Documente Academic

Documente Profesional

Documente Cultură

PX 2100 TDS 2016

Încărcat de

odbayTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PX 2100 TDS 2016

Încărcat de

odbayDrepturi de autor:

Formate disponibile

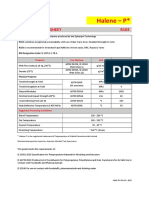

LINE-X® PAXCON PX-2100

December 2016

PRODUCT MANUFACTURER

LINE-X LLC

1862 Sparkman Dr.

Huntsville, AL 35816

877-330-1331

GENERAL PRODUCT DESCRIPTION

PAXCON PX-2100 is a two-component, high Temperature Settings

performance aromatic polyurea/polyurethane Iso “A” Block Heater: 140°F - 160°F

hybrid spray elastomer system zero VOC Resin “B” Block Heater: 140°F - 160°F

(Volatile Organic Compounds), 100% solid. Hoses (Iso and Polyol): 130°F - 150°F

PAXCON PX-2100 offers outstanding

performance and superior elastomeric protective Hydraulic Pressure Setting

coatings for various substrates. PAXCON PX- Equipment Hydraulic Pressure: 2,000 - 2,500 psi

2100 is designed as a user-friendly product with

a built-in activator for quick cure times, and offers EQUIPMENT CLEAN UP

exceptional adhesion properties on properly Spray equipment should be cleaned immediately

prepared substrates. The high performance after use following equipment manufacturer’s

formulation of PAXCON PX-2100 produces an recommended procedures. Please refer to spray

excellent skin formation for chemical resistance equipment operating and maintenance procedures

and moisture protection. for further details. PAXCON PX-2100 should be

cleaned with environmentally safe urethane-grade

APPLICATION GUIDELINES cleaners. Cleaning materials must be free of reactive

Both the Iso “A” Side and Resin “B” Side should contaminants such as water and alcohol. All gun

be pre-conditioned between 70°F to 90°F (21°C cleaners and spray equipment cleaning materials

to 32°C) before application. PAXCON PX-2100 must be used and disposed of as permitted under

must be applied using high-pressure, plural local rules and regulations.

component, heated, 1:1 by volume, spray

equipment with 2,000 psi fluid pressure MATERIAL STORAGE

capability. PAXCON PX-2100 material (both Iso PAXCON PX-2100 has a shelf life of twelve (12)

“A” Side and Resin “B” Side) should be heated months from manufacture date in factory-sealed

between 120°F to 150°F (49°C to 66°C). Spray containers. PAXCON PX-2100 should be stored

equipment must generate adequate fluid between 60°F to 100°F (16°C to 38°C). Do not

pressure for proper mixing and best expose unused materials to high humidity

polymerization results. conditions. Always provide airtight reseal conditions

to unused materials. For materials that are currently

APPLICATION EQUIPMENT connecting to the pumps, always provide as much

PAXCON PX-2100 is designed to be sprayed airtight and moisture free conditions to unused

through high-pressure impingement mixing materials as possible to ensure proper chemical

equipment. Plural component spray equipment performance. Drums should be stored on pallets to

must have material heat-control capability, 1:1 by avoid direct contact with the warehouse

volume, and sprayable with round or flat tip. Refer floor/ground.

to equipment manufacturer for equipment

specifics and accessories. SAFETY AND HANDLING

Please refer to Safety Data Sheets (SDS) for safety

EQUIPMENT SETTING PARAMETERS and handling of this material. All personnel working

Iso “A” and Polyol “B” components must be with this material are expected to read and

pumped by low-pressure transfer pumps to a understand all safety recommendations per SDS. All

suitable high-pressure proportional pumping Personal Protection Equipment must be properly

system. worn to comply with worker health and safety

requirements.

LINE-X LLC | 1862 Sparkman Drive | Huntsville, AL 35816 | 877-330-1331 | LINE-X.COM

Page 1

LINE-X® PAXCON PX-2100

December 2016

CHEMICAL TECHNICAL DATA Test Name Test Methods Value

Mix Ratio by Volume: 1A:1B Thermal Conductivity ASTM E1952 .14 W/Km

Gel Time: 6 - 9 sec (DSC)

Tack Free Time: 10 - 15 sec Water Vapor Trans. ASTM E96 0.796

Viscosity (cP) @ 77°F grains/ft²/hr

“A” Iso Side: 550 ± 100

“B” Resin Side: 1100 ± 100 ADDITIONAL PRODUCT CERTIFICATIONS

Material Density (lbs/gal) @ 77°F MIL-STD-810F - Fungus Resistance

“A” Iso Side: 9.6 lbs/gal

“B” Resin Side: 8.6 lbs/gal

BASIC PHYSICAL PROPERTIES

All tests are performed by independent third-party

material test laboratories:

OCM Test Laboratories

ISO 17025 Certified

American Association for Laboratory

Accreditation (A2LA)

Truesdail Laboratories, Inc.

Pira International Material Test Lab

Test Name Test Methods Value

Coefficient of Friction ASTM D1894

Static 0.546

Kinetic 0.185

Dielectric Const. ASTM D150 3.5

Dielectric Strength ASTM D149 440 volts/mil

Dissipation Factor ASTM D150 0.025

Volume Resistance ASTM D257 2.4 x 1013

ohm cm

DMA Test ASTM D4065 -39°C

(Loss Modulus, E” Tg)

Elongation ASTM D412 91%

Flexural Strength ASTM D790 1,190 psi

Flexural Modulus ASTM D790 0.024 msi

Fungus Resistance MIL-STD 810F Pass

Hardness Shore D ASTM D2240 50 ± 1

Impact ASTM D2794 134 in-lbs

Methane Permeability ASTM D1434 132 cc/m².d

Pull-off Test–Adhesion ASTM C297

To Metal – No Primer 1,300 psi

To Metal – XPM Primer 1,750 psi

To Metal – LX SF-515 Primer 1,930 psi

Safe Walking Surfaces ASTM F1637.95 .98 - Dry

.87 - Wet

Salt Spray ASTM B117 Rating 10

(3,000 hrs.)

Taber Abrasion ASTM D4060 152.4

(mg Loss/1000 cycles)

Tear Strength ASTM D624 490 lbs/in

Tensile Strength ASTM D412 2,150 psi

LINE-X LLC | 1862 Sparkman Drive | Huntsville, AL 35816 | 877-330-1331 | LINE-X.COM

Page 2

LINE-X® PAXCON PX-2100

December 2016

CHEMICAL RESISTANCES PER ASTM D543 FOR IMMERSION IN FLUIDS METHODS

PAXCON PX-2100 materials are immersed in the chemicals below for a period of 7 days; physical properties of

pre- and post-immersion were measured to quantify the changes in product physical properties.

Elongation Tensile

Chemical Names Volume Hardness ASTM D412 Strength ASTM Recommendations

Change Change Change (%) D412 Change

(%) (%) (%)

Ammonium Chloride 30% 2% -11% NA NA Yes

Ammonium Hydroxide 3% -2% 125% -45% Yes

Automotive Gasoline 11% -29% -46% -57% Yes

Automotive Oil 0.5% -11% 113% -37% Yes

Aviation J.P. Fuel 19% -31% -29% -42% Yes

Baking Soda 25% 3% -17% 108% -46% Yes

Benzene -2% -19% 108% -61% Yes

Boric Acid 3% 17% -2% 4% -44% Yes

Calcium Chloride 50% 4% -27% 3% -42% Yes

Calcium Hypochloride 5% 4% -13% 0.4% -48% Yes-Secondary Containment

Citric Acid 10% 5% -23% 111% -46% Yes

Club Soda 0% -3% 59% 0.6% Yes

Cream Soda 4% -21% 9% -45% Yes

Crude Oil (Heating) 12% -15% 10% -48% Yes

Diesel Fuel 8% -15% 2% -42% Yes

Ethylene Glycol 4% -20% 3% -53% Yes

Hydraulic Fluid (Oil) 4% -20% 4% -37% Yes

Hydrogen Peroxide 10% 9% -22% 130% -54% Yes

Kerosene 8% -17% 77% -51% Yes

Lactic Acid 20%` 11% -28% 101% -54% Yes

Methylene Chloride 1% -20% NA NA Yes

Mineral Spirits 8% -16% -6% -45% Yes

Nitric Acid 10% 13% -28% 122% -54% Yes-Secondary Containment

Potassium Hydroxide 50% 4% -17% -10% -5% Yes

Saline Solution 30% 3% -19% 2.8% -41% Yes

Sea Water 3% -20% 5% -44% Yes

Sodium Carbonate 10% 2% -19% 8% -38% Yes

Sodium Chloride 30% 4% -13% 29% -38% Yes

Sodium Hydroxide 50% 23% -15% 95% -46% Yes

Sodium Hydroxide 10% -12% -13% 102% -45% Yes

Sodium Sulfate 30% 3% -21% 143% -39% Yes

Sodium Sulfate 20% 3% -17% 125% -44% Yes

Sugar Solution 30% 4% -20% 20% -45% Yes

Sulfuric Acid 10% 6% -26% 2% -40% Yes

Toluene -1% -21% 82% -66% Yes

Water (H2O) 3% -20% -5% -45% Yes

LINE-X LLC | 1862 Sparkman Drive | Huntsville, AL 35816 | 877-330-1331 | LINE-X.COM

Page 3

LINE-X® PAXCON PX-2100

December 2016

LIMITATIONS

The chemical resistance chart should be a corporate officer of the manufacturer. Technical

consulted prior to application; this is an and application information is provided for the

exhaustive chemical compatibility list quantifying purpose of establishing a general profile of the

pre and post physical properties for chemicals material and proper application procedures. Test

exposure per ASTM D543. Application specific performance results were obtained in a controlled

processing parameters such as temperature and environment and LINE-X makes no claim that

operating pressure of coated objects must be these tests or any other tests accurately

considered before installing PAXCON PX-2100 represent all environments.

coatings system.

PRODUCT USER RESPONSIBILITIES

Users of PAXCON PX-2100 product are

responsible for reading the general guidelines,

product data sheets, specifications and Safety

Data Sheets (SDS) before using this material.

Printed technical data and instructions are

subject to change without notice. Contact your

local LINE-X representative or visit our website

www.LINE-X.com for current technical data

instructions.

PRODUCT DISCLAIMER

All guidelines, recommendations, statements,

and technical data contained herein are based on

information and tests we believe to be reliable

and correct, but accuracy and completeness of

said tests are not guaranteed and are not to be

construed as a warranty, either expressed or

implied. It is the user’s responsibility to satisfy

himself, by his own information and test, to

determine suitability of the product for his own

intended use, application and job situation and

user assumes all risk and liability resulting from

his use of the product. We do not suggest or

guarantee that any hazards listed herein are the

only ones that may exist. Neither seller nor

manufacturer shall be liable to the buyer or any

third person for any injury, loss or damage directly

or indirectly resulting from use of, or inability to

use, the product. Recommendations or

statements, whether in writing or oral, other than

those contained herein shall not be binding upon

the manufacturer, unless in writing and signed by

LINE-X LLC | 1862 Sparkman Drive | Huntsville, AL 35816 | 877-330-1331 | LINE-X.COM

Page 4

S-ar putea să vă placă și

- Linex XS350Document4 paginiLinex XS350Dan AyalaÎncă nu există evaluări

- Operator'S Manual Px01X-Xxx-Xxx-Axxx: 1/4" Diaphragm PumpDocument12 paginiOperator'S Manual Px01X-Xxx-Xxx-Axxx: 1/4" Diaphragm PumpAir PumpingÎncă nu există evaluări

- Operator'S Manual Px10P-Xxs-Xxx-Axxx: 1" Diaphragm PumpDocument12 paginiOperator'S Manual Px10P-Xxs-Xxx-Axxx: 1" Diaphragm PumpjarosÎncă nu există evaluări

- Operator'S Manual Px05P-Xxx-Xxx-Bxxx: 1/2" Diaphragm PumpDocument12 paginiOperator'S Manual Px05P-Xxx-Xxx-Bxxx: 1/2" Diaphragm PumpjarosÎncă nu există evaluări

- Operator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpDocument12 paginiOperator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpNashrullah AhmadÎncă nu există evaluări

- Haldia PP Raffia - R103 DatasheetDocument2 paginiHaldia PP Raffia - R103 DatasheetNarender RawatÎncă nu există evaluări

- Electrodeposition Andreas Tolz PPGDocument14 paginiElectrodeposition Andreas Tolz PPGAndi MusdalifahÎncă nu există evaluări

- PX01X XXX XXX Axxx enDocument12 paginiPX01X XXX XXX Axxx enPatrick BrilhanteÎncă nu există evaluări

- Operator'S Manual PM10X-XXX-XXX-A02: 1" Diaphragm PumpDocument8 paginiOperator'S Manual PM10X-XXX-XXX-A02: 1" Diaphragm PumpArif Fatkhur RahmanÎncă nu există evaluări

- Soft Natural Rubber Lining: Technical Data SheetDocument2 paginiSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalÎncă nu există evaluări

- HT 521 86181 000 ENDocument6 paginiHT 521 86181 000 ENEdward AguillónÎncă nu există evaluări

- Operator'S Manual Px15X-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpDocument12 paginiOperator'S Manual Px15X-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpMECANICA ELECTRICA TSAVINGÎncă nu există evaluări

- Epofine 179-1: Finehard 906-1Document4 paginiEpofine 179-1: Finehard 906-1Karishma PrabhuÎncă nu există evaluări

- Flowcoat-Esd v10Document2 paginiFlowcoat-Esd v10Luis RiosÎncă nu există evaluări

- Alphasyn HG RangeDocument2 paginiAlphasyn HG RangeAlin BAMÎncă nu există evaluări

- Operator'S Manual Px03P-Xxx-Xxx-Axxx: 3/8" Diaphragm PumpDocument12 paginiOperator'S Manual Px03P-Xxx-Xxx-Axxx: 3/8" Diaphragm PumpjarosÎncă nu există evaluări

- Ancamide 261A: Curing AgentDocument11 paginiAncamide 261A: Curing AgentBERKAT RAJA SEMESTAÎncă nu există evaluări

- Manual 6661 - InglesDocument12 paginiManual 6661 - InglesJose Afonso JuniorÎncă nu există evaluări

- Derakane Momentum 470-300Document5 paginiDerakane Momentum 470-300maniastur365100% (1)

- HT 521 86151 307 ENDocument5 paginiHT 521 86151 307 ENEdward AguillónÎncă nu există evaluări

- Overview of Polyurea TechnologyDocument42 paginiOverview of Polyurea TechnologyA MahmoodÎncă nu există evaluări

- Arkema CPI 2017 PaperDocument10 paginiArkema CPI 2017 PaperNicola MelaÎncă nu există evaluări

- Pds Psx700 Jan 2008Document3 paginiPds Psx700 Jan 2008mjayhawk28Încă nu există evaluări

- ARO 2019 6661XX 1 1 2 Inch Non Metallic PRO SERIES Diaphragm Pump Manual Air Motor SectionDocument8 paginiARO 2019 6661XX 1 1 2 Inch Non Metallic PRO SERIES Diaphragm Pump Manual Air Motor Sectionboy tryadiÎncă nu există evaluări

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 paginiFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezÎncă nu există evaluări

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 paginiAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarÎncă nu există evaluări

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDocument5 paginiInterior Fluid Resistant Epoxy Primer: Technical Data SheetPannha LangÎncă nu există evaluări

- Chemflake SpecialDocument5 paginiChemflake Specialmajmor-1Încă nu există evaluări

- Alphasyn HG RangeDocument2 paginiAlphasyn HG RangecarmaÎncă nu există evaluări

- PUF - Voracor CD 1786 Polyol With CD345 TDS PDFDocument2 paginiPUF - Voracor CD 1786 Polyol With CD345 TDS PDFRajendra Kumar SharmaÎncă nu există evaluări

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 paginiTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhÎncă nu există evaluări

- Operator'S Manual PD20E-X-X: 2" Diaphragm PumpDocument8 paginiOperator'S Manual PD20E-X-X: 2" Diaphragm Pumpmerajulhaque1986dudeÎncă nu există evaluări

- API 16C Annex B Approved Materials For Riser System Choke and Kill EquipmentDocument2 paginiAPI 16C Annex B Approved Materials For Riser System Choke and Kill EquipmentDhanraj VasanthÎncă nu există evaluări

- Ankcela Original CaseDocument1 paginăAnkcela Original CaseCleniltonAndreGomesÎncă nu există evaluări

- PPS120 Rev10 0309 PDFDocument2 paginiPPS120 Rev10 0309 PDFArfanAliÎncă nu există evaluări

- ARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid SectionDocument12 paginiARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid Sectionduc tranÎncă nu există evaluări

- Technical Information Sheet 949Document2 paginiTechnical Information Sheet 949SUBHOMOYÎncă nu există evaluări

- 1 - Intro - MS071004Document24 pagini1 - Intro - MS071004Ahmad SalahÎncă nu există evaluări

- Pyroclad X1: Selection & Specification DataDocument6 paginiPyroclad X1: Selection & Specification DataDuongthithuydungÎncă nu există evaluări

- Tds Infinam RG 7100 LDocument2 paginiTds Infinam RG 7100 LKacperÎncă nu există evaluări

- Zap-Lok System For Pipeline Installation January 2019 PDFDocument35 paginiZap-Lok System For Pipeline Installation January 2019 PDFmutadiÎncă nu există evaluări

- HSS (Heat-Shrinkable Sleeve) Installation ProcedureDocument60 paginiHSS (Heat-Shrinkable Sleeve) Installation ProcedureIntegrity EngineerÎncă nu există evaluări

- ElastoporDocument3 paginiElastoporAlvaro BenitoÎncă nu există evaluări

- Polyken 1600 High TempDocument2 paginiPolyken 1600 High TempKyaw Kyaw AungÎncă nu există evaluări

- Tankguard SF: Technical Data SheetDocument5 paginiTankguard SF: Technical Data SheetRifki ArifinÎncă nu există evaluări

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 paginiArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalÎncă nu există evaluări

- VersaFlex FS45DC DatasheetDocument2 paginiVersaFlex FS45DC DatasheetShaheerKhaleequzzamanÎncă nu există evaluări

- Coaltar EpoxyDocument2 paginiCoaltar EpoxyAnonymous YN4aNlÎncă nu există evaluări

- Deliver High Performance: Advanced MaterialsDocument6 paginiDeliver High Performance: Advanced Materialsmkamat007Încă nu există evaluări

- TEL: 82-31-491 1611/ FAX:82 31491 7400 E Mail:Hepce@Document4 paginiTEL: 82-31-491 1611/ FAX:82 31491 7400 E Mail:Hepce@geoeidÎncă nu există evaluări

- TDS 2063 Tankguard 412 Euk GBDocument6 paginiTDS 2063 Tankguard 412 Euk GBSrimathi VijayakumarÎncă nu există evaluări

- PCRS9309-QT TDSDocument5 paginiPCRS9309-QT TDSDaniele CatacchioÎncă nu există evaluări

- TDS - Epikure Curing Agent 3015Document4 paginiTDS - Epikure Curing Agent 3015zianiÎncă nu există evaluări

- Belzona 1111ps EnglDocument2 paginiBelzona 1111ps EnglNikolay GuerreroÎncă nu există evaluări

- Anvol SWX RangeDocument2 paginiAnvol SWX Rangeel pro jajaja GonzalezÎncă nu există evaluări

- ARO-Expert Series-PD10P-1-Inch-Non-Metallic-Diaphragm-Pump-ManualDocument8 paginiARO-Expert Series-PD10P-1-Inch-Non-Metallic-Diaphragm-Pump-ManualArif Fatkhur RahmanÎncă nu există evaluări

- Anquamine 728: Curing AgentDocument4 paginiAnquamine 728: Curing AgentGreg PanganÎncă nu există evaluări

- Chemflake Special: Technical Data SheetDocument5 paginiChemflake Special: Technical Data SheetSalmanÎncă nu există evaluări

- Barrier 80 PDFDocument5 paginiBarrier 80 PDFBalaji GuruÎncă nu există evaluări

- The World's Tallest BuildingsDocument25 paginiThe World's Tallest BuildingsodbayÎncă nu există evaluări

- Liebherr All Terrain Cranes Spec E35cd6Document12 paginiLiebherr All Terrain Cranes Spec E35cd6odbayÎncă nu există evaluări

- Effect of Aggregate Flakiness On The CompressiveDocument14 paginiEffect of Aggregate Flakiness On The CompressiveiftekharulÎncă nu există evaluări

- Elements of Ecology, 9e, Global Edition (Smith) Chapter 1 The Nature of EcologyDocument77 paginiElements of Ecology, 9e, Global Edition (Smith) Chapter 1 The Nature of Ecologyodbay100% (2)

- Design Criteria of Eco-Buildings and The Benefits To HumanityDocument4 paginiDesign Criteria of Eco-Buildings and The Benefits To HumanityodbayÎncă nu există evaluări

- Vegetation: Effects On Weather and ClimateDocument20 paginiVegetation: Effects On Weather and ClimateodbayÎncă nu există evaluări

- Potain Range TowerCranes MetricDocument2 paginiPotain Range TowerCranes MetricEstiningtyas ReskiÎncă nu există evaluări

- 3.7 Wronskians and Variation of Parameters: 3.7.1 The WronskianDocument7 pagini3.7 Wronskians and Variation of Parameters: 3.7.1 The WronskianodbayÎncă nu există evaluări

- ch5 pt1Document40 paginich5 pt1odbayÎncă nu există evaluări

- Arkeng Katalog PDF 11Document20 paginiArkeng Katalog PDF 11odbayÎncă nu există evaluări

- Worksheet October 24 SolutionsDocument12 paginiWorksheet October 24 SolutionsodbayÎncă nu există evaluări

- 2008F ENGI 6723 Guest Lecture McAfeeDocument37 pagini2008F ENGI 6723 Guest Lecture McAfeeRuHuiÎncă nu există evaluări

- Why Business Ethics?: Why Should One Be Ethical?Document7 paginiWhy Business Ethics?: Why Should One Be Ethical?rajarajkumar543Încă nu există evaluări

- Ammar WorkbookDocument26 paginiAmmar WorkbookodbayÎncă nu există evaluări

- Nanobent PF PDFDocument1 paginăNanobent PF PDFodbayÎncă nu există evaluări

- Nanobent PFDocument1 paginăNanobent PFodbayÎncă nu există evaluări

- 334 1 10 hw4 Sol PDFDocument4 pagini334 1 10 hw4 Sol PDFodbayÎncă nu există evaluări

- 250 Book Laplace PT 2Document14 pagini250 Book Laplace PT 2odbayÎncă nu există evaluări

- KOCO Composite ConstructionDocument10 paginiKOCO Composite ConstructionTenkre TenÎncă nu există evaluări

- Polymer ScienceDocument101 paginiPolymer SciencereddyÎncă nu există evaluări

- Geotech - 2Document2 paginiGeotech - 2Sanket AgrawalÎncă nu există evaluări

- Base Metals and Base-Metal Family Groups: Metallurgical ReactionsDocument114 paginiBase Metals and Base-Metal Family Groups: Metallurgical ReactionsYasa CossioÎncă nu există evaluări

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 paginiFosroc Conbextra BB80: Constructive SolutionsVincent JavateÎncă nu există evaluări

- 730al 370-Automotive LRDocument14 pagini730al 370-Automotive LRlongÎncă nu există evaluări

- How To Conform To ASME B40-100 (Summary)Document13 paginiHow To Conform To ASME B40-100 (Summary)Mátyás KabaiÎncă nu există evaluări

- Dyeing OverviewDocument38 paginiDyeing OverviewAmdeworkÎncă nu există evaluări

- Types of Building Materials Used in Construction and Their PropertiesDocument4 paginiTypes of Building Materials Used in Construction and Their PropertiesAravindanÎncă nu există evaluări

- Aromatic WatersDocument5 paginiAromatic WatersManjeeta Mandlik90% (10)

- Adv Synth Catal - 2020 - Wirtanen - Recent Advances in The Electrochemical Reduction of Substrates Involving N O BondsDocument14 paginiAdv Synth Catal - 2020 - Wirtanen - Recent Advances in The Electrochemical Reduction of Substrates Involving N O Bondssamuele marinariÎncă nu există evaluări

- Iso 9809 1 2010 en PDFDocument11 paginiIso 9809 1 2010 en PDFgabrielÎncă nu există evaluări

- 1993-Schmalzried - Internal Solid State ReactionsDocument57 pagini1993-Schmalzried - Internal Solid State ReactionsDavid Hernández EscobarÎncă nu există evaluări

- Chemistry in The LaundryDocument38 paginiChemistry in The LaundryAldayantiÎncă nu există evaluări

- Determination of True Stress-Strain Curve of Type 304 and 316 Stainless Steels Using A Typical Tensile Test and Finite Element AnalysisDocument10 paginiDetermination of True Stress-Strain Curve of Type 304 and 316 Stainless Steels Using A Typical Tensile Test and Finite Element AnalysisDavid GuzmanÎncă nu există evaluări

- Basics of Resin Based Water SofteningDocument31 paginiBasics of Resin Based Water SofteningalexÎncă nu există evaluări

- Fiberglass Gravity Sewer Pipe: Part 1: GeneralDocument2 paginiFiberglass Gravity Sewer Pipe: Part 1: GeneralDaniel MoralesÎncă nu există evaluări

- Unit 4 QB Chemistry AktuDocument35 paginiUnit 4 QB Chemistry AktuVAISHNAVI SINGHÎncă nu există evaluări

- Emailing Oil-Well-Cement-Additives-A-Review-Of-The-Common-Types-Ogr-1000112 PDFDocument6 paginiEmailing Oil-Well-Cement-Additives-A-Review-Of-The-Common-Types-Ogr-1000112 PDFMary Krinzy Charm BañaderaÎncă nu există evaluări

- Soil TypesDocument3 paginiSoil TypesAnonymous jdC36sKP57Încă nu există evaluări

- Fact Sheet Steel and Raw MaterialsDocument2 paginiFact Sheet Steel and Raw MaterialsSravanÎncă nu există evaluări

- Cold StretchingDocument2 paginiCold StretchingAgustin ParadisoÎncă nu există evaluări

- Direct Posterior Restoration PDFDocument14 paginiDirect Posterior Restoration PDFياسر نادر حسين فليحÎncă nu există evaluări

- G.C.S Moisture ContentDocument18 paginiG.C.S Moisture ContentDaniel KariukiÎncă nu există evaluări

- PO CatalogueDocument26 paginiPO CatalogueJitendra KumarÎncă nu există evaluări

- Acelerated Corrosion Testiog of Maintenance PartsDocument10 paginiAcelerated Corrosion Testiog of Maintenance Partsnikopigni2100% (1)

- MATERIALS ENGINEER REVIEWER - III (Asphalt Technology)Document28 paginiMATERIALS ENGINEER REVIEWER - III (Asphalt Technology)pablojab100% (1)

- Layer Stack InformationDocument9 paginiLayer Stack InformationMadhav DimbleÎncă nu există evaluări

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 paginiQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentÎncă nu există evaluări

- Dynamic Response of A Space Framed Structure Subjected To Blast LoadDocument8 paginiDynamic Response of A Space Framed Structure Subjected To Blast LoadNguyen ThangÎncă nu există evaluări

- Oriss Quartz Kitchen Sink Price ListDocument4 paginiOriss Quartz Kitchen Sink Price ListamitÎncă nu există evaluări