Documente Academic

Documente Profesional

Documente Cultură

Stone Indusrty PDF

Încărcat de

AhmadTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Stone Indusrty PDF

Încărcat de

AhmadDrepturi de autor:

Formate disponibile

Dear Eng.

Bilal;

Assalmau Alykom WA Rahmatu ALLAH WA Barakatuh

This is to explain to you about the natural stone processing industry.

Kindly note that I'll describe it in brief as I can, and the photos I'll Attach

it with this document via email or WhatsApp.

1- Introduction:

Stones for the construction industry could be obtained from natural

quarries areas; known then as a natural stone, or could be obtained

as manufactured from specialized factories, which called artificial

stone, in this brief; I'll describe the both types.

2- Natural Stones:

Such as Lime stone, Granit, Basalt and Marble.

These stones quarried from mountains or valleys in a form of blocks

(2-6 cubic meters), then transported to the processing unit.

This processing unit established from these methods:

- Ordinary method:

It consists of a stone saw with manual efforts for handling.

• Cost of the equipment and the operational costs is (60-65) K

Jordanian dinar

• The production varies between (500-600) meter length (1

length meter equals 0.25 square meter of processed stone).

- Semi – Automatic method:

It consists from ordinary stone saw with automatic handling for

stones but needs human efforts for arranging and organizing final

products.

• Cost of the equipment and the operational costs is (100-120) K

Jordanian dinar

• The production varies between (1200-1500) meter length (1

length meter equals 0.25 square meter of processed stone).

- Fully Automatic method:

It consists of a full automated stone saw with belts, conveyors and

cranes that operated through a PLC system.

• Cost of the equipment and the operational costs is (200-220) K

Jordanian dinar

• The production varies between (2000-2200) meter length (1

length meter equals 0.25 square meter of processed stone).

3- Artificial stone:

Cement and gypsum used with a specialized blend to form a

natural stone looking.

(additional data will be provided upon request)

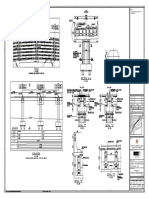

4- Typical Stones Processing units:

As we described above; the typical stone processing units consists of:

1- Handling Cranes

2- Fork lift (20-40) Ton

3- Fork lift (5-10) Ton

4- Blade Saw machine (32" – 120")

5- Chain Saw Machine (for marble and Granit

6- Burnishing & Refining Table.

7- Packaging Units.

The general cost started from 60K Jordanian dinars and increased as it

automated up to 220K JOD.

5- Stone Craving:

All stone craving or patterning procedures are manual only.

Need a craftsman to do such a procedure because its only on the

demand.

The cost around (0.50) JOD per square meter for hand craving

pattern.

They used a hammer machine types (HILTI or Makita).

6- Stone fixing / Installing:

Two methods:

- Building stones with cement and mortar.

- Mechanical erecting by steel fasteners and fittings.

** Note: a factory for manufacturing steel fittings for the mechanical

stone procedures costs around (45)K JOD.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Field Report RizalDocument31 paginiField Report RizalPaul Emirique B. Ibanez100% (1)

- PEAC CIDAM Template 2019 Earth ScienceDocument10 paginiPEAC CIDAM Template 2019 Earth ScienceJaruay Celeridad100% (1)

- Lesson Plan Science 4 Classifying RocksDocument4 paginiLesson Plan Science 4 Classifying RocksJam ValenzuelaÎncă nu există evaluări

- Sheetrock Mold Tough Gypsum Liner Panels TDSDocument2 paginiSheetrock Mold Tough Gypsum Liner Panels TDSAhmadÎncă nu există evaluări

- Drain Repairs: Should The Word Drainage Be Replaced by Pipework?Document1 paginăDrain Repairs: Should The Word Drainage Be Replaced by Pipework?AhmadÎncă nu există evaluări

- Laattalattia Ontelolaataston Pã Ã LlãDocument28 paginiLaattalattia Ontelolaataston Pã Ã LlãAhmadÎncă nu există evaluări

- Notes: 1-All Dimensions Are Given in Millimeters .: A B C DDocument1 paginăNotes: 1-All Dimensions Are Given in Millimeters .: A B C DAhmadÎncă nu există evaluări

- Comparison of Concrete Road Vs Asphalt RoadDocument6 paginiComparison of Concrete Road Vs Asphalt RoadAhmadÎncă nu există evaluări

- Bearing Replacement STUs M4 Hambrook ViaductDocument1 paginăBearing Replacement STUs M4 Hambrook ViaductAhmadÎncă nu există evaluări

- CIVL2360 Cheat Sheet CIVL2360 Cheat SheetDocument3 paginiCIVL2360 Cheat Sheet CIVL2360 Cheat SheetAhmadÎncă nu există evaluări

- Concrete & Asphalt Roads - Pros & ConsDocument4 paginiConcrete & Asphalt Roads - Pros & ConsAhmadÎncă nu există evaluări

- Finite Elements in Autodesk Robot Structural AnalysisDocument2 paginiFinite Elements in Autodesk Robot Structural AnalysisAhmadÎncă nu există evaluări

- Precast Concrete Catch Basins and Inlets: Unmatched Strength and DurabilityDocument3 paginiPrecast Concrete Catch Basins and Inlets: Unmatched Strength and DurabilityAhmadÎncă nu există evaluări

- Down - Tecnospan Dossier - Recycled Aggregates in Concrete For PrecastDocument2 paginiDown - Tecnospan Dossier - Recycled Aggregates in Concrete For PrecastAhmadÎncă nu există evaluări

- A B C D: General Arrangement PHASE "1"Document1 paginăA B C D: General Arrangement PHASE "1"AhmadÎncă nu există evaluări

- Watertight Shotcrete For Swimming Pools: ASA Pool and Recreational Shotcrete CommitteeDocument2 paginiWatertight Shotcrete For Swimming Pools: ASA Pool and Recreational Shotcrete CommitteeAhmadÎncă nu există evaluări

- Voided and Ribbed SlabsDocument17 paginiVoided and Ribbed SlabsAhmadÎncă nu există evaluări

- Manhole Installation Guide-PDF-rev2Document68 paginiManhole Installation Guide-PDF-rev2AhmadÎncă nu există evaluări

- Ascon Design Department: Comparision Based On Value Engineered OptionDocument5 paginiAscon Design Department: Comparision Based On Value Engineered OptionAhmadÎncă nu există evaluări

- Cat Lifting Devices 2Document1 paginăCat Lifting Devices 2AhmadÎncă nu există evaluări

- Bison Hollowcore Floors Bearing DetailsDocument4 paginiBison Hollowcore Floors Bearing DetailsAhmadÎncă nu există evaluări

- Chapter 2-Geology ExplorationDocument21 paginiChapter 2-Geology ExplorationNazmi RafianÎncă nu există evaluări

- Schedule Standard and Syllabus: Section A: Geomorphology and Remote SensingDocument6 paginiSchedule Standard and Syllabus: Section A: Geomorphology and Remote SensingPankaj SharmaÎncă nu există evaluări

- Curriculum Vitae (Alex Candra)Document2 paginiCurriculum Vitae (Alex Candra)AliMahmudÎncă nu există evaluări

- Respuestas A Las FuerzasDocument11 paginiRespuestas A Las FuerzasZSHADISHÎncă nu există evaluări

- Chocolate Rock CycleDocument3 paginiChocolate Rock CycleKhynia DijenoÎncă nu există evaluări

- Walker, J. Douglas - Cohen, Harvey A.-Geoscience Handbook - AGI Data Sheets (4th Edition) - American Geosciences Institute (2009) PDFDocument308 paginiWalker, J. Douglas - Cohen, Harvey A.-Geoscience Handbook - AGI Data Sheets (4th Edition) - American Geosciences Institute (2009) PDFRicky Chiu100% (1)

- High-Grade Metamorphism in The Chapleau-Foleyet Area, OntarioDocument20 paginiHigh-Grade Metamorphism in The Chapleau-Foleyet Area, OntarioDikky ChoiyÎncă nu există evaluări

- A Drilling Guide To Shales and Related Borehole ProblemsDocument41 paginiA Drilling Guide To Shales and Related Borehole ProblemsNitul DoleyÎncă nu există evaluări

- 09.roof SupportsDocument22 pagini09.roof SupportsLavudiya RajkumarÎncă nu există evaluări

- M.Sc. Applied Geology: Unit-1: Physical Geology 4X1 4 MarksDocument7 paginiM.Sc. Applied Geology: Unit-1: Physical Geology 4X1 4 MarksMahboob HassanÎncă nu există evaluări

- Experiences in Barcelona With The Use of Fibers in Segmental LiningsDocument18 paginiExperiences in Barcelona With The Use of Fibers in Segmental LiningselitvdisÎncă nu există evaluări

- A Method For Determining Optimum Drilling Techniques: This Is TODocument16 paginiA Method For Determining Optimum Drilling Techniques: This Is TOMontadher Al-saediÎncă nu există evaluări

- ICSE Geography Class 9Document12 paginiICSE Geography Class 9Omkar mantri100% (1)

- Almeida Et Al 1981 Brazilian Strucuctural Provinces An IntroductionDocument29 paginiAlmeida Et Al 1981 Brazilian Strucuctural Provinces An IntroductionLuanna AzevedoÎncă nu există evaluări

- An Overview of Mineral Resources Development in Nigeria: Problems and ProspectsDocument9 paginiAn Overview of Mineral Resources Development in Nigeria: Problems and Prospectswilolud672080% (5)

- Rock Resources of UAE PosterDocument1 paginăRock Resources of UAE PostericiarÎncă nu există evaluări

- Rocks and StonesDocument24 paginiRocks and StonesqwerrÎncă nu există evaluări

- Bastin. Interpretation of Ore Textures PDFDocument142 paginiBastin. Interpretation of Ore Textures PDFrodolfoÎncă nu există evaluări

- Grammar TestDocument67 paginiGrammar TestDima OmelyanÎncă nu există evaluări

- Cobb County School District 2018-2019 6 Grade Earth Science Teaching & Learning FrameworkDocument1 paginăCobb County School District 2018-2019 6 Grade Earth Science Teaching & Learning Frameworkapi-298427905Încă nu există evaluări

- Dimension Stone: Standard Terminology Relating ToDocument8 paginiDimension Stone: Standard Terminology Relating Toeduardo bonillaÎncă nu există evaluări

- Dairi ZN-PB Deposit, North Sumatera, IndonesiaDocument6 paginiDairi ZN-PB Deposit, North Sumatera, IndonesiaYudha SiahaanÎncă nu există evaluări

- Chapter 5 Sedimentary RocksDocument44 paginiChapter 5 Sedimentary Rockslilian_ayalaÎncă nu există evaluări

- Fossil FuelsDocument8 paginiFossil Fuelsapi-293431691100% (1)

- Detailed Lesson Plan (DLP) June 26, 2019: 16 and Life Science Quarter Duration: 60 MinutesDocument4 paginiDetailed Lesson Plan (DLP) June 26, 2019: 16 and Life Science Quarter Duration: 60 MinutesJuliville Hora Salinas100% (1)

- DS13-15 Foundation GroutingDocument175 paginiDS13-15 Foundation GroutingMarijoÎncă nu există evaluări

- FGDC Geolsym PatternchartDocument1 paginăFGDC Geolsym Patternchartkasemelk1990Încă nu există evaluări