Documente Academic

Documente Profesional

Documente Cultură

Extracted Pages From 106

Încărcat de

abhay9411Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Extracted Pages From 106

Încărcat de

abhay9411Drepturi de autor:

Formate disponibile

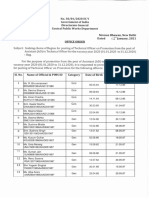

HIGH-RISE: PRECAST BUILDING

part of this year. All apartments of Phase 1 are identical that

made precast technology a viable option.. Figure 2 shows the

overall layout of Phase 1 of the project. Table 1 shows the

overall scope of precast construction for Phase 1 Buildings

along with other building details.

Pragati Towers - Phase 1 – Six High-rise Buildings

Overall Built Up Area 1.2 million square feet

Structural Frame G + 23 Levels

2024 Apartments; 14-16

Total Apartments

Apartments per Level

Structural System – Super- Large Panel Precast Shear

structure Walls

Structural System - Sub- Pile Foundation or Raft

structure Foundation

Ground and Terrace Work Cast In Situ

1st to 23rd Floor Work Precast Members

Total Precast Member

~ 40,000 Fig. 4 Pragati Towers - Precast Panel Layout for the Typical Apartment Floor

Count

Plan

Table 2- Pragati Towers – Phase 1 Project Details

Design Implementation

Foundation system of the project consists of piles with

pile caps connected with tie beams. Ground floors were-

constructedby conventional method i.e In-situ construction.

Superstructure (i.e 1st to 23rd floor) consists of precast con-

struction of RC walls&solid floor slabs, columns, and beams

Floor slab is considered to act as a rigid diaphragm to trans-

fer the lateral forces to walls/columns. Precast concrete RC/

shear walled structures, also called large panel systems,are

load bearing members and are capable of carrying the verti-

cal and lateral loads. The wall panels can be connected to

each other and to the floor diaphragm to form an emulative

monolithic structure.

Design Codes

Fig. 2 Pragati Towers - Overall Phase 1 Layout

Mumbai region is categorized as Seismic Zone 3 (Mod-

A typical apartment floor plan is shown in Figure 3. Each erate Seismic Zone - typical Seismic Zones are defined

apartment comprising of 269 square feet of carpet area, from Zone 2 (Least Active) to Zone 5 (Highest)). Mumbai is

consists of a living room, a study room, and a kitchen along also a coastal city with design wind speed of 44m/s (~ 98.5 The Masterbuilder | October 2014 | www.masterbuilder.co.in

with toilet and bath units, planned for a typical EWS family of mph) which was considered for this project. Seismic forces

four. Figure 4 shows the precast panel layout used for the governed the design. The Bureau of Indian Standards (BIS)

project. specifies building codes in India. IS 456 - 2006 is regarded as

the primary building code for reinforced concrete structures.

IS 1893 – 2002 provides guidelines for earthquake resistant

design and IS 13920–1993 provides detailing requirements

for ductility in concrete structures subjected to seismic forc-

es. IS 11447 - 1985 provides design guidelines for large panel

prefabricated construction. IS 15916-2010 is the most recent

addition that provides guidelines for Design and Erection of

Prefabricated Concrete.

Design Philosophy

As precast technology was adopted for a high-rise resi-

dential structure in India, the emulative design philosophy

was selected based on mutual agreement between the Cli-

ent, Consultant and Contractor. Onsite, wet grouted joints

for horizontal and vertical connections between walls and in-

107

Fig. 3 Pragati Towers - Typical Apartment Floor Plan

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- New Text DocumentDocument77 paginiNew Text Documentabhay9411Încă nu există evaluări

- Construction SpecificationsDocument6 paginiConstruction SpecificationsRogerine Roy100% (2)

- Types of SlabsDocument8 paginiTypes of SlabsTannum Negi90% (29)

- Ecm 216 Building Services Bab 3.2 Water Supply PDFDocument6 paginiEcm 216 Building Services Bab 3.2 Water Supply PDFAZUAN BIN AHMAD FAUZI100% (8)

- Sample Detailed Specification - CSI FormatDocument12 paginiSample Detailed Specification - CSI FormatInah Quiniquini ManaleseÎncă nu există evaluări

- BB87 Guidelines Gor Environmental Design in SchoolsDocument37 paginiBB87 Guidelines Gor Environmental Design in SchoolsJames Allard100% (2)

- Date: 0 7, JAN: DDG (Pers) /DDG (HR) - /DDG (HR)Document2 paginiDate: 0 7, JAN: DDG (Pers) /DDG (HR) - /DDG (HR)abhay9411Încă nu există evaluări

- Op Letterwritingsz PDFDocument1 paginăOp Letterwritingsz PDFabhay9411Încă nu există evaluări

- 6-Interest Payable by The TaxpayerDocument13 pagini6-Interest Payable by The Taxpayerabhay9411Încă nu există evaluări

- Dated: 30/01 /2O2Oecv Government India Directorate General Central Public Works Department Nirman Delhi OffjanuaDocument2 paginiDated: 30/01 /2O2Oecv Government India Directorate General Central Public Works Department Nirman Delhi Offjanuaabhay9411Încă nu există evaluări

- Is To To This: Directed NoDocument3 paginiIs To To This: Directed Noabhay9411Încă nu există evaluări

- Thyagraj Nagar Air PollutionDocument2 paginiThyagraj Nagar Air Pollutionabhay9411Încă nu există evaluări

- Extracted Pages From PLINTH AREA RATES 2019Document7 paginiExtracted Pages From PLINTH AREA RATES 2019abhay9411Încă nu există evaluări

- Bar Bending Schedule of Box CulvertDocument1 paginăBar Bending Schedule of Box CulvertUnggul WahyuÎncă nu există evaluări

- Water Cement Ratio (Gate60 Short Notes)Document4 paginiWater Cement Ratio (Gate60 Short Notes)akash rathodÎncă nu există evaluări

- Metal Profiled Sheet Decking Operations Technical ManualDocument40 paginiMetal Profiled Sheet Decking Operations Technical ManualsivakumarÎncă nu există evaluări

- Technical Specification For Proposed Two-Storey House: House Construction Tips and GuidelinesDocument9 paginiTechnical Specification For Proposed Two-Storey House: House Construction Tips and GuidelinesNovel LopezÎncă nu există evaluări

- Penetration FirestoppingDocument8 paginiPenetration FirestoppinginstrengÎncă nu există evaluări

- SectVI Specification V4of4Document157 paginiSectVI Specification V4of4kongkixÎncă nu există evaluări

- Shower Hinge: Door Closer Series Patch FittingDocument5 paginiShower Hinge: Door Closer Series Patch FittingMehdi Hajd KacemÎncă nu există evaluări

- MEP NormsDocument4 paginiMEP NormsDilip Kumar75% (4)

- Planitop HPCDocument4 paginiPlanitop HPCdraganugÎncă nu există evaluări

- Chapter 5Document59 paginiChapter 5Nur Ain ZainuddinÎncă nu există evaluări

- Wire Guard PDFDocument4 paginiWire Guard PDFKavyatanuja NomulaÎncă nu există evaluări

- WBSDocument6 paginiWBSRenevKÎncă nu există evaluări

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument19 paginiFM Global Property Loss Prevention Data Sheets: List of FigureswipiriÎncă nu există evaluări

- Unit 7-Partition WallsDocument19 paginiUnit 7-Partition WallsSamhithaÎncă nu există evaluări

- Carrier VRFTIP-18-02 Data SheetDocument2 paginiCarrier VRFTIP-18-02 Data SheetXAVIER RUBIOÎncă nu există evaluări

- Study of Tunnel Formwork System Comparative Analysis With Conventional FormworkDocument6 paginiStudy of Tunnel Formwork System Comparative Analysis With Conventional Formworkshubham guleriaÎncă nu există evaluări

- Load ScheduleDocument10 paginiLoad Schedulemaharot_0Încă nu există evaluări

- Manual Técnico y de Aplicación PROMAT® - Entrepisos y Cielos FalsosDocument72 paginiManual Técnico y de Aplicación PROMAT® - Entrepisos y Cielos FalsosJonathan SanchezÎncă nu există evaluări

- Shading Devices: Introduction: Windows May Contain Several Elements Including Shading Devices. The Design of TheseDocument2 paginiShading Devices: Introduction: Windows May Contain Several Elements Including Shading Devices. The Design of Thesesusmita sethiÎncă nu există evaluări

- C D F S: Proposal of A Revision of EN 14511-1 "Terms and Definitions"Document14 paginiC D F S: Proposal of A Revision of EN 14511-1 "Terms and Definitions"Bruno de RossoÎncă nu există evaluări

- Specification and Building EstimateDocument7 paginiSpecification and Building Estimatenikkie De jesusÎncă nu există evaluări

- Civil Engineering Lectures, Notes, Tutorials, Past Papers, Softwares and BooksDocument1 paginăCivil Engineering Lectures, Notes, Tutorials, Past Papers, Softwares and BooksManiko ManikoÎncă nu există evaluări

- ESCSI Floor Drying Report - Info 4366.1 - Peter Craig 2011 PDFDocument13 paginiESCSI Floor Drying Report - Info 4366.1 - Peter Craig 2011 PDFamirkhanlouÎncă nu există evaluări

- Easyflex Bro enDocument16 paginiEasyflex Bro enMarcelo AlbuquerqueÎncă nu există evaluări

- Catalogo ComptekDocument16 paginiCatalogo ComptekMatias Charras100% (2)