Documente Academic

Documente Profesional

Documente Cultură

Pump-Head Calc Tool

Încărcat de

energymahesh20 evaluări0% au considerat acest document util (0 voturi)

209 vizualizări2 paginiDrepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

XLS, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

209 vizualizări2 paginiPump-Head Calc Tool

Încărcat de

energymahesh2Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

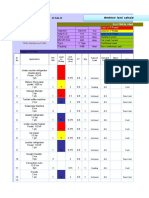

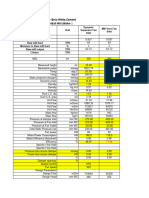

Pumping System Head Calculation Tool

System Parameters Symbol Unit Present Proposed

Diameter of Pipe d M 1.2 1.5

Liquid to be pumped Water Water

Density of liquid kg/M3 991 991

Required flow Q M3/sec 5 5

Flow velocity V m/s 4.42 2.83

Actual Pipe length 20.00 20.00

Frictional loss calculation:

List of Pipe Fittings

No. of 90 deg bends 4.00 2.00

No. of 45 deg bends 1.00 1.00

No. of Gate Valves 2.00 1.00

No. of Check Valves 0.00 0.00

No. of Angle Valves 2.00 1.00

No. of Globe Valves 1.00 1.00

No. of Butterfly Valves 2.00 1.00

No. of NRVs 1.00 1.00

No. of Strainers 1.00 1.00

Flow Elements 0.00 0.00

Total Sum of Friction Factors W 2.20 2.00

Equivalent Length of Bends &

Valves W*d/λ 164.73 196.49

Total Equivalent Length of pipe Le M 184.73 216.49

Roughness co-eff k 0.0005 0.0005

Factor for l Calculation 3.71*d/k 8904 11130

Frictional factor l 0.0160 0.0153

Frictional Head Hf M of WC 2.46 0.90

Head Loss Across Strainer/Others M of WC 2.1 2.1

Sum of Frictional Head M of WC 4.56 3.00

Potential Head Z M of WC 3 3

Pressure Head hp M of WC 0 0

Velocity Head hv M of WC 1.00 0.41

Total System Head M of WC 8.55 6.41

Pumping Energy Required Pp kW 415.7 311.4

Pump Efficiency@operating point % 60% 65%

Motor Efficiency@operating point % 90% 90%

Input Electric power Pe 769.9 532.35

Power Saved kW 0.0 237.55

% Reduction in power % 0 30.85

Operating hours per day 12 12

Operating days per year 330 330

Energy Saved per year kWh 0 940690.99

Average Energy Cost Rs/kWh 3.5 3.50

Savings per year Rs. Lakhs 0 32.92

Cost of implementing the ECM Rs. Lakhs 0 4.00

Simple Payback period Months #DIV/0! 1.46

S-ar putea să vă placă și

- Gullu HEP (Hume Pipe)Document2 paginiGullu HEP (Hume Pipe)satyakam0601050Încă nu există evaluări

- Conical Tank Design For OSCARDocument2 paginiConical Tank Design For OSCARArie Emmanuel ListonÎncă nu există evaluări

- Data Solution: C F L DDocument27 paginiData Solution: C F L DJMVÎncă nu există evaluări

- Calculo Hidraulico Anular - Villa OlimpicaDocument2 paginiCalculo Hidraulico Anular - Villa OlimpicaYuber Eudis Toro MejiaÎncă nu există evaluări

- Design of Vertical Drop Fall: Surface FlowDocument3 paginiDesign of Vertical Drop Fall: Surface FlowMohammedÎncă nu există evaluări

- M S Pipe Weight CalculationDocument3 paginiM S Pipe Weight CalculationArun NandaÎncă nu există evaluări

- Transformer Sizing & Tentative Load List: Description Installed Power Power Consumption Sl. NoDocument1 paginăTransformer Sizing & Tentative Load List: Description Installed Power Power Consumption Sl. Nobashok20Încă nu există evaluări

- Khudi BOQ HMDocument37 paginiKhudi BOQ HMBishal PokharelÎncă nu există evaluări

- Friction Loss.Document1 paginăFriction Loss.JhonJairoMurilloVelezÎncă nu există evaluări

- Saddle Support SpacingDocument1 paginăSaddle Support SpacingdishkuÎncă nu există evaluări

- Electrical Load Data Sheet: Facility Name: Date: Address: City/State/Zip: Directions or Nearest Intersecting StreetDocument1 paginăElectrical Load Data Sheet: Facility Name: Date: Address: City/State/Zip: Directions or Nearest Intersecting Streetgag aaÎncă nu există evaluări

- Cable Size Calculations SpreadsheetDocument4 paginiCable Size Calculations Spreadsheetkiki270977Încă nu există evaluări

- Bhauta Khola HydrologyDocument30 paginiBhauta Khola HydrologyMilan ShresthaÎncă nu există evaluări

- Project:: Weir WesthgardDocument4 paginiProject:: Weir WesthgardRamachandran VenkateshÎncă nu există evaluări

- Kaplan Design Marko KogovsekDocument10 paginiKaplan Design Marko KogovsekIvan Batistic BeloÎncă nu există evaluări

- ABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksDocument5 paginiABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksMashudi FikriÎncă nu există evaluări

- 2) BOQ - Nibu Khola IX MHS (12 KW) Nawmidanda VDC Panchthar - 20120928040957Document3 pagini2) BOQ - Nibu Khola IX MHS (12 KW) Nawmidanda VDC Panchthar - 20120928040957barukomkssÎncă nu există evaluări

- Relay Coordination Study - 8 CurvesDocument2 paginiRelay Coordination Study - 8 CurvessalmanÎncă nu există evaluări

- Electrical Load CalculationDocument9 paginiElectrical Load CalculationAbdelaziz RagabÎncă nu există evaluări

- Relay Settings: Operation CurveDocument6 paginiRelay Settings: Operation Curvemaruf048Încă nu există evaluări

- Energy Calc IRRPayback PeriodCost of ProjectDocument15 paginiEnergy Calc IRRPayback PeriodCost of ProjectArjun BaralÎncă nu există evaluări

- Sickle PlateDocument8 paginiSickle PlatepitamberÎncă nu există evaluări

- ERHARD Needle Valve BrochureDocument20 paginiERHARD Needle Valve BrochurephanishankarÎncă nu există evaluări

- Calculation of DischargeDocument2 paginiCalculation of DischargeCristina OrmenisanÎncă nu există evaluări

- Chapter 8. Hydraulic Formulas Used in Designing Fish FarmsDocument41 paginiChapter 8. Hydraulic Formulas Used in Designing Fish FarmsEphrem GizachewÎncă nu există evaluări

- Pulichintala ProjectDocument5 paginiPulichintala Projectrn_nadhamÎncă nu există evaluări

- Valve Sizing - Flow RateDocument19 paginiValve Sizing - Flow RateMohammed AzeemÎncă nu există evaluări

- Sizing of Water Piping System PDFDocument18 paginiSizing of Water Piping System PDForganicspolybondÎncă nu există evaluări

- Strength Calculation of Clamping Structure FinalDocument3 paginiStrength Calculation of Clamping Structure FinalFasil ParuvanathÎncă nu există evaluări

- Water HammerDocument3 paginiWater HammerSrinivas ReddyÎncă nu există evaluări

- 110kv Sagtension Calculation 1 PDF FreeDocument13 pagini110kv Sagtension Calculation 1 PDF FreeAnonymous 5XvUbWynnÎncă nu există evaluări

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Document30 paginiHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Eng-CalculationsÎncă nu există evaluări

- Preliminary Design Hydroelectric Station Problem Without Prime UnitsDocument13 paginiPreliminary Design Hydroelectric Station Problem Without Prime UnitsadnanÎncă nu există evaluări

- 3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardDocument160 pagini3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardFarid Ahmad Shalahuddin100% (1)

- Hyd 201Document48 paginiHyd 201sandeep shuklaÎncă nu există evaluări

- Analisis RiesgoDocument2 paginiAnalisis RiesgoabenitechÎncă nu există evaluări

- Recommendationsfordesign Oftrashracksforintakes (: Indian StandardDocument8 paginiRecommendationsfordesign Oftrashracksforintakes (: Indian StandardFilip StojkovskiÎncă nu există evaluări

- Fire Fighting CO2-CalcDocument8 paginiFire Fighting CO2-Calcjhaamit4Încă nu există evaluări

- Unconfined Aquifer TrenshDocument2 paginiUnconfined Aquifer TrenshAhmed RamadanÎncă nu există evaluări

- Appl 17 Protection of Three Winding Transformer enDocument10 paginiAppl 17 Protection of Three Winding Transformer enSristi MitraÎncă nu există evaluări

- ENCE 647 ENCE 647 Stability of Slopes Dr. Ahmet AydilekDocument23 paginiENCE 647 ENCE 647 Stability of Slopes Dr. Ahmet AydilekHoracioCruiseÎncă nu există evaluări

- FOX 3F As Water Anti-Slam Air Valve 11.2021Document4 paginiFOX 3F As Water Anti-Slam Air Valve 11.2021bre brilianÎncă nu există evaluări

- Electrical Panel Load Calculation (14.1.14)Document22 paginiElectrical Panel Load Calculation (14.1.14)Hassen LazharÎncă nu există evaluări

- 04-04-2019 Surge Tank Design Calculation ReportDocument16 pagini04-04-2019 Surge Tank Design Calculation ReportCloradoJuniorÎncă nu există evaluări

- Complete Syllabus Mechanical-MinDocument191 paginiComplete Syllabus Mechanical-MinSalman Mohd HÎncă nu există evaluări

- 02 Curva Chave BaDocument9 pagini02 Curva Chave BaJCS EngenhariaÎncă nu există evaluări

- Reactor Switching Voltage Drop CalculationDocument2 paginiReactor Switching Voltage Drop Calculationbalaeee123Încă nu există evaluări

- Data sheet-MCB PDFDocument4 paginiData sheet-MCB PDFrijoÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument18 paginiDisclosure To Promote The Right To Informationharish babu aluruÎncă nu există evaluări

- Lowering in Calculation: Calculation of Deflection CheckDocument5 paginiLowering in Calculation: Calculation of Deflection CheckVinodParameswaran NairÎncă nu există evaluări

- Spillway Flow OptimizationDocument3 paginiSpillway Flow OptimizationPujan NeupaneÎncă nu există evaluări

- Hydraulic Jump Length Calculator 111205Document2 paginiHydraulic Jump Length Calculator 111205abhishek5810Încă nu există evaluări

- DG SizingDocument2 paginiDG SizingGireeshÎncă nu există evaluări

- Design of Orifice BahirisenDocument2 paginiDesign of Orifice Bahirisenujjwal sapkotaÎncă nu există evaluări

- Calculate Size of Diesel Generator SetDocument2 paginiCalculate Size of Diesel Generator SetFuad Al-AwzariÎncă nu există evaluări

- PUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Document1 paginăPUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Bimal DeyÎncă nu există evaluări

- Raw Mill - Birla White CementDocument9 paginiRaw Mill - Birla White Cementanurag soniÎncă nu există evaluări

- 02 - Pump Calculation For Office BuildingDocument16 pagini02 - Pump Calculation For Office BuildingErni Abd GhaniÎncă nu există evaluări

- Hydraulic Cal - Tanks Vent To FlareDocument1 paginăHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsDe la EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsÎncă nu există evaluări

- Ecologikol Green Building ProfileDocument21 paginiEcologikol Green Building Profileenergymahesh2Încă nu există evaluări

- General CF and CDM Jan 2011Document25 paginiGeneral CF and CDM Jan 2011energymahesh2Încă nu există evaluări

- Green Buildings PebsDocument15 paginiGreen Buildings Pebsenergymahesh2Încă nu există evaluări

- Pump Head Tool GuideDocument12 paginiPump Head Tool Guideenergymahesh2Încă nu există evaluări

- 630 enDocument20 pagini630 enAvishay TufikianÎncă nu există evaluări

- MASTER LIST OF CATALOGeDocument3 paginiMASTER LIST OF CATALOGePrathamesh Pradeep MashilkarÎncă nu există evaluări

- Industrial Hydraulic OilsDocument11 paginiIndustrial Hydraulic OilsSuprastowo Bin SarinoÎncă nu există evaluări

- Relief ValveDocument2 paginiRelief ValveRobertoÎncă nu există evaluări

- G-Series Back Pressure Valves: FeaturesDocument2 paginiG-Series Back Pressure Valves: FeaturesGab FernÎncă nu există evaluări

- Pressure Reducing Valve in Straightway Form DN 15 - 150Document6 paginiPressure Reducing Valve in Straightway Form DN 15 - 150Riza BagusÎncă nu există evaluări

- Techflow TV - Series: Vacuum Jacketed Cryogenic ValvesDocument2 paginiTechflow TV - Series: Vacuum Jacketed Cryogenic ValvesJust RysdanÎncă nu există evaluări

- Application For Vacuum Pumps 2005Document9 paginiApplication For Vacuum Pumps 2005jogik123456Încă nu există evaluări

- Certificate of Compliance: Certificate Number Report Reference Issue DateDocument5 paginiCertificate of Compliance: Certificate Number Report Reference Issue DateBryan S. AlejandroÎncă nu există evaluări

- Concentric EccentricDocument4 paginiConcentric EccentricGabbar SinghÎncă nu există evaluări

- Customer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormDocument2 paginiCustomer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormGustavo GarciaÎncă nu există evaluări

- CH 3Document5 paginiCH 3Amaterasu Susanoo Tsukuyomi100% (3)

- Reference - PIM-SU-3541-D - HydrotestDocument14 paginiReference - PIM-SU-3541-D - Hydrotestaslam.ambÎncă nu există evaluări

- Transport Phenomena 3Document19 paginiTransport Phenomena 3Kaify PeshmergaÎncă nu există evaluări

- Ibr RegulationsDocument9 paginiIbr RegulationsAJITSPATILÎncă nu există evaluări

- Hydraulic Fan Bypass Valve: 12M, 120M, 140M, and 160M Hydraulic System Series 2 Motor GraderDocument4 paginiHydraulic Fan Bypass Valve: 12M, 120M, 140M, and 160M Hydraulic System Series 2 Motor GraderRembertoÎncă nu există evaluări

- Pipeline LosessDocument23 paginiPipeline Losessasl91Încă nu există evaluări

- FM 24 Manual - Bernoullis TheoremDocument30 paginiFM 24 Manual - Bernoullis TheoremNORHAFINI HAMBALIÎncă nu există evaluări

- ANSI-AWWA (American Water Works Association)Document1 paginăANSI-AWWA (American Water Works Association)Vaniya GoelÎncă nu există evaluări

- OISD-106 (Pressure Relief and Disposal System)Document33 paginiOISD-106 (Pressure Relief and Disposal System)dantuluri chandu100% (3)

- Bunker Lines TestingDocument2 paginiBunker Lines Testinghackey720Încă nu există evaluări

- Ebsray RC Series - Models RC20 & RC25: Regenerative Turbine Pump For LPG ApplicationsDocument2 paginiEbsray RC Series - Models RC20 & RC25: Regenerative Turbine Pump For LPG ApplicationsagomezyÎncă nu există evaluări

- 357-05 Regeneration Circuit OperationDocument24 pagini357-05 Regeneration Circuit Operationmliugong100% (3)

- 50 BBL Surge Tank Design CalculationDocument22 pagini50 BBL Surge Tank Design CalculationLaskar Pejuang100% (1)

- Releasable Check Valve Type RHC and RHCE: Product DocumentationDocument26 paginiReleasable Check Valve Type RHC and RHCE: Product DocumentationVic CastilloÎncă nu există evaluări

- Typical Arrangement of Air Cooler PipingDocument4 paginiTypical Arrangement of Air Cooler Pipingvedadon100% (1)

- Air Systems R 01 160820223826 PDFDocument120 paginiAir Systems R 01 160820223826 PDFArrokhman Bagus DharmawanÎncă nu există evaluări

- 50 HZ Multistage Centrifugal Blowers Exhausters BrochureDocument1 pagină50 HZ Multistage Centrifugal Blowers Exhausters BrochureLuis Fernando BravoÎncă nu există evaluări

- 500MW Turbine O&M Manual Part#1of3Document170 pagini500MW Turbine O&M Manual Part#1of3Lakshmi Narayan100% (1)

- Om-03 Hose Handling Crane PDFDocument126 paginiOm-03 Hose Handling Crane PDFcpîndaruÎncă nu există evaluări