersion 100 days at +95°C [+203°F]

A)

Peel strength ≥ 0.2 N/mm [≥ 18 oz/in]

Features:

Controlled cold flow providing inflow into the finest pores of the substrate In all cases:

Resistant to high temperatures Cohesive separation mode

Inert to ageing and weathering ≥ 95% coverage of surface

Conforms to irregular shapes Lap shear tests Tested on carbon steel Sa 2½ A)

Self-healing of small dents, voids and cracks Lap shear strength:

Low surface tension; adheres on many dry substrates at a molecular level @+23°C [+73°F] ≥ 0.02 N/mm² [≥ 2.9 psi]

Adhesion based on vanderWaals forces @+95°C [+203°F] ≥ 0.002 N/mm² [≥ 0.29 psi]

Surface tolerant: no blasting techniques required, wire brushing is sufficient Cohesive separation mode

Constant film thickness ≥ 95% coverage of surface

Environmentally friendly, no health and safety hazards to humans Specific electrical Rs100 > 108 Ω.m² [> 107 Ω.ft²] A)

Resistant to many chemicals like water, salts, acids, alkalis, polar solvents, etc. insulation resistance

For additional information, please consult Stopaq B.V. Ageing resistance test Acc. ISO 20340:2009 Annex A (4200 h), tested on

carbon steel (St 3, Sa 2 ½), on 304 stainless steel, and

Benefits: on existing liquid epoxy coating over carbon steel

Very well suited for application on new-built pipes, and for pipe coating Corrosion creep from scribe: M ≤ 8.0 mm

rehabilitation ISO 4628-2 Blistering: 0(S0)

Fast and easy field application ISO 4628-3 Rusting: Ri 0

Can be moulded onto various types of irregular shaped objects ISO 4628-4 Cracking: 0(S0)

No osmosis or underfilm migration of moisture ISO 4628-5 Flaking: 0(S0)

No cathodic disbondment ISO 4628-6 Chalking: 0

Cathodic Protection (CP) of steel structures is not affected

Properties of coating system comprising Stopaq® Wrappingband

Guaranteed performance

CZHT and Stopaq® Outerwrap HTPP

Impact resistance Tested at 15 J [132 in.lbf] A) and at 40 J [354 in.lbf]

Application examples

@+23°C [+73°F]: no holidays A)

@+95°C [+203°F]: no holidays

Buried and immersed pipes: For protection against external corrosion of buried

and immersed pipes, fittings and field joints made of carbon steel, alloy steel or Indentation resistance Tested with 10 N/mm² [1450 psi] A) @ +23°C [+73°F] and

ductile iron. @ +95°C [+203°F]:

no holidays, residual thickness ≥ 0.6 mm [24 mils] B)

Above ground and offshore pipes and risers: For protection against external Cathodic disbondment Tested @ +23°C [+73°F] and @ +95°C [+203°F] A)

corrosion of carbon steel, alloy steel and ductile iron pipes, field joints and fittings resistance Disbondment 0 mm, no holiday. Defect Ø 6mm [1/4”]

exposed to extreme atmospheric conditions. self-healed within 24 hours.

Corrosion Under Insulation: For protection against corrosion under insulation of Self-healing test Tested @ +23°C [+73°F] and @ +95°C [+203°F]

thermally insulated pipes, field joints and fittings made of carbon steel, alloy steel Completed < 24 hours, no holiday.

pipes and ductile iron.. Cyclic thermal shock After hot dry/wet thermal shock cycling C)

Pipe coating repair and rehabilitation: For repair and rehabilitation and resistance Peel strength ≥ 0.2 N/mm [≥ 18 oz/in]

protection against external corrosion of pipeline coating defects. Cohesive separation

≥ 95% coverage of surface

General order information Cyclic freeze/thaw After immersed freeze/thaw cycling D)

resistance Peel strength ≥ 0.2 N/mm [≥ 18 oz/in]

Product Stopaq® Wrappingband CZHT is available in rolls:

Art. Nr.: Product dimensions and contents: Cohesive separation

6301 50mm x 10m; 12 pcs/box; 360 pcs/pallet ≥ 95% coverage of surface

A)

6302 100mm x 10m; 6 pcs/box; 180 pcs/pallet According to ISO 21809-3:2016 (2nd ed.) for coating type 13

B)

6303 200mm x 10m; 2 pcs/box; 96 pcs/pallet After removal of load within 3 hrs.

C)

6304 200mm x 20m; 2 pcs/box; 96 pcs/pallet 80 cycles 1 ) ≥16h dry +120°C; 2) 1m water quench +10°C; 3) 8h water quench +95°C

D)

6305 300mm x 10m; 2 pcs/box; 80 pcs/pallet 50 cycles immersed in water 1) in 24h to +95°C; 2) in 24h to -15°C

Handling Handle with care. Keep boxes upright.

Storage and shelf life Store indoor, clean and dry, away from direct sunlight

in a cool place below +45°C [113°F].

Unlimited shelf life.

V 5 / 20160422 (EN) Page 1 / 2

®

PRODUCT DATA SHEET STOPAQ WRAPPINGBAND CZHT

Application instruction - Job preparation Application instruction - Brief version

Tools, equipment Temperature probe, Dew point tester, High See specific Stopaq coating instructions for e.g. field joints, pipe

and auxiliaries voltage holiday tester wrapping, coating repair, fittings, etc.

Scissors, Knife, Measuring tape Wrapping Start with removal of a small part of the release

Abrading pads, Wire brushes liner and apply the Wrappingband on the

SFL Substrate cleaner – or, alternatively - substrate. Apply Wrappingband without any

Isopropyl alcohol, cas. nr. 67-63-0 tension onto the substrate. Avoid air-enclosures.

Personal protective gear, if applicable Mould the Wrappingband tight onto the

Additional coating Stopaq® Wrappingband CZHT requires substrate.

materials application of a polymeric outerwrap, such as: Release foil Do not remove the release foil before application

Stopaq® Outerwrap HTPP of the Wrappingband. Remove just prior to

Stopaq® High Impact Shield HT application of the Wrappingband to the surface.

Additional mechanical protective layers may Overlap of wraps Side-by-side overlap: ≥ 10 mm [3/8“]

also be applied over the complete coating, e.g. Consecutive rolls: ≥ 50 mm [2”]

Stopaq® Polyester Overlap on factory applied coating: see specific

Stopaq® Vinylester Stopaq coating instructions.

Stopaq® Outerglass Shield XT

High humidity Stopaq® Wrappingband CZHT can be applied in Application instruction - Quality control

a humid atmosphere. The substrate should be Visual inspection The appearance of Stopaq® Wrappingband

free from condensing water which can be CZHT must look smooth and tight and should be

reached by keeping the temperature at least 3°C shaped around all details and into corners.

[6°F] above dew point. Holiday detection Immediately after application of Stopaq®

Work area and The substrate should be dry, clean and Wrappingband CZHT, holiday testing should be

substrate protected against negative weather influences. carried out with a voltage of 15 kV. A brush

Product conditions Stopaq® Wrappingband CZHT should be dry probe is recommended. No further testing is

and the temperature should preferably be required.

between +20°C [+68°F] and +50°C [+104°F] for

the ease of application. Application instruction – Mechanical protection

Mechanical Once applied, Stopaq® Wrappingband CZHT

Application instruction - Surface preparation protection should be protected against impacts,

General The area to be coated has to be clean, dry, and indentations, soil pressure and other influences

free from oil, grease and dust. All contamination by application of Stopaq® Outerwrap or Stopaq®

including mill-scale has to be removed. High Impact Shield HT, eventually followed by

Degreasing Degrease surfaces with SFL Substrate Cleaner Stopaq® Polyester, Stopaq® Vinylester or

and e.g. a lint-free cloth. Alternatively Isopropyl Stopaq® Outerglass Shield XT. Please consult

alcohol can be used. Stopaq B.V. for further information.

Salts and bacteria No need for additional cleaning.

Condensation of Prior to and during the application, the Handling and commissioning

water temperature of the substrate(s) must be at least Exposure to loads Objects coated with Stopaq® Wrappingband

3°C [6°F] above the dew point. CZHT should not be exposed to loads e.g. from

Substrate Temperature of the substrate should preferably supports- or lifting equipment.

temperature be +30°C [+86°F] or more for fast and easy Immersion or Immersion or burying is possible immediately

application. Preheating may be required. burying after completion of the coating application.

Steel Minimum requirement for surface preparation is Consult data sheets for specific instructions of

St 2 according to ISO 8501-1. Roughness profile additional materials used. Backfill and compact

is not essential for adhesion but In case with clean sand and filling material without sharp

abrasive blast techniques are used, the stones or hard lumps of soil.

preferred roughness is less than 50 μm.

Other substrates De-gloss and degrease the surfaces by using an Information

abrasive pad and SFL Substrate Cleaner. Documentation Extensive information is available on our web-

Alternatively Isopropyl alcohol can be used. site. Application instructions and other

Cleanliness check Take a piece of Wrappingband of ± 150 mm [6”] documentation can be obtained by contacting

length, remove the release foil and fold it back our head office, from our local distributor or by

for about 25 mm [1”]. Put the Wrappingband sending email to info@stopaq.com

onto the surface, press it firmly for 5 minutes. Certified staff Application of the described coating system

Pull the Wrappingband from the substrate with should be carried out by certified personnel.

an angle of app. 135 deg. and a speed of 100 Stopaq ® Extensive laboratory tests and more than 15

mm/min [4”/min]. Cohesive separation should performance years of service in extreme wet and chemical

occur and coverage of the surface with

aggressive environments have proven that

remaining material should be ≥ 95%. If this is corrosion, bacterial growth or stress corrosion

less, surface cleaning is insufficient. Note: at too cracking cannot develop on substrates coated

low substrate temperatures this test may not be

with Stopaq® coating systems.

successful. Preheat the substrate to adequate

temperature and repeat the test.

Seal For Life Industries LLC Seal For Life Industries Mexico Seal For Life Industries Seal For Life Industries BVBA Seal For Life India Private Ltd.

Franklin, MA, USA S de R.L. de C.V. Stopaq B.V. Westerlo, Belgium Baroda, India

Tel: +1 508 918 1600 Tijuana, Mexico Stadskanaal, the Netherlands Tel: +32 14 722 500 Tel: +91 2667 264 721

Toll Free: +1 800 248 7659 Tel USA: +1 858 633 9797 Tel: +31 599 696 170 Fax: +32 14 722 570 Fax: +91 2667 264 724

Fax:+1 508 918 1905 Fax USA: +1 858 633 9740 Fax: +31 599 696 177 belgium@sealforlife.com india@sealforlife.com

franklin@sealforlife.com Tel Mx: +52 664 647 4397 info@sealforlife.com

Fax Mx: +52 664 607 9105

mexico@sealforlife.com

Anodeflex® - Stopaq® - Polyken® - Covalence® - Powercrete® - Sealtaq® - Blockr® - Easy.Qote® - SynergyQ®

DISCLAIMER: Seal For Life Industries warrants that the product(s) represented within conform(s) to its/their chemical and physical description and is appropriate for the use as stated on the respective technical data sheet when used in

compliance with Seal For Life Industries written instructions. Since many installation factors are beyond the control of Seal For Life Industries, the user is obligated to determine the suitability of the products for the intended use and assume all

risks and liabilities in connection herewith. Seal For Life Industries liability is stated in the standard terms and conditions of sale. Seal For Life Industries makes no other warranty either expressed or implied. All information contained in the

respective technical data sheet(s) should be used as a guide and is subject to change without notice. This document supersedes all previous revisions. Please see revision date on the left. Stopaq® is a registered trademark of Seal For Life

Industries.

V 5 / 20160422 (EN) Page 2 / 2

S-ar putea să vă placă și

- Stage 1 Handwriting Program Term 2Document4 paginiStage 1 Handwriting Program Term 2api-206221838Încă nu există evaluări

- Crop MicrometeorologyDocument22 paginiCrop Micrometeorologyrajkumarpai100% (1)

- Zhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)Document465 paginiZhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)IrinaÎncă nu există evaluări

- Siwes Report CHISOM SAM ORJIDocument41 paginiSiwes Report CHISOM SAM ORJISOMSKI1100% (2)

- PDS Stopaq Wrappingband CZ V6 ENDocument2 paginiPDS Stopaq Wrappingband CZ V6 ENDavid RodriguesÎncă nu există evaluări

- Stopaq® Paste CZH: Product Data SheetDocument2 paginiStopaq® Paste CZH: Product Data SheetKUMAR RÎncă nu există evaluări

- PDS Stopaq Outerwrap HTPP V4 EN PDFDocument2 paginiPDS Stopaq Outerwrap HTPP V4 EN PDF今夕何夕Încă nu există evaluări

- Stopaq® Outerwrap PVC: Product Data SheetDocument2 paginiStopaq® Outerwrap PVC: Product Data SheetKUMAR RÎncă nu există evaluări

- 503 Pds Stopaq Wrappingband CZHT v4 (En)Document2 pagini503 Pds Stopaq Wrappingband CZHT v4 (En)EngTamerÎncă nu există evaluări

- PDS Stopaq Wrappingband CZH V8 enDocument2 paginiPDS Stopaq Wrappingband CZH V8 enMajid SattarÎncă nu există evaluări

- 455 - Product - Data - Sheet - Stopaq - Wrapping Band - CZHDocument3 pagini455 - Product - Data - Sheet - Stopaq - Wrapping Band - CZHFatin ZawawiÎncă nu există evaluări

- Stopaq Outerwrap PVC PDFDocument2 paginiStopaq Outerwrap PVC PDFDeepak YadavÎncă nu există evaluări

- Stopaq Outerwrap PVCDocument2 paginiStopaq Outerwrap PVCDeepak YadavÎncă nu există evaluări

- PDS Stopaq Outerglass Shield V2 (En)Document2 paginiPDS Stopaq Outerglass Shield V2 (En)Gulf Trans PowerÎncă nu există evaluări

- 460 Pds Stopaq Outerwrap PVC v7 (En) PDFDocument2 pagini460 Pds Stopaq Outerwrap PVC v7 (En) PDFEngTamerÎncă nu există evaluări

- STOPAQ® Outerwrap PVC PDFDocument2 paginiSTOPAQ® Outerwrap PVC PDFEngTamerÎncă nu există evaluări

- PDS Stopaq Wrappingband CZ V5 enDocument2 paginiPDS Stopaq Wrappingband CZ V5 enAndyÎncă nu există evaluări

- Stopac Outer Wrap PE PDS-Stopaq-Outerwrap-PE-V8-ENDocument2 paginiStopac Outer Wrap PE PDS-Stopaq-Outerwrap-PE-V8-ENvaradarajck893Încă nu există evaluări

- STOPAQ® CZH PasteDocument2 paginiSTOPAQ® CZH PasteEngTamerÎncă nu există evaluări

- Thixoflex Orange & Thixoflex Gray: Product Information SheetDocument2 paginiThixoflex Orange & Thixoflex Gray: Product Information SheetValerio CadedduÎncă nu există evaluări

- PDS Stopaq High Impact Shield V5 enDocument2 paginiPDS Stopaq High Impact Shield V5 enAndyÎncă nu există evaluări

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 paginiVISCOWRAP-HT Product Data Sheet EnglishJA BustosÎncă nu există evaluări

- PDS Stopaq Outerwrap HTPP V3 enDocument2 paginiPDS Stopaq Outerwrap HTPP V3 enAndyÎncă nu există evaluări

- Sikadur 42 Vle PlusDocument4 paginiSikadur 42 Vle PlusMohammed AwfÎncă nu există evaluări

- PDS Stopaq Outerwrap HSPEX V1 enDocument2 paginiPDS Stopaq Outerwrap HSPEX V1 enAndyÎncă nu există evaluări

- PDS Stopaq Outerwrap HTPE V1ENDocument2 paginiPDS Stopaq Outerwrap HTPE V1ENAndyÎncă nu există evaluări

- Fiche Technique Colle ThermiqueDocument2 paginiFiche Technique Colle ThermiqueAnouer BelkadiÎncă nu există evaluări

- 226NDocument2 pagini226NUmaibalanÎncă nu există evaluări

- Turbo-Coat Acrylic Conformal Coating: Product# 2108Document5 paginiTurbo-Coat Acrylic Conformal Coating: Product# 2108Compras MareinsaÎncă nu există evaluări

- Zerust AxxaCoat90 TechnicalDataSheet RevD2Document3 paginiZerust AxxaCoat90 TechnicalDataSheet RevD2ccorp0089Încă nu există evaluări

- 18 - Sikafloor - 264 - SGDocument6 pagini18 - Sikafloor - 264 - SGPaul ManiquisÎncă nu există evaluări

- Duraplate 8200Document4 paginiDuraplate 8200Carlos VillacrizÎncă nu există evaluări

- 460 Stopaq - Product Data Sheet - Stopaq Outerwrap PVC - Version April 2009 (Uk)Document2 pagini460 Stopaq - Product Data Sheet - Stopaq Outerwrap PVC - Version April 2009 (Uk)EngTamerÎncă nu există evaluări

- PS 870 Class C TDS 03 - 21Document2 paginiPS 870 Class C TDS 03 - 21Ever LopezÎncă nu există evaluări

- Hempaline Defend 630: Product DescriptionDocument3 paginiHempaline Defend 630: Product DescriptionSalas VinicioÎncă nu există evaluări

- SP-9888® Tank Lining: Selection & Specification DataDocument4 paginiSP-9888® Tank Lining: Selection & Specification DataSatees KrishnanÎncă nu există evaluări

- PDS Stopaq Wrappingband SZ V3 EN1Document2 paginiPDS Stopaq Wrappingband SZ V3 EN1AndyÎncă nu există evaluări

- Sikadur - 42 MP inDocument4 paginiSikadur - 42 MP inJU SHUANGÎncă nu există evaluări

- Technical Data Sheet: Acrylic Removable CoatingDocument5 paginiTechnical Data Sheet: Acrylic Removable CoatingsidwalÎncă nu există evaluări

- Sikadur - 42 Hes inDocument4 paginiSikadur - 42 Hes insandeepÎncă nu există evaluări

- Technical Data Sheet: Acrylic Removable CoatingDocument5 paginiTechnical Data Sheet: Acrylic Removable CoatingsidwalÎncă nu există evaluări

- Hempaline Defend 630: Product DescriptionDocument3 paginiHempaline Defend 630: Product DescriptionJorge Alberto MontalatÎncă nu există evaluări

- LR-C-VentureClad Catalogue 01Document16 paginiLR-C-VentureClad Catalogue 01himanshu desaiÎncă nu există evaluări

- Ultraply™ Tpo Membrane: Product InformationDocument3 paginiUltraply™ Tpo Membrane: Product InformationCarlos CorregidorÎncă nu există evaluări

- Epofine 556 - Finehard 22962Document5 paginiEpofine 556 - Finehard 22962Karishma PrabhuÎncă nu există evaluări

- Pds CPD Sikadur55SLV UsDocument2 paginiPds CPD Sikadur55SLV UsMikeÎncă nu există evaluări

- Grasa AeroShell 5Document2 paginiGrasa AeroShell 5epesanoÎncă nu există evaluări

- Soft Natural Rubber Lining: Technical Data SheetDocument2 paginiSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanÎncă nu există evaluări

- DuraplateDocument4 paginiDuraplatelovaldes62Încă nu există evaluări

- Sikafloor - 161 G PDFDocument4 paginiSikafloor - 161 G PDFShaik FazilÎncă nu există evaluări

- TDS For Rubber Lining 1056HTDocument2 paginiTDS For Rubber Lining 1056HTYao WangÎncă nu există evaluări

- Pds CPD D30 SikaGrout 300 PT UsDocument2 paginiPds CPD D30 SikaGrout 300 PT UsJonathan FelixÎncă nu există evaluări

- Sikagrout - 528 SFDocument4 paginiSikagrout - 528 SFManuel CardosoÎncă nu există evaluări

- Cicol NT Slurry: Constructive SolutionsDocument3 paginiCicol NT Slurry: Constructive SolutionstalatzahoorÎncă nu există evaluări

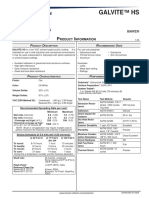

- Protective & Marine Coatings: Galvite™ HsDocument4 paginiProtective & Marine Coatings: Galvite™ HsAna CabreraÎncă nu există evaluări

- Sikadur - 42 ZaDocument4 paginiSikadur - 42 ZaPatrickKisulaÎncă nu există evaluări

- Sikadur®-30 LP - PDS - 2014 GCCDocument4 paginiSikadur®-30 LP - PDS - 2014 GCCameerÎncă nu există evaluări

- Zwaluw Gasket Sealant Red enDocument2 paginiZwaluw Gasket Sealant Red enAngelo Carlo MalabananÎncă nu există evaluări

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 paginiPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerÎncă nu există evaluări

- Sikadur - 43 TaDocument3 paginiSikadur - 43 TaSylvester WafulaÎncă nu există evaluări

- Aeroshell Grease 64Document2 paginiAeroshell Grease 64S. MadaniÎncă nu există evaluări

- Sikafloor - 264 EngDocument5 paginiSikafloor - 264 Engbassem kooliÎncă nu există evaluări

- High Performance Lubricants Molykote: 55 O-Ring GreaseDocument2 paginiHigh Performance Lubricants Molykote: 55 O-Ring Greasesatheez3251Încă nu există evaluări

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- VISCOTAQR PE Outer Wrap February 2014Document2 paginiVISCOTAQR PE Outer Wrap February 2014Sinan A AzizÎncă nu există evaluări

- Nitocote ET402: Constructive SolutionsDocument4 paginiNitocote ET402: Constructive SolutionsSinan A AzizÎncă nu există evaluări

- 0 - Zia Ul Haq Instrument TechnicianDocument6 pagini0 - Zia Ul Haq Instrument TechnicianSinan A AzizÎncă nu există evaluări

- Paint CalculatorDocument4 paginiPaint CalculatorSinan A AzizÎncă nu există evaluări

- Thurmolox PdsDocument3 paginiThurmolox PdsSinan A AzizÎncă nu există evaluări

- Bloem Direct Shrink Tracking SheetDocument4 paginiBloem Direct Shrink Tracking SheetSinan A AzizÎncă nu există evaluări

- Jotun Solvalitt Alu 11A TDSDocument4 paginiJotun Solvalitt Alu 11A TDSSinan A AzizÎncă nu există evaluări

- Interzone 485Document4 paginiInterzone 485Sinan A AzizÎncă nu există evaluări

- Piping Engineer Resume Samples - JobHeroDocument5 paginiPiping Engineer Resume Samples - JobHeroSinan A AzizÎncă nu există evaluări

- Non-Conformance ReportDocument1 paginăNon-Conformance ReportSinan A AzizÎncă nu există evaluări

- Entrepreneurship 1 Burt S BeesDocument5 paginiEntrepreneurship 1 Burt S BeesAly BhamaniÎncă nu există evaluări

- NAGA3-DWG-0032 (C) - Diaphragm Wall Details Type 1C-2 REV-Jacobs ReplyDocument2 paginiNAGA3-DWG-0032 (C) - Diaphragm Wall Details Type 1C-2 REV-Jacobs ReplyShafiq ZakariahÎncă nu există evaluări

- Exile in Dapitan 1892 1896Document33 paginiExile in Dapitan 1892 1896Jirah Joy PeañarÎncă nu există evaluări

- P6 Set Up Performance %Document10 paginiP6 Set Up Performance %Bryan JacksonÎncă nu există evaluări

- Summer Training Emp. SatisfactionDocument34 paginiSummer Training Emp. SatisfactionAkash DixitÎncă nu există evaluări

- Iteh Standard Preview (Standards - Iteh.ai) : SIST EN 837-1:1997 Slovenski StandardDocument13 paginiIteh Standard Preview (Standards - Iteh.ai) : SIST EN 837-1:1997 Slovenski StandardJAMSHIL.T JjÎncă nu există evaluări

- Ieee-Pc57 12 80-2002Document4 paginiIeee-Pc57 12 80-2002Dioven A. CadungogÎncă nu există evaluări

- Global Leprosy StrategyDocument36 paginiGlobal Leprosy StrategyBlue PielagoÎncă nu există evaluări

- Julia CheatsheetDocument1 paginăJulia CheatsheetmixarimÎncă nu există evaluări

- Accuracy Standards: and ISOIDocument4 paginiAccuracy Standards: and ISOIali_yy2003100% (1)

- The Ouranos RiteDocument5 paginiThe Ouranos RiteliebofreakÎncă nu există evaluări

- ELTJ (1990) Pyramid Discussions - JordanDocument9 paginiELTJ (1990) Pyramid Discussions - Jordanmariangoud100% (2)

- Amazon Web ServicesDocument85 paginiAmazon Web ServicesSrinivasa Reddy KarriÎncă nu există evaluări

- Erickson - 1981 - Secret Societies and Social StructureDocument24 paginiErickson - 1981 - Secret Societies and Social StructureRene PlascenciaÎncă nu există evaluări

- Significance Testing (T-Tests)Document3 paginiSignificance Testing (T-Tests)Madison HartfieldÎncă nu există evaluări

- Current Trends On Syllabus Design PDFDocument5 paginiCurrent Trends On Syllabus Design PDFBosque AgujasÎncă nu există evaluări

- FKBI VI - ACED - 03 - Oktaviani Rita P Teti Rahmawati - Universitas KuninganDocument8 paginiFKBI VI - ACED - 03 - Oktaviani Rita P Teti Rahmawati - Universitas KuninganAndriiÎncă nu există evaluări

- Introduction To Media ART: Course: History of Media Art Instructor: Zeib JahangirDocument17 paginiIntroduction To Media ART: Course: History of Media Art Instructor: Zeib JahangirLiaqat AleeÎncă nu există evaluări

- 22 Oktober 2019 - EP UNPARDocument73 pagini22 Oktober 2019 - EP UNPARGina AnindithaÎncă nu există evaluări

- Lampiran 1 Instrumen Penilaian: A. Complete The Incomplete Dialogue Above by Choosing A, B, C or D!Document10 paginiLampiran 1 Instrumen Penilaian: A. Complete The Incomplete Dialogue Above by Choosing A, B, C or D!avivah indah yuliansyahÎncă nu există evaluări

- Master Syllabus Fix TOM-JAN2019-BOED PDFDocument4 paginiMaster Syllabus Fix TOM-JAN2019-BOED PDFBogiÎncă nu există evaluări

- CREW: Department of Defense: Department of The Army: Regarding PTSD Diagnosis: 6/30/2011 - Release Pgs 1-241 On 24 May 2011Document241 paginiCREW: Department of Defense: Department of The Army: Regarding PTSD Diagnosis: 6/30/2011 - Release Pgs 1-241 On 24 May 2011CREWÎncă nu există evaluări

- SIX SIGMA at GEDocument11 paginiSIX SIGMA at GE1987dezyÎncă nu există evaluări

- Chapter 5, Soil Engineering For Highway DesignDocument57 paginiChapter 5, Soil Engineering For Highway DesignIsmail Hrichi100% (1)

- Detailed Lesson PlanDocument7 paginiDetailed Lesson PlanMarjen MabasagÎncă nu există evaluări

- SCITECH - OBE SyllabusDocument12 paginiSCITECH - OBE SyllabusMary Athena100% (1)