Documente Academic

Documente Profesional

Documente Cultură

De Ethanizer+de Propylenizer

Încărcat de

Zohaib Ali0 evaluări0% au considerat acest document util (0 voturi)

8 vizualizări12 paginiTitlu original

De-ethanizer+De-propylenizer.xlsx

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLSX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

8 vizualizări12 paginiDe Ethanizer+de Propylenizer

Încărcat de

Zohaib AliDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 12

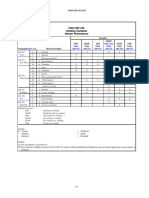

De-ethanizer

Input (kmol/hr) Output (kmol/hr)

Component Kmol/hr Mole fr. Distallate Bottom Y(feed) Y(Distiilate) Y(Bottom)

Methane 10.2 0.008055 10.2 0 0.008055402 0.012040187 0

Ethane 50.62746 0.039983 50.62746418 0.039982803 0.059761191 0

Ethylene 777.4462 0.613984 776.6687074 0.777446 0.613984457 0.916787909 0.00185518

Propane 9.339047 0.007375 0 9.339047 0.007375468 0 0.02228526

Propylene 266.0809 0.210136 1.310743409 264.7702 0.210136154 0.001547215 0.63180657

iso-butane 0.163843 0.000129 0 0.163843 0.000129394 0 0.00039097

n-butane 1.310743 0.001035 0 1.310743 0.001035153 0 0.00312776

Propadiene 0.327686 0.000259 0 0.327686 0.000258788 0 0.00078194

Acetylene 7.209089 0.005693 7.209089 0 0.005693344 0.008509684 0

trans-2-butene 3.768387 0.002976 0 3.768387 0.002976066 0 0.0089923

1-butene 84.87064 0.067026 0 84.87064 0.067026187 0 0.20252216

iso-butylene 0.819215 0.000647 0 0.819215 0.000646971 0 0.00195485

cis-2-butene 3.113016 0.002458 0 3.113016 0.002458489 0 0.00742842

trans-2-pentene 49.80825 0.039336 0 49.80825 0.039335832 0 0.1188547

Methyl Acetylene 1.1469 0.000906 1.1469 0.000905759 0.001353813 0

1266.231 1 847.162904 419.0684 1.000000269 1 1.00000009

Aspen Plus Calculations

Minimum reflux ratio 0.238681622

Actual reflux ratio 0.6

Minimum number of stages 8.32019514

Number of actual stages 14.7846388

Feed stage 5.14665131

Number of actual stages above feed 4.14665131

Reboiler heating required 601267.146 cal/sec

Condenser cooling required 163236.732 cal/sec

Distillate temperature -50.6037197 C

Bottom temperature 36.5419855 C

Distillate to feed fraction 0.668083971

HETP

0.0080554

From where the input comes atDe-ethanizer

From where the output comes atDe-ethanizer

Theoretical Stages Reflux Ratio

10 2.56131408

11 1.3063645

12 0.980253987

13 0.814302763

14 0.690426168

15 0.57450553

16 0.459823582

17 0.397870637

18 0.367571769

19 0.348783406

20 0.335583882

Input to Aspen Sheet

De-propylenizer

Input Output

Component Kmol/hr Mole fr. Distallate Bottom Y(feed)

Methane 0 0 0 0

Ethane 0 0 0 0

Ethylene 0.777446154 0.001855 0.7774461536 0 0.001855177

Propane 9.339046791 0.022285 0.0224137123 9.316633079 0.022285257

Propylene 264.7701687 0.631807 263.7110880162 1.059080675 0.631806571

iso-butane 0.163842926 0.000391 0 0.163842926 0.000390969

n-butane 1.310743409 0.003128 0 1.310743409 0.003127755

Propadiene 0.327685852 0.000782 0 0.327685852 0.000781939

Acetylene 0 0 0

trans-2-butene 3.768387302 0.008992 0 3.768387302 0.008992296

1-butene 84.87063575 0.202522 0 84.87063575 0.202522156

iso-butylene 0.819214631 0.001955 0 0.819214631 0.001954847

cis-2-butene 3.113015597 0.007428 0 3.113015597 0.007428419

trans-2-pentene 49.80824955 0.118855 0 49.80824955 0.118854701

Methyl Acetylene 0 0

419.0684367 1 264.5109478821 154.5574888 1.000000087

Aspen Plus Calculations

Y(Distiilate) Y(Bottom) Minimum reflux ratio 11.1846667

0 0 Actual reflux ratio 18

0 0 Minimum number of stages 137.652211

0.0029391833 0 Number of actual stages 196.123605

8.47364258E-05 0.0602794 Feed stage 103.365868

0.9969760802 0.0068523 Number of actual stages above f 102.365868

0 0.0010601 Reboiler heating required 4136649.77 cal/sec

0 0.0084806 Condenser cooling required 3833947.05 cal/sec

0 0.0021202 Distillate temperature 38.6942781 C

0 0 Bottom temperature 96.8040315 C

0 0.0243818 Distillate to feed fraction 0.636711614

0 0.5491202 HETP

0 0.0053004

0 0.0201415

0 0.3222636 From where the output comes atDe-propanizer

0 0 From where the output comes atDe-propanizer

0.9999999999 1

TheoreticalReflux Ratio

191 18.6771599

192 18.5341355

193 18.3968763

194 18.264845

195 18.1375924

196 18.0147195

197 17.8958706

198 17.7807267

199 17.6690008

200 17.5604332

201 17.4547883

Aspen Input form to De-propylenizer

Ethane/ethylene Seperator

Component feed(kmol/hr) Mole fr. Distallate Bottom Y(Distiilate)

Methane 10.2 0.0120401873 0 0 0

Ethane 50.62746418 0.0597611911 0 50.62746 0

Ethylene 776.6687073965 0.9167879091 772.7854 3.883344 0.9893027867

Propane 0 0 0

Propylene 1.310743409 0.0015472153 0

iso-butane 0 0 0 0

n-butane 0 0 0 0

Propadiene 0 0 0 0

Acetylene 7.209089 0.0085096845 7.209089 0.0092289168

trans-2-butene 0 0 0 0

1-butene 0 0 0 0

iso-butylene 0 0 0 0

cis-2-butene 0 0 0 0

trans-2-pentene 0 0 0 0

Methyl Acetylene 1.1469 0.0013538128 1.1469 0.0014682361

847.1629039855 1 781.1414 54.51081 0.9999999397

Equipment Split Light/Heavy key

C2-splitter Ethane/ethylene 99.00/0.06 2.7

Why is light key and heavy key of 99/0.0

Y(Bottom)

0

0.9287600786 Why there is 0 in feed and at distillate and bottom

0.0712398795

0

0

0

0

0

0

0

0

0

0

0

0

0.9999999581

Pressure (Mpa)

Reflux ratio Condenser Reboiler Temperature

2.7 0.4 1.1 -76/ethylene

ht key and heavy key of 99/0.06

S-ar putea să vă placă și

- 18487900Document22 pagini18487900Zohaib Ali100% (2)

- Boiler Calculation/ Stack DesignDocument32 paginiBoiler Calculation/ Stack DesignZohaib AliÎncă nu există evaluări

- 7 Repl - Quant Blue Dye in Comm Drinks - ModFall2012Document7 pagini7 Repl - Quant Blue Dye in Comm Drinks - ModFall2012Zohaib AliÎncă nu există evaluări

- Homework 1: Instructions and NotesDocument2 paginiHomework 1: Instructions and NotesZohaib AliÎncă nu există evaluări

- CHEN 623 Problems Old Examination Problems: 1.: (P + A /V) (V B) RTDocument34 paginiCHEN 623 Problems Old Examination Problems: 1.: (P + A /V) (V B) RTZohaib Ali0% (1)

- Prep Assignments: CHM 1045 GravesDocument8 paginiPrep Assignments: CHM 1045 GravesZohaib AliÎncă nu există evaluări

- Diffusion Model and Analysis of Diffusion Process at Lagrangian MethodDocument30 paginiDiffusion Model and Analysis of Diffusion Process at Lagrangian MethodZohaib AliÎncă nu există evaluări

- Question NoDocument14 paginiQuestion NoZohaib AliÎncă nu există evaluări

- Crypto Currencies and Their Impact On Economy and Banking SystemsDocument18 paginiCrypto Currencies and Their Impact On Economy and Banking SystemsZohaib AliÎncă nu există evaluări

- Review of Optimization Strategies For System-Level Design in Hybrid Electric VehiclesDocument15 paginiReview of Optimization Strategies For System-Level Design in Hybrid Electric VehiclesZohaib AliÎncă nu există evaluări

- PH Probe Calibration: Submitted To Miss Anam SaeedDocument5 paginiPH Probe Calibration: Submitted To Miss Anam SaeedZohaib AliÎncă nu există evaluări

- ANSWERDocument5 paginiANSWERZohaib AliÎncă nu există evaluări

- Case Study Replacing FWA: A. Research OptionsDocument4 paginiCase Study Replacing FWA: A. Research OptionsZohaib AliÎncă nu există evaluări

- Optical Fiber CommunicationDocument5 paginiOptical Fiber CommunicationZohaib AliÎncă nu există evaluări

- MATLAB Work - ElectricalDocument7 paginiMATLAB Work - ElectricalZohaib AliÎncă nu există evaluări

- Smart Shopping CartDocument10 paginiSmart Shopping CartZohaib AliÎncă nu există evaluări

- Air Pollution in Smart CitiesDocument5 paginiAir Pollution in Smart CitiesZohaib AliÎncă nu există evaluări

- Bessel Filter, Discussion in Analog and Digital SystemDocument7 paginiBessel Filter, Discussion in Analog and Digital SystemZohaib AliÎncă nu există evaluări

- Ricardo WAVE REPORTDocument7 paginiRicardo WAVE REPORTZohaib AliÎncă nu există evaluări

- PM in Network SolutionDocument8 paginiPM in Network SolutionZohaib AliÎncă nu există evaluări

- Environmental Management SystemDocument7 paginiEnvironmental Management SystemZohaib AliÎncă nu există evaluări

- Gaussian Filter, Discussion in Analog and Digital SystemDocument8 paginiGaussian Filter, Discussion in Analog and Digital SystemZohaib AliÎncă nu există evaluări

- Digital System Desgin Study AssignmentDocument5 paginiDigital System Desgin Study AssignmentZohaib AliÎncă nu există evaluări

- 3.2 Practical 2 Laboratory Assessments-24983Document5 pagini3.2 Practical 2 Laboratory Assessments-24983Zohaib AliÎncă nu există evaluări

- Optical Fiber Communication Satellite Communication Global Positioning System (GPS)Document2 paginiOptical Fiber Communication Satellite Communication Global Positioning System (GPS)Zohaib AliÎncă nu există evaluări

- 06 - Intern Feedback FormDocument1 pagină06 - Intern Feedback FormZohaib AliÎncă nu există evaluări

- Complex Engineering Problem: Expert Excel SimulatorDocument6 paginiComplex Engineering Problem: Expert Excel SimulatorZohaib AliÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Methanol SynthesisDocument21 paginiMethanol SynthesisAnonymous cenxRyKU5Încă nu există evaluări

- Chemicals: Project Specification 106Document4 paginiChemicals: Project Specification 106Hernán GarcíaÎncă nu există evaluări

- Prometheus BoundDocument36 paginiPrometheus BoundGiovanni TapangÎncă nu există evaluări

- Metric Tons Day Ammonia PlantDocument34 paginiMetric Tons Day Ammonia PlantEleonoraÎncă nu există evaluări

- Inventaris Alkes Yang BenerDocument127 paginiInventaris Alkes Yang BenerYuni Syalawiyah IIÎncă nu există evaluări

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)Document5 paginiGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)joshi madhavÎncă nu există evaluări

- 062-0064 BDocument3 pagini062-0064 BMarthin PurbaÎncă nu există evaluări

- Linde PSAsDocument8 paginiLinde PSAsSiji AntonyÎncă nu există evaluări

- First Upstream Projects-Epc PlanDocument13 paginiFirst Upstream Projects-Epc PlanRccg DestinySanctuaryÎncă nu există evaluări

- Sgt-700 Dle Combustion System Extending The Fuel FlexibilityDocument13 paginiSgt-700 Dle Combustion System Extending The Fuel FlexibilityMahsaÎncă nu există evaluări

- Petrochemicals An Overview (STUDENT) (2of3)Document224 paginiPetrochemicals An Overview (STUDENT) (2of3)Chuah Chong YangÎncă nu există evaluări

- WPS 02Document2 paginiWPS 02ZaidiÎncă nu există evaluări

- UBE Separation Membrane - BioGas CustomerDocument18 paginiUBE Separation Membrane - BioGas CustomerSatish Shinde0% (1)

- Gandhar - Reliance Industries Limited.Document2 paginiGandhar - Reliance Industries Limited.ash61117Încă nu există evaluări

- Latest Edit2Document4.912 paginiLatest Edit2Rahul PandeyÎncă nu există evaluări

- Integration of Petrochemical and Refinery Plants As An Approach To Compete in Hydrocarbon MarketDocument31 paginiIntegration of Petrochemical and Refinery Plants As An Approach To Compete in Hydrocarbon MarketHuiJooHweeÎncă nu există evaluări

- ACH 2103 - Experiment 1 - Preparation & Standardization of SolutionsDocument3 paginiACH 2103 - Experiment 1 - Preparation & Standardization of SolutionsShinobu OshinoÎncă nu există evaluări

- Domestic Production and Foreign Trade The American Capital Position Re-ExaminedDocument23 paginiDomestic Production and Foreign Trade The American Capital Position Re-ExaminedKevin Mcdonald100% (2)

- Given: F 100 Mol (N-Pentane) 0.60 (N - Heptane) 0.40 101.32 40 60Document6 paginiGiven: F 100 Mol (N-Pentane) 0.60 (N - Heptane) 0.40 101.32 40 60Yasmin KayeÎncă nu există evaluări

- Production of Oxygen From Cryogenic Air SeparationDocument4 paginiProduction of Oxygen From Cryogenic Air SeparationAbdullah N. TahirÎncă nu există evaluări

- Fuel Properties TablesDocument11 paginiFuel Properties TablesSaravanapriya KarthikÎncă nu există evaluări

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 paginăTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Pharmaceuticals & Cosmetics Production Plant & Equipment Firms in MX (1) MexicoDocument14 paginiPharmaceuticals & Cosmetics Production Plant & Equipment Firms in MX (1) Mexicomarketing lakshÎncă nu există evaluări

- Ethylene Dichloride (Edc) / Vinyl Chloride Monomer (VCM) : Customer Process BrochureDocument4 paginiEthylene Dichloride (Edc) / Vinyl Chloride Monomer (VCM) : Customer Process Brochurerkapoor584199Încă nu există evaluări

- PRACTICA 3: Remoción de Impurezas - Etapa 1ADocument7 paginiPRACTICA 3: Remoción de Impurezas - Etapa 1AOsmar Monja LopezÎncă nu există evaluări

- Hysys Simulation of N 2 Extraction ProceDocument11 paginiHysys Simulation of N 2 Extraction Proceabdullah farhanÎncă nu există evaluări

- (Supercritical Unit) Date: 02.05.2011: 1 X 660 MW TPP For Visa Power Limited at RaigarhDocument4 pagini(Supercritical Unit) Date: 02.05.2011: 1 X 660 MW TPP For Visa Power Limited at RaigarhirfanÎncă nu există evaluări

- Ozone Layer DepletionDocument14 paginiOzone Layer DepletionRai HrithikÎncă nu există evaluări

- SKKK1113 Tutorial Assignment-04-ReactiveDocument2 paginiSKKK1113 Tutorial Assignment-04-ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194Încă nu există evaluări

- Empirical Carbon Isotope/maturity Relationships For Gases From Algal Kerogens and Terrigenous Organic Matter, Based On Dry, Open-System PyrolysisDocument9 paginiEmpirical Carbon Isotope/maturity Relationships For Gases From Algal Kerogens and Terrigenous Organic Matter, Based On Dry, Open-System PyrolysisPracoyo Adi PÎncă nu există evaluări